Ultrasonic flaw detection auxiliary device and operating method thereof

A technology of auxiliary device and operation method, which is applied to measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve problems such as low work efficiency, influence on flaw detection efficiency, and large influence of human factors, so as to improve work efficiency , Guarantee the quality of detection and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

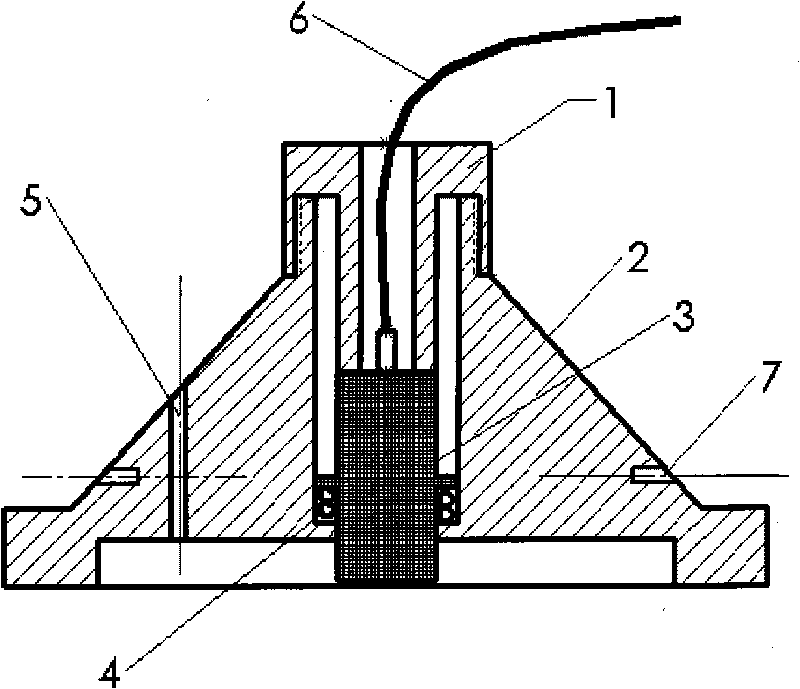

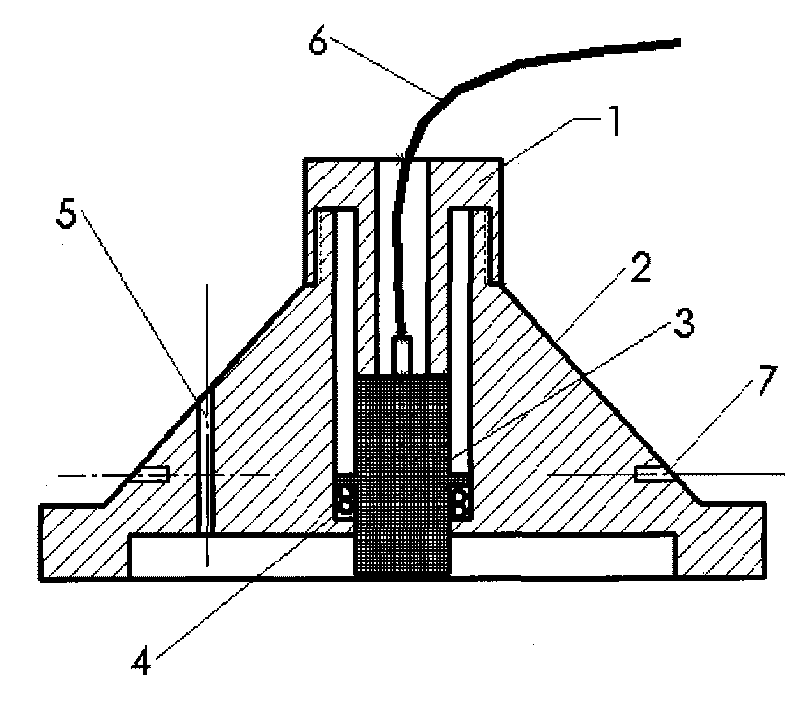

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, an auxiliary device for ultrasonic flaw detection includes a housing 2, a gland 1 and a spring 4. The housing 2 is conical and has a circular hole in the center for placing the probe 3. The spring 4 is located at the bottom of the circular hole. On the platform, the gland 1 is installed on the upper part of the casing 2 by threaded connection, and the casing 2 is provided with a water injection hole 5 , and the diameter and height of the circular hole are determined according to the size of the probe 3 .

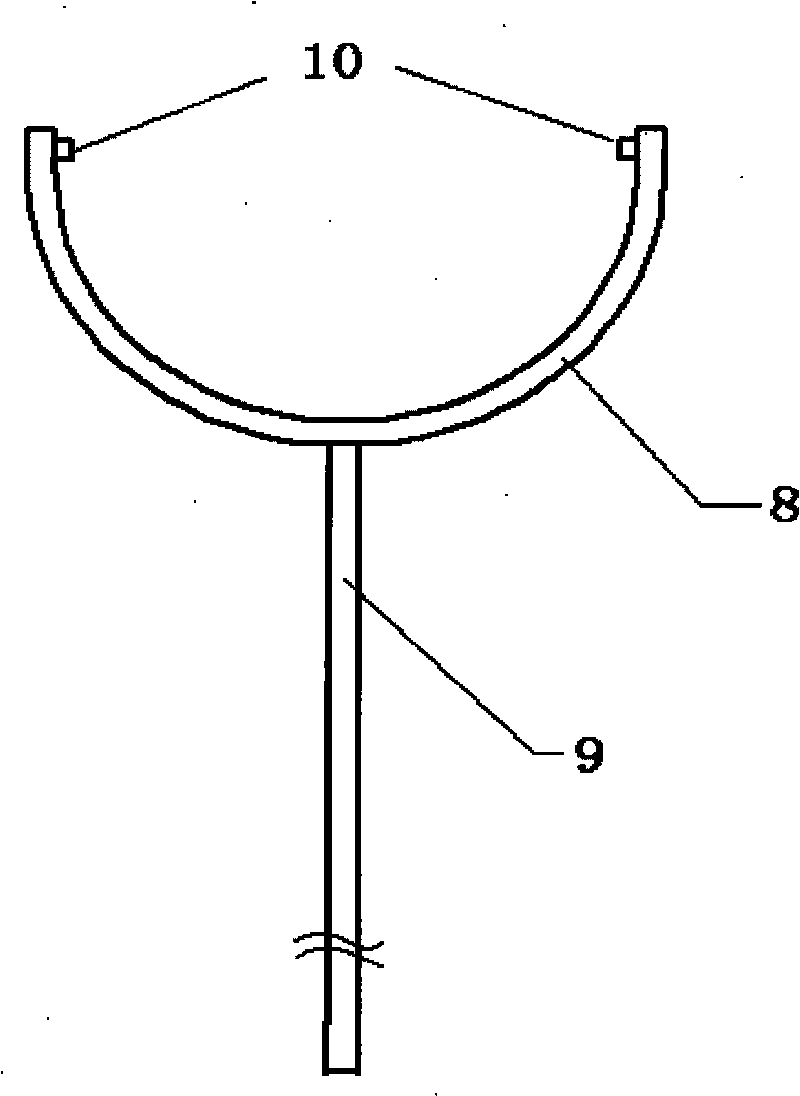

[0027] The casing 2 of the present invention is also connected with an extension rod 9 , and the clip 8 at one end of the extension rod 9 is installed in the pin hole 7 on the casing 2 through the pin shaft 10 .

[0028] An operation method of an ultrasonic flaw detection auxiliary device includes the following steps: put the probe 3 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com