Patents

Literature

38results about How to "Improve mud scraping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

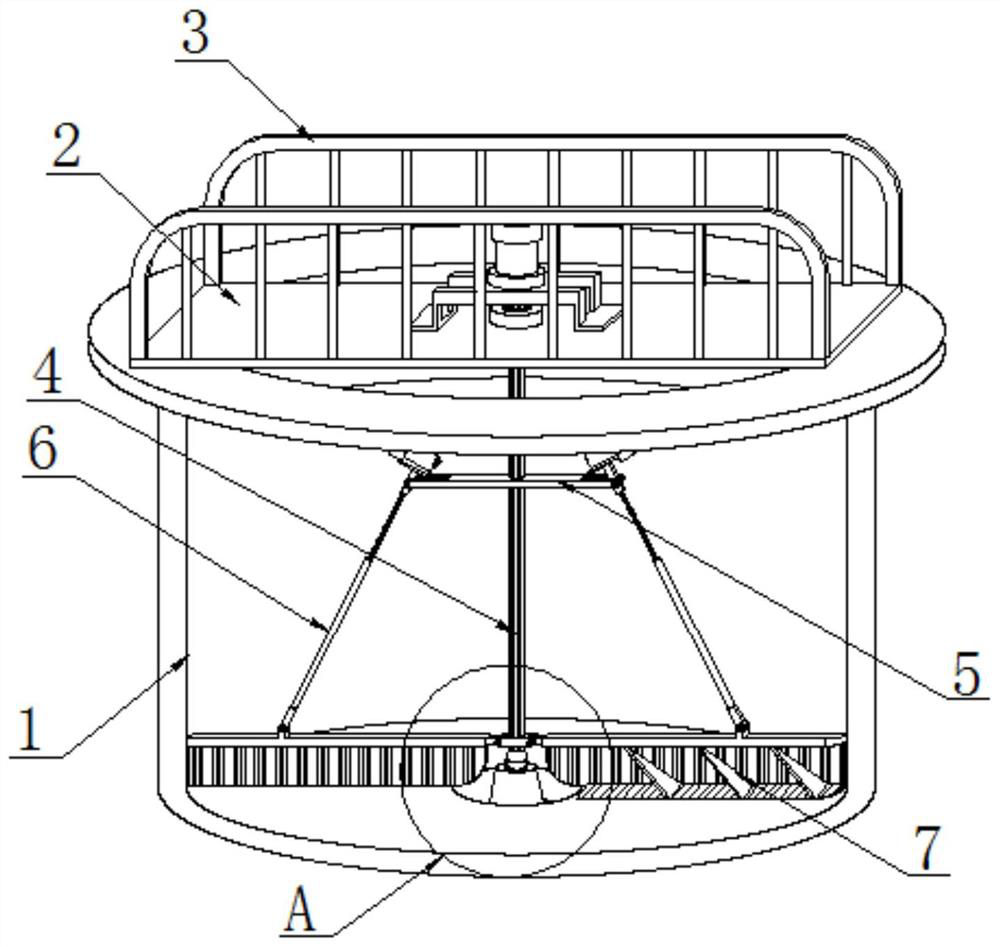

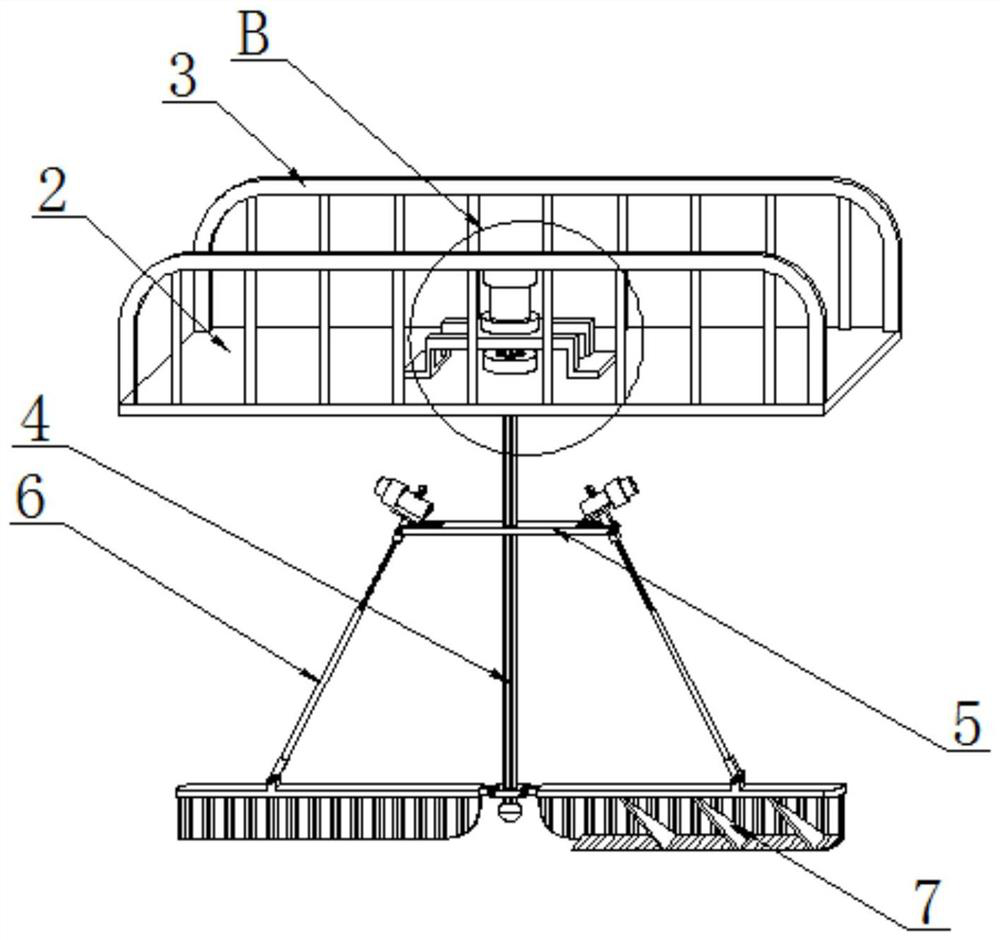

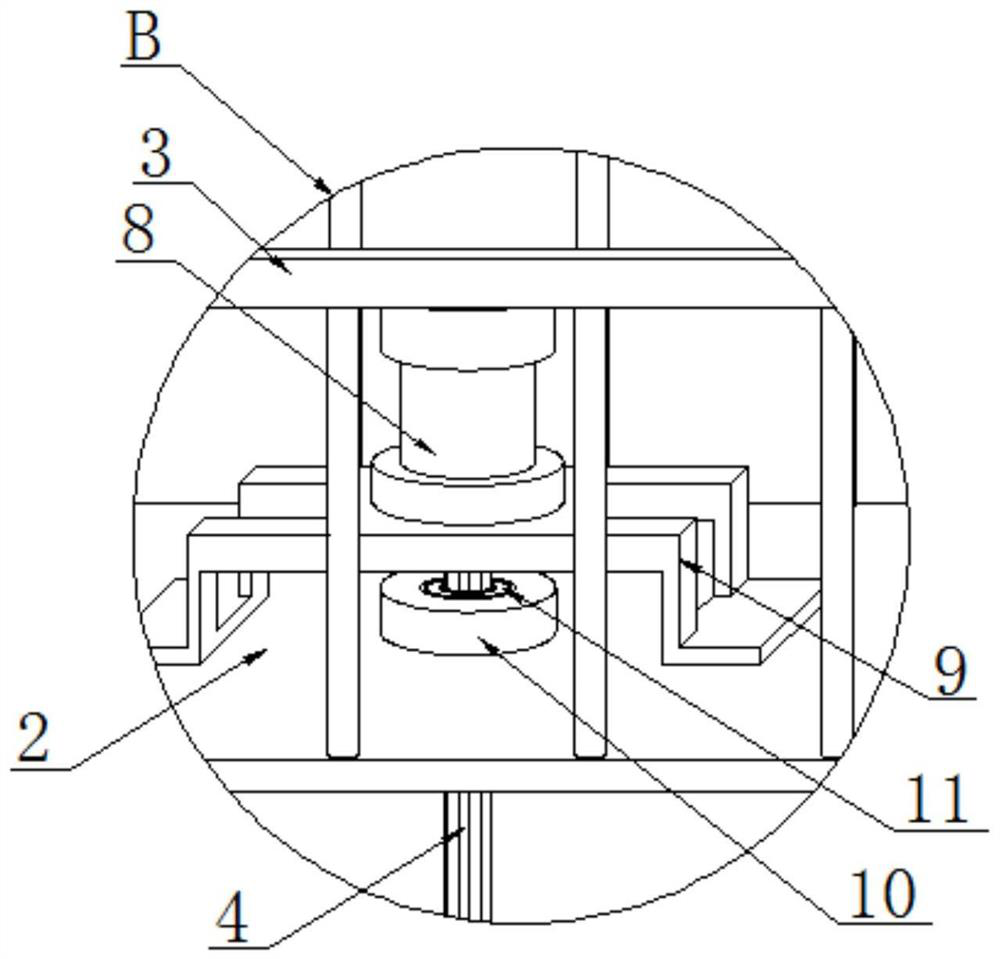

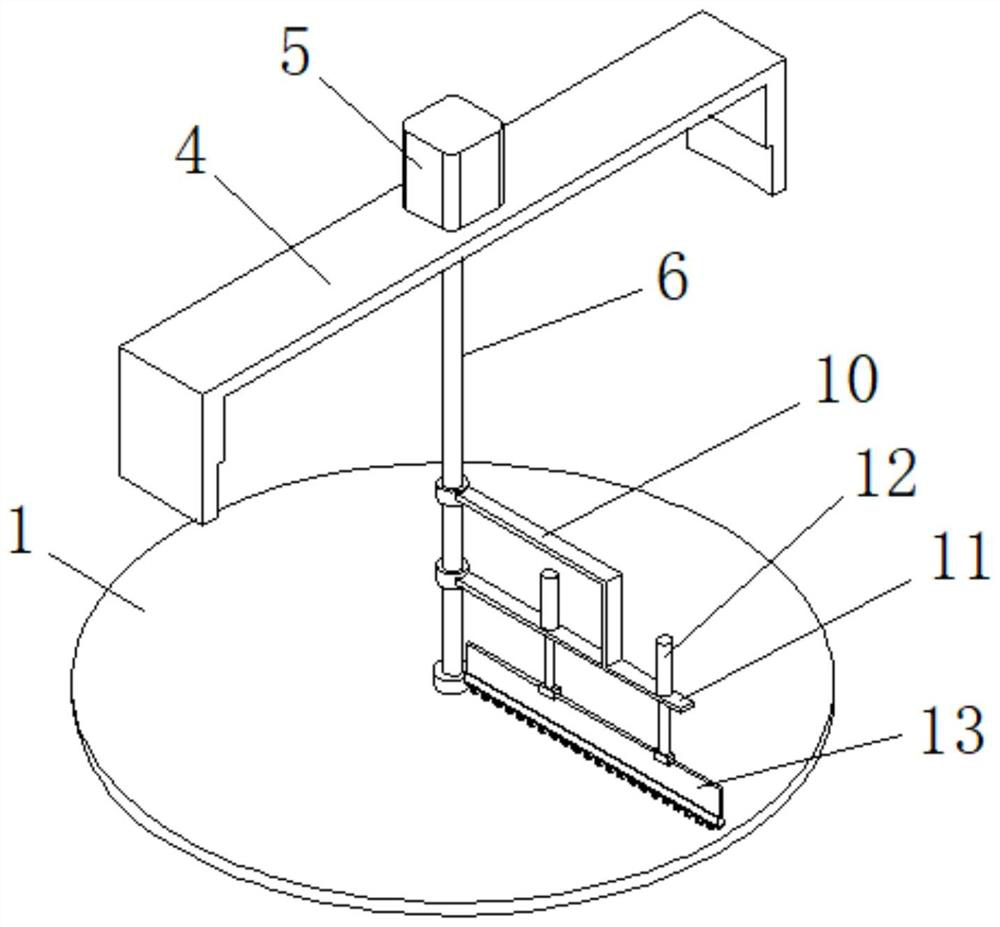

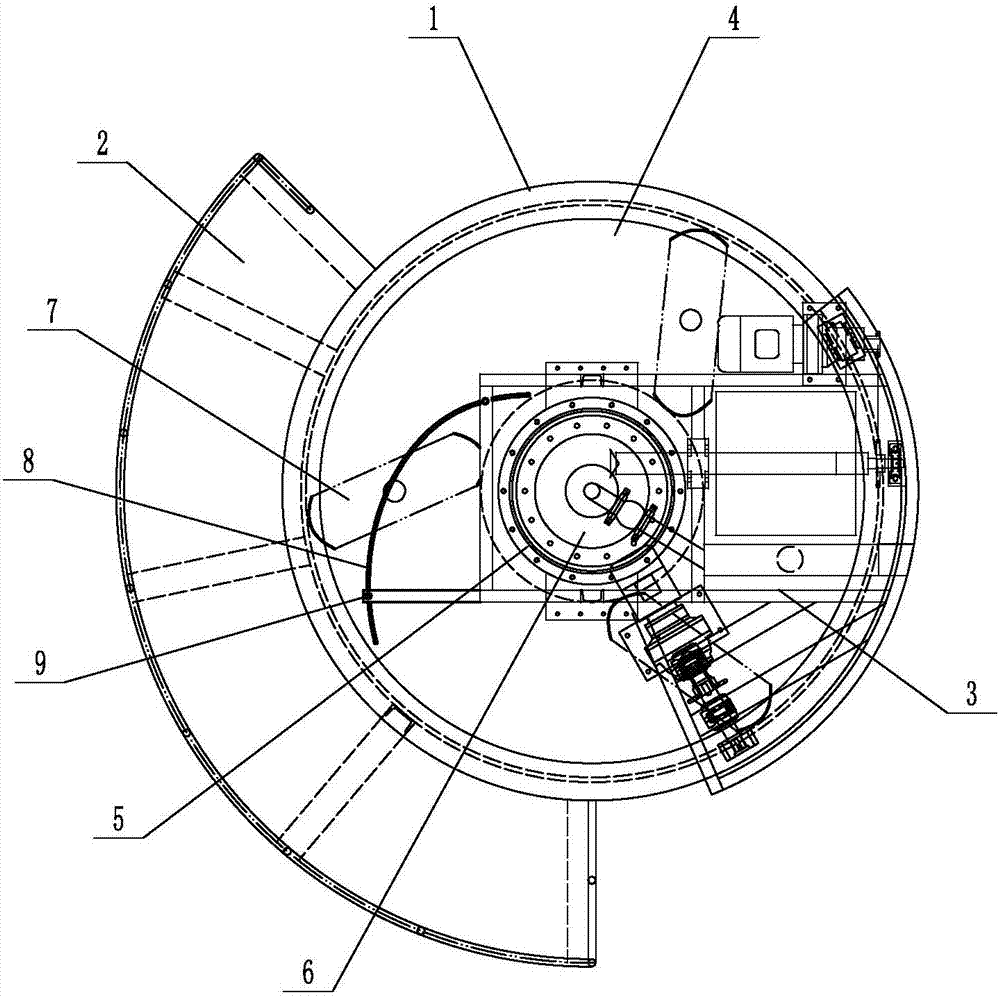

Periphery driving sludge sucking and scraping machine for sewage treatment

InactiveCN109011727AGuaranteed service lifeGuaranteed stabilitySludge treatment by de-watering/drying/thickeningFiltration circuitsSludgeEngineering

