Efficient detection device for polymer cable production

A detection device and polymer technology, applied in the direction of measuring devices, using mechanical devices, analyzing materials, etc., can solve the problems of high manufacturing cost and poor detection effect, and achieve the goal of reducing production cost, enhancing the scope of use, and ensuring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

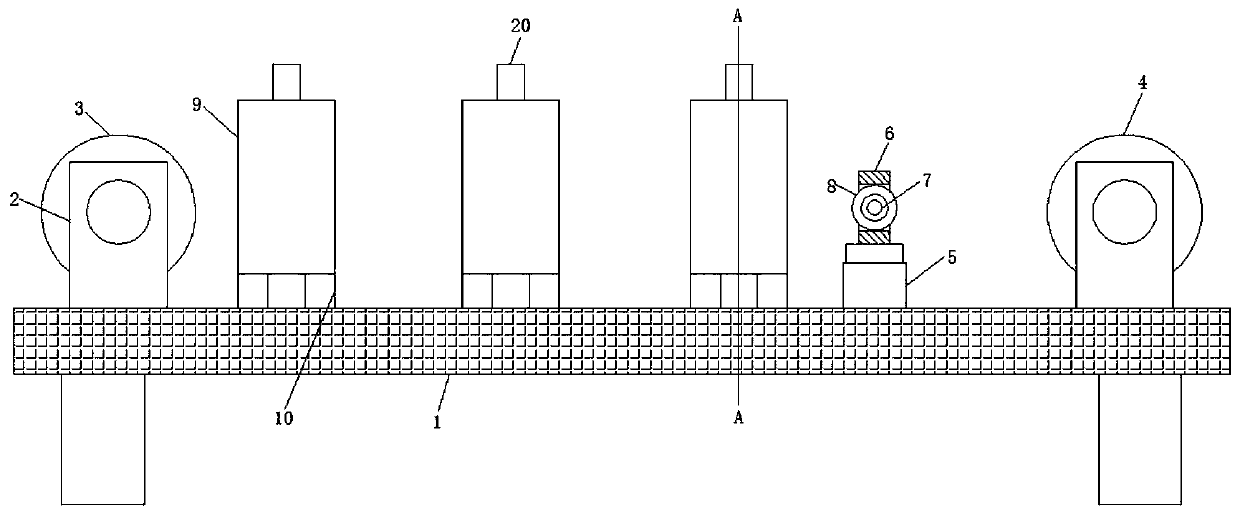

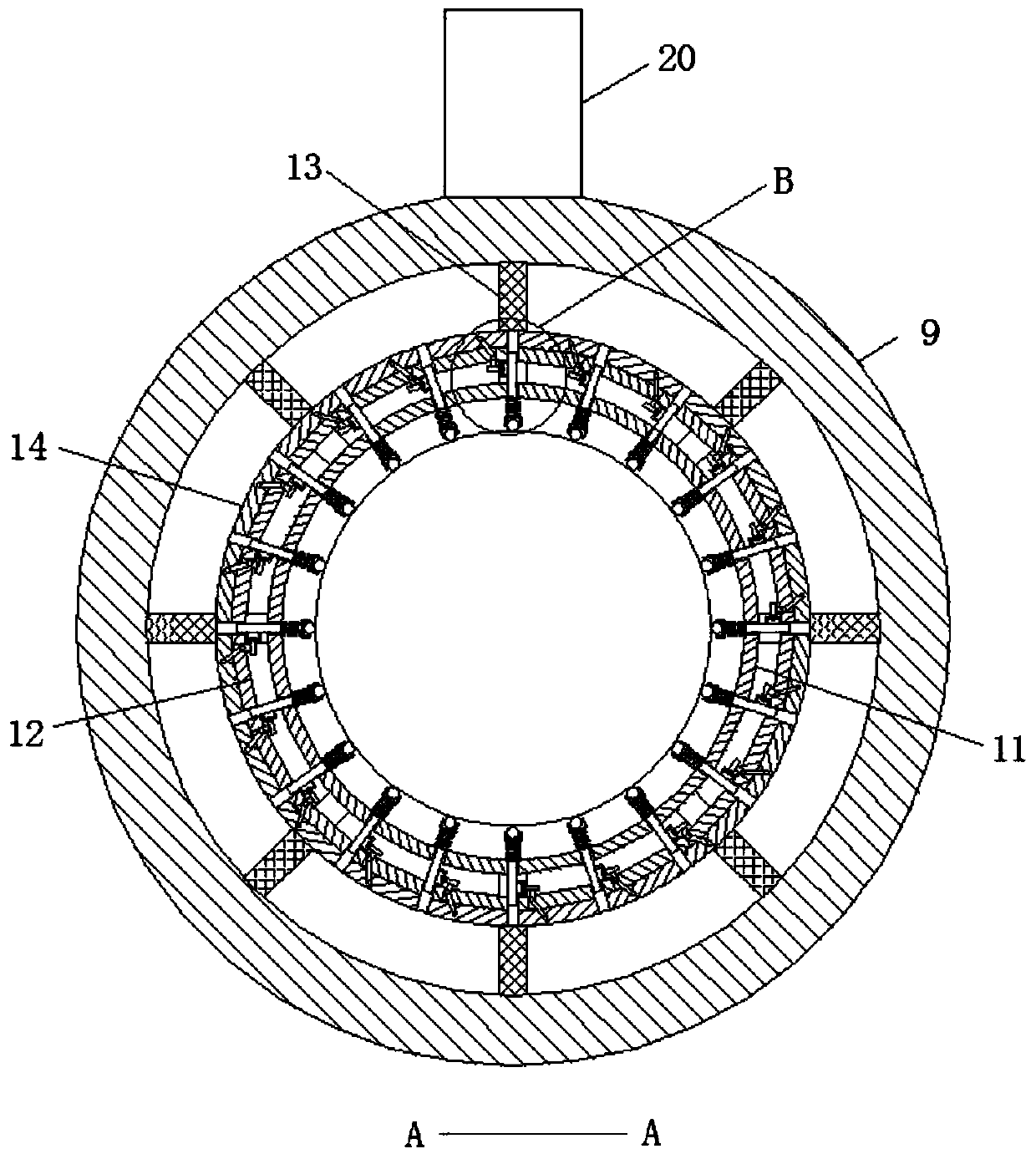

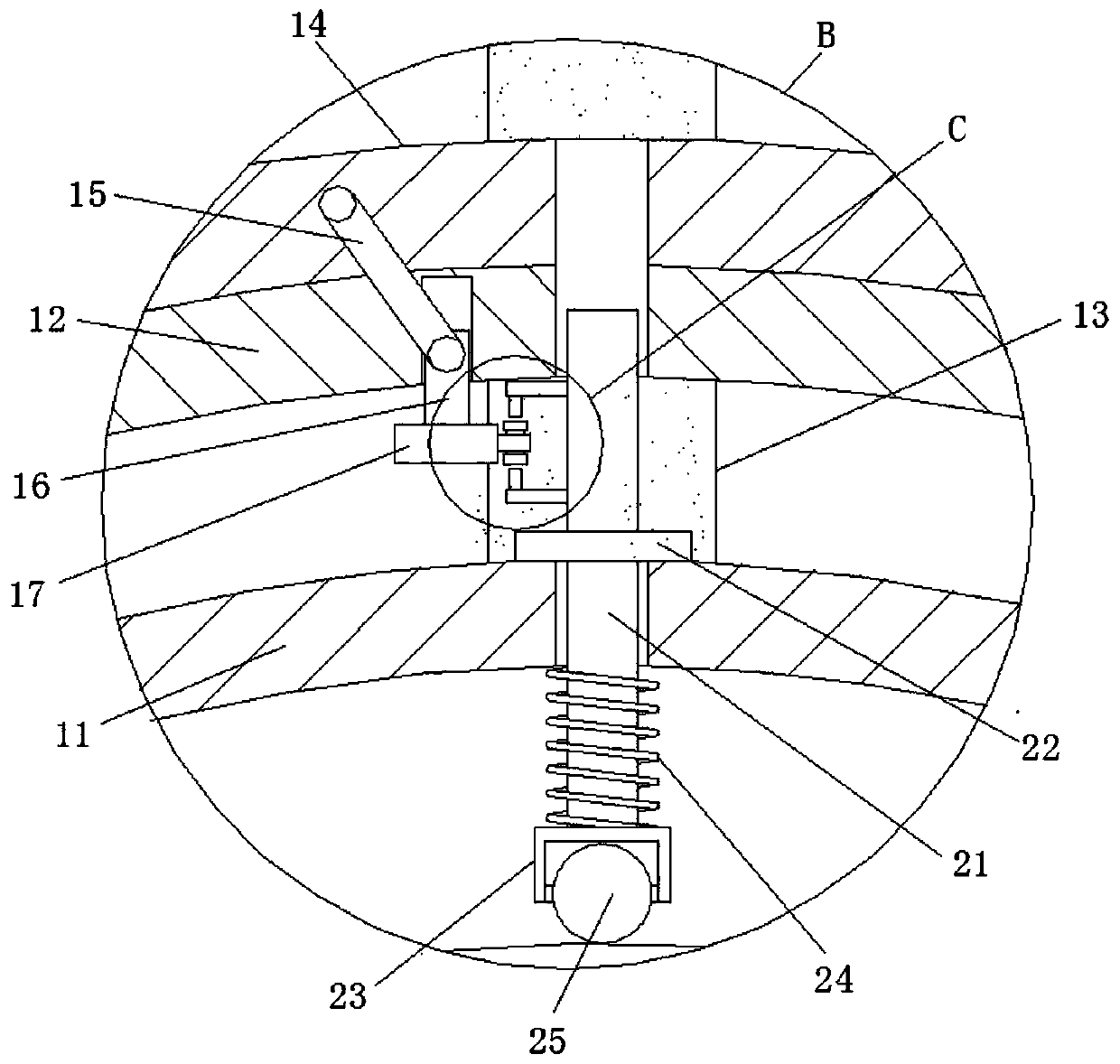

[0026] refer to Figure 1-4 , a high-efficiency detection device for polymer cable production, including a detection platform 1, the four corners of the lower end surface of the detection platform 1 are fixedly connected with support legs by screws, and both sides of the upper end surface of the detection platform 1 are fixedly connected with support seats by screws 2. There are two support bases 2, a take-up roller 3 and