Film laying system for copper-clad laminate combination equipment and copper-clad laminate combination equipment comprising same

A technology of combining equipment and copper clad laminates, which is applied in the directions of spreading thin soft materials, sending objects, and thin material processing. The effect of good film laying effect, reduced operator configuration and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

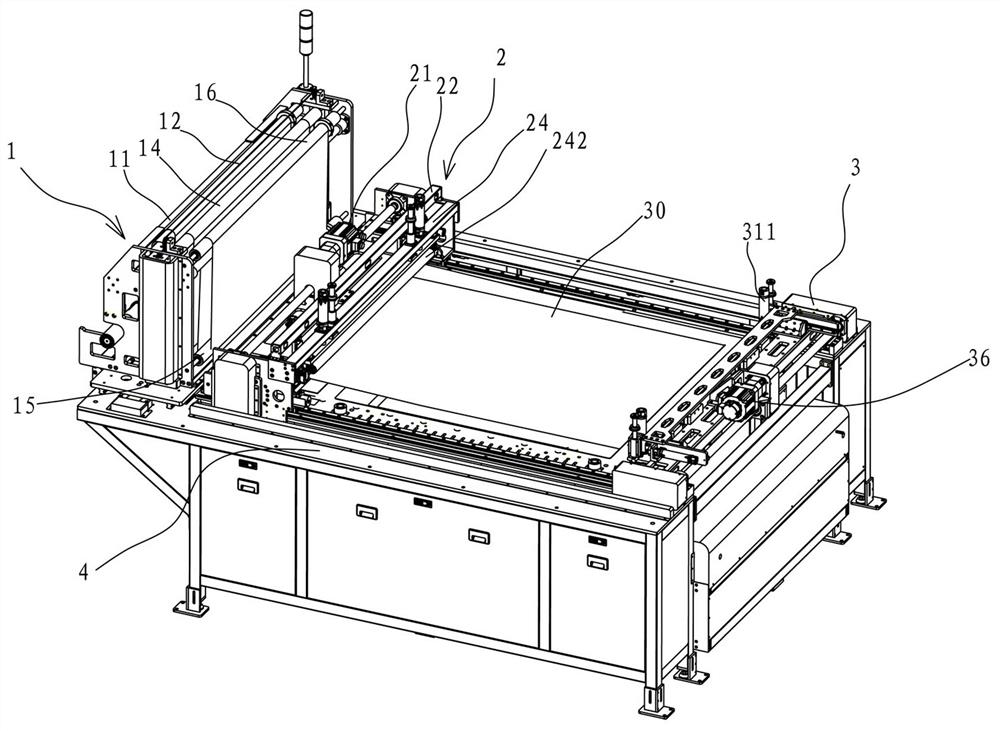

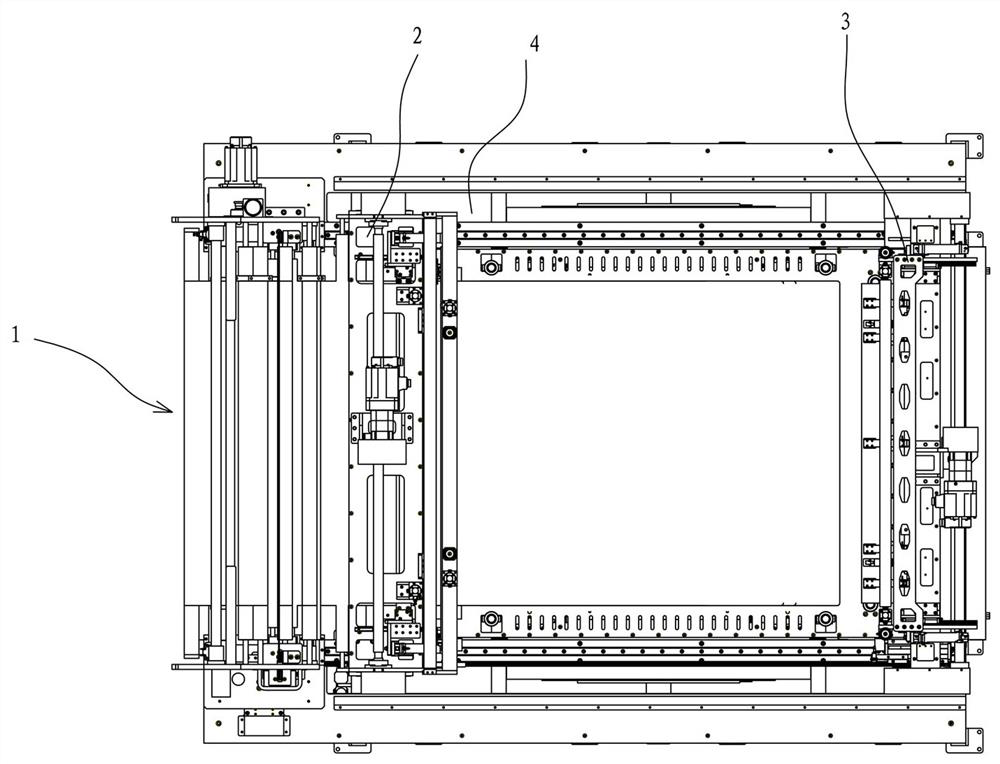

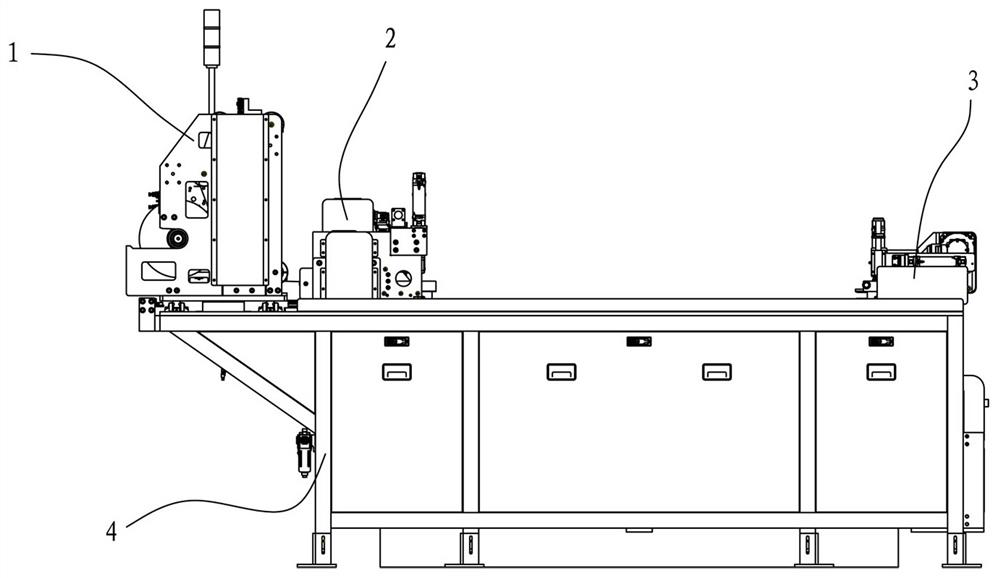

[0026] See Figure 1 to Figure 10 , Figure 1 to Figure 10 Disclosed is a film laying system of copper clad laminate assembly equipment, including a film supply mechanism 1, a film laying mechanism 2 and a film pressing mechanism 3, and the film laying mechanism 2 is arranged between the film supply mechanism 1 and the film pressing mechanism 3 between; the film laying mechanism 2 includes a drive assembly 21, a film clamping assembly 22, a film cutting assembly 23 and a film laying assembly 24; the film clamping assembly 22 clamps the film provided by the film supply mechanism 1, and the Under the drive of 21, the film is sent to the film pressing mechanism 3 to press the film head of the film, the film clamping assembly 22 releases the film, and retreats to the film cutting assembly 23, and the film laying assembly 24 presses the film 30 down, The film laying mechanism 2 retreats to a predetermined position, and the film cutting assembly 23 cuts off the film 30 . In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com