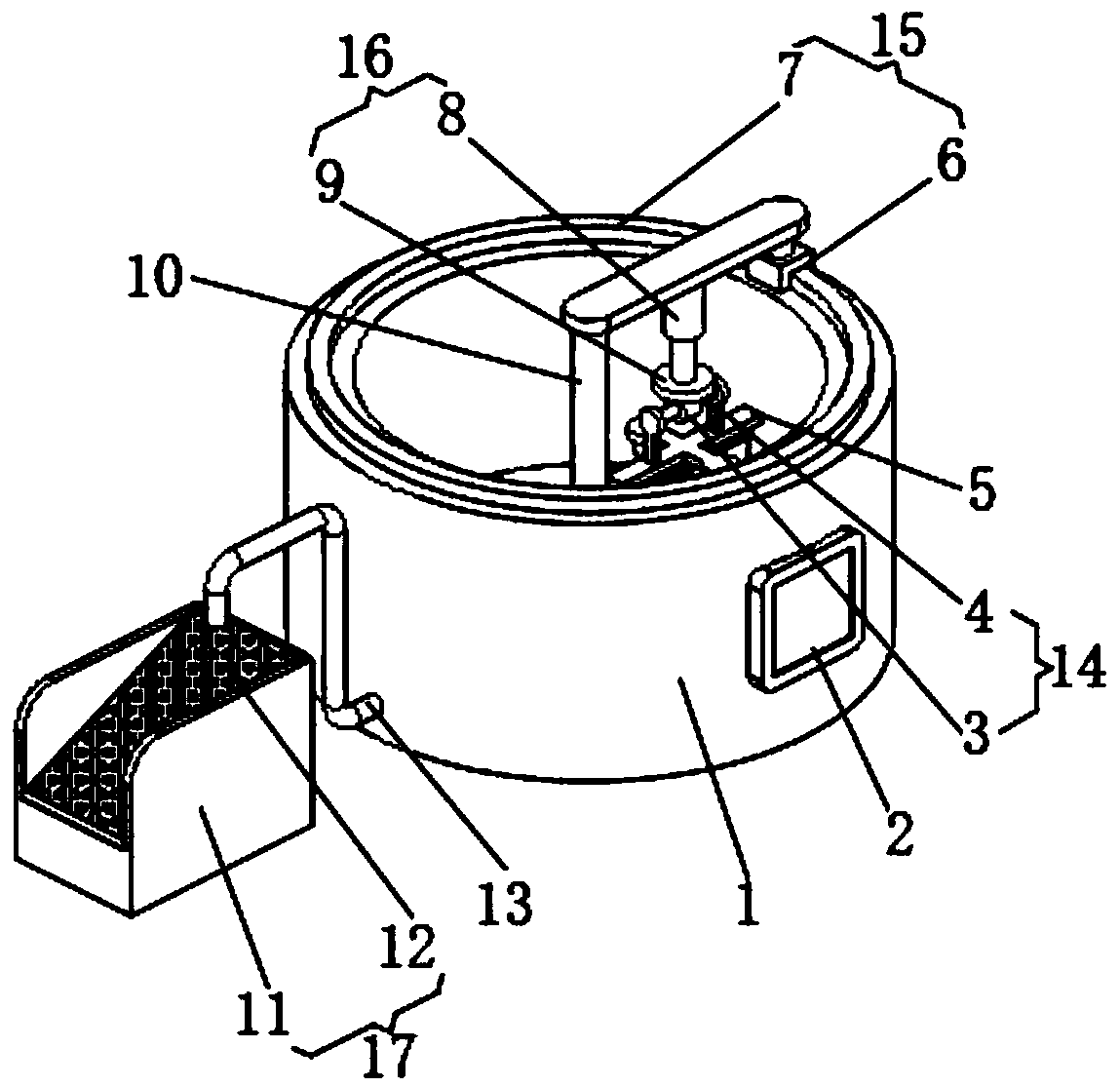

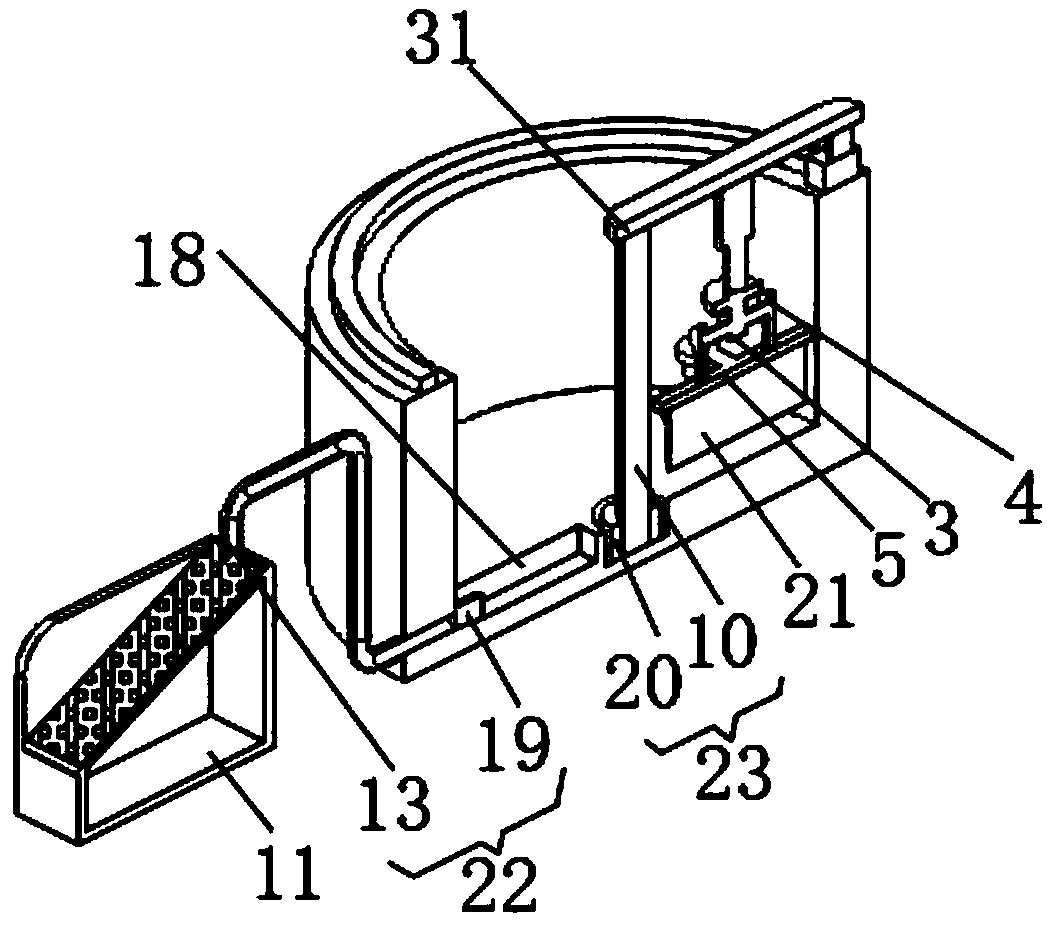

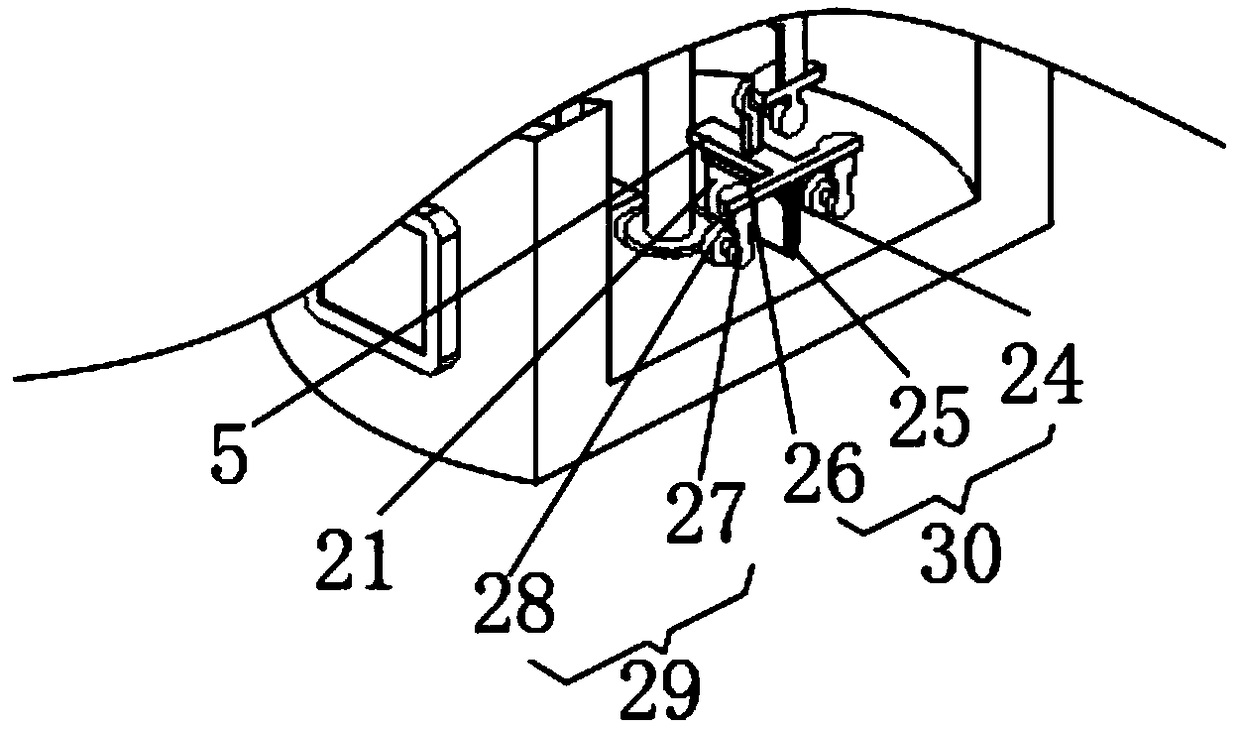

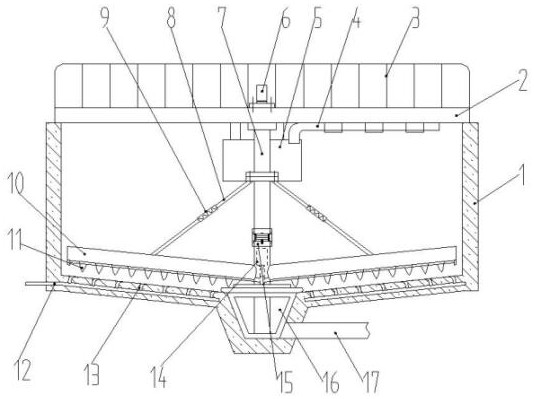

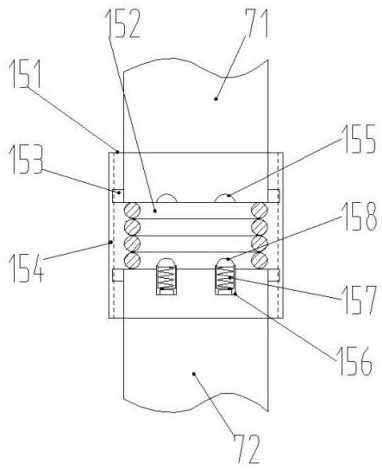

The invention discloses a periphery driving sludge sucking and scraping machine for sewage treatment. The periphery driving sludge sucking and scraping machine for sewage treatment includes a sedimentation tank and a dehydration device. A control switch block is installed on the side of the sedimentation tank, a driving device is installed at the top of the sedimentation tank, a cross beam is fixed at the top of the driving device, and the cross beam is in rotating connection with the bottom of the sedimentation tank through a rotating mechanism. The periphery driving sludge sucking and scraping machine for sewage treatment provided by the invention utilizes a lifting mechanism to adjust the sludge scraping thickness of a sludge scraping plate, avoids the overload work of a driving devicecaused by an excessive sludge scraping thickness of the sludge scraping plate, guarantees the service life of the sludge sucking and scraping machine, adjusts the working angle of the sludge scrapingplate through an angle adjustment device, is convenient for cooperating with the driving device to undergo reciprocating sludge scraping operation, thus greatly improving the sludge scraping efficiency, a walking mechanism is employed for walking operation and ensures the operation stability of the sludge sucking and scraping machine, and a cleaning device is employed for cleaning of the sludge scraping plate, the cleaning is convenient, and is time-saving and labor-saving.

Owner:惠州市第五污水处理有限公司

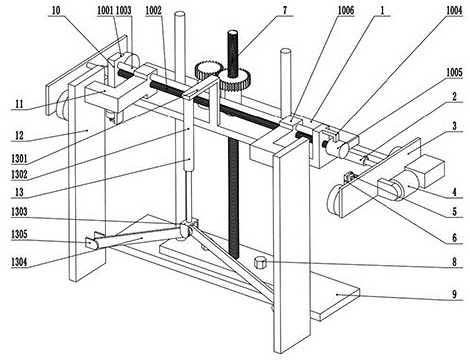

Environment-friendly self-adaptive adjustment type sedimentation tank mud scraper

InactiveCN112354223AAchieve mud scraping effectImprove mud scraping efficiencySettling tanks feed/dischargeLifting devicesSludgeMechanical engineering

The invention discloses an environment-friendly self-adaptive adjusting type sedimentation tank mud scraper, which relates to the technical field of environmental protection, and comprises a mountingbase, the side edge of the mounting base is fixedly connected with two telescopic mechanisms, the telescopic mechanisms are fixedly connected with a side plate, the side plate is rotatably connected with a moving mechanism, and the inner side of the side plate is fixedly connected with a limiting mechanism; the limiting mechanism is fixedly connected with the limiting wheel mechanism, the upper surface of the mounting base is fixedly connected with the lifting mechanism, the lifting mechanism is provided with a first bolt, the first bolt is in threaded connection with the bottom mud scraper, the upper surface of the mounting base is fixedly connected with the adjusting mechanism, and the adjusting mechanism is fixedly connected with two connecting rods which are fixedly connected with theside mud scrapers. The sludge scraping device can adapt to sludge scraping of sedimentation tanks with different widths through the arrangement of the telescopic mechanism, the movement of the whole device can be achieved through the arrangement of the moving mechanism, the sludge scraping effect on the whole sedimentation tank is achieved, the sludge scraping efficiency of the sedimentation tankis improved, and meanwhile the labor cost is reduced.

Owner:山东锦绣山河环境工程有限公司

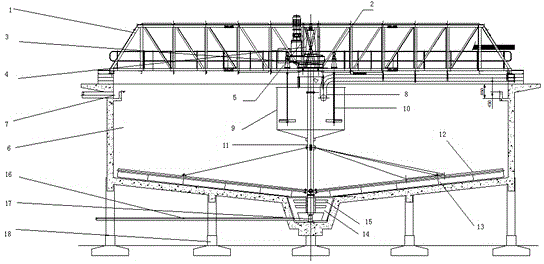

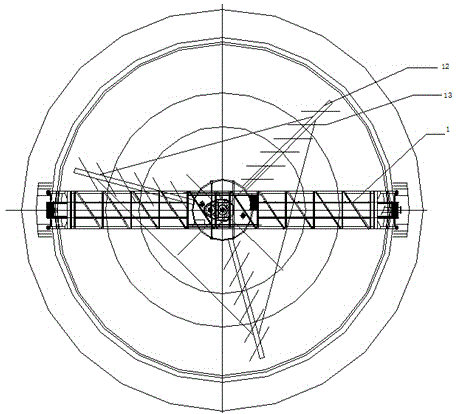

Arc-shaped scraper plate center transmission mud scraper

The invention relates to an arc-shaped scraper plate center transmission mud scraper. The mud scraper comprises a support, a sewage barrel, a service bridge, a main driving motor, a speed reducer, a center transmission shaft, flocculation mixers, a flocculation barrel and a scraper arm. The service bridge is arranged at top of the sewage barrel, the sewage barrel is arranged on the support, a loop of the overflow weirs are arranged at the surrounding of the sewage barrel, a center bearer is arranged at the center of the service bridge, the main driving motor and the speed reducer are fixed on the center bearer, the flocculation mixers are respectively arranged at two sides of the center bearer, a stirring device is connected with the lower end of the flocculation mixer, a water inlet pipeline is arranged between the service bridge and the sewage barrel, an outlet of the water inlet pipeline is placed in the flocculation barrel, an outlet of the overflow weir is arranged at the upper part of the side wall of the sewage barrel, an output shaft of the motor is connected with the speed reducer, a base plate of the sewage barrel is the tapered base plate, a downwardly recessed mud collecting cavity is arranged at a top angle position of the tapered base plate, the mud collecting cavity is the tapered cavity, the scraper plate employs an arc-shaped structure, and an anticorrosion coating layer is arranged on the scraper plate.

