Ultrasonic flaw detection method

A technology of ultrasonic and flaw detector, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., which can solve the problems of high labor intensity and low work efficiency of inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

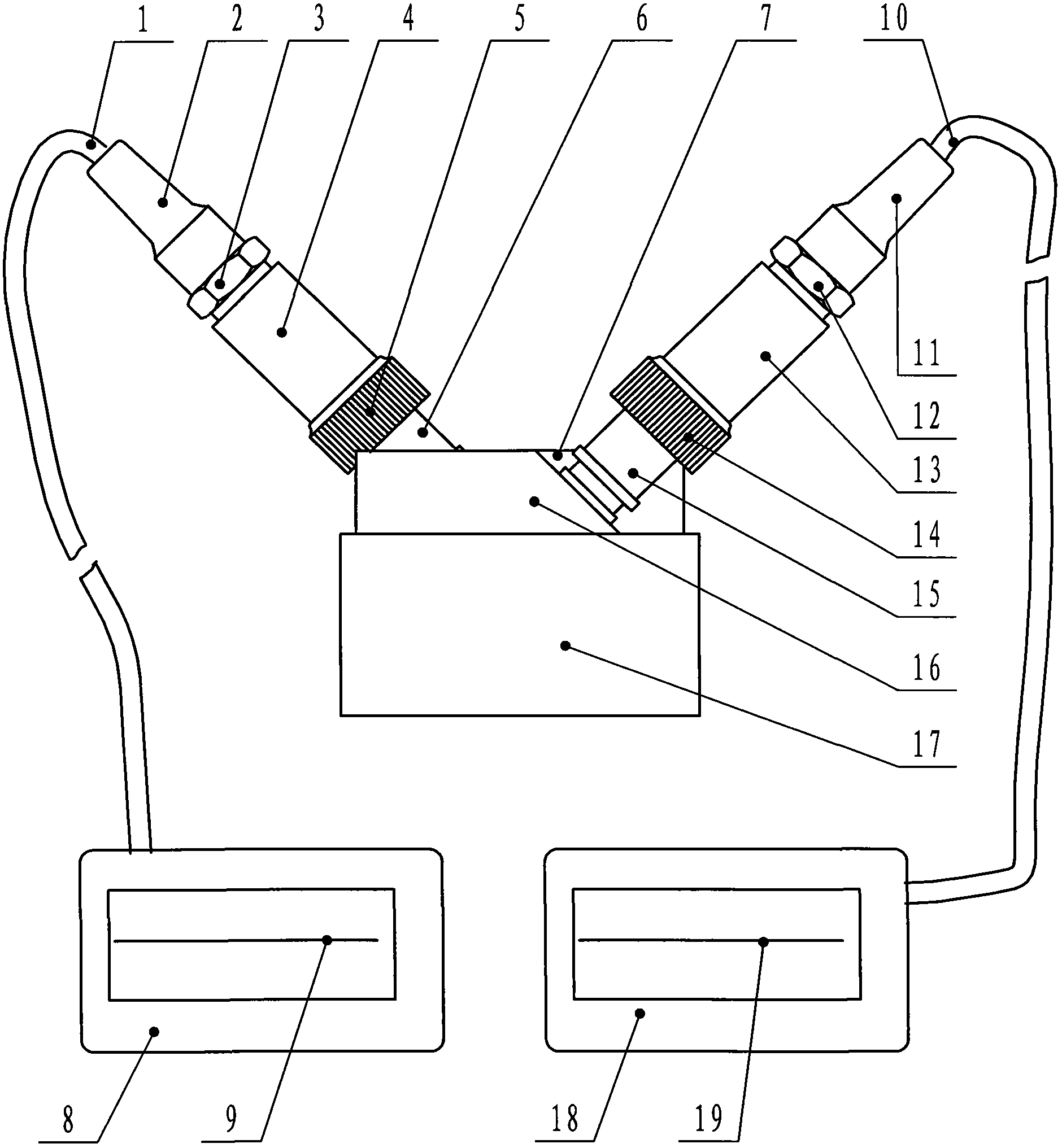

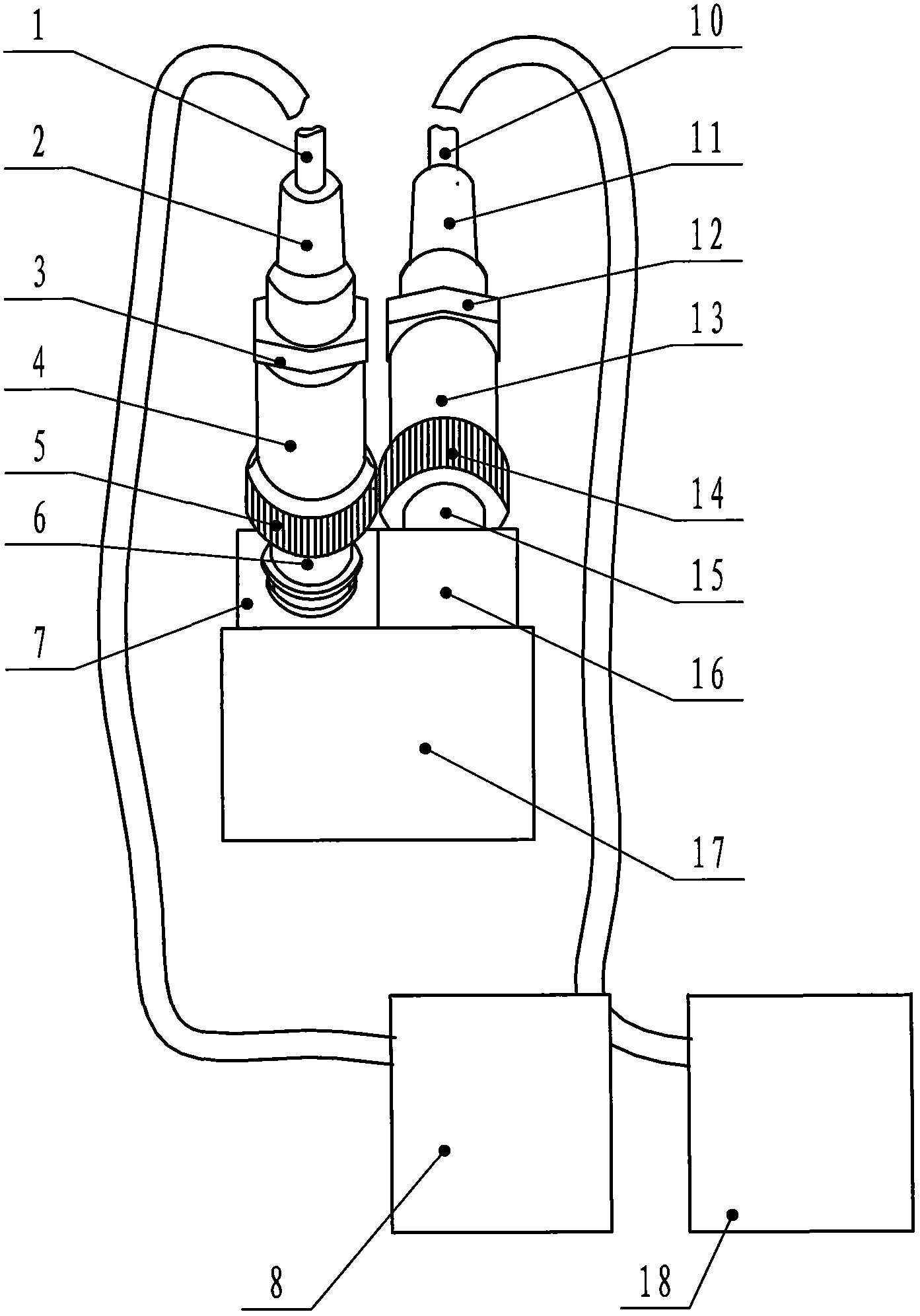

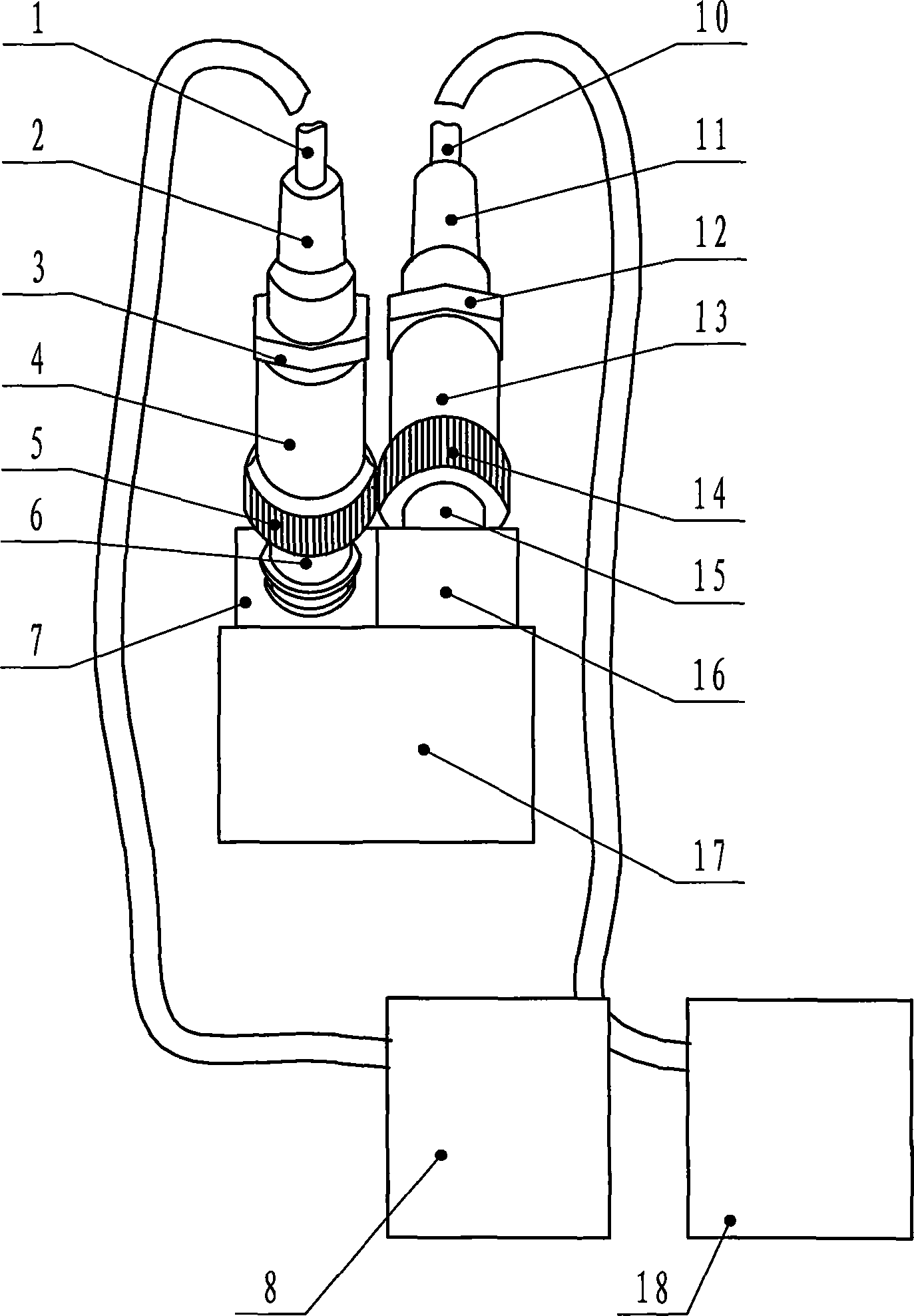

[0024] This embodiment is used to detect butt-welded steel plates with a thickness of 8-120 mm.

[0025] This embodiment is the following sequential steps:

[0026] 1 is according to steel plate thickness 20mm, the ultrasonic probe 7 and the ultrasonic probe 16 of two transverse waves of thickness selection K=2;

[0027] II Connect the ultrasonic probe 7 to the ultrasonic flaw detector 8, and connect the ultrasonic probe 16 to the ultrasonic flaw detector 18; use the test block CSK-I A to measure the actual K values and incident points of the two ultrasonic probes respectively, and the actual value of the ultrasonic probe 7 The K1 value is 1.98, the incident point S1 is 12 mm, the actual K2 value of the ultrasonic probe 16 is 1.99, and the incident point S2 is 12 mm.

[0028] III First place the ultrasonic probe 7 connected to an ultrasonic flaw detector 8 on the test block CSK-III A (short horizontal hole ¢1×6mm contrast test block, thickness 30mm), adjust the gain knob of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com