Stirring process for water-free taphole clay production process

A mixing process and production process technology, applied in the field of refractory materials, can solve the problems of poor wettability of the binder, long stirring time, poor homogeneity, etc., and achieve good dry powder wettability, high mixing efficiency, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is carried out as follows:

[0026] (1) Dry mixing, put the brown corundum, silicon carbide, coke, clay, asphalt, and ferrosilicon nitride weighed according to the formula into the RV19 mixer for dry mixing, the stirring speed of the rotor is 85r / m, and the stirring time for 100S.

[0027] (2) Add binder tar, add the tar weighed according to the formula into the mixer, the tar adding speed is 1.4Kg / s, and the rotor stirring speed is 85r / m.

[0028] (3) Wet mixing, at first mixer carries out high-speed mixing, and rotor stirring speed is 153r / m, and stirring time is 200S; Then carry out low-speed stirring, and rotor stirring speed is 108r / m, and stirring time is 500S; Obtain thus the present invention Anhydrous gunpowder.

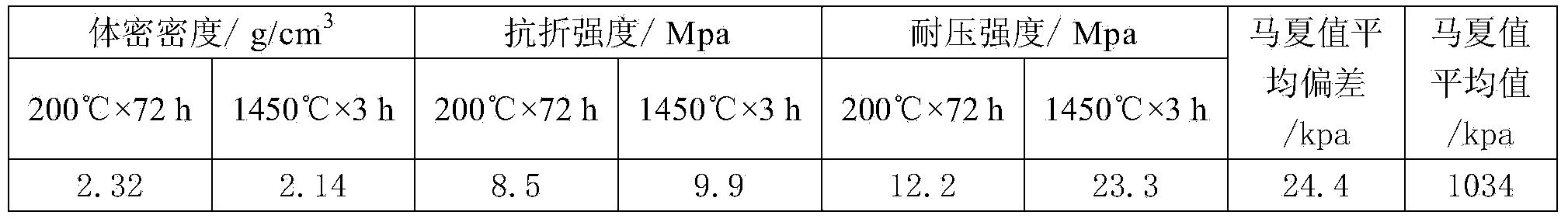

[0029] The performance index of embodiment 1

[0030]

Embodiment 2

[0032] The anhydrous taphole clay of the present invention was prepared in the same manner as in Example 1, except that the high-speed rotation part in the wet mixing step was 144 r / m.

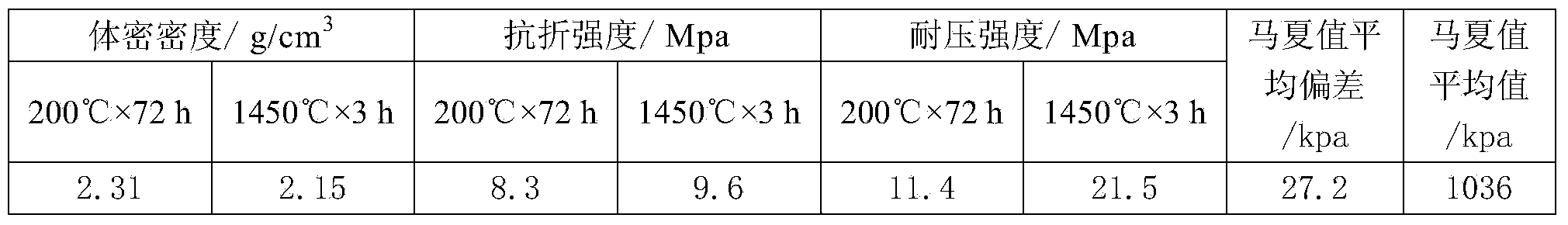

[0033] The performance index of embodiment 2

[0034]

Embodiment 3

[0036] The anhydrous taphole clay of the present invention was prepared in the same manner as in Example 1, except that the high-speed rotation part in the wet mixing step was 162 r / m.

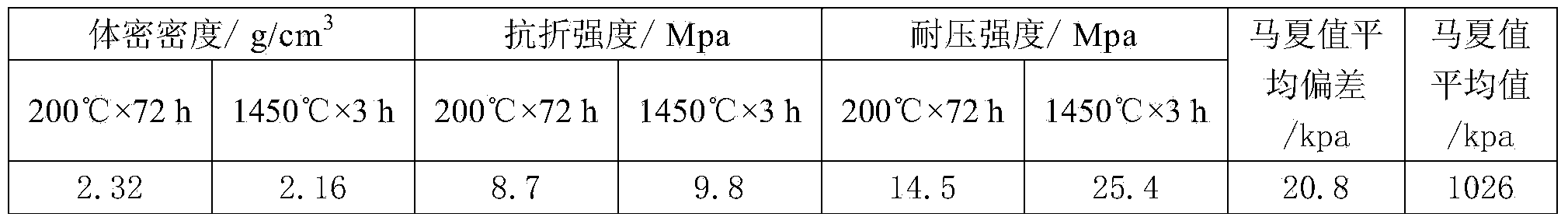

[0037] The performance index of embodiment 3

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com