Internal thread detection method and system based on machine vision

A technology of machine vision and detection methods, applied in instruments, measuring devices, optical devices, etc., can solve the problems of limited size range of laser vision equipment, inability to obtain detection results at one time, and high cost of replacement of detection systems, and achieve a reasonable detection method. The effect of simplicity, guaranteed detection quality and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

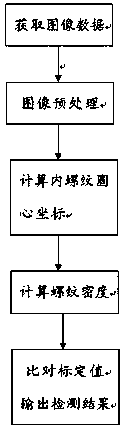

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0035] This embodiment takes the detection of a through-hole internal thread workpiece with a length of 20mm as an example of M8X1, and the specific implementation steps are as follows:

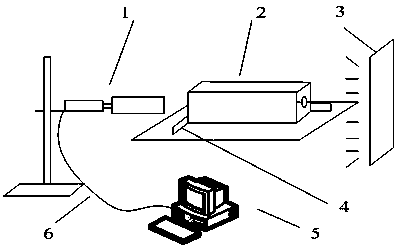

[0036] First, build an optical detection system, such as figure 1 Shown: an internal thread detection system based on machine vision, including: positioning tool 4, light source 3, industrial camera 1, host computer 5, the right side of the positioning tool 4 is provided with a light source 3, and the left side is provided with an industrial camera 1, so The industrial camera 1 is connected with the upper computer 5 through the data line 6; the positioning tool 4 is provided with a positioning structure to ensure that the distance between the threaded port of each internally threaded workpiece 2 to be detected and the lens of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com