a pay-off roll 4 are respectively installed between the two support bases on the same side, and a detection ring 9 is provided in the middle of the detection table 1, and the detection ring 9 is provided with three One, both sides of the lower end of the detection ring 9 are welded with fixed columns 10, the lower end of the fixed column 10 is fixed on the detection platform 1 by screws, the inner side of the detection ring 9 is provided with an installation ring 11, and the outer side of the installation ring 11 is provided with an adjustment ring 12 , the m...

Embodiment 2

[0029] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the side of the upper end surface of the detection table 1 close to the pay-off roller 4 is fixedly connected with a cylinder 5 by screws, and the output end of the cylinder 5 is fixedly connected with a guide plate 6 by screws. The side wall of guide plate 6 runs through and is provided with rectangular hole, and between the front and rear end sidewalls of rectangular hole, is connected with installation rod 7 by rolling bearing rotation, and the rod outer wall of installation rod 7 is fixedly connected with guide wheel 8 by key.

[0030] In this embodiment, through the cooperative use of the cylinder 5, the guide plate 6, the installation rod 7 and the guide wheel 8, it is ensured that the cable enters the detection ring in a horizontal position, and the sound alarm 20 is prevented from being squeezed by the gravity on the lower ball of the cable. The occurrence of the alarm ...

Embodiment 3

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the control switches 19 are electrically connected to the sound alarm 20 through wires.

[0033] In this embodiment, the control switch 19 is connected to the sound alarm 20 through wires, so as to ensure that the sound alarm 20 will generate an alarm after the control switch is squeezed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com