Owner:JIANGSU WATER ENVIRONMENTAL PROTECTION

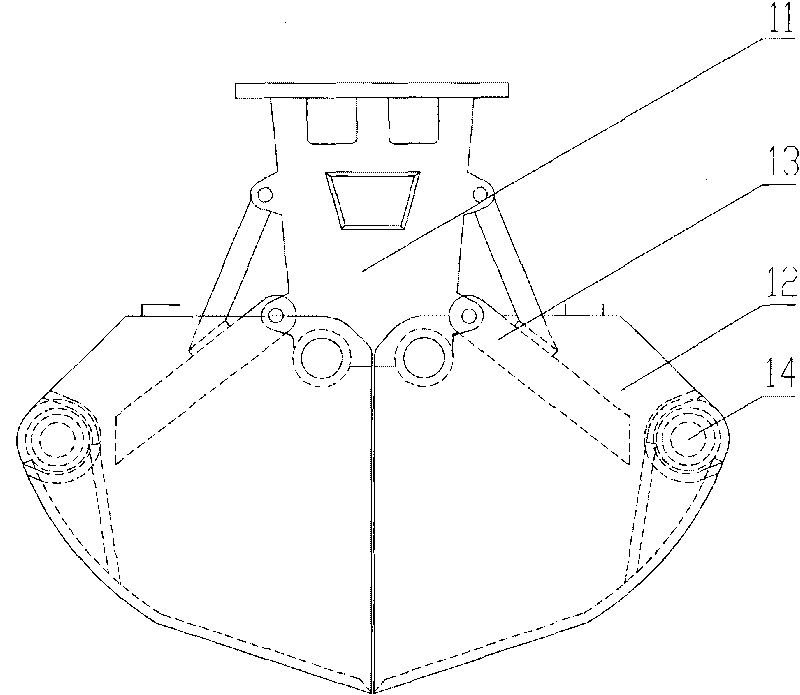

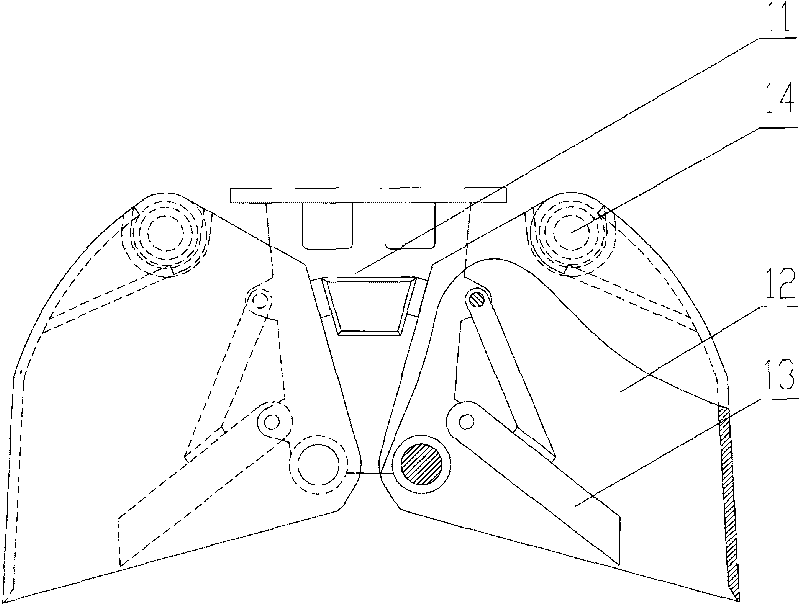

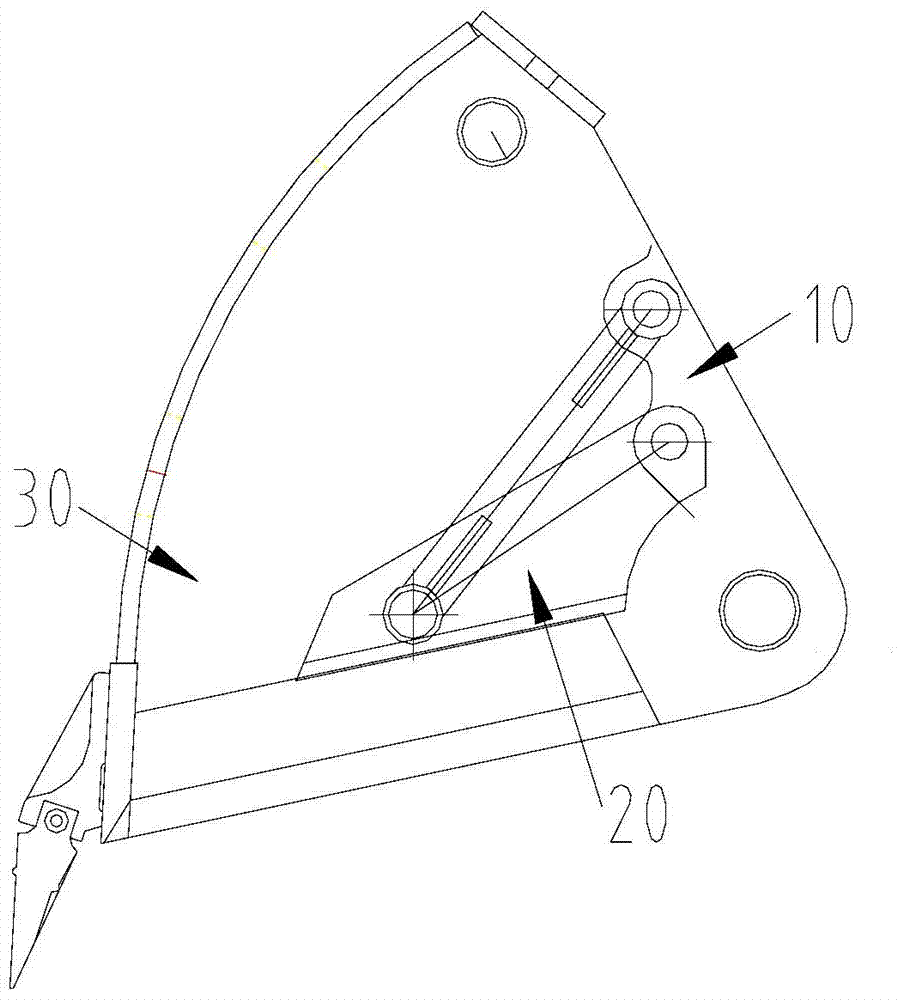

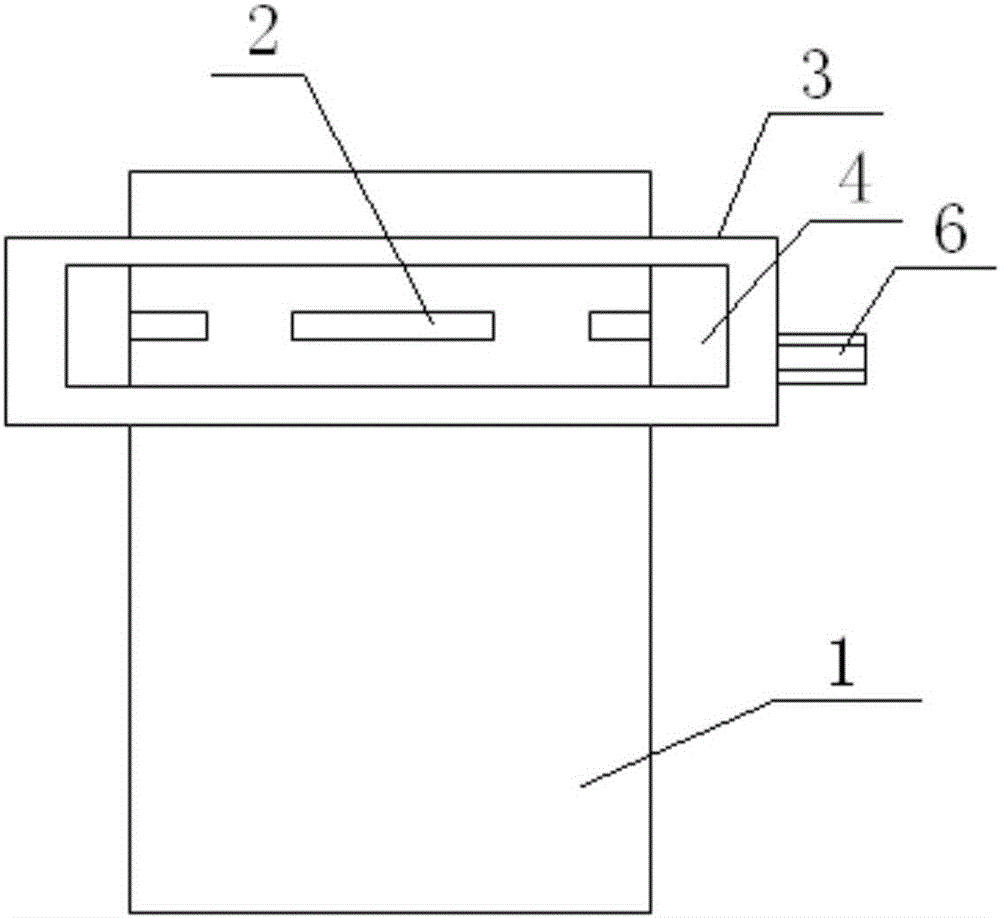

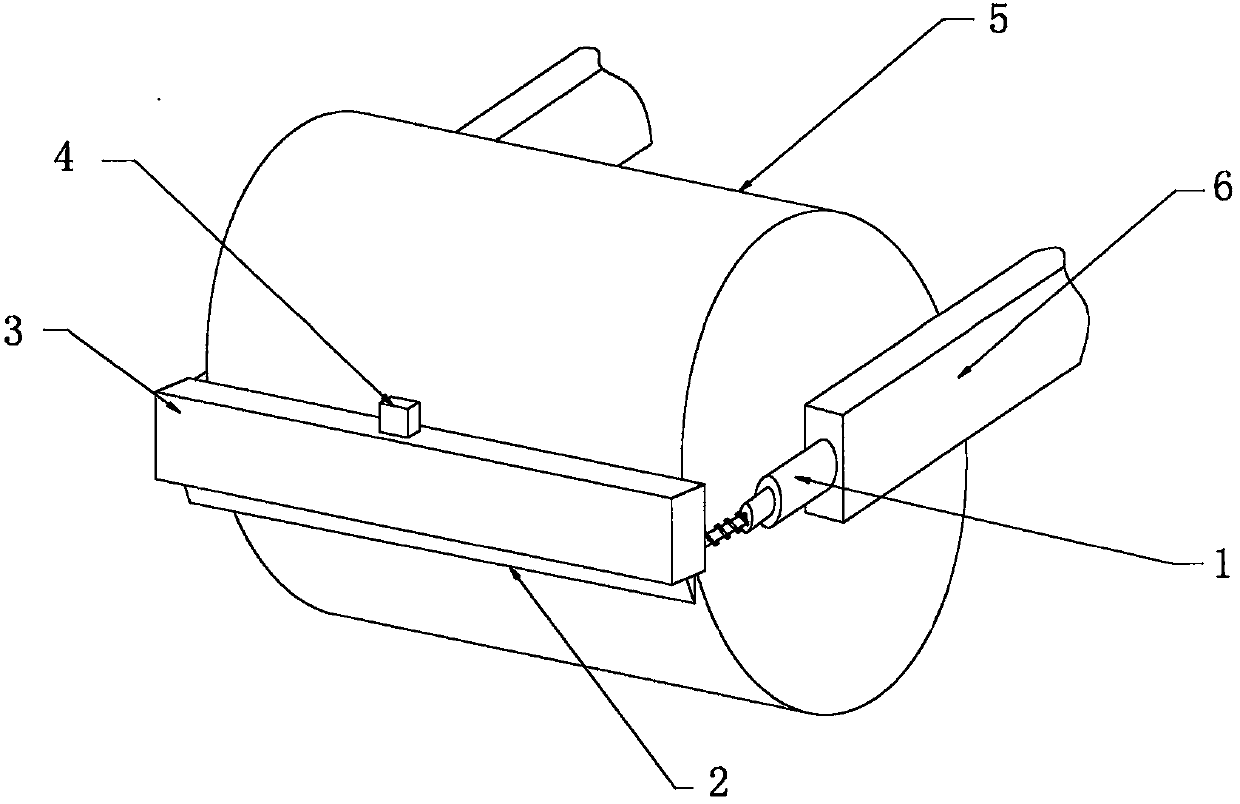

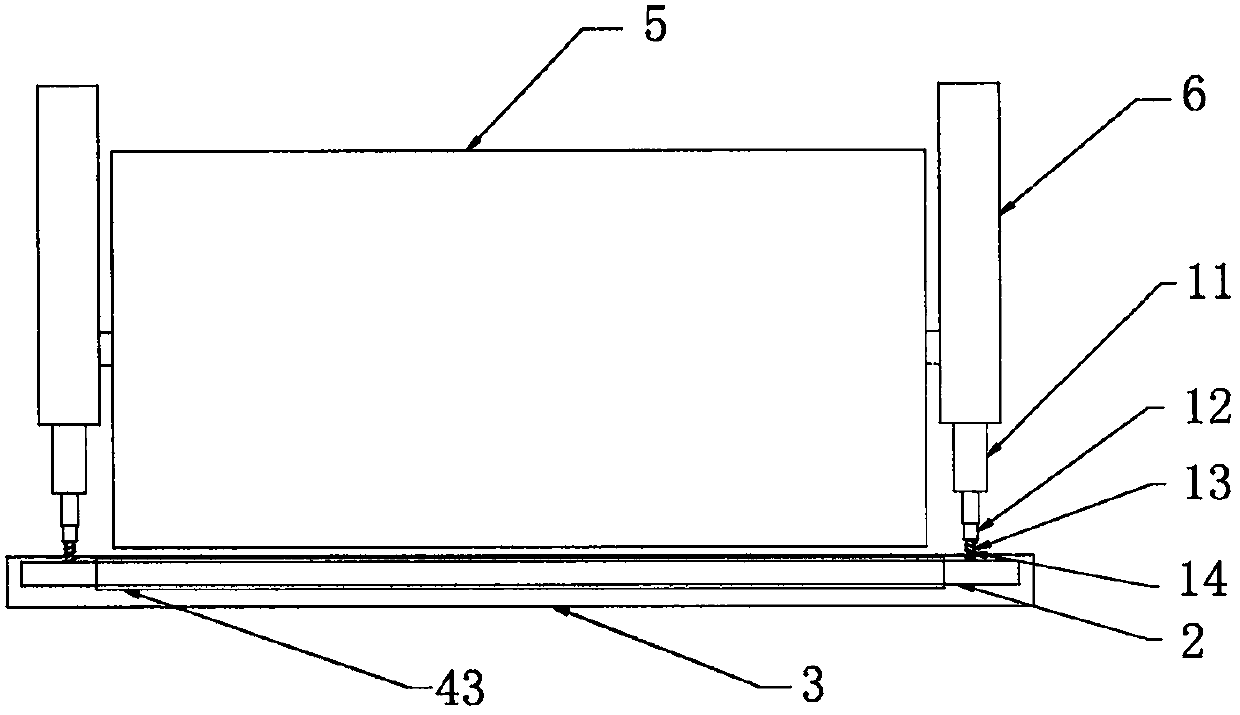

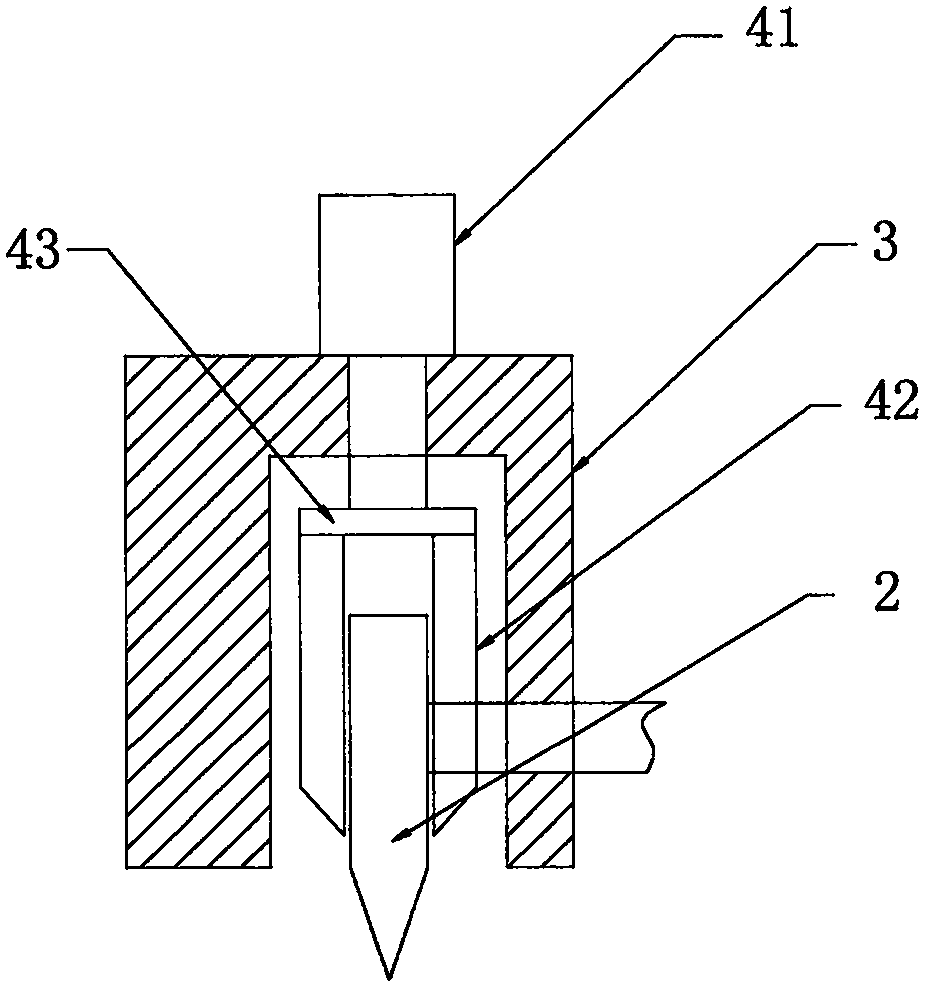

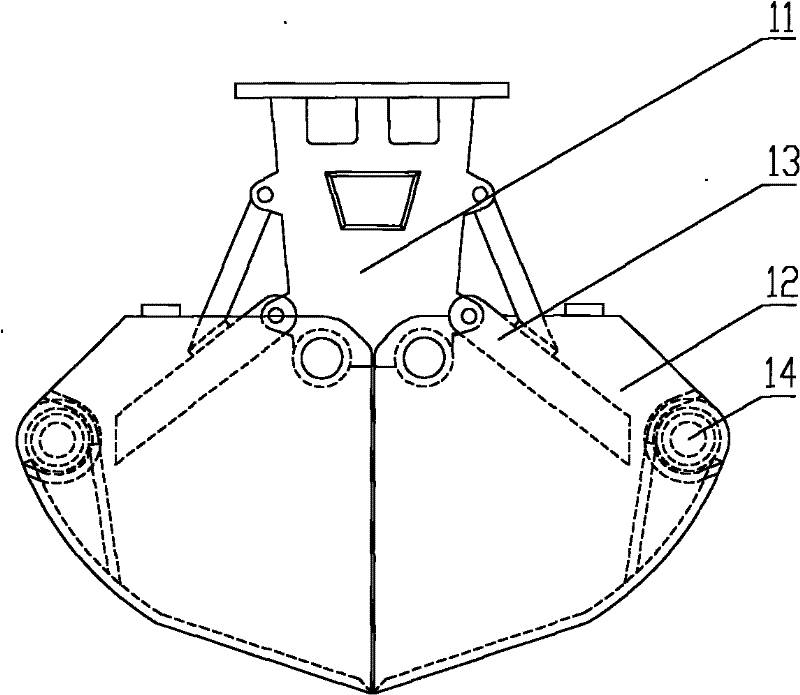

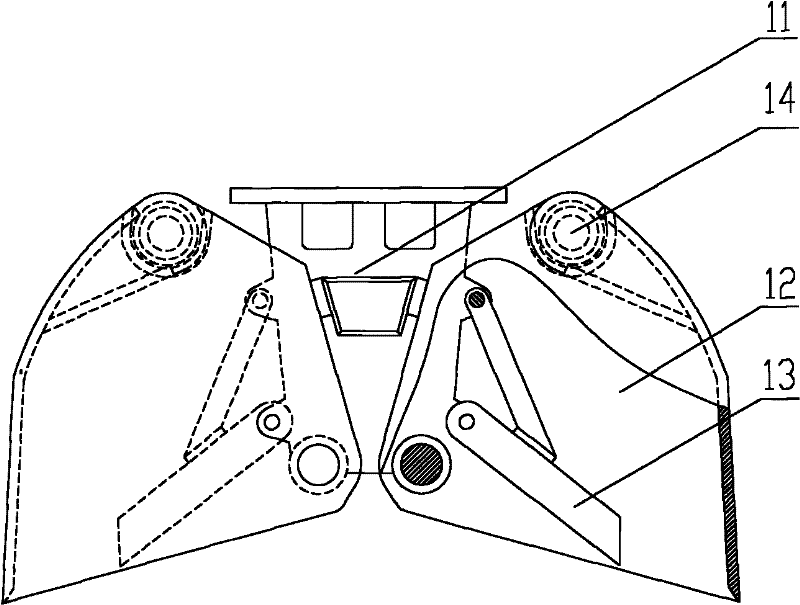

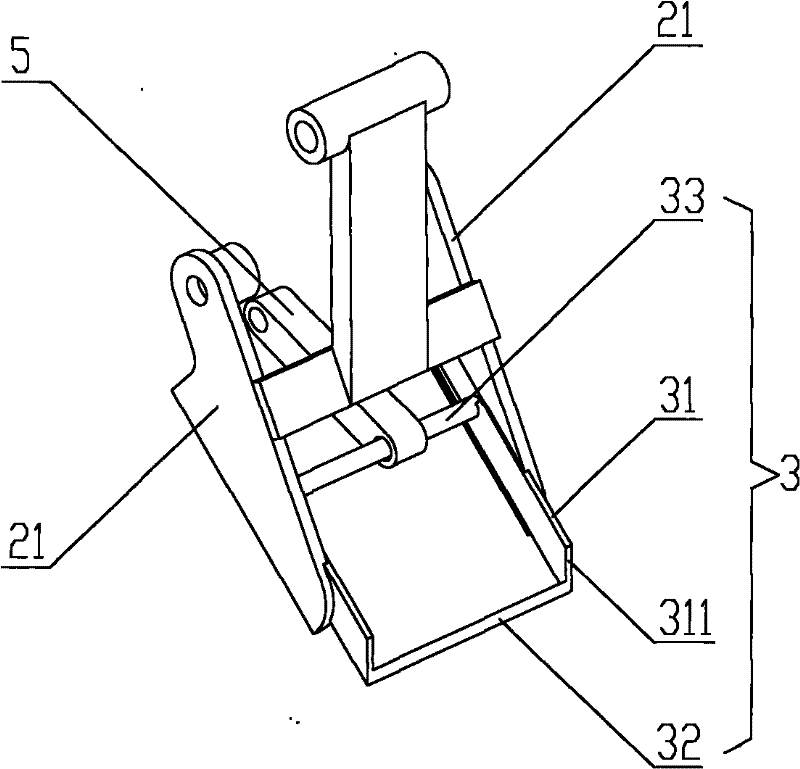

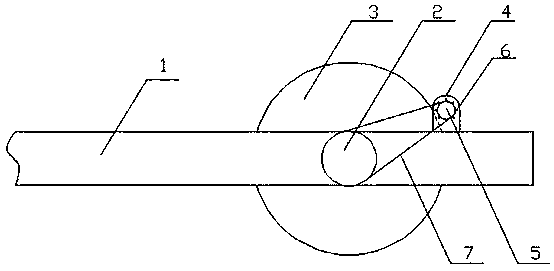

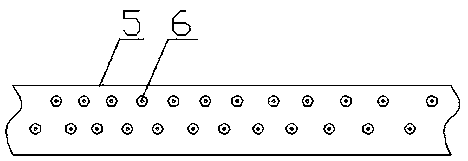

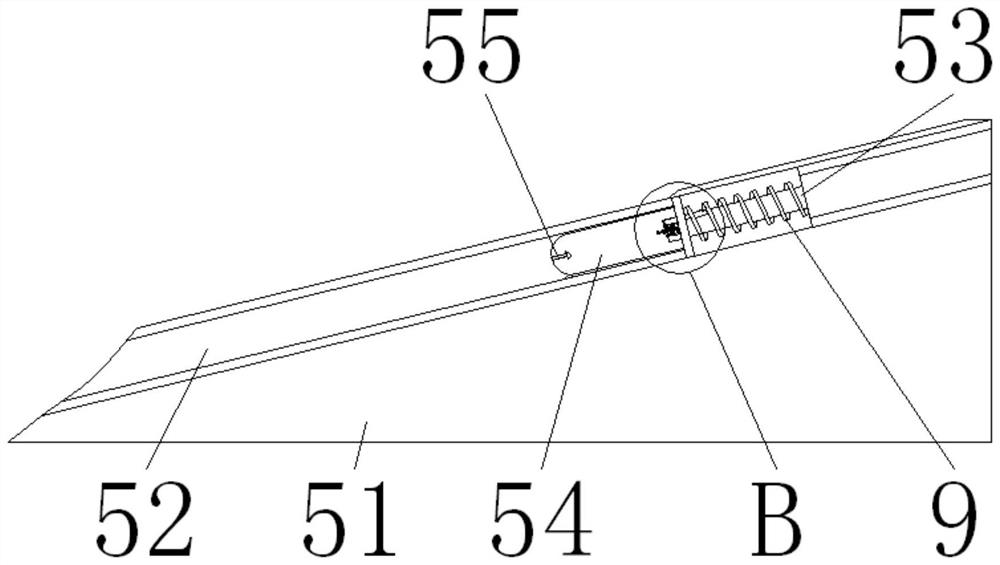

Grab bucket and sludge scraper thereof

InactiveCN101701463ASimple structureReduce processing costsMechanical machines/dredgersSludgeEngineering

The invention discloses a sludge scraper for a grab bucket, and the sludge scraper comprises a fixed mud scraper (2), a movable mud scraper (3) and a rigid connecting rod (5), wherein the fixed mud scraper (2) is fixed with a grab bucket bracket (6); the movable mud scraper (3) is connected with the fixed mud scraper (2) in a sliding mode; and one end of the rigid connecting rod (5) is hinged with a grab bucket body (4) of the grab bucket, and the other end is hinged with the movable mud scraper (2), so that the grab bucket body (4) drives the movable mud scraper (3) to slide relatively to the fixed mud scraper (2). The movable mud scraper (3) of the sludge scraper can slide in the extending direction of the fixed mud scraper (2), so that the overall length of the sludge scraper can increase as the opening degree of the grab bucket body (4) increases, and decrease as the closing degree of the grab bucket body (4) increases, thereby enhancing the mud scraping efficiency and the working efficiency of the grab bucket without influencing the normal operation of the grab bucket body. The invention also discloses a grab bucket comprising the sludge scraper.

Owner:BEIJING SANY HEAVY MASCH CO LTD

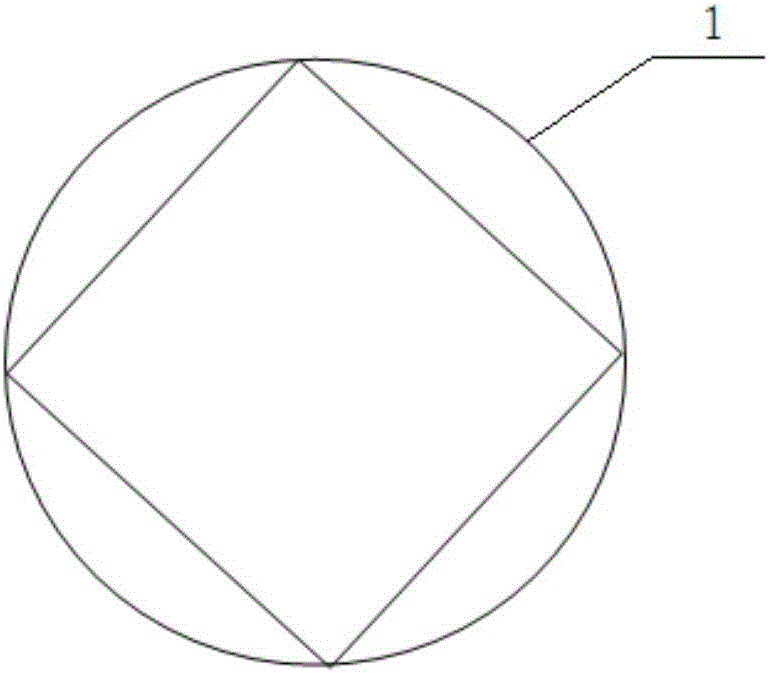

Mud scraping device of static pile pressing machine

The invention provides a mud scraping device of a static pile pressing machine. The mud scraping device comprises four scraping plates capable of moving, and a support, wherein a square is formed by the four scraping plates in a surrounding manner; the tops of the scraping plates are connected to rotary driving devices; scraping edges are arranged at the bottoms of the scraping plates; the rotarydriving devices can drive the scraping plates to rotate around the tops of the scraping plates, so that the four scraping edge are simultaneously pressed against a square pipe pile; and the rotary driving devices are arranged on the support. The mud scraping device is provided with the four scraping plates capable of rotating; when the four scraping plates are closed, the mud scraping device can scrape mud on the square pipe pile; and the mud scraping device can be applicable to pipe piles of different sizes by simultaneously controlling the rotating angles of the scraping plates and has strong applicability. The resistance to the square pipe pile can be eliminated by simultaneously loosening the four scraping plates, and thus, the high-efficiency press-in operation on the square pipe pileis facilitated.

