Supersonic and eddy composite automatic detector for pipe

A technology of automatic detection device and automatic control device, which is used in the analysis of solid and material magnetic variables using sonic/ultrasonic/infrasonic waves, which can solve the problems of large plant area, wear of probe racks, and complicated equipment adjustment, so as to reduce plant occupation. area, ensuring accuracy and reliability, and the effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

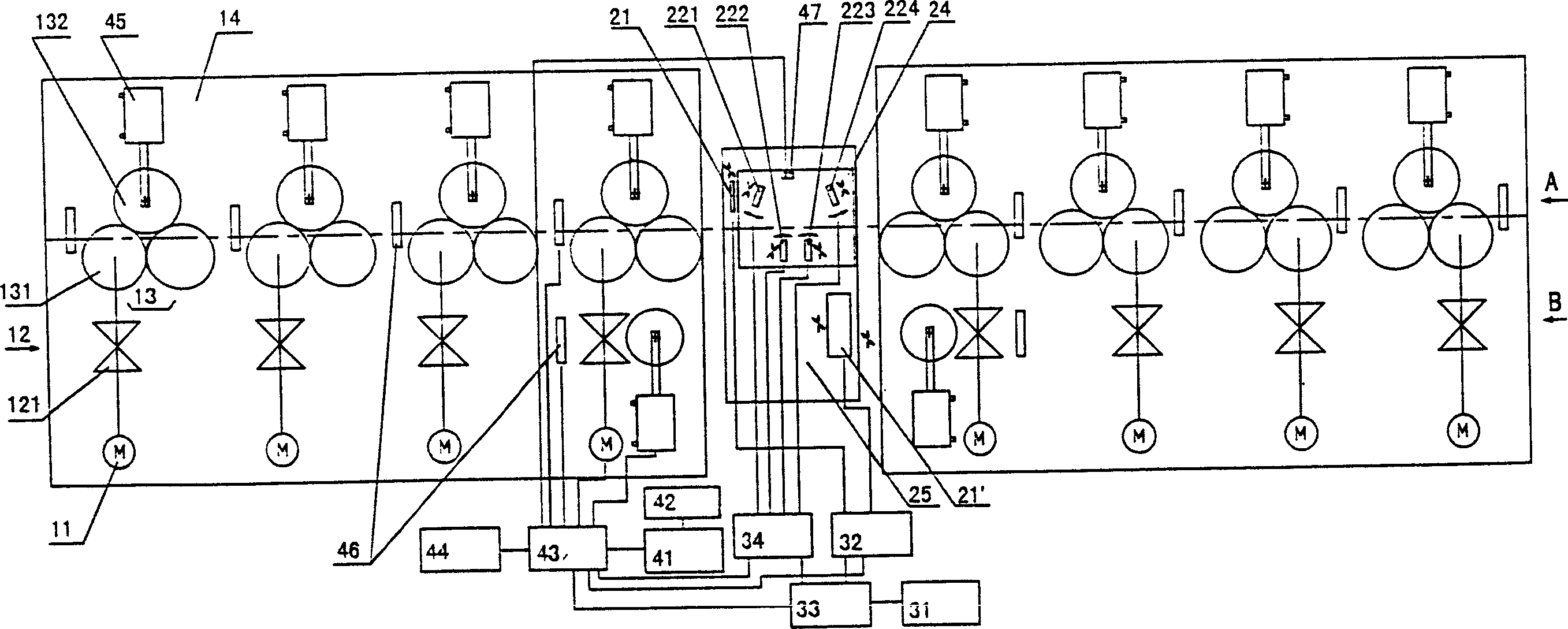

[0027] Such as figure 1 , 2-1 , 2-2, 3-1, 3-2, and 4, the present invention is made up of transmission mechanism, detection device, detection display and recording device and automatic control device, wherein:

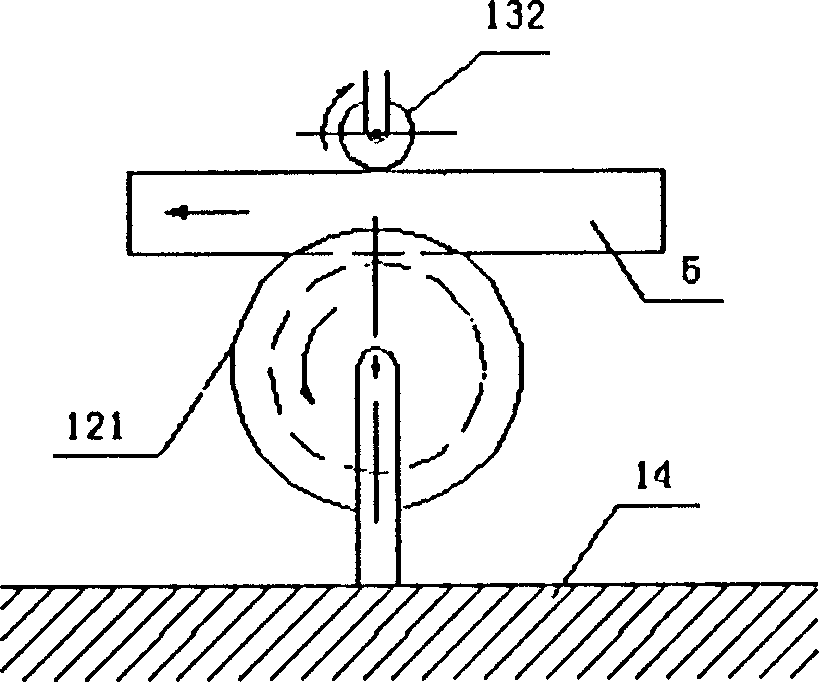

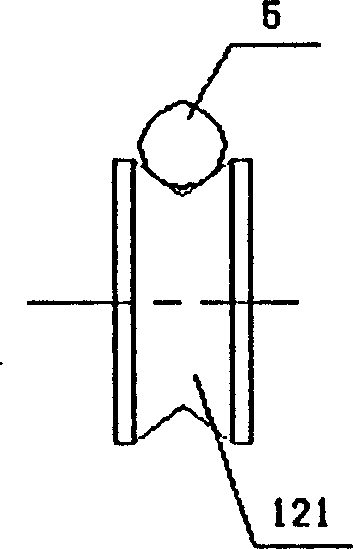

[0028] The transmission mechanism is a vortex detection line A and a vortex penetration detection line B composed of a DC speed regulating motor 11, a transmission roller table 12 and a three-wheel drive 13, and the transmission roller table 12 of the eddy penetration detection line B is a set of belts The cylindrical roller 121 with "V" shaped groove is fixed on the workbench 14 of the transmission mechanism for feeding and discharging. On the two cylindrical rollers 121 near the two sides of the probe group, there are respectively equipped with an automatic The small pressing wheel 132 driven by the cylinder 45 in the control device prevents the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com