Dual internal spline coaxiality inspection device

A coaxiality and inspection tool technology, applied in measuring devices, instruments, and mechanical devices, etc., can solve the problem of not being able to detect the coaxiality deviation of two inner splines in time, unable to test the coaxiality of two inner splines, and inconsistency. It is suitable for production site inspection and other problems, and achieves the effect of easy production, convenient installation and reliable positioning reference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

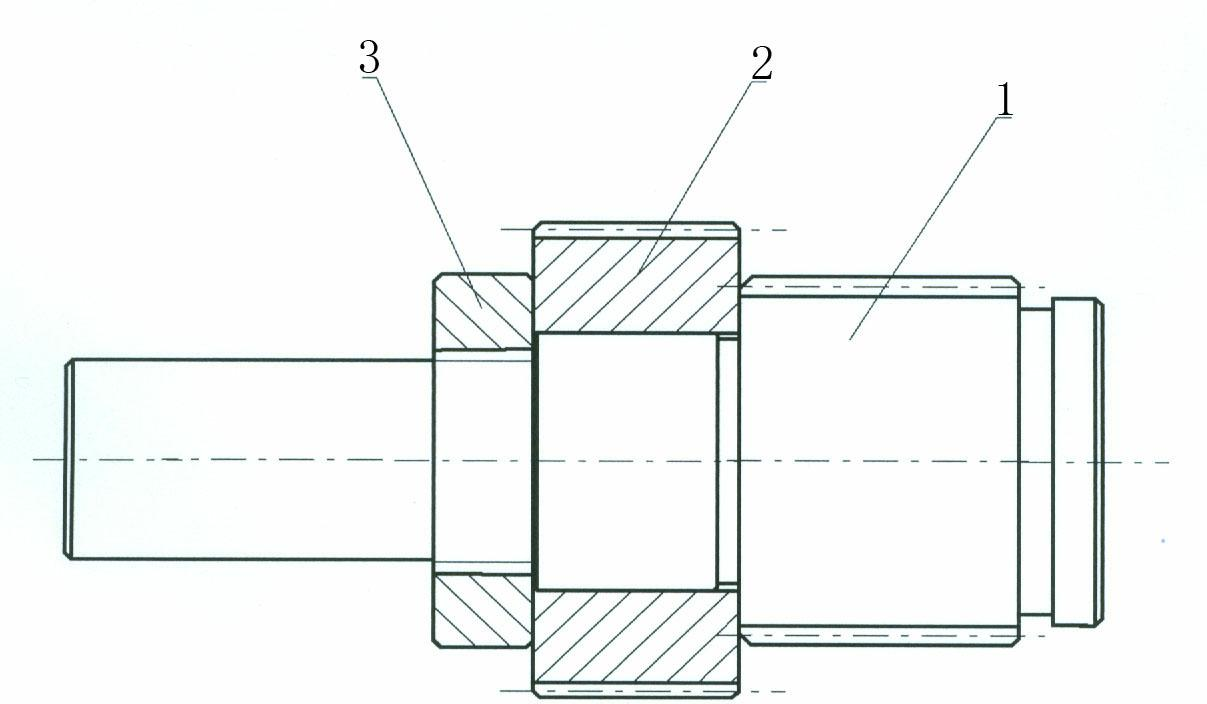

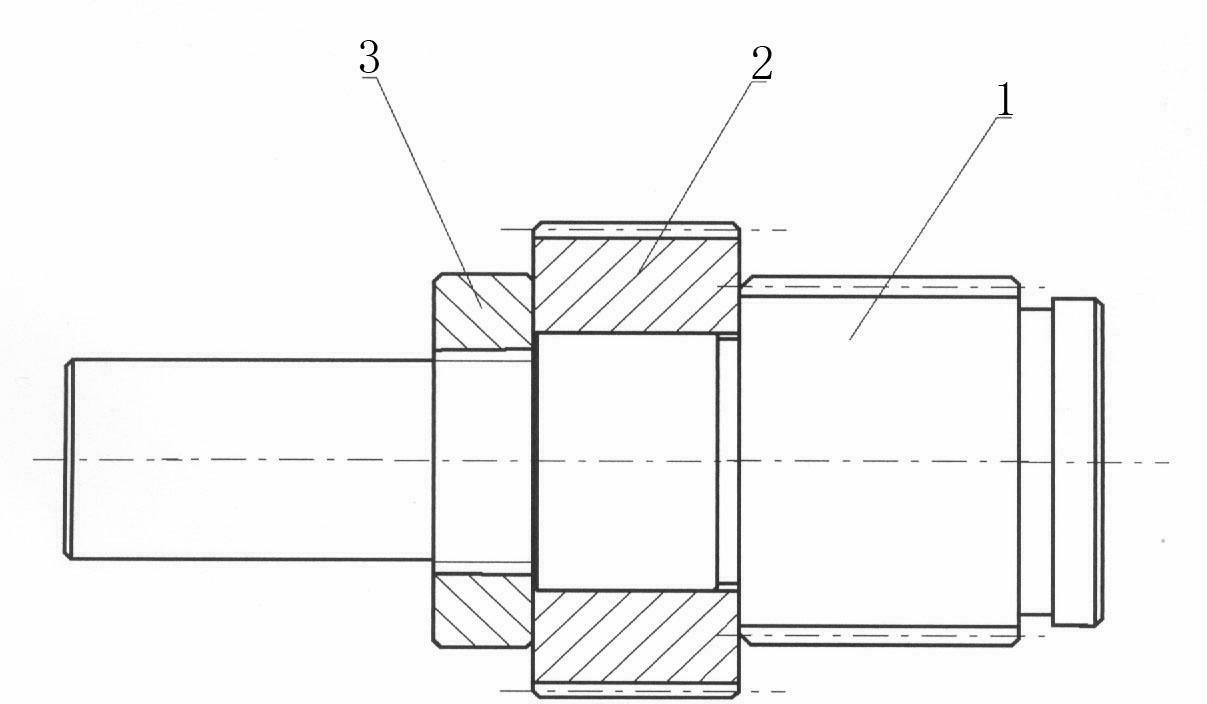

[0012] The following is based on figure 1 And in conjunction with embodiment, the present invention will be further described.

[0013] figure 1 The double internal spline coaxiality inspection tool shown is composed of a fixed plug gauge 1, a moving plug gauge 2 and a nut 3. The fixed plug gauge 1 is a vertically stepped shaft structure with a shaft diameter that is thinner at the top and thicker at the bottom. The outer wall of the bottom section is axially provided with external splines, the middle section is a cylindrical shaft, and the adjacent shaft section above the cylindrical shaft section is provided with a nut. 3 matching external threads. The moving plug gauge 2 is in the shape of a flange with holes, the middle through hole is in clearance fit with the middle cylindrical shaft of the fixed plug gauge 1, and the outer wall is axially provided with external splines. The coaxial sleeve of the movable plug gauge 2 and the fixed plug gauge 1 is combined and axially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com