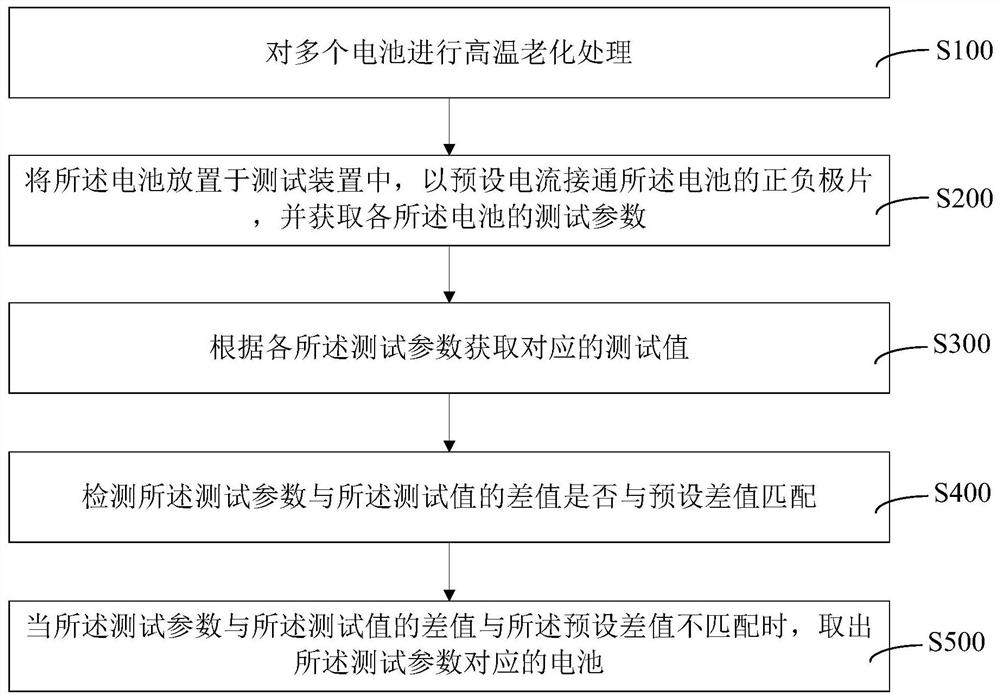

Battery pole piece breakage detection method and system

A battery pole piece and detection method technology, which is applied in the field of battery pole piece fracture detection method and system, can solve the problems of low battery detection pass rate, low accuracy rate, and inability to effectively identify battery cells, etc., so as to improve the detection quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

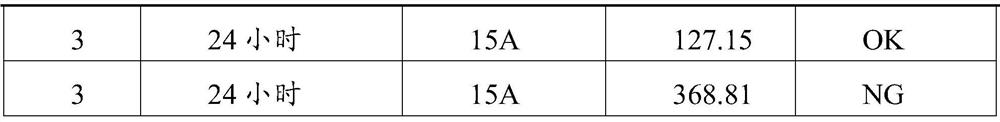

[0053] See Table 1 for details of the internal resistance detection embodiment of the battery pole piece fracture detection method.

[0054] Table 1

[0055]

[0056]

[0057] It can be seen from Table 1 that for the internal resistance detection of multiple batteries, different high-temperature aging times and detection currents cause a large change in the internal resistance, and the changed battery is the same, which causes the pole pieces to break More batteries are screened out, unqualified batteries are accurately screened out, the pass rate of battery testing is improved, and unqualified products are reduced from being used as qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com