Owner:江苏燕舞建设有限公司

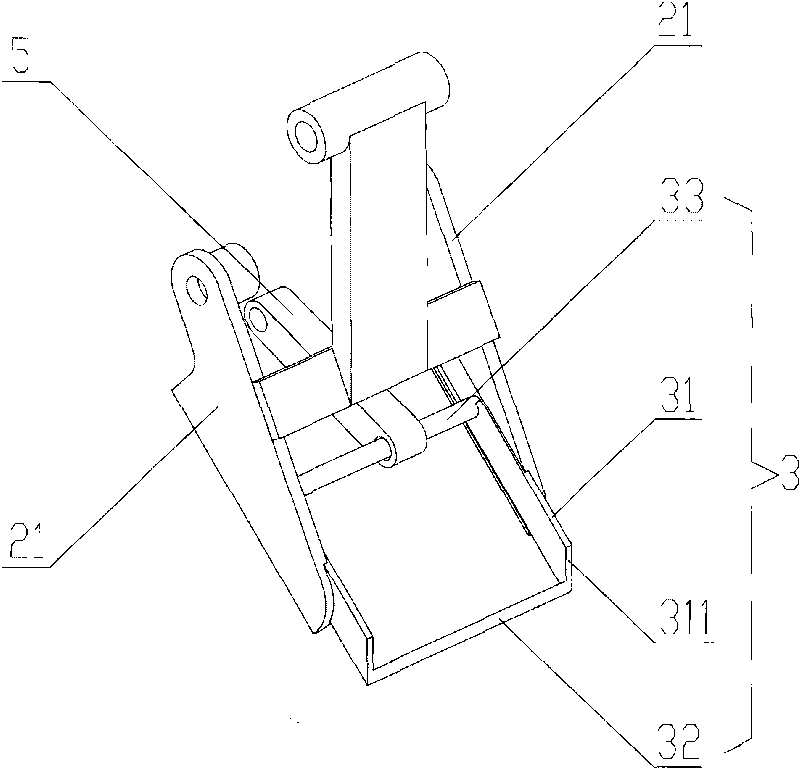

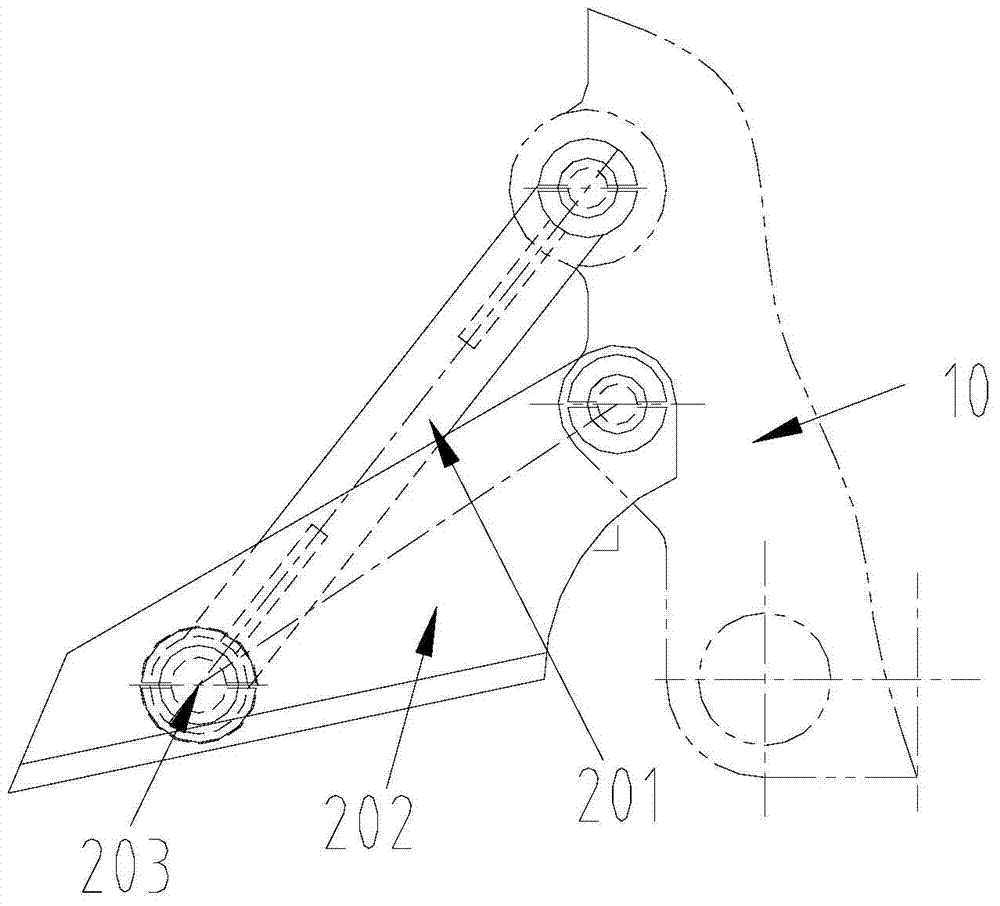

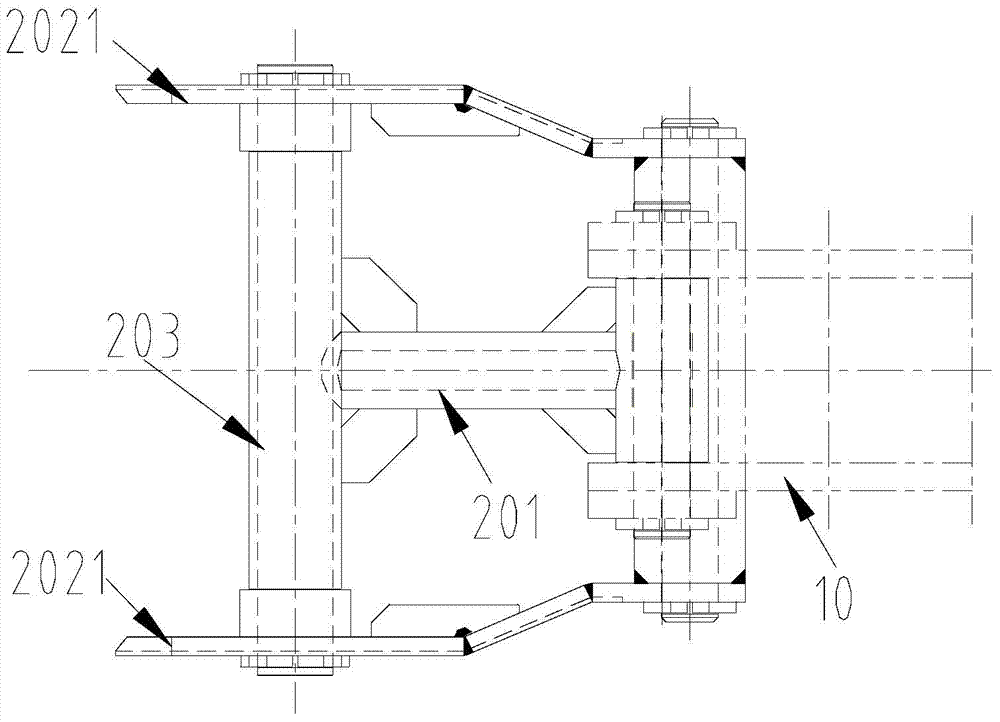

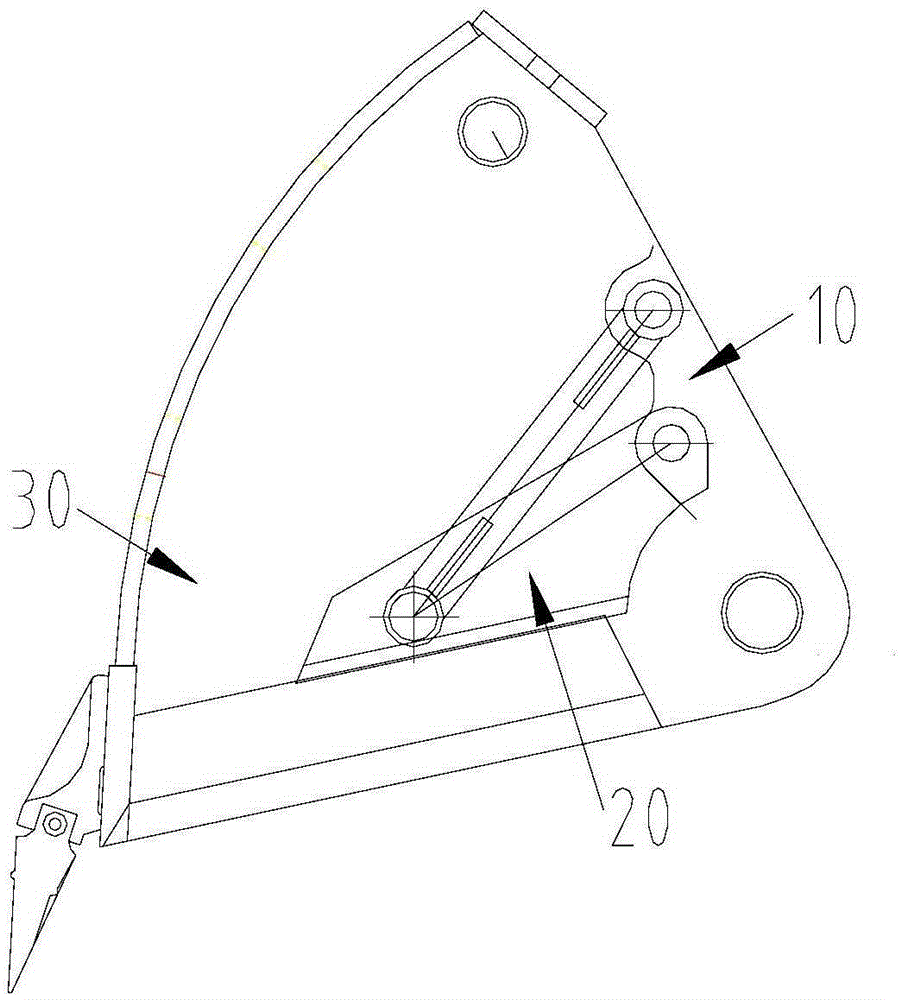

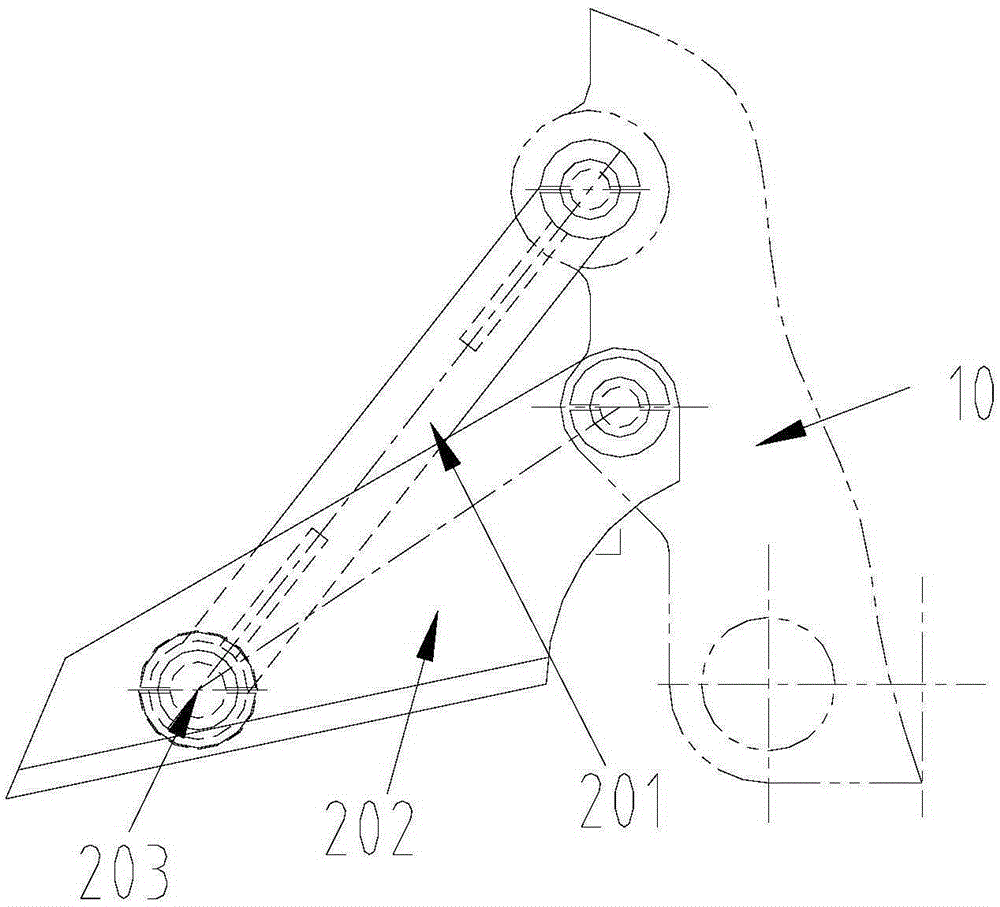

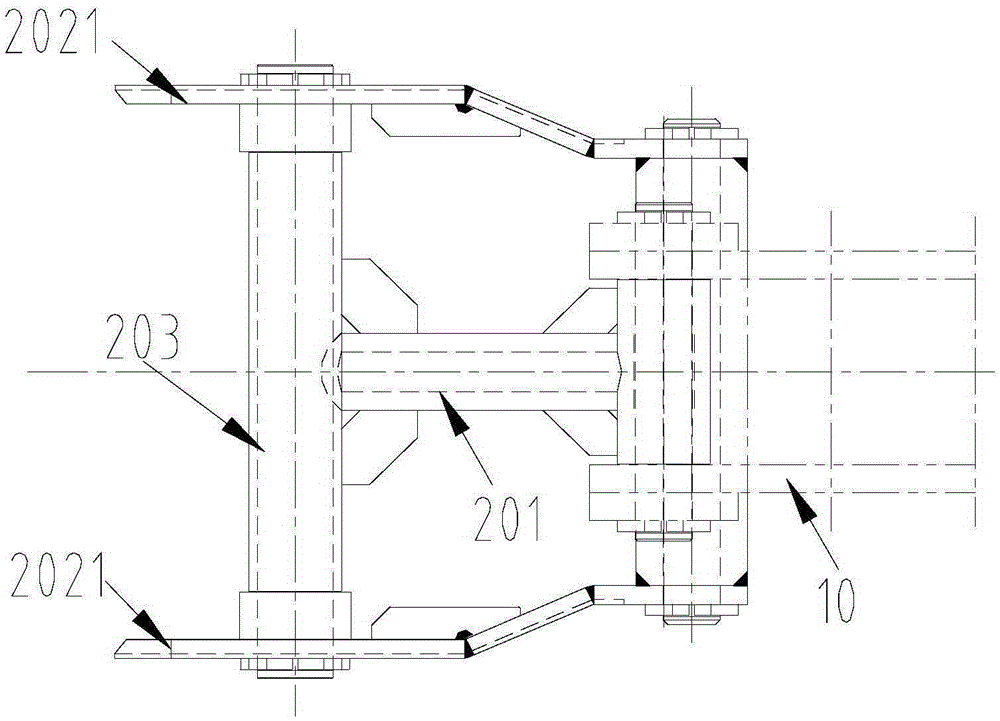

Grab bucket, continuous wall hydraulic grab bucket grooving machine and grab bucket working method

ActiveCN103572791AImprove mud scraping efficiencyImprove work efficiencySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention provides a grab bucket, a continuous wall hydraulic grab bucket grooving machine and a grab bucket working method. The grab bucket comprises a grab bucket base, a grab bucket shell and a scraper, wherein the grab bucket shell is connected to the grab bucket base in a pivot mode, and the scraper is located in the grab bucket shell; the scraper includes a scraper body which is of a platy structure; when the grab bucket shell is in a fully open state, the scraper body is connected to the grab bucket base in a pivot mode in the form of at least covering a part of a soil inlet of the grab bucket shell, so that the scraper can rotate freely when the grab bucket grabs soil; in this way, the scraper will not cover the soil inlet of the grab bucket shell, and therefore the soil feeding amount of the grab bucket shell is not affected; furthermore, the scraper body is of the platy structure, so that the scraping area of the scraper is greatly increased when the grab bucket discharges the soil, and working efficiency of the grab bucket can be improved. Besides, in the working process of the grab bucket, the scraper can further compress ground for squeezing and draining, so that accumulated water in the grab bucket does not need to be drained by utilizing extra tools and time, the working efficiency of the grab bucket can be further improved, and the use cost of the grab bucket is saved.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

