SMT production line detection threshold setting method based on particle swarm optimization algorithm

A technology of particle swarm optimization and threshold setting, which is applied in the direction of structured data retrieval, calculation, calculation model, etc., can solve the problems of low product qualification rate and unreasonable threshold setting of SMT production line detection, so as to improve the product qualification rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

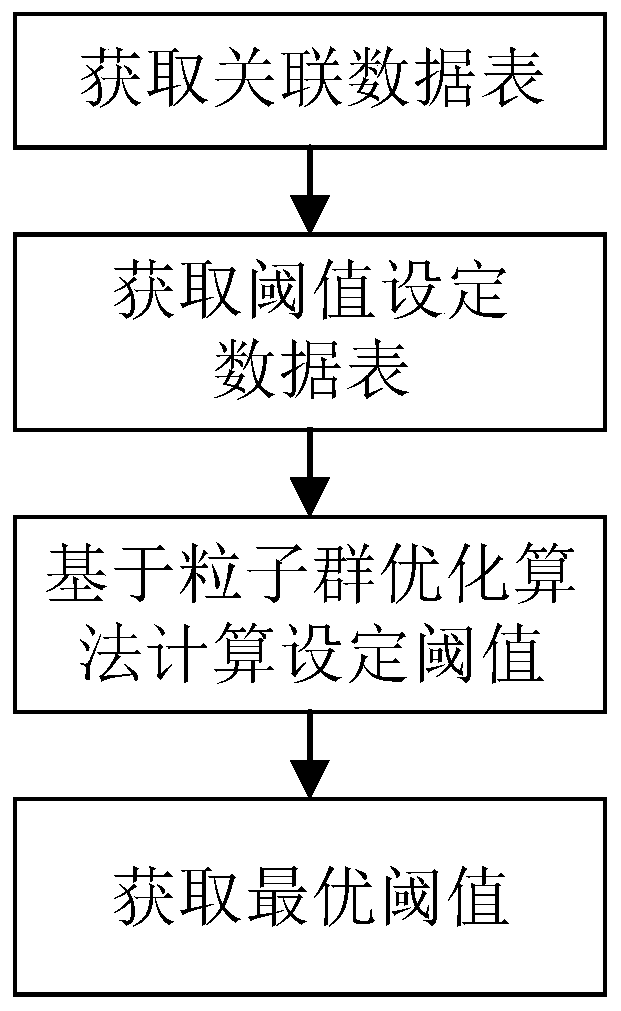

[0034] refer to figure 1 , the present invention comprises the following steps:

[0035] Step 1) Get the associated data table:

[0036]Obtain the solder paste amount data table that records the detection results of the SPI solder paste detector during the production process of the SMT production line. The field names included in the table are: PCB number, pad number, Component_id, vol, testresult, and Classification, and record AOI automatic optics The solder paste welding result data table of the detector test results. The field names included in this table are: PCB number, pad number, Component_id and Alarm, and the data table for recording manual repair defect types. The field names included in this table are: PCB number, pad number, Component_id, and Reason_Name, and the data in the three data tables with the same public field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com