Preparation method of special phthalocyanine blue 15:3 pigment for offset printing ink

A technology of phthalocyanine blue and offset printing, which is applied in the direction of ink, application, organic dyes, etc., can solve the problems of outstanding production safety, high requirements for explosion-proof technology, and high energy consumption of the kneading machine method, and achieve low cost, little environmental pollution, and flow The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

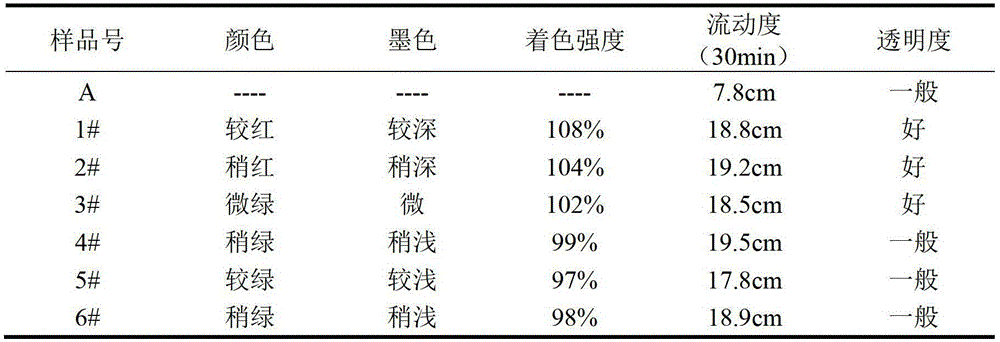

Examples

Embodiment 1

[0019] The crude copper phthalocyanine is produced by the solvent method. Urea, phthalic anhydride, cuprous, and ammonium molybdate are condensed in an alkylbenzene solvent at a high temperature of 160-190°C, and then the alkylbenzene solvent is separated by a distillation device. It is obtained by boiling to remove impurities, filtering, washing with water, drying and crushing.

[0020] Add 1000kg of crude copper phthalocyanine with a purity ≥ 98.5% and free copper ≤ 1000ppm to an 8000L ball mill, turn on the ball mill for ball milling, and control the temperature of the material in the machine at 105±2°C by adjusting the cooling water, and ball mill for 18 hours to obtain Ball milled product containing 40% α crystal form. Pass the ball-milled product through a magnetic filter in the discharge system to remove iron that is harmful to offset printing inks, and collect the product to produce Phthalocyanine Blue 15:3, the average particle size of which is less than 1 μm.

[002...

Embodiment 2

[0023] The production method of the crude copper phthalocyanine in this example is the same as that in Example 1. Add 1000kg of crude copper phthalocyanine with purity ≥ 98.5% and free copper ≤ 1000ppm to a 10000L ball mill, turn on the ball mill for ball milling, and control it by adjusting the cooling water The material temperature in the machine is 130±2°C, ball milled for 20 hours, and the ball milled product containing 20% α crystal form is obtained. Pass the ball-milled product through a magnetic filter in the discharge system to remove iron that is harmful to offset printing inks, and collect the product to produce phthalocyanine blue 15:3, the average particle size of which is less than 1 μm.

[0024] Measure the offset printing ink resin, phthalocyanine blue 15:3, vegetable oil, and solvent according to the formula, mix and pre-stir for 1 hour, then heat up to 70 degrees Celsius and knead for 6 hours, and after ink pricking and tempering, the α and β mixed crystals w...

Embodiment 3

[0026] The production method of the crude copper phthalocyanine in this example is the same as in Example 1. Add 1000kg of crude copper phthalocyanine with a purity ≥ 98.5% and free copper ≤ 1000ppm to a 12000L ball mill, turn on the ball mill for ball milling, and control it by adjusting the cooling water The material temperature in the machine is 110±2°C, ball milled for 25 hours, and the ball milled product containing 32% of α crystal form is obtained. Pass the ball-milled product through a magnetic filter in the discharge system to remove iron that is harmful to offset printing inks, and collect the product to produce phthalocyanine blue 15:3, the average particle size of which is less than 1 μm.

[0027] Measure the offset printing ink resin, phthalocyanine blue 15:3, vegetable oil, and solvent according to the formula, mix and pre-stir for 1 hour, then heat up to 70 degrees Celsius and knead for 6 hours, and after ink pricking and tempering, the α and β mixed crystals wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com