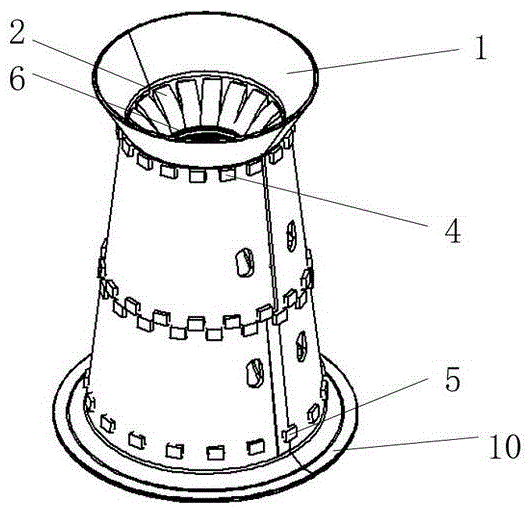

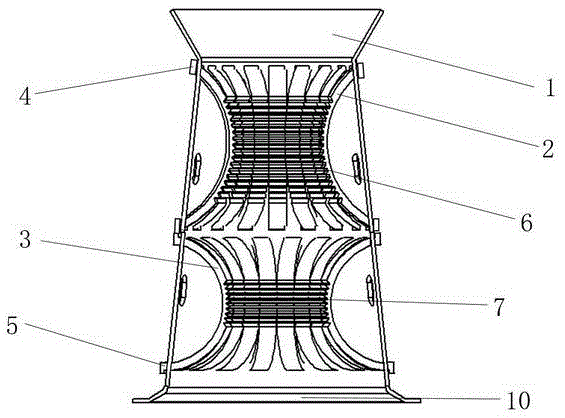

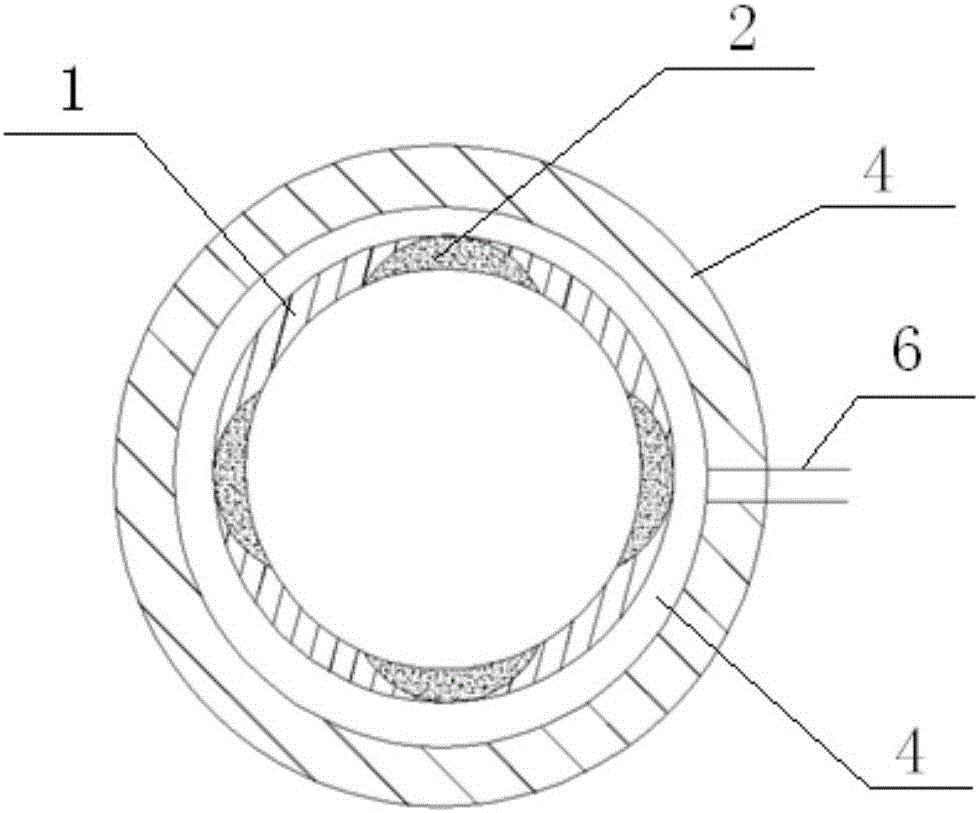

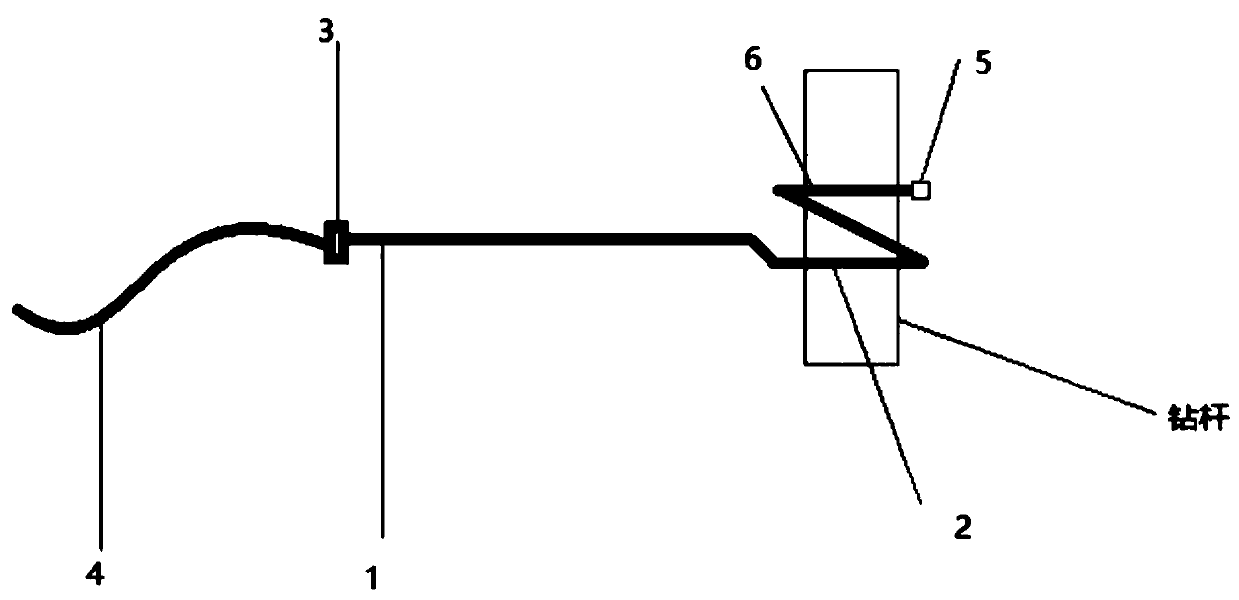

Device for removing slurry on outer wall of drilling rig

InactiveCN105484702AImprove mud scraping efficiencyEasy to insertCleaning apparatusDrilling fluidCombined use

The invention discloses a device for removing slurry on the outer wall of a drilling rig. The device is composed of an outer supporting cylinder, a plurality of upper slurry scraping units and a plurality of lower slurry scraping units. The slurry scraping units are fixedly arranged in the outer supporting cylinder in two or more layers according to the combined use condition of the drilling rig in the drilling process, and thus the effect of full-dimension slurry scraping of a whole drilling column is achieved. The drilling rig transmits deformation stress to an outer cylinder through the slurry scraping units when being lifted. In the using process, force applied by the drilling rig makes the slurry scraping units to have elastic deformation, gaps appear between the slurry scraping units, and due to the fact that insertion openings for installing the slurry scraping units are staggered at the horizontal position, slurry on the whole periphery of the outer wall of the drilling rig can be effectively scraped away. The slurry scraping units are convenient to demount and mount, drilling fluid on the outer wall of the drilling rig can be disposed in time, the ambient of a drill floor is protected, manpower cost can be reduced, labor intensity can be relived, and safety can be ensured.

Owner:JILIN UNIV

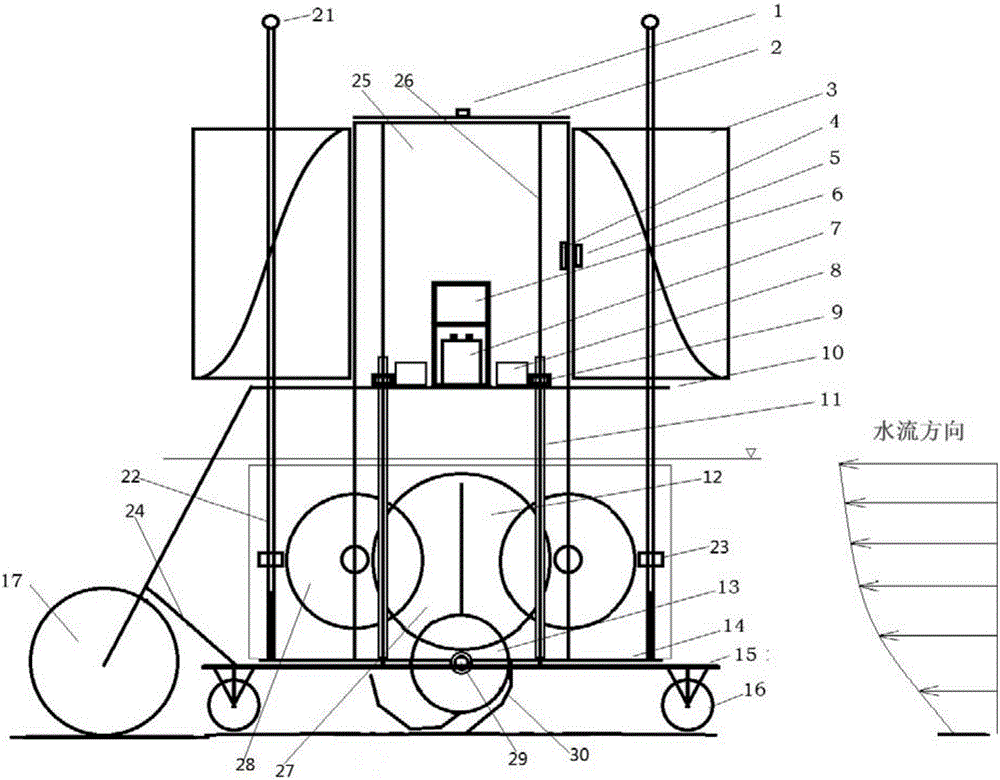

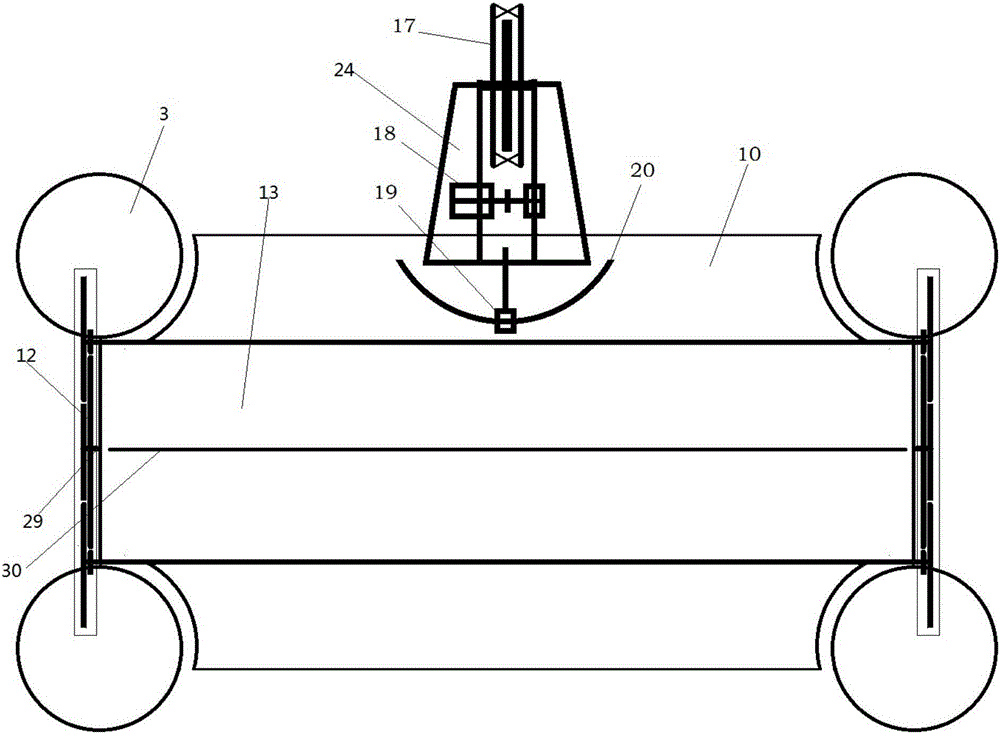

River desilting water vehicle

The invention discloses a river desilting water vehicle which comprises an above-water platform (10), an underwater platform (15) and a lifting platform (14). The middle of the lifting platform (14) is provided with a flexible impeller (13) used for scooping up riverbed silt in a penetrating mode. The four corners of the lifting platform (14) are each provided with a rotary rod (22). Fans (3) are arranged on the portions, located above the above-water platform (10), of the rotary rods (22). The two ends of a drive gear shaft (29) of the flexible impeller (13) are separately engaged with reduction gear sets (12) which are engaged with fan rotary rod gears (23) arranged on the rotary rods (22) in a sleeving mode. According to the river desilting water vehicle, riverbed bottom mud is stirred through kinetic energy of flowing water and transported to downstream ocean along with the flowing water, no secondary transport cost exists, water surface wind energy and solar energy are used as additional power, the desilting efficiency is improved, clean energy is used, and zero-carbon emission is achieved.

