Product detection and sorting device for detecting aperture and sorting unqualified products

A sorting device and technology for qualified products, applied in sorting, mechanical diameter measurement, etc., can solve problems such as low efficiency, and achieve the effect of high efficiency and high detection pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

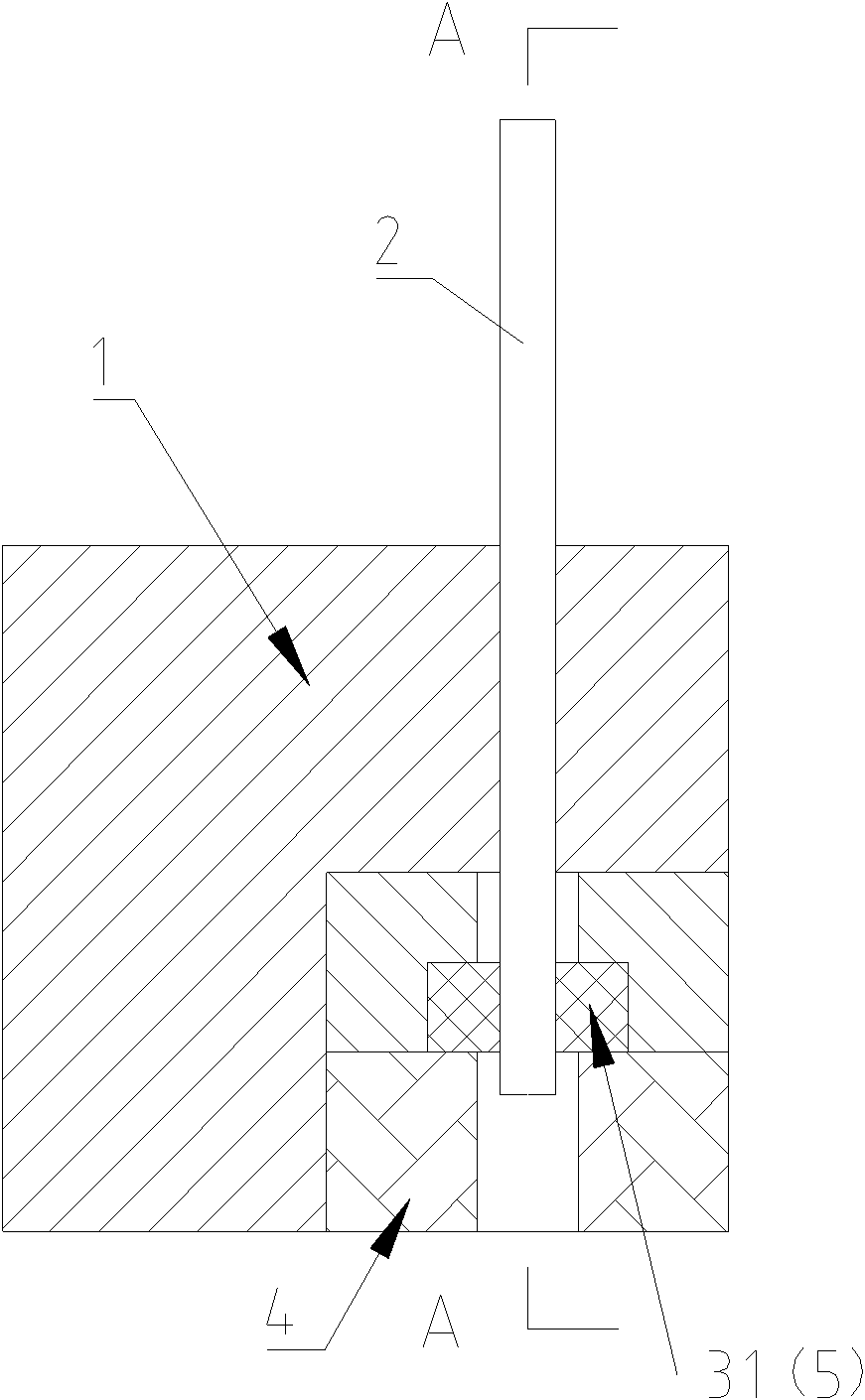

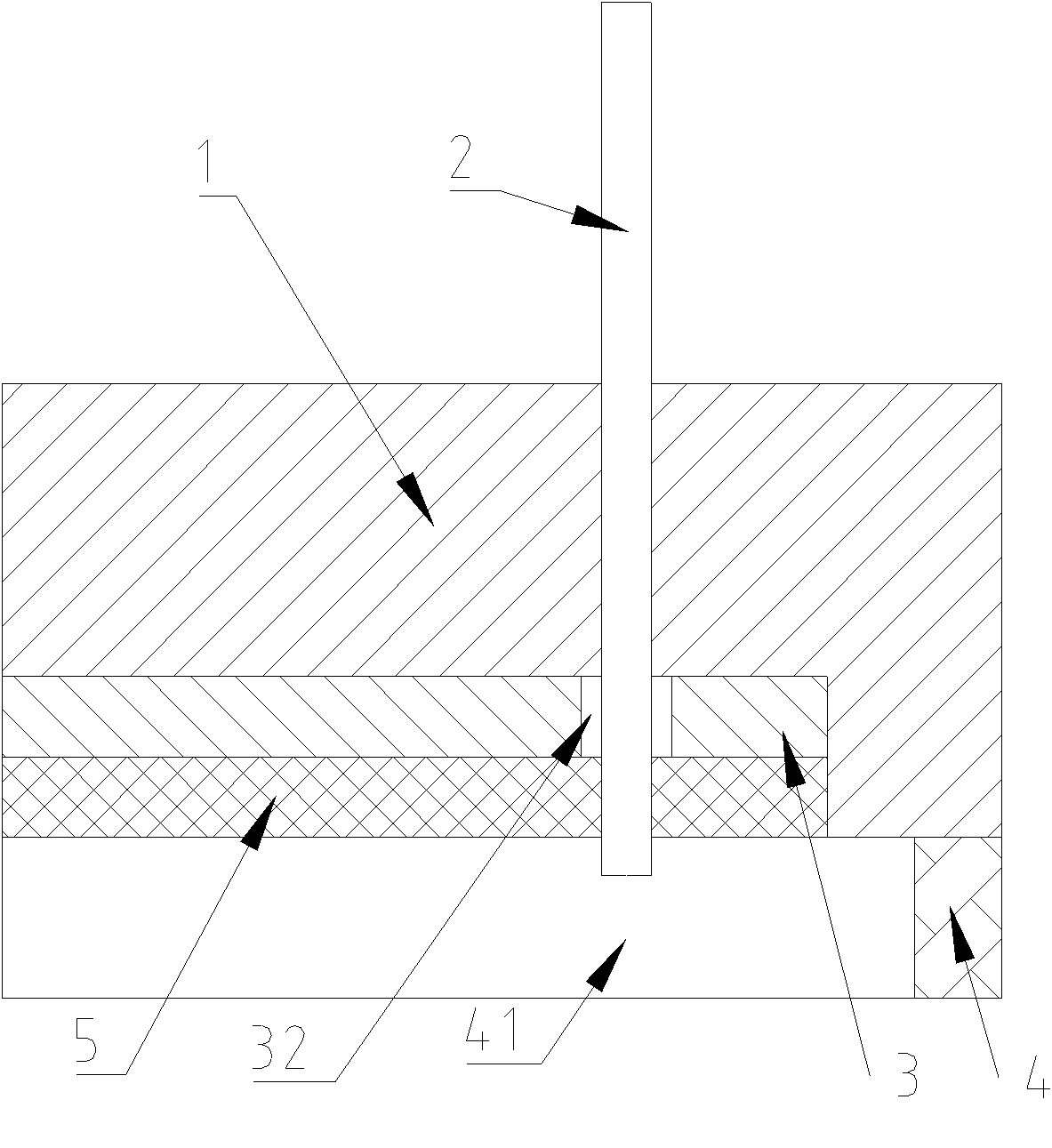

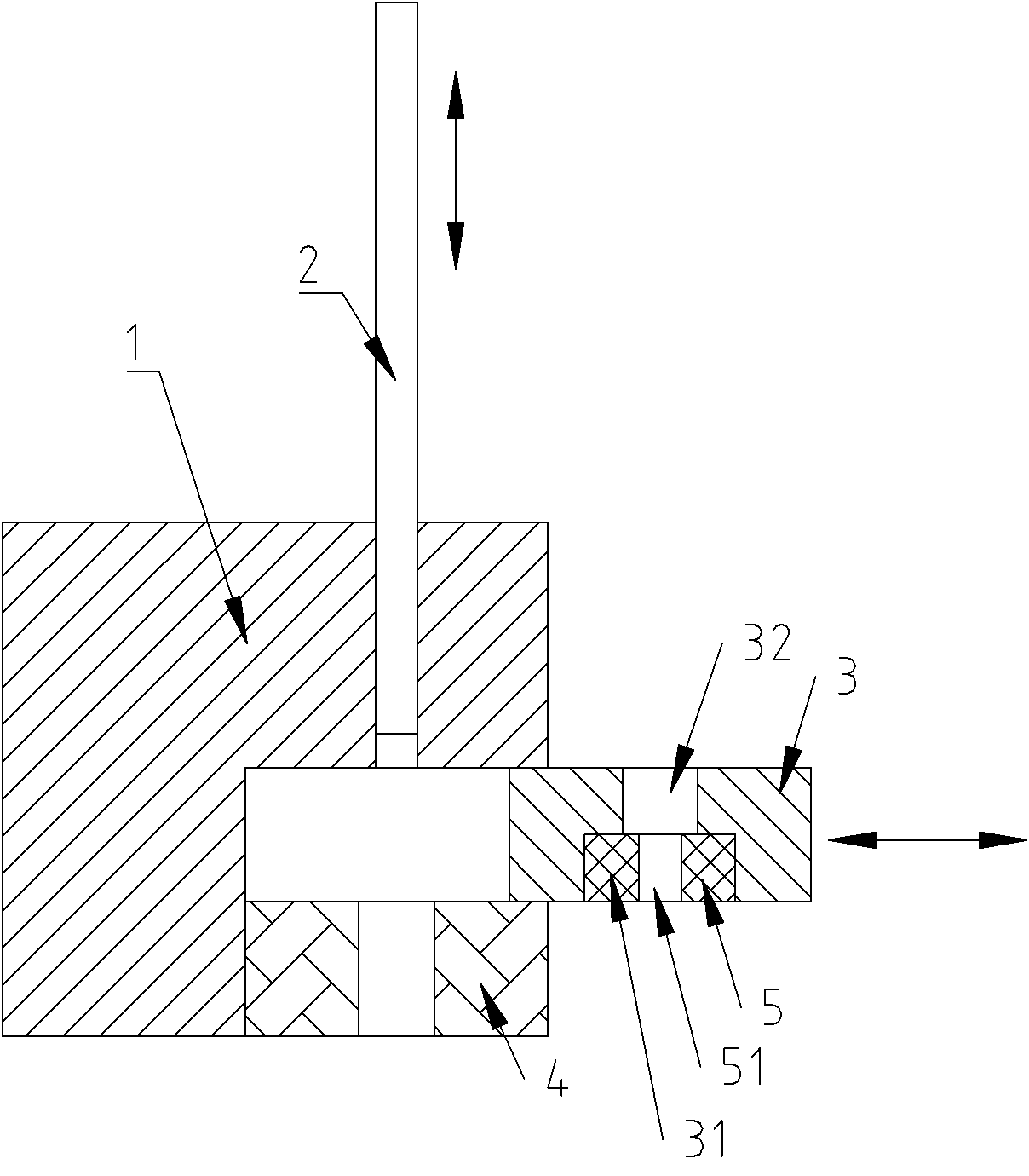

[0020] see Figure 1-7 As shown, the product detection and sorting device that detects the aperture and sorts the unqualified products includes a support 1, a go-no-go gauge for detecting whether the aperture is qualified 2, a pull-out plate for qualified products 3, and a drop plate for unqualified products 4 etc. 41 The lower end of the no-go gauge 2 is a no-go end 21, and what is connected with the no-go end is a no-go end 22. The go-no-go gauge is connected with an up and down movement mechanism (not shown) arranged on the support to drive it to move up and down. The qualified product pull-out plate 3 and the unqualified product drop plate 4 placed up and down are arranged on the side lower part of the support.

[0021] The bottom surface of qualified product pull-out plate has groove 31, and the qualified product pull-out plate also has vertical let-off hole 32. The go-no-go gauge can pass through the exit hole 32 and extend into the inspected hole 51 on the product 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com