Method and device for confirming irradiation orientation of pressure container weld seam ray detecting ray bundle

A technology for radiographic inspection and pressure vessels, which is applied in the field of determining the orientation of radiation beams for radiographic inspection of pressure vessel welds, can solve the problems of wasting test films, affecting testing costs and work efficiency, etc., to reduce film waste, improve work efficiency, Guarantee the effect of testing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

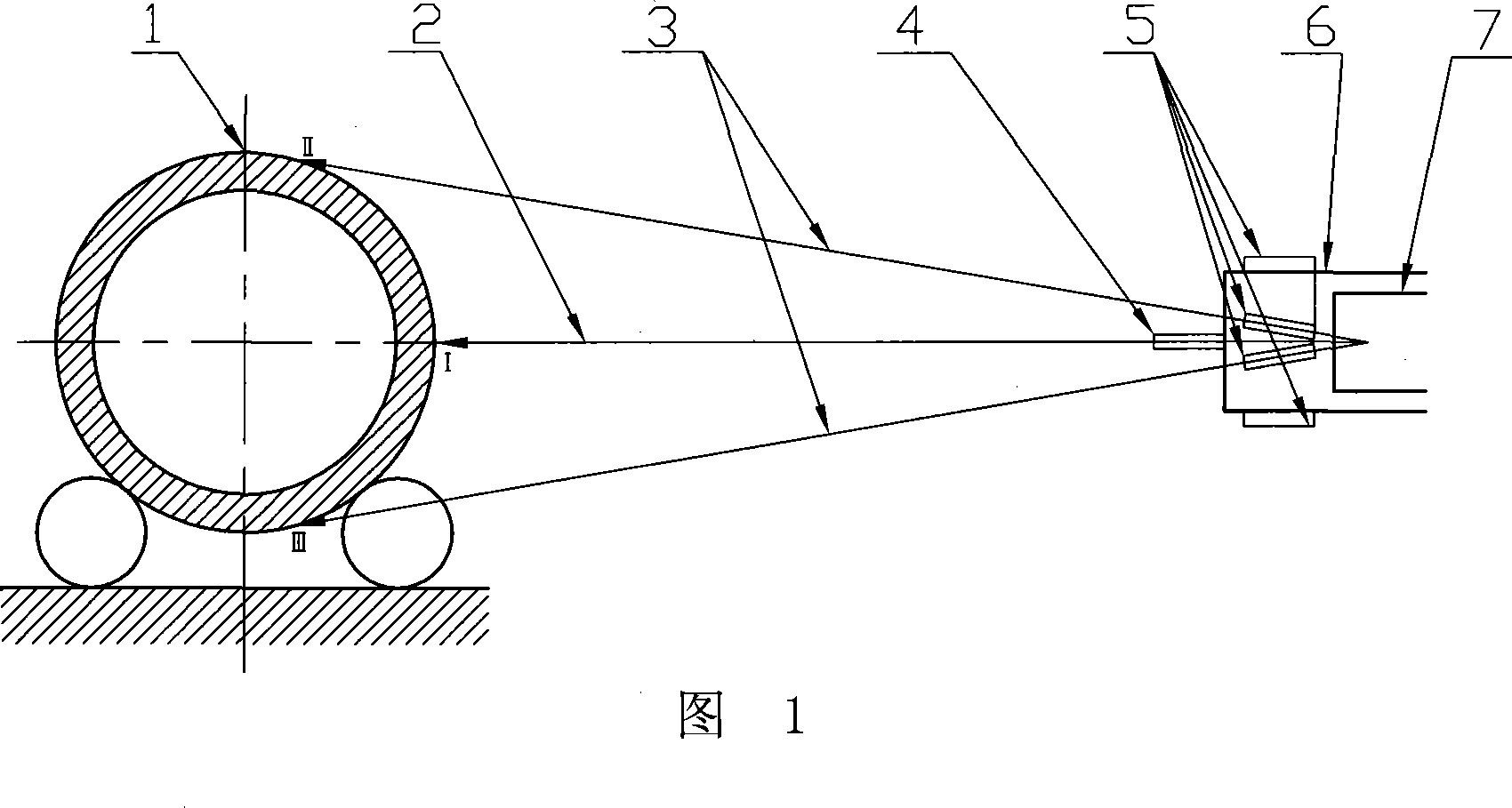

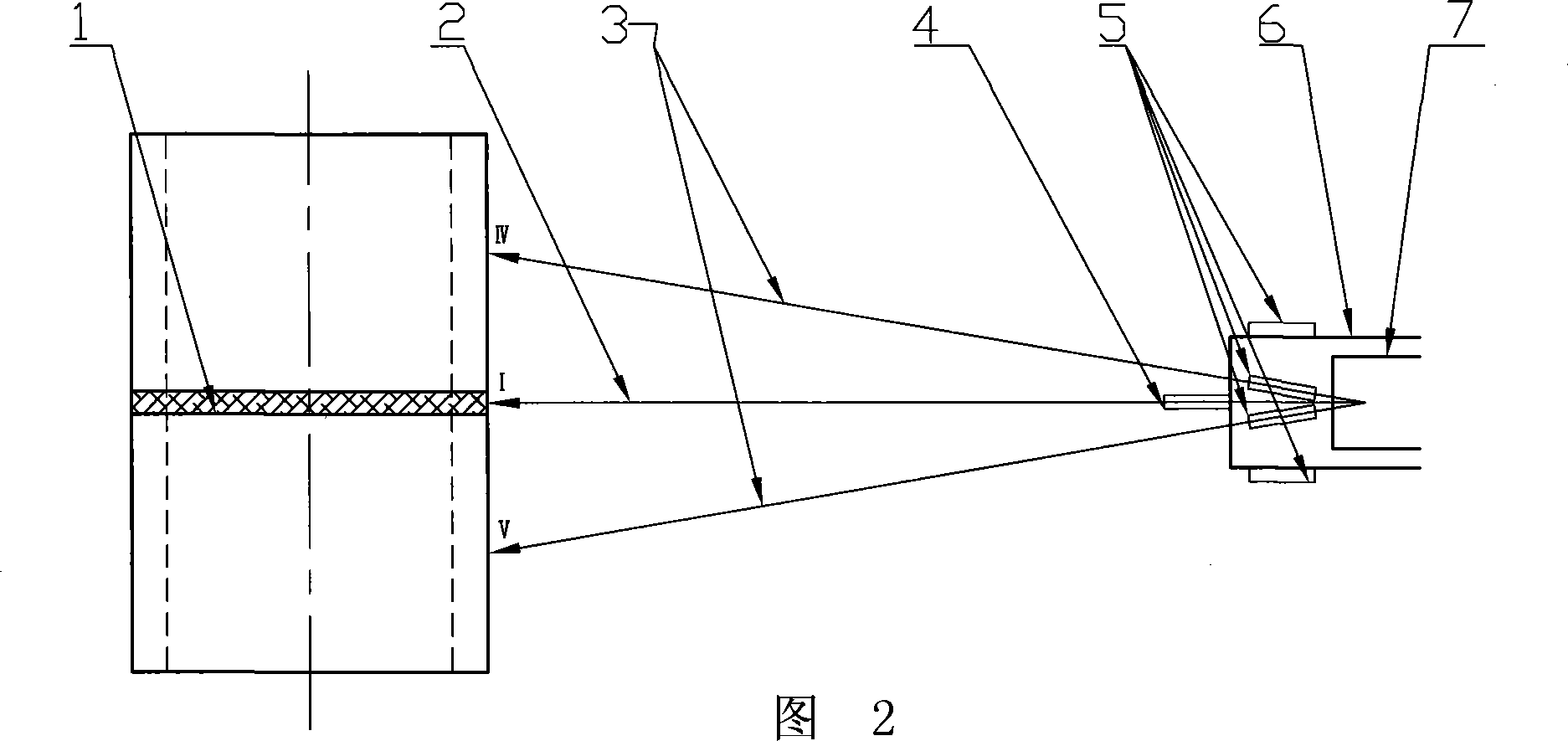

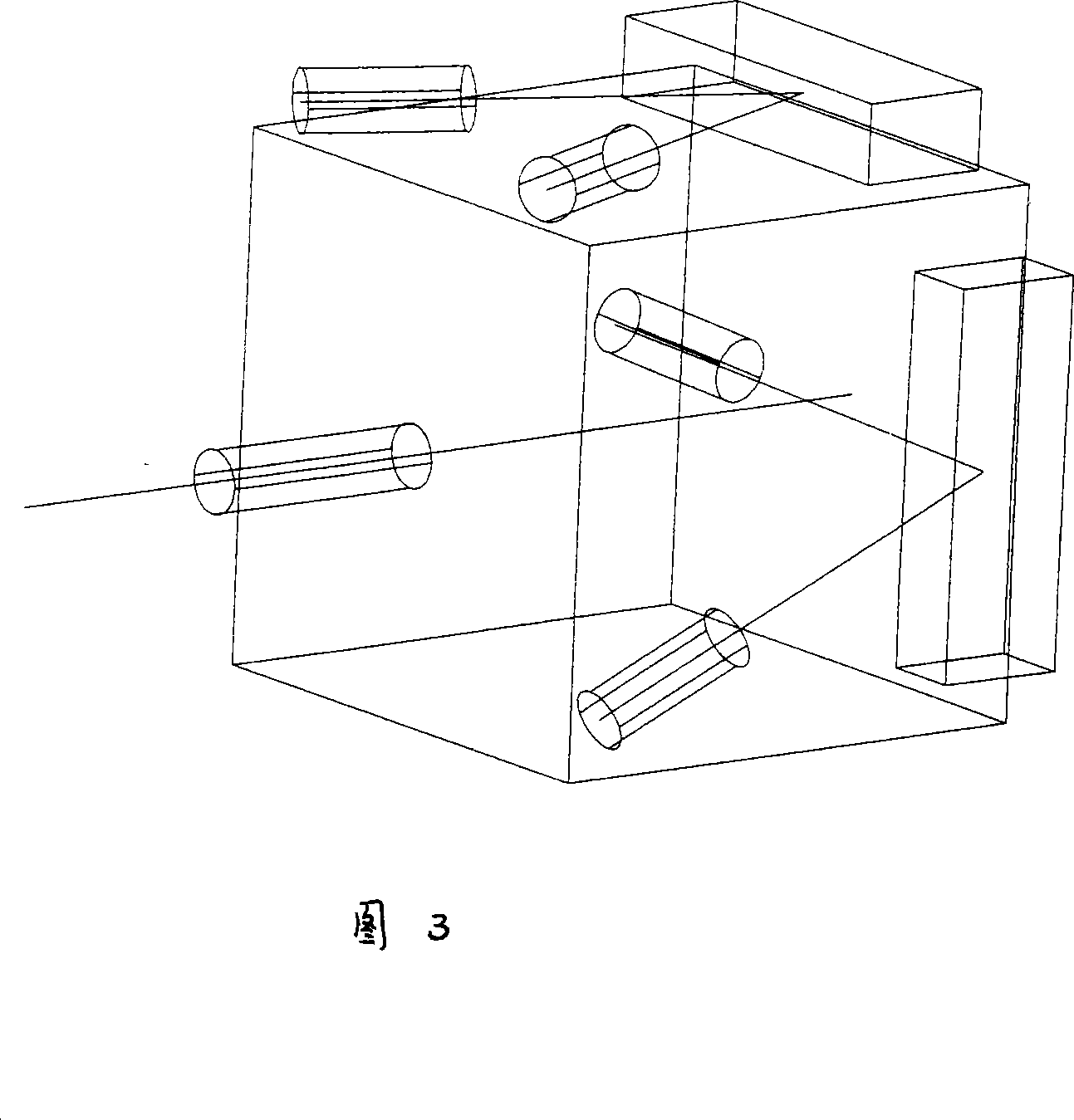

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail as follows:

[0028] Utilize the high-energy ray machine-electron linear accelerator to transilluminate the girth weld 1 of the cylindrical pressure vessel. First, the casing 6 of the device of the present invention is nested with the X-ray head 7, and the positioning laser pointer 4 is installed and fixed on the front end of the casing 6. The axes of the device 4 coincide with each other; two dividers with directional laser pointers 5 and meshing gears 8 and gear boxes are fixed on the two adjacent faces of the regular square prism housing 6, and ensure that each divider The axis of the opening and closing hinge is perpendicular to the axis of the positioning laser pointer 4 , and the angle bisector of each divider is parallel to the axis of the positioning pointer 4 . Then adjust the angle between the two pairs of directional laser pointers 5 to make it suitable for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com