Owner:HOHAI UNIV

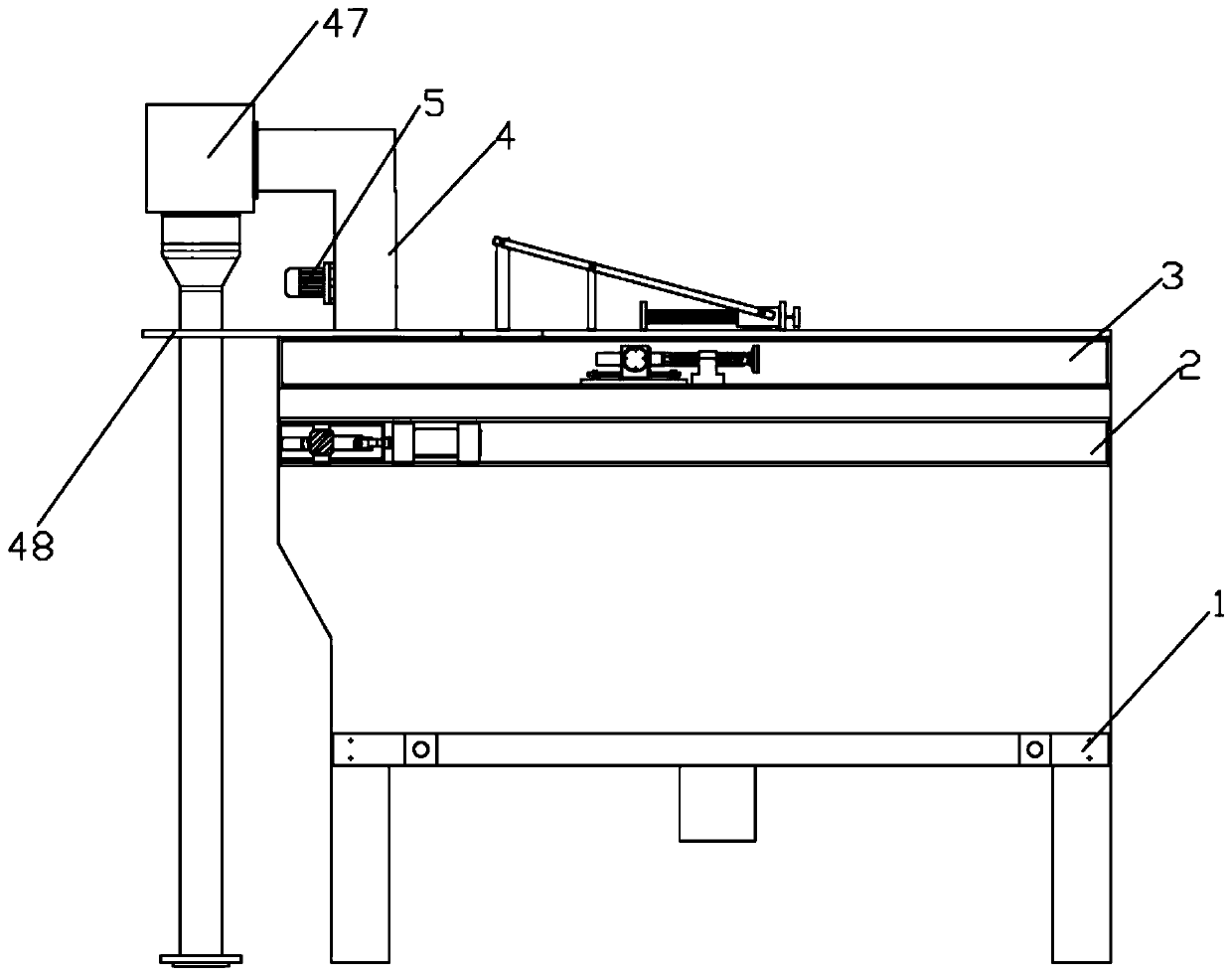

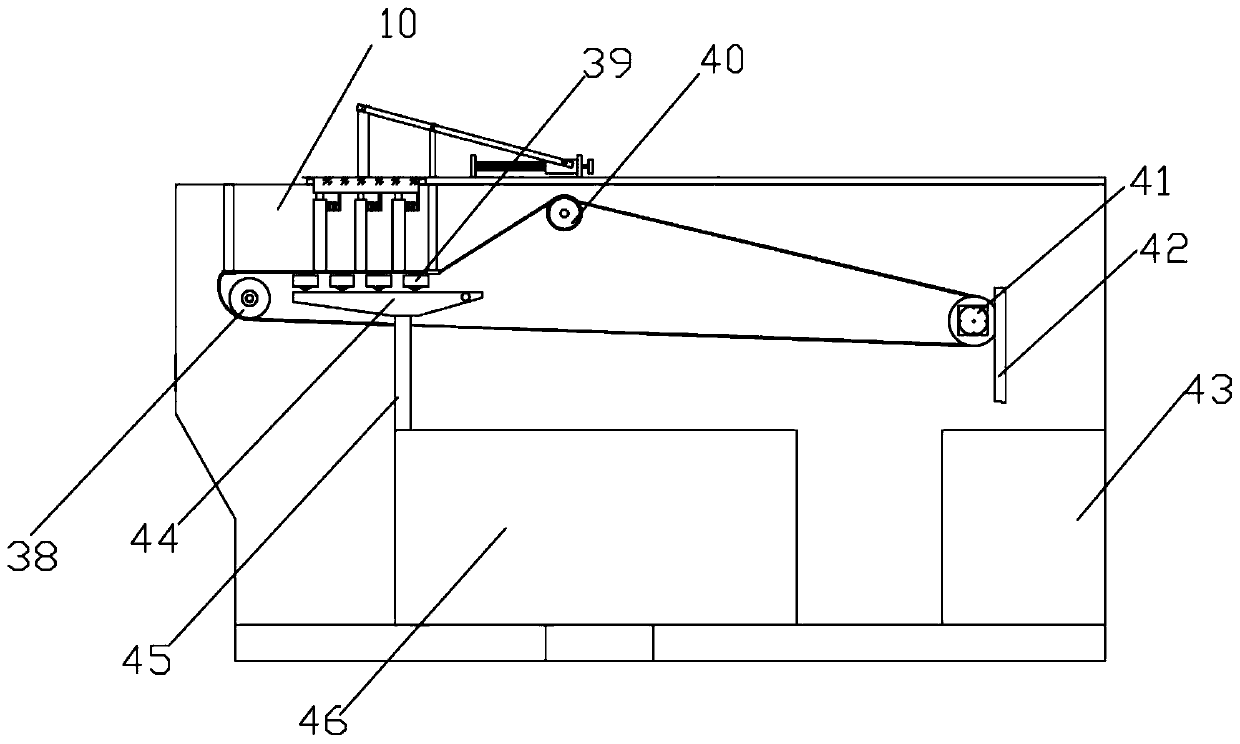

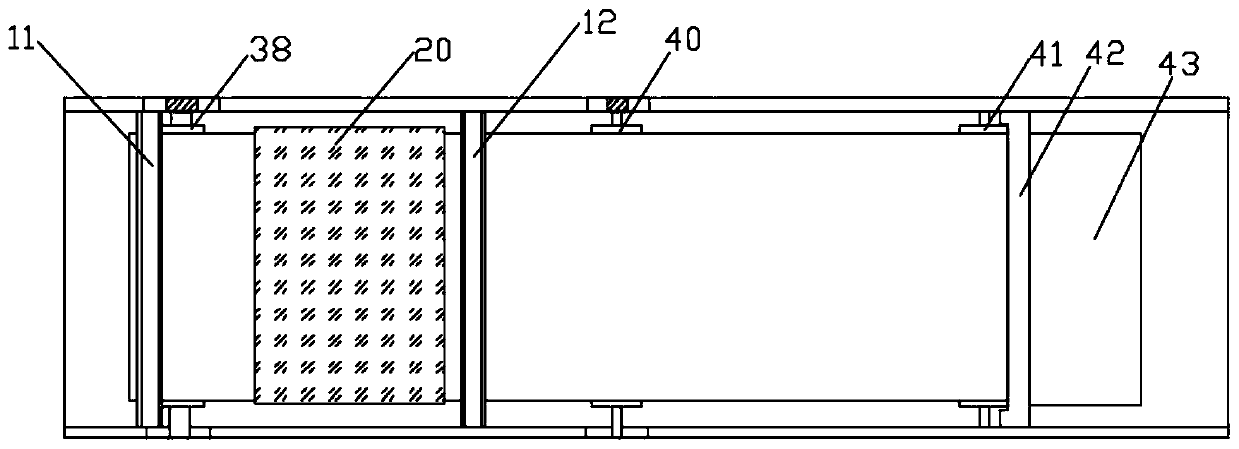

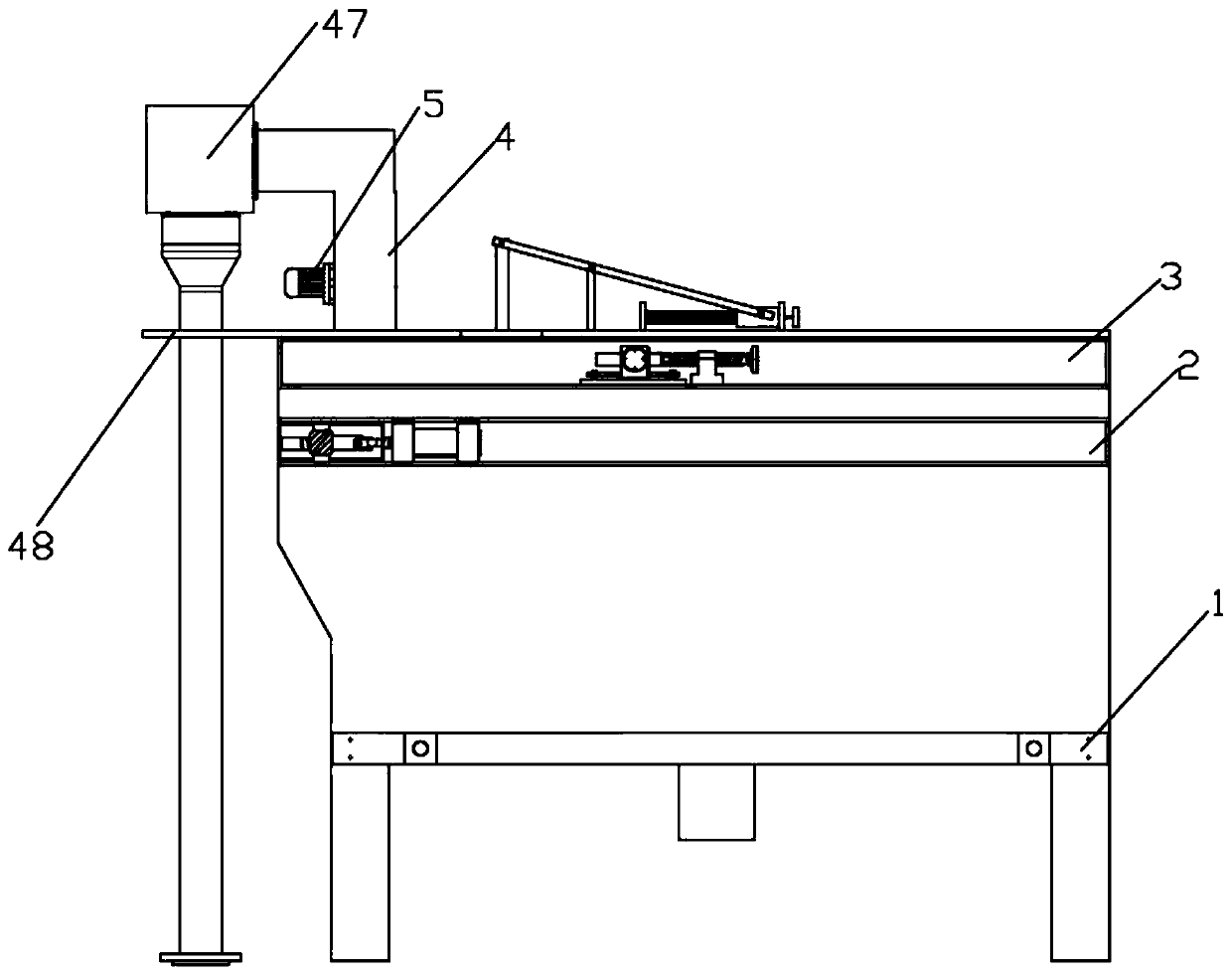

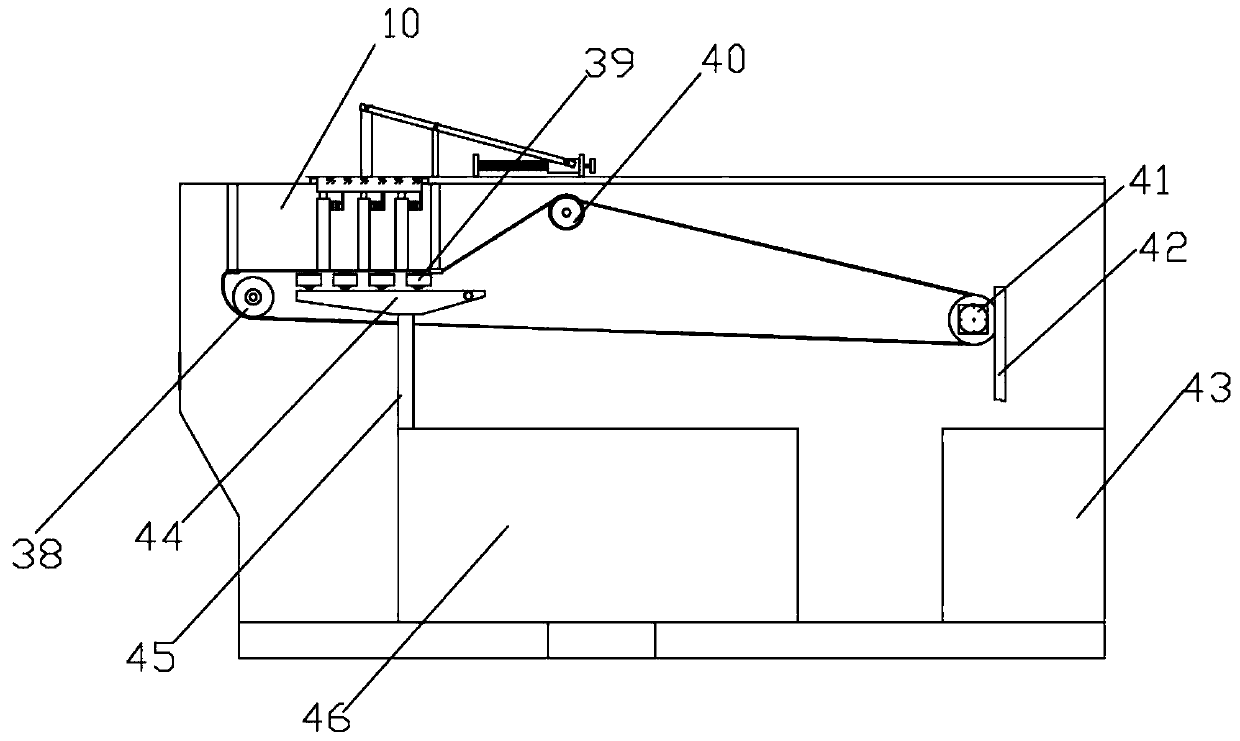

Watercourse sludge desilting treatment equipment

ActiveCN110318436ALow manufacturing costImprove mud scraping efficiencySludge treatmentMechanical machines/dredgersSludgeWater filter

The invention discloses watercourse sludge desilting treatment equipment. The device comprises an equipment main body, wherein a first steel channel and a second steel channel are correspondingly fixed on the same side outer wall of the equipment main body from bottom to top, and a mud scraping cavity is fixedly arranged at the top of an inner cavity of the equipment main body; and the mud scraping cavity comprises a front mudguard and a rear mudguard, a movable top cover is arranged on the top of one side of the mud scraping cavity, a first connecting rod which is longitudinally arranged is fixedly connected to the upper end surface of the movable top cover, and a second connecting rod is hinged to one end, far away from the movable top cover, of the first connecting rod. According to thewatercourse sludge desilting treatment equipment, the mud scraping cavity and a filtering belt can be cleaned without dismounting the equipment, so that the cleaning of the equipment is more convenient, and meanwhile, the time cost for cleaning the equipment is saved; and sludge in a sludge inlet pipe is optimized and stirred through a bidirectional motor, the stirring efficiency of the sludge isensured while the use number of stirring blades is reduced, the manufacturing cost of the equipment is saved, and fine sand in the sludge can be effectively prevented from being adsorbed on the surface of the filtering belt so as to affect the water filtering efficiency of the filtering belt.

Owner:SHANGHAI RUIHUI ENVIRONMENTAL PROTECTION TECH

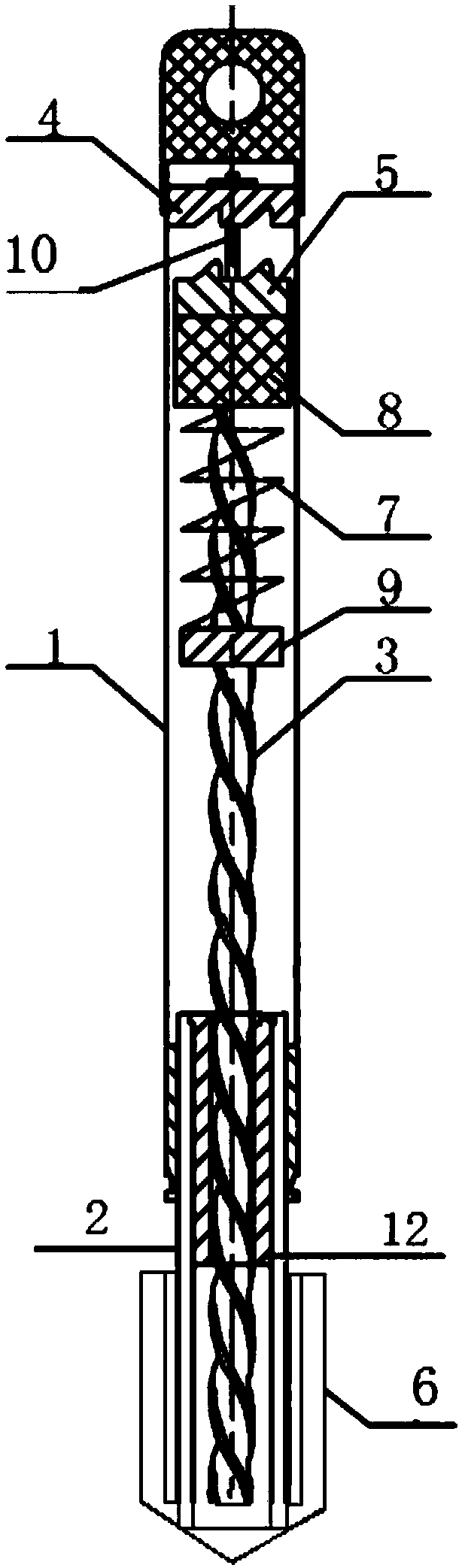

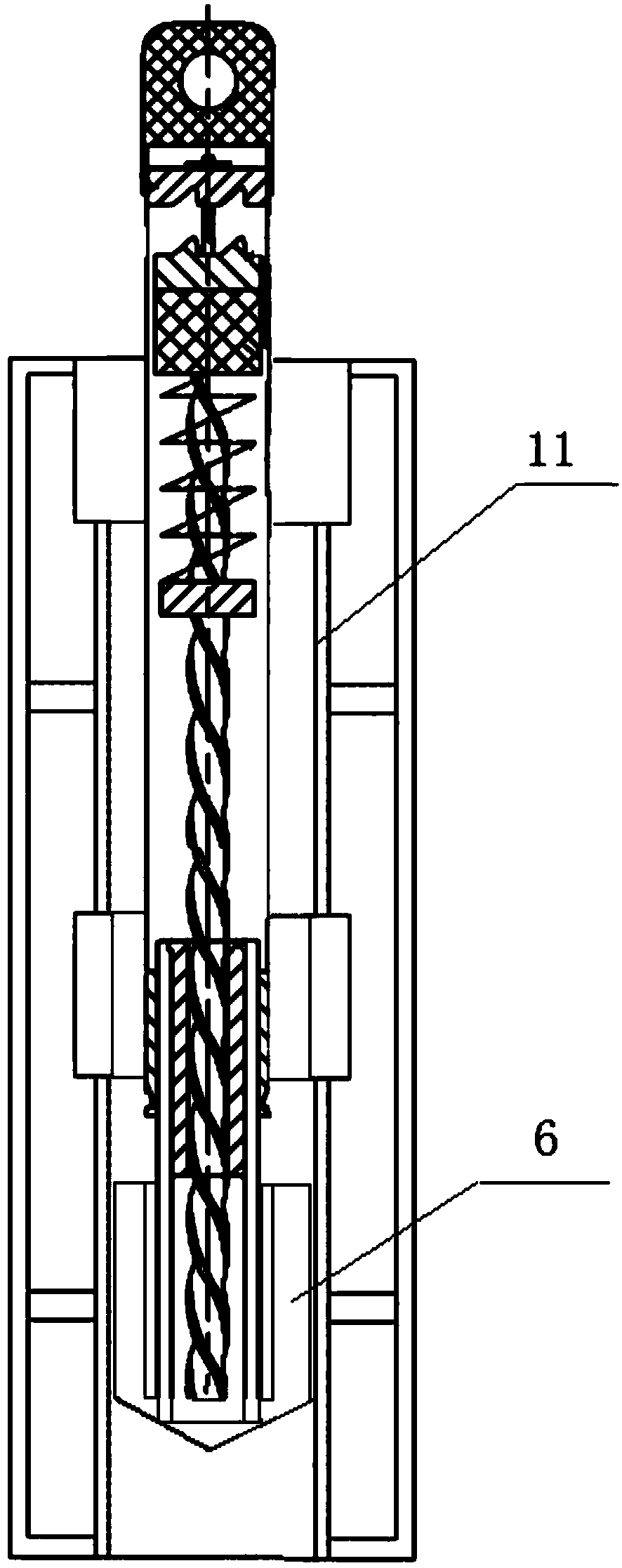

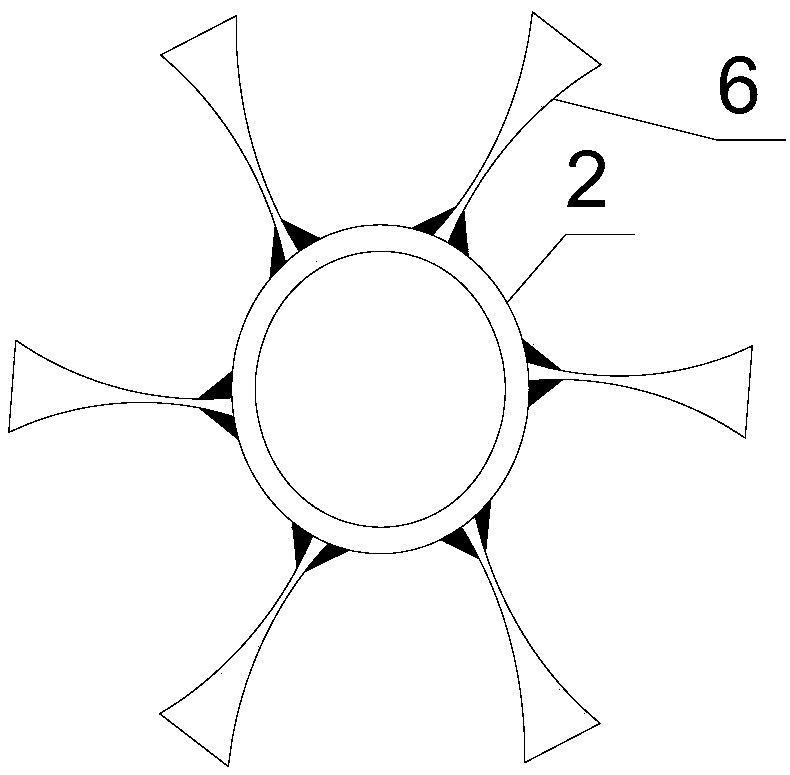

Oil scraping device of petroleum engineering oil production well and using method thereof

InactiveCN109113662AImprove mud scraping efficiencyOvercoming Motor LockupCleaning apparatusOil productionPetroleum

The invention discloses an oil scraping device of a petroleum engineering oil production well and a using method thereof. The oil scraping device comprises a top pressing rod, a blade rotating rod, apair of one-way gears which mesh with each other, a screw rod, a transmission part and blades. The top pressing rod and the blade rotating rod are hollow sleeves correspondingly, the lower end of thetop pressing rod is connected with the upper end of the blade rotating rod in a sleeving mode, multiple blades are connected to the outer wall of the lower portion of the blade rotating rod, a certaindistance between the blades and the top pressing rod is provided, and the distance is greater than that of motion of the top pressing rod relative to the blade rotating rod; the pair of one-way gearsare arranged in the top pressing rod in an up-down mode, lower gears are connected with the screw rod, and the screw rod is movably connected into the top pressing rod and extends into the blade rotating rod; and the transmission part is fixedly connected to the blade rotating rod, the transmission part is provided with a threaded hole matched with the screw rod in a threaded mode, and a ball matched with the screw rod is arranged in the transmission part. According to the oil scraping device, the blades are driven to rotate at high speed by the blade rotating rod, and the efficiency of oil scraping is improved.

