Fully-automatic die pressing lid maker

A fully automatic capping machine technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of difficult control of feeding accuracy, low running stability, and influence on the quality of bottle cap molding, and achieves an increase in automation. Guarantee the quality of detection and the effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

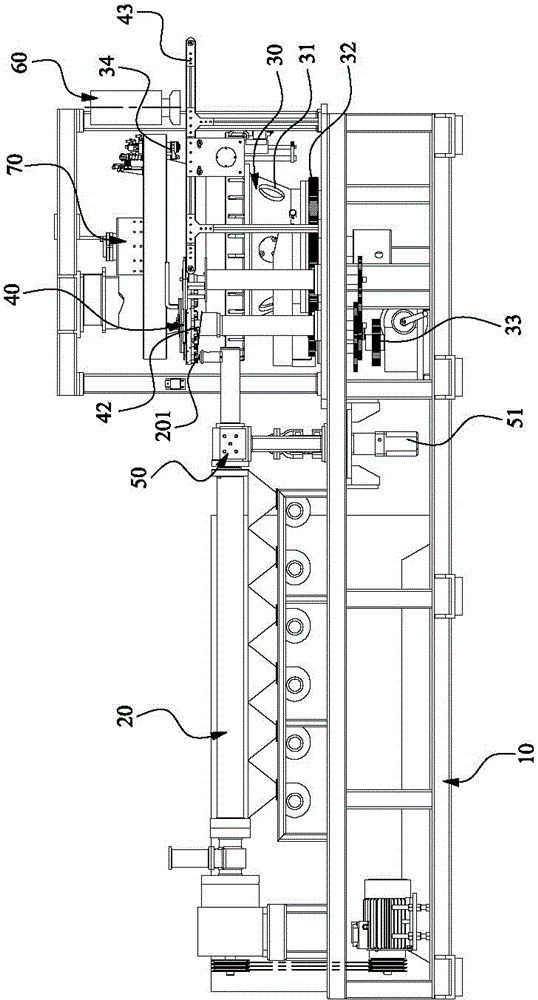

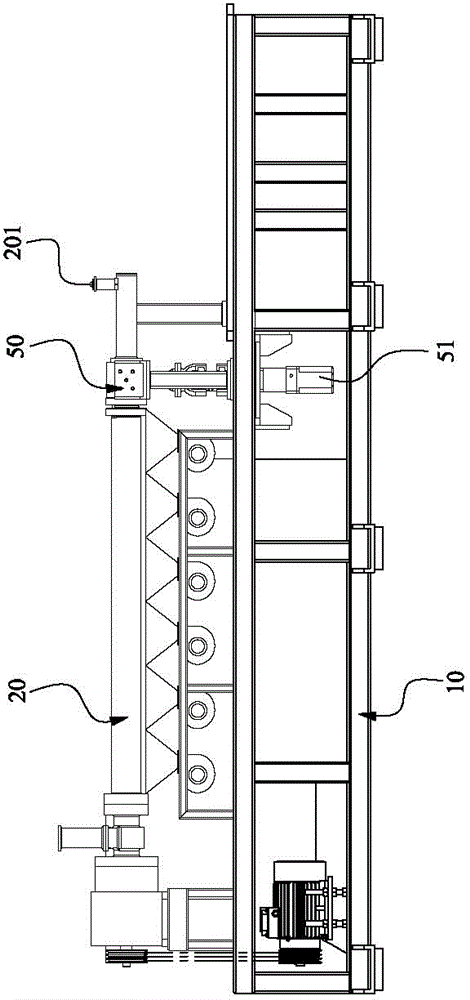

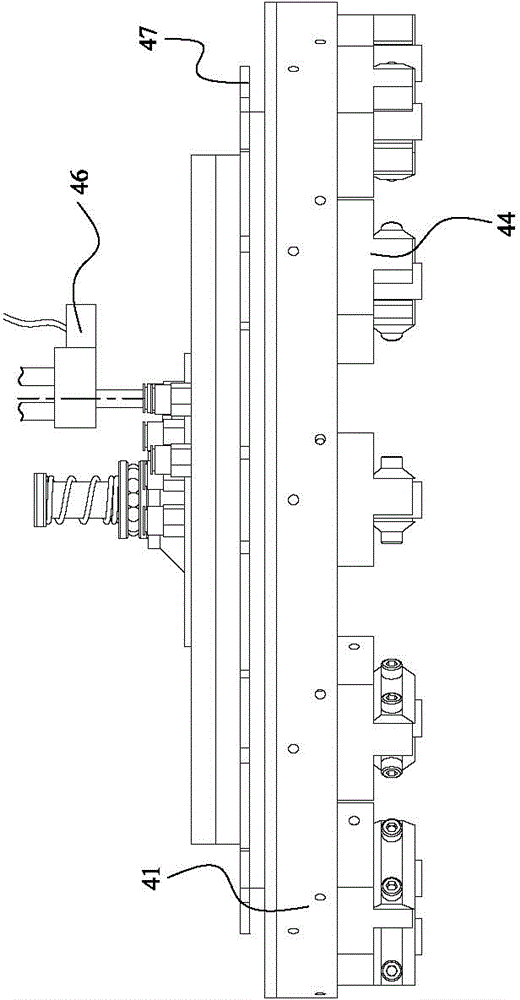

[0044] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10 and an extrusion die set 20 , a pressing die set 30 and a feeding and discharging die set 40 arranged on the frame 10 .

[0045] Wherein, the output end of the extrusion die group 20 has an extrusion port 201 with an opening upward, and the output end of the extrusion die group 20 is provided with a metering pump 50 that enables the extrusion port 201 to output the billet accurately, and the metering pump 50 is controlled by a servo The motor 51 is driven to stabilize the speed of the metering pump 50. Tests have shown that by using the metering pump 50 and subtracting the fluctuation of the screw of the extrusion module 20, the deviation of the feed is ±0.02g, which realizes accurate control of the feed. .

[0046] The pressing die set 30 includes a rotating main body 31, a slewing support 32 and a driving device 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com