Testing clamp and method for improving mechanical fatigue performance of composite material

A technology of mechanical fatigue and composite materials, which is applied in the field of sample preparation methods and supporting fixtures for enhancing the detection strength of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

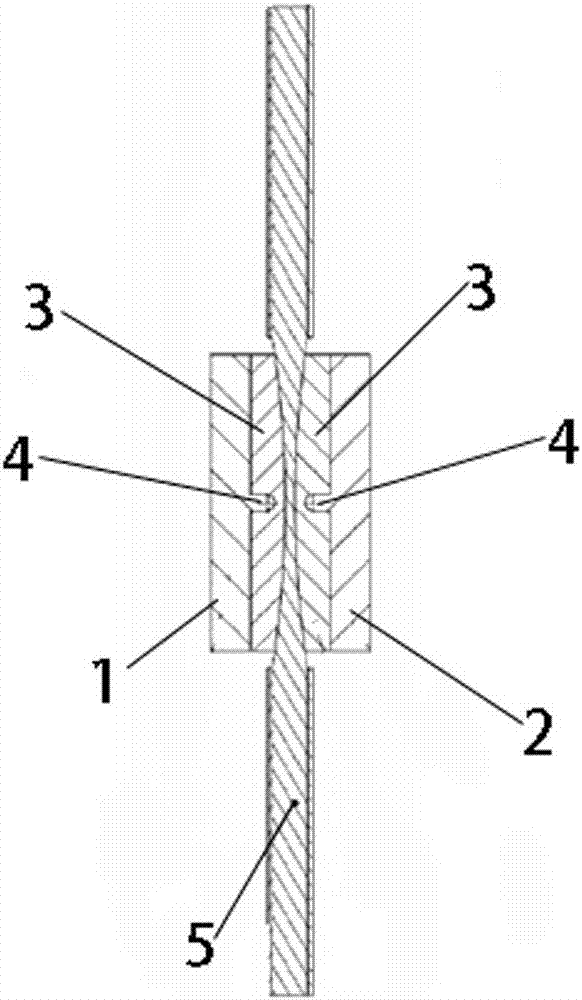

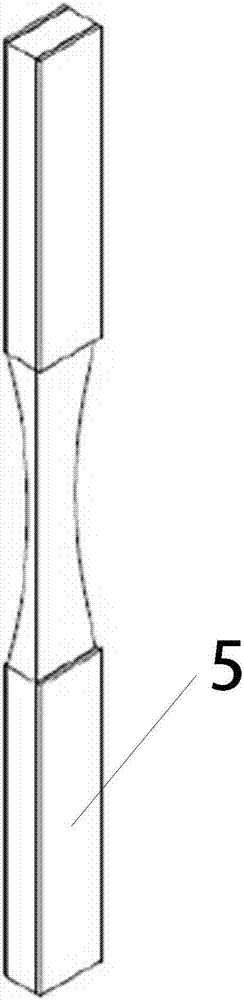

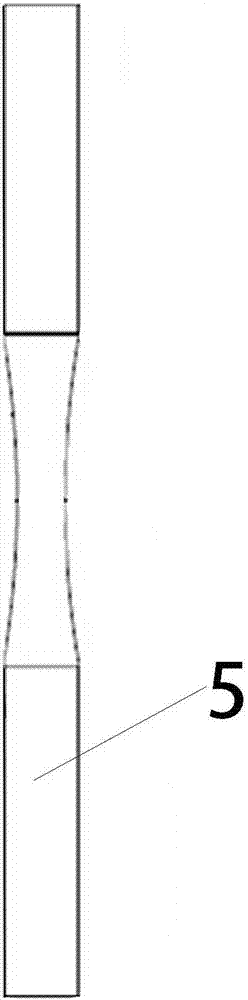

[0041] Such as figure 1 As shown, a detection fixture for improving the mechanical fatigue performance of composite materials includes a left splint 1, a right splint 2, the bottom surface of the left splint 1, and the top surface of the right splint 2 are fixedly connected with a protection pad 3 at the same time, and the protection pad 3 has a prominent arc. The protective pad 3 of the left splint 1 is fixedly connected through the positioning column 4 fixedly connected at the center of the left splint 1 . Firmly fix the protective pad 3 on the left splint 1. Similarly, the protective pad 3 of the right splint 2 is fixedly connected through the positioning column 4 fixedly connected at the center of the right splint 2, so that the protective pad 3 is firmly fixed on the right splint 2. Specifically, the bottom surface of the left splint 1 is fixedly connected with the positioning column 4, and the left splint 1 is fixedly connected with the protective pad 3 on the left spl...

Embodiment 2

[0044] Such as figure 1 As shown, a clamping tool for materials to be inspected includes a left splint 1, a right splint 2, the bottom surface of the left splint 1, and the top surface of the right splint 2 are fixedly bonded with a protective pad 3 at the same time, and the protective pad 3 has Prominent camber. The protective pad 3 of the left splint 1 is fixedly connected through the positioning column 4 fixedly connected at the center of the left splint 1 . Firmly fix the protective pad 3 on the left splint 1. Similarly, the protective pad 3 of the right splint 2 is fixedly connected by the positioning column 4 fixedly connected at the center of the right splint 2, so that the protective pad 3 is firmly fixed on the right splint 2. Specifically, the bottom surface of the left splint 1 is fixedly connected with the positioning column 4, and the left splint 1 is fixedly connected with the protective pad 3 on the left splint 1 through the positioning column 4. The position...

Embodiment 3

[0047] Such as figure 1 As shown, a material fixing tool to be inspected comprises a left splint 1 and a right splint 2, the bottom surface of the left splint 1 is a protruding arc surface, and the top surface of the right splint 2 is a protruding arc surface, the left splint 1 and the The radians of the arc surfaces of the right splint 2 are identical. A protection pad 3 is bonded to the protruding arc surface of the left splint 1 , and a protection pad 3 is also bonded to the protruding arc surface of the right splint 2 . In this embodiment, the left splint 1 and the right splint 2 are quadrilateral structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com