Owner:李如平

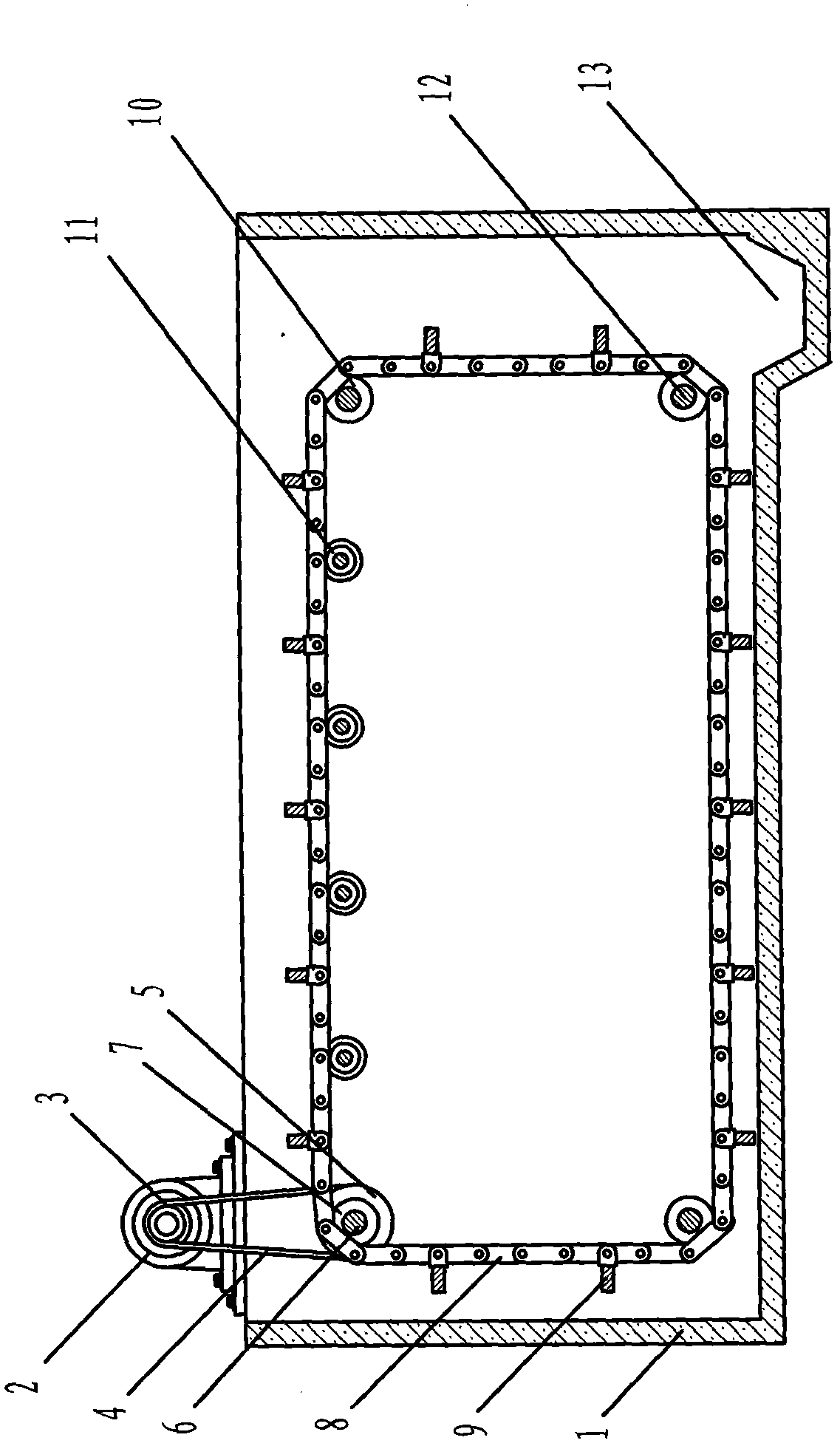

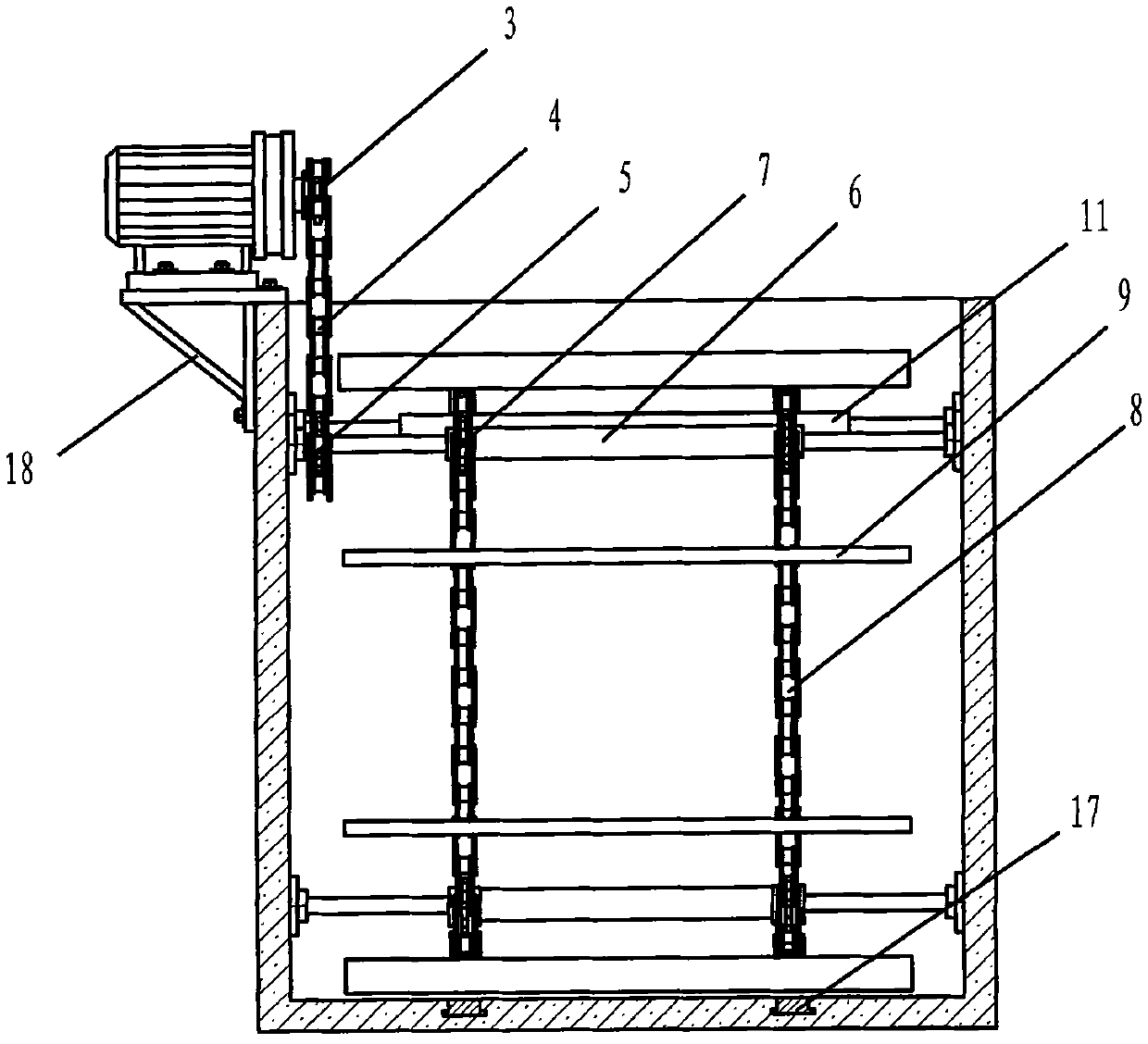

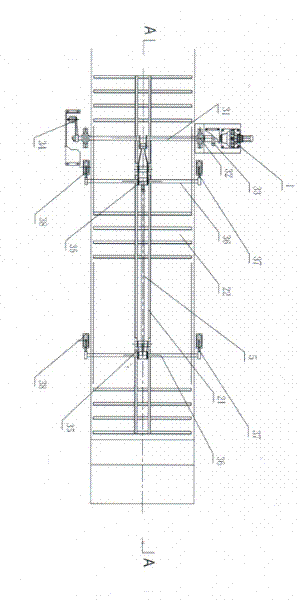

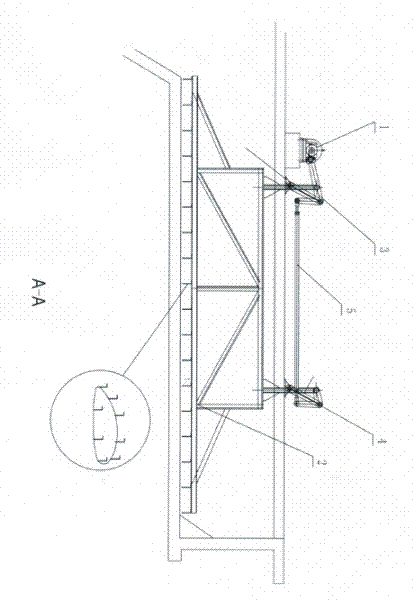

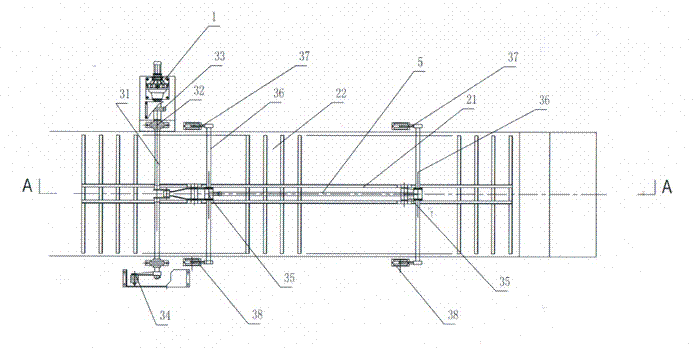

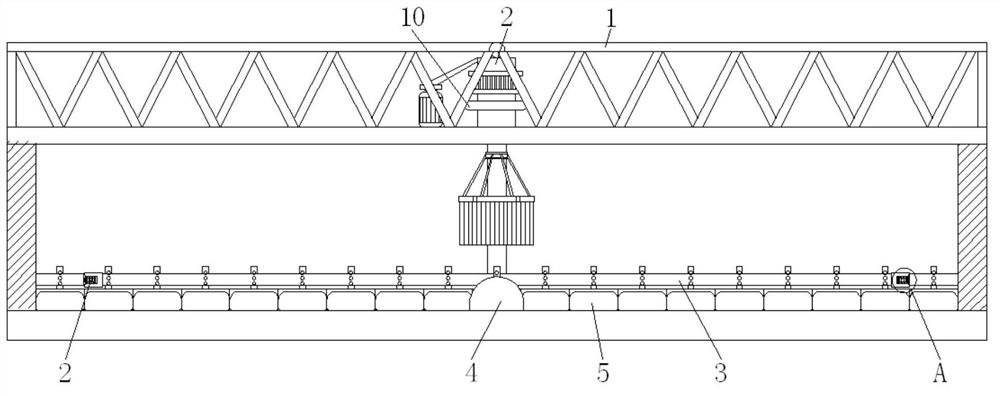

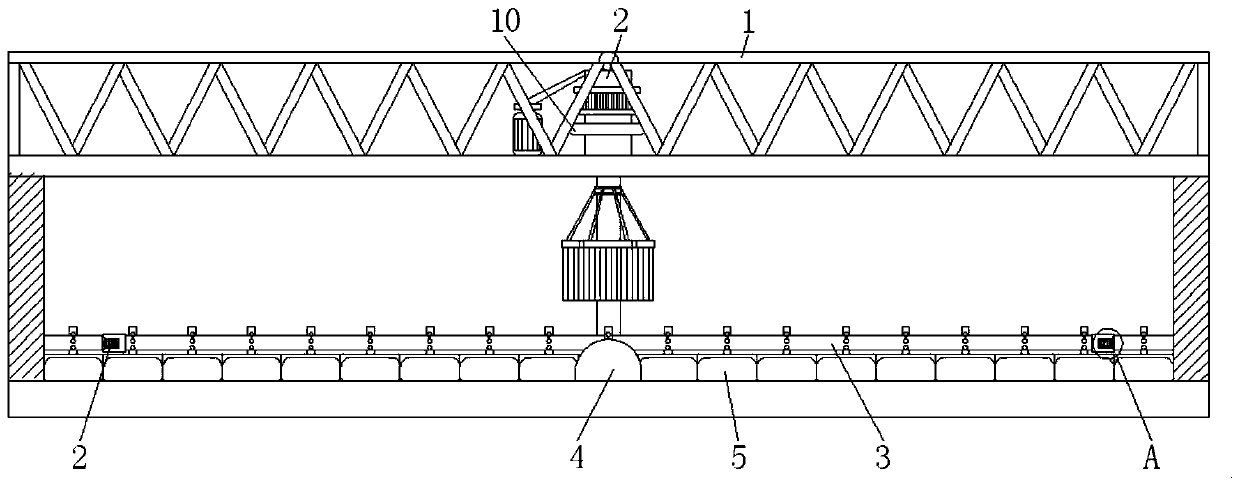

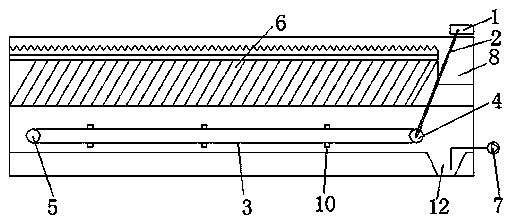

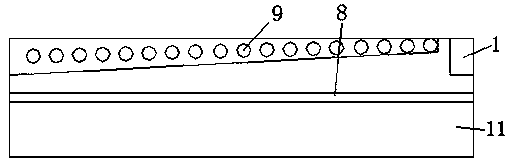

Double-chain driven sludge scraper

InactiveCN104190117AStable structureImprove mud scraping efficiencySettling tanks feed/dischargeWear resistantSprocket

The invention discloses a double-chain driven sludge scraper. A motor base is arranged on the upper surface of a settling pool and is provided with a tripod which is arranged in the settling pool; a speed reducer is arranged on the upper surface of the motor base and is provided with a small chain wheel; a driving shaft is arranged at the upper side in the settling pool; a big chain wheel is arranged at one end of the driving shaft; a transmission chain is arranged for connecting the small and big chain wheels; the driving shaft is provided with a driving chain wheel; bearing boxes are arranged at two ends of the driving shaft and are arranged on the wall of the settling pool; driven shafts are arranged at the upper and lower sides of the settling pool and are provided with driven chain wheels; bearing boxes are arranged two ends of each driven shaft and are arranged on the wall of the settling pool; a chain is arranged for connecting the driving chain wheels and the driven chain wheels; a sludge scraping plate is arranged on the upper surface of the chain; a welding connecting element of the sludge scraping plate is arranged on the upper surface of the chain by virtue of a pin roll; a support roller is arranged at the lower surface of the chain at the upper side of the settling pool; wear resistant parts are arranged at the bottom of the settling pool; a sludge groove is arranged at one end of the bottom of the settling pool; the speed reducer is arranged on the upper surface of the motor base and a control cabinet of the speed reducer is provided with a safety device for self-stopping when the reducer is overloaded.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

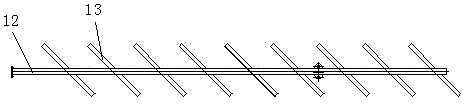

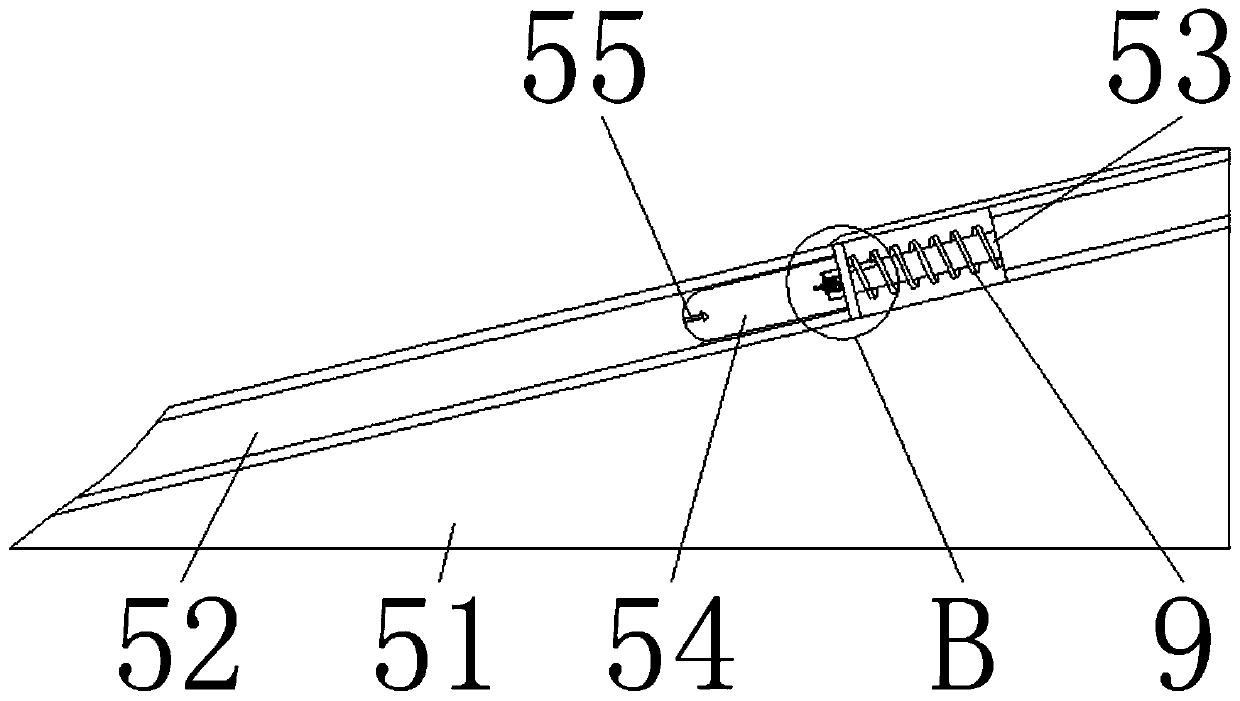

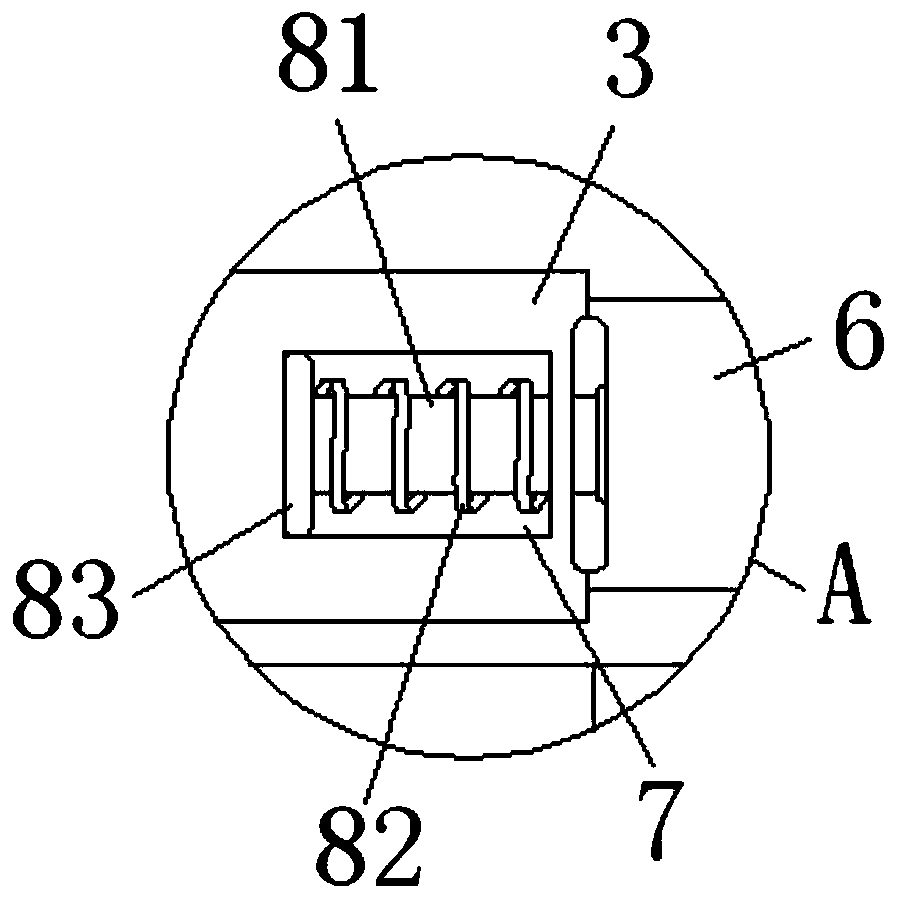

Jet-propelled scraper

InactiveCN105888563AImprove mud scraping efficiencyReduce labor intensityEarth drilling toolsLine tubingOperational safety

The invention relates to auxiliary machinery for petroleum drilling operation and particularly relates to a jet-propelled scraper. The jet-propelled scraper comprises an anti-overflow pipe, multiple gas nozzles, a rigid air supply pipe wrapper and a gas pipe; the anti-overflow pipe is sleeved with the rigid air supply pipe wrapper, a gas cavity is formed between the outer wall of the anti-overflow pipe and the inner wall of the rigid air supply pipe wrapper, and the rigid air supply pipe wrapper is connected with the gas pipe which is connected with a gas source; the gas nozzles are installed on the pipe wall of the anti-overflow pipe, a gas outlet of each gas nozzle faces a pipe cavity of the anti-overflow pipe, and a gas inlet of each gas nozzle faces the gas cavity. The jet-propelled scraper is high in mud-scraping efficiency, low in labor intensity, safe and convenient to operate, fully mechanized in operation, labor saving, efficient and safe.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Central transmission mud scraper

InactiveCN111760337AEasy to cleanImprove mud scraping efficiencySedimentation settling tanksSludgeSewage

The invention relates to the technical field of sludge treatment, and concretely relates to a central transmission mud scraper. The mud scraper comprises a sewage pool, and a working bridge is mountedon the upper surface of the sewage pool; a handrail is welded on the upper surface of the working bridge; a rotating rod is rotationally mounted on the lower surface of the working bridge; an upper hinge plate is welded at the upper end of the rotating rod; and an adjusting supporting rod is rotationally installed in one end of the upper hinge plate. A lower hinge plate is welded at the lower endof the outer surface of the rotating rod, a scraping plate is rotatably mounted in the lower hinge plate, a sludge pit is formed in the lower surface of the interior of the sewage pool, a base is mounted on the lower surface of the interior of the sludge pit, a rotating ball is welded to the lower surface of the rotating rod, a bearing seat is welded to the upper surface of the working bridge, and a bearing is mounted in the bearing seat. According to the center transmission mud scraper, the scraping plate can be lifted, the angle of the scraping plate can be adjusted, the scraping plate is provided with a scraper knife and a dirt collecting plate structure, and sludge can be collected through the dirt collecting plate.

Owner:YANGZHOU RENZHI INFORMATION TECH CO LTD

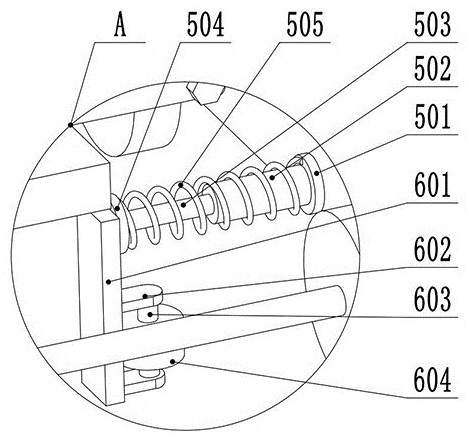

Handheld pneumatic sludge scraping device and using method thereof

PendingCN110685641ASimple structureImprove mud scraping efficiencyCleaning apparatusWellheadProcess engineering

The invention relates to the technical field of engineering machinery, in particular to a handheld pneumatic sludge scraping device and a using method thereof. One end of a body is held by hand, and ahelical structure formed by arranging the other end of the body is sleeved with a drilling tool to be scraped; and then, after an air source pipeline is ventilated, airflow passes through blow holesformed in the body of the helical structure for scraping the drilling tool to be scraped. According to the pneumatic sludge scraping device of this structure, the drilling tool for a wellhead and large and small rat holes can be scraped safely and conveniently, and meanwhile operators can be reduced by one; and the drilling tool for the wellhead and the large and small rat holes are purged and scraped cleanly and thoroughly, and the structure is simple; and the sludge scraping efficiency is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

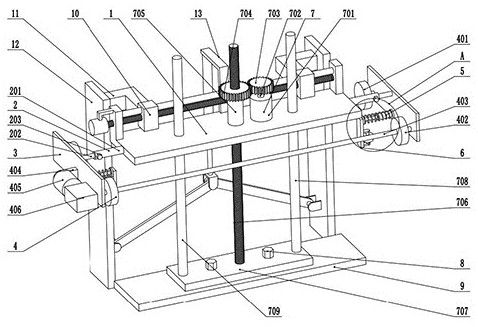

An adjustable road roller mud scraper

InactiveCN106758697BReduce wearReduce labor intensityRoads maintainenceHydraulic cylinderAgricultural engineering

The invention provides an adjustable type road roller mud scraper. The adjustable type road roller mud scraper comprises support transverse beams, a steel wheel, a protective cover, a mud scraper body, hydraulic cylinders, guide sleeves, guide rods, return springs, an electric cylinder, scraping knives and a connecting base, wherein the hydraulic cylinder is arranged in the middle part of front end surface of each support transverse beam; each guide sleeve is assembled at the front end surface of the corresponding hydraulic cylinder; the back end of each guide rod is arranged in the corresponding guide sleeve, and the front end of each guide rod penetrates through the protective cover and is connected with the mud scraper body; each return spring is coated at the outer surface of the corresponding guide rod, the front end of each return spring is connected with the mud scraper body, and the back end of each return spring is connected with the corresponding guide sleeve; the electric cylinder is arranged in the middle part of the upper end surface of the protective cover; the connecting base is arranged in the protective cover; the upper end of the connecting base is connected with the electric cylinder; the upper ends of the two groups of scraping knives are fixedly arranged on the connecting base, and are symmetrically arranged at the front and back sides of the mud scraper body. The adjustable type road roller mud scraper has the advantages that the structure is reasonable, the mud scraping efficiency is improved, the adjusting is convenient, the stability is good, and the reliability is high.

