Phased array detection and evaluation method for austenitic stainless steel small-diameter pipe welding joint

A technology of austenitic stainless steel and welded joints, which is used in measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as analysis of defect patterns in scanning device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

[0084] Embodiment The phased array detection is carried out on the welded joint of austenitic stainless steel small-diameter pipe with a specification of Φ76×10 and a material of TP310H.

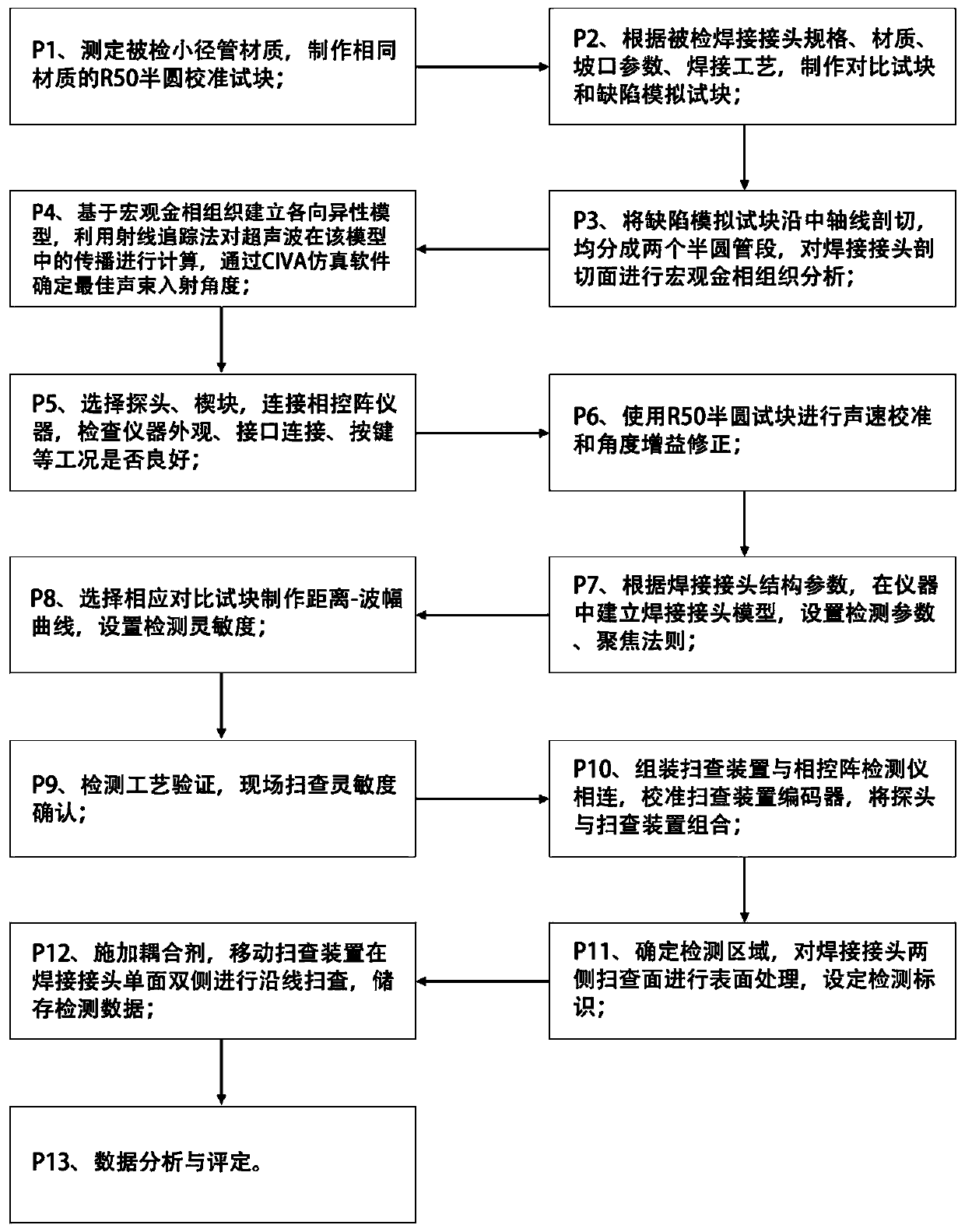

[0085] figure 1 Shown is the phased array detection flow chart of the welded joint of austenitic stainless steel small-diameter pipe according to the present invention.

[0086] P1. Make a R50 semicircle calibration test block made of TP310H, the thickness of the test block is 30mm, such as Figure 8 shown;

[0087] P2. Make Type II comparison test block. The material and welding process of the welded joint in the middle of the comparison test block are the same as those of the workpiece to be inspected. The external dimensions of the test block are as follows: Figure 10a , Figure 10b As shown (when the wall thickness of the austenitic stainless steel smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com