Automatic detection and screening system with multiple conveying disks

An automatic detection and conveying tray technology, applied in sorting and other directions, can solve problems such as dust or impurities blowing in, single image, damage, etc., to improve detection accuracy and precision, avoid missed or wrong detection, and ensure detection quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

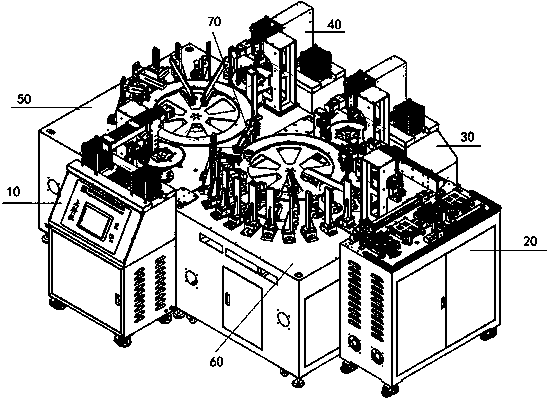

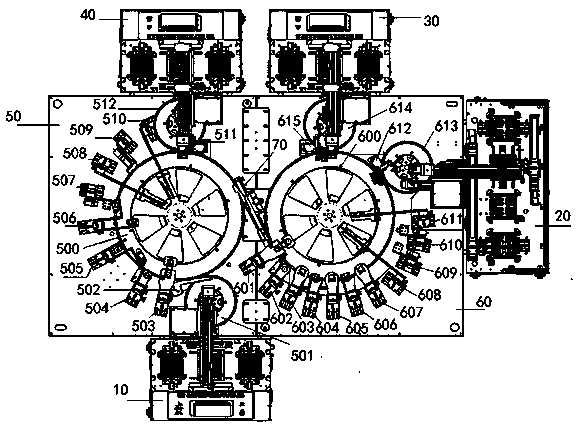

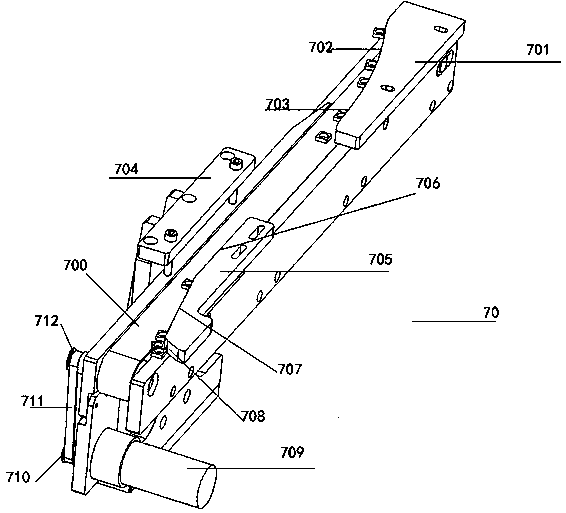

[0048] Combine below Figure 1 to Figure 8 , the present invention is further described:

[0049] Such as figure 1 As shown, the automatic detection and screening system of the multi-transport tray of the present invention includes a feeding device 10, a first unloading device 20, a second unloading device 30, a third unloading device 40, a first detection unit 50 and a second detection unit Unit 60.

[0050] The feeding device 10 guides the object to be detected into the first rotating disk body of the first detection unit 50, and multiple phase detection devices in the first detection unit 50 around the first rotating disk body take pictures of the detection object from different directions , the object to be detected enters the second rotating disc body of the second detecting unit 60 through the connecting mechanism between the first detecting unit 50 and the second detecting unit 60, and a plurality of pick-ups in the second detecting unit 60 around the second rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com