Automatic cleaner for greasy dirt on surface of petroleum drilling tool joint outside screw

A surface oil stain and oil drilling technology, which is applied in the field of automatic cleaners for oil stains on the external thread surface of oil drilling tool joints, can solve the problems of high potential danger, low cleaning efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

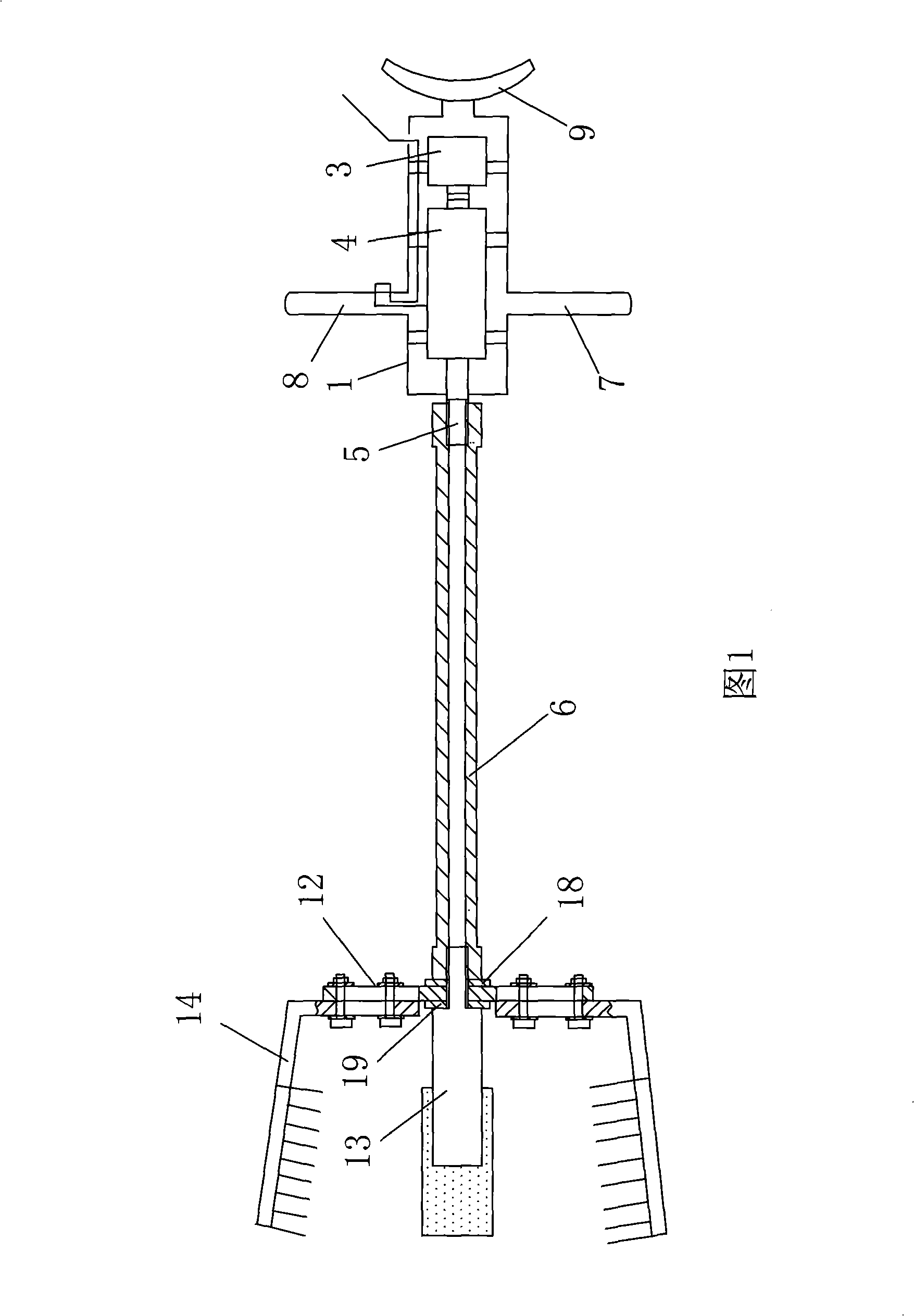

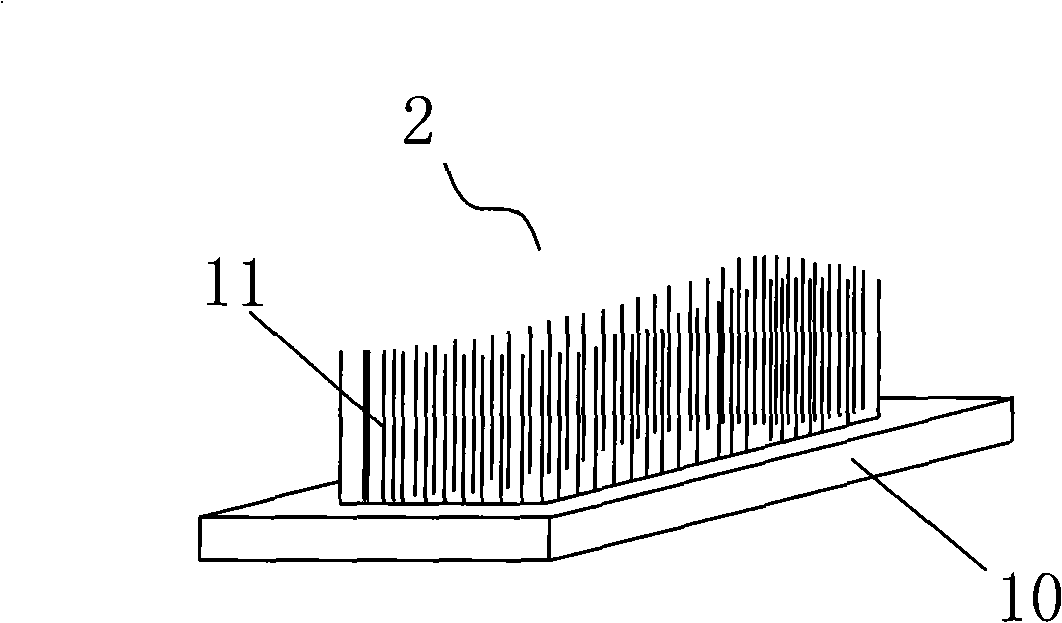

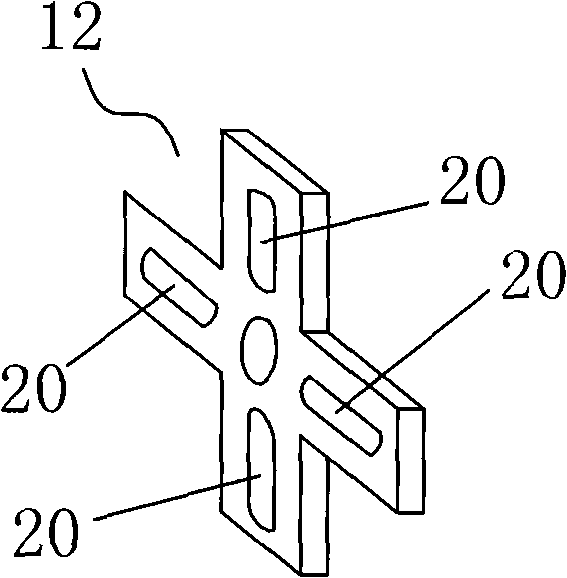

[0021] Figure 1, figure 2 , image 3 , Figure 4 As shown, the present invention is an automatic cleaner for oil stains on the external thread surface of a petroleum drilling tool joint, which is characterized in that it includes: a power unit and a wire brush;

[0022] The power device includes a housing 1, a motor 3 and a reducer 4 fixed in the housing 1;

[0023] The wire brush includes: a hollow connecting sleeve 6, a cross-shaped connecting frame 12 with a central through hole, a stepped shaft-shaped stabilizing bar 13, four brush heads 2 and four splints 14; the hollow connecting sleeve 6 One end is screwed to the output shaft 5 of the reducer 4, the cross-shaped connecting frame 12 is sleeved on the thin end of the stabilizer bar 13 through its central through hole, and the other end of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com