Owner:王江丽

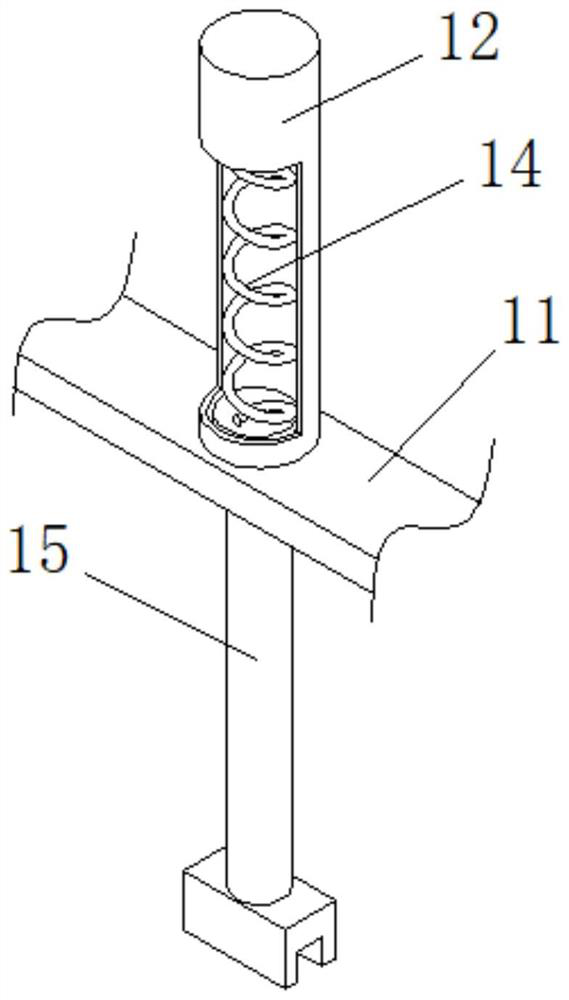

Mud scraping device for sewage treatment sedimentation tank

ActiveCN114191858AImprove precipitation effectEasy dischargeSettling tanks feed/dischargeSludgeSewage

The invention provides a sludge scraping device for a sewage treatment sedimentation tank, and relates to the field of sewage treatment. Comprising a sedimentation tank, a water inlet and a water outlet are fixedly mounted at the left top end and the right top end of the sedimentation tank respectively, and a supporting plate is fixedly mounted at the top end of the sedimentation tank. According to the sludge scraping device for the sewage treatment sedimentation tank, by arranging a spring barrel, a buffer spring and a spring rod, when sludge settled on the inner bottom wall of the sedimentation tank is treated, the spring rod can extrude the buffer spring to buffer the resistance brought by the sludge to a fender, so that the fender can stably and continuously move, and a motor is prevented from being burnt out due to short circuit; the sludge treatment device has the advantages that the sludge treatment device is provided with the sludge discharge pipe, the sludge pump and the control valve, the loose sludge can be discharged from the sludge discharge pipe by starting the sludge pump, and the sludge in the sedimentation tank can be quickly pumped out, so that space can be reserved, and dirt carried by sewage can be effectively settled.

Owner:山西碧海机械有限公司

Grab bucket and sludge scraper thereof

InactiveCN101701463BSimple structureReduce processing costsMechanical machines/dredgersSludgeEngineering

The invention discloses a sludge scraper for a grab bucket, and the sludge scraper comprises a fixed mud scraper (2), a movable mud scraper (3) and a rigid connecting rod (5), wherein the fixed mud scraper (2) is fixed with a grab bucket bracket (6); the movable mud scraper (3) is connected with the fixed mud scraper (2) in a sliding mode; and one end of the rigid connecting rod (5) is hinged with a grab bucket body (4) of the grab bucket, and the other end is hinged with the movable mud scraper (2), so that the grab bucket body (4) drives the movable mud scraper (3) to slide relatively to the fixed mud scraper (2). The movable mud scraper (3) of the sludge scraper can slide in the extending direction of the fixed mud scraper (2), so that the overall length of the sludge scraper can increase as the opening degree of the grab bucket body (4) increases, and decrease as the closing degree of the grab bucket body (4) increases, thereby enhancing the mud scraping efficiency and the workingefficiency of the grab bucket without influencing the normal operation of the grab bucket body. The invention also discloses a grab bucket comprising the sludge scraper.

Owner:BEIJING SANY HEAVY MASCH CO LTD

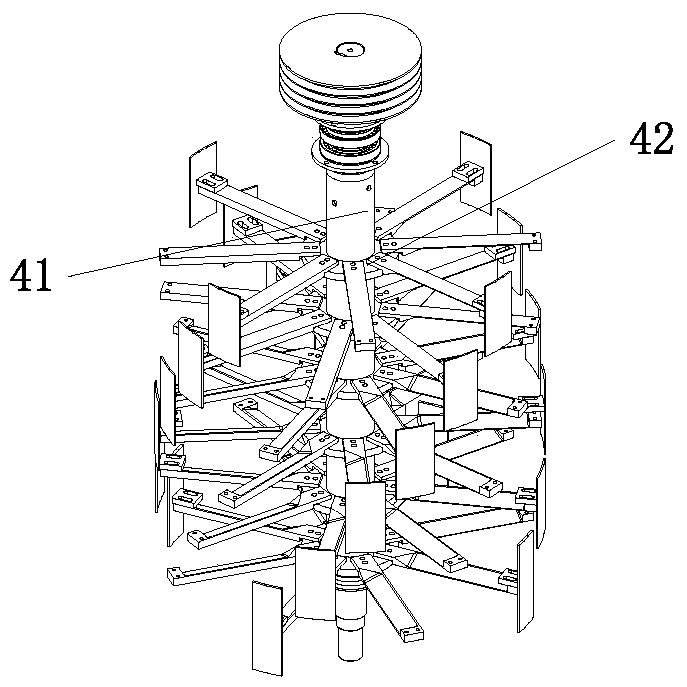

High-speed mud cutting equipment

ActiveCN111376379APlay the role of cleaning the inner wall of the mud cutting binReduce volumeCeramic shaping apparatusGrain treatmentsMining engineeringStructural engineering

The invention relates to the technical field of ceramic powder preparation equipment, in particular to high-speed mud cutting equipment. The high-speed mud cutting equipment comprises a mud cutting bin, a mud baffle bin and a mud cutting mechanism, wherein the mud cutting mechanism comprises a rotary shaft and mud cutting knife tackles; a rotary shaft can be rotatably mounted on the middle part ofthe mud cutting bin; the mud cutting knife tackles are sequentially arranged and fixedly mounted on the rotary shaft; the mud baffle bin sleeves the mud cutting bin; a plurality of through holes areformed in the mud cutting bin; a mud scraping knife is driven by the rotary shaft to rotate; a plurality of through holes are formed in the mud cutting bin; each mud cutting knife tackle comprises oneor more mud cutting knifes, and upper and lower adjacent mud cutting knifes are arranged in a staggered mode; the through holes are formed in the mud cutting bin, so that the size of mud adhered on the mud cutting bin can be reduced, and contact area between the mud and the mud cutting bin is reduced, and therefore, adhesion force is reduced, and mud is easily scraped off by the mud scraping knife; and the mud scraping knife can scrape off mud adhered on the inner wall of the mud cutting bin, so that the effect of clearing the inner wall of the mud cutting bin is achieved.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

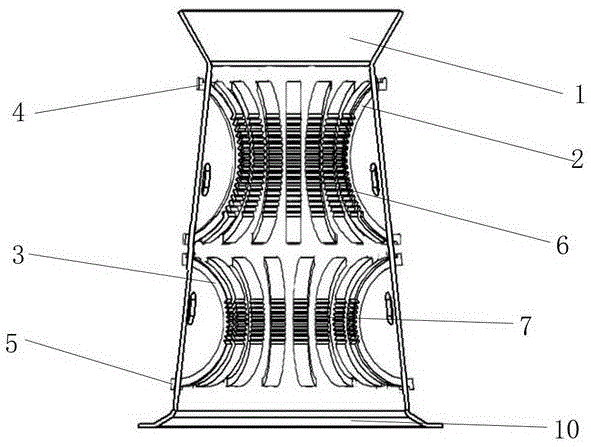

Convoluted swing type mud scraper

The invention provides a convoluted swing type mud scraper, relating to sewage treatment equipment. A set of crank rocker four bar mechanism and a plurality of sets of parallel type connecting rod rocker four bar mechanism are sequentially connected in series by virtue of a parallel long rod; the two ends of the crank shaft of the crank rocker four bar mechanism are supported by a bearing block, the crank section at the middle part of the crank shaft is connected with the crossbar end of a L-shaped connecting rod in a looping way, the L-shaped connecting rod is supported by a horizontal shaft, the nook thereof is connected with the horizontal shaft in a free way, the two ends of the horizontal shaft are respectively hinged with rockers arranged at the two sides of a sedimentation tank, and the other end of the parallel long rod is connected with the crossbar end of the L-shaped connecting rod of the next parallel type connecting rod rocker four bar mechanism in a looping way. The device can operate stably, mud scrapping efficiency is high, and intermittent mud scrapping is realized.

Owner:江苏通用环境工程有限公司

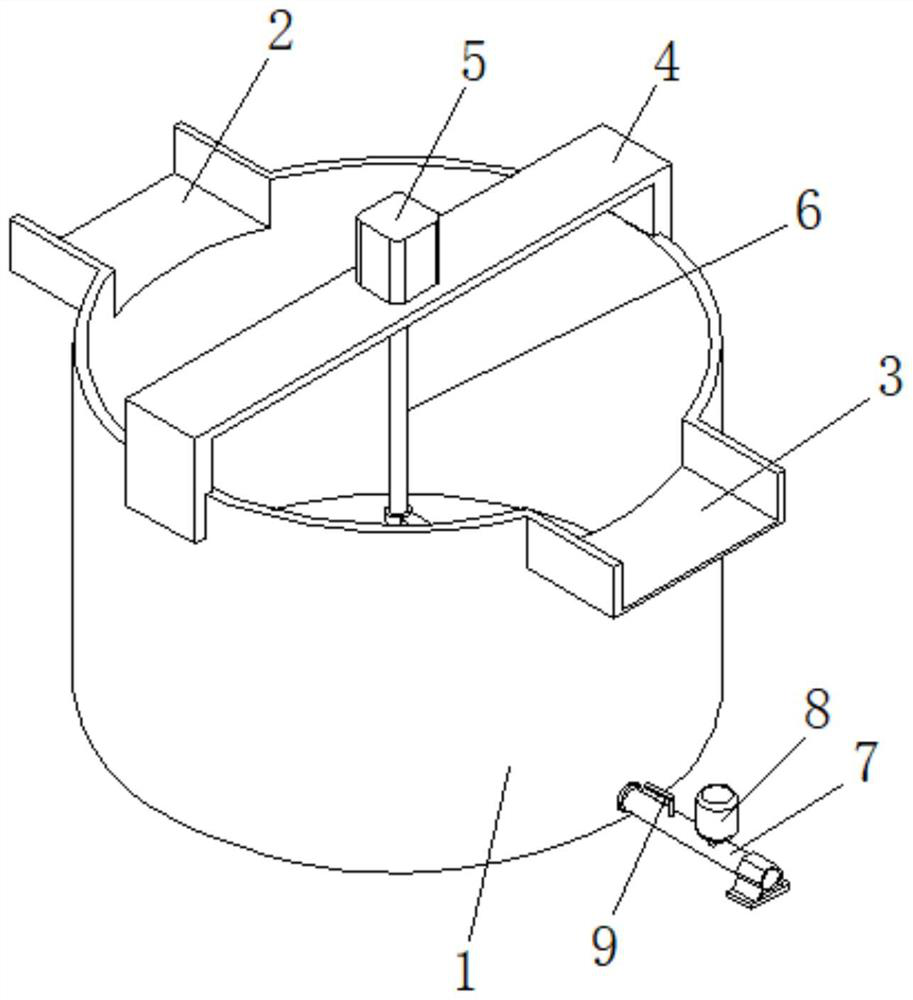

A kind of sludge thickening equipment based on sbr treatment process

ActiveCN108751661BSimple structureEasy to useSludge treatmentSettling tanks feed/dischargeAugerSludge

The invention discloses a sludge thickening device based on an SBR treatment process, which includes a sedimentation tank, a mud scraping mechanism and an aeration mechanism; the mud scraping mechanism is installed at the center of the sedimentation tank through a working bridge, and the aeration mechanism is installed at the bottom of the sedimentation tank; The mud scraping mechanism includes driving device 1, rotating main shaft, screw auger and driving device 2; the driving device is installed on the working bridge and connected with the rotating main shaft; the screw auger is parallel to the bottom of the sedimentation tank and connected with the rotating main shaft, and the The driving device 2 for driving its rotation is separately connected to the top; the mud scraper is also connected to the bottom end of the rotating main shaft, and a mud discharge pipe extending out of the sedimentation tank is installed in the center of the bottom of the sedimentation tank; The supporting installation structure that cooperates with it enables the mud scraper to not only move and scrape mud well along the bottom of the pool, but also have a good mud scraping effect, which ensures the mud scraping time of the mud scraper and greatly saves energy consumption. Has good performance.

Owner:四川意德康环保科技有限公司

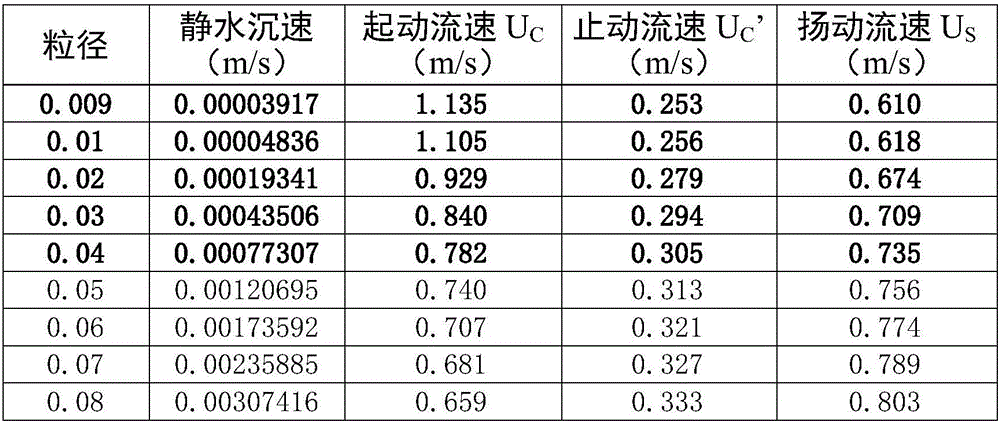

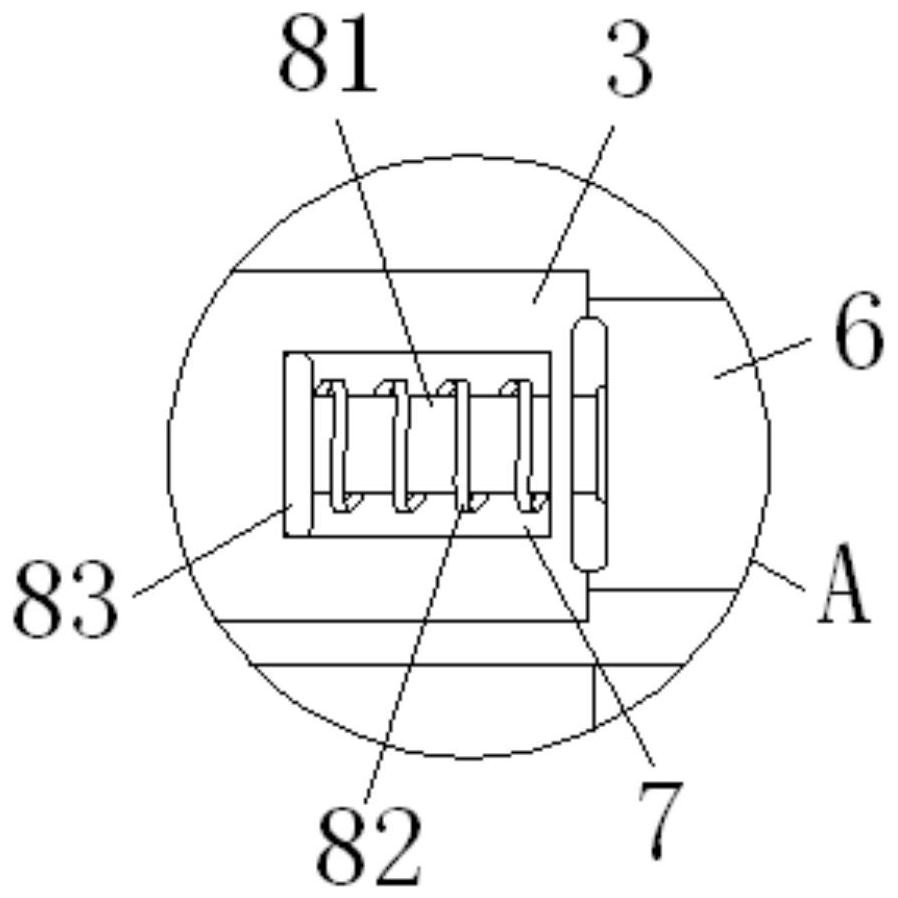

A sewage magnetic loading clarification process and its system

ActiveCN112110528BReduce disturbancePrevent leakageWater/sewage treatment by magnetic/electric fieldsFlocculationCurrent limiting

The invention relates to a sewage magnetic loading clarification process and system, comprising a floc generation unit, a nucleation unit, a magnetic floc generation unit and a precipitation unit. Wherein, the sedimentation unit includes a sedimentation tank, and the two side walls of the sedimentation tank are provided with a first limiting groove, a second limiting groove, a third limiting groove, a fourth limiting groove, a fifth limiting groove and a mud scraper Guide groove. The mud scraping device includes a first mud scraper, a second mud scraper and a flow restrictor. Since the first guide column and the second guide post on the flow restrictor slide along the guide groove of the mud scraper, the inclination of the flow restrictor The angle is always the direction of its displacement track, which greatly reduces the disturbance of the restrictor plate to the sedimentation tank. And because the flow restrictor is connected with the upper end of the most mud scraper, so that after the mud scraping device finishes scraping, the flow restrictor is folded down to be parallel to the second mud scraper, which can reduce the lifting and lowering of the mud scraper. Disturbance of the sludge in the sedimentation tank during the process.

Owner:JIANGSU QICHUANG ENVIRONMENTAL SCI & TECH

Mud-scraping mechanism for press wheel

InactiveCN107787626ANovel structureImprove mud scraping efficiencySpadesPloughsEngineeringMechanical engineering

The invention discloses a mud-scraping mechanism for a press wheel. The mud-scraping mechanism comprises a frame, a suppressing shaft, a press wheel, installation seats, a mud-scraping shaft, taperedprotrusions and a driving belt. The suppressing shaft is installed on the right side of the frame through a bearing. The press wheel is installed on the press shaft. The mud-scraping mechanism is characterized in that the two installation seats are respectively installed inside and outside of the frame; a connecting line between the two installation seats is parallel to the press shaft; the mud-scraping shaft is installed between the two installation seats through a bearing; the outer peripheral surface of the mud-scraping shaft is fixedly connected with the tapered protrusions; outer ends ofthe press shaft and the mud-scraping shaft are fixedly connected with a rotary disk; and additionally, the press shaft is connected with the mud-scraping shaft through the driving belt. The mud-scraping mechanism for the press wheel is advantaged by being novel in structure and high in mud-scraping efficiency.

Owner:灵璧九瑞农发科技有限公司

A river sludge dredging treatment equipment

ActiveCN110318436BEasy to cleanSave time and costSludge treatmentSpecific water treatment objectivesRiver routingSludge

The invention discloses watercourse sludge desilting treatment equipment. The device comprises an equipment main body, wherein a first steel channel and a second steel channel are correspondingly fixed on the same side outer wall of the equipment main body from bottom to top, and a mud scraping cavity is fixedly arranged at the top of an inner cavity of the equipment main body; and the mud scraping cavity comprises a front mudguard and a rear mudguard, a movable top cover is arranged on the top of one side of the mud scraping cavity, a first connecting rod which is longitudinally arranged is fixedly connected to the upper end surface of the movable top cover, and a second connecting rod is hinged to one end, far away from the movable top cover, of the first connecting rod. According to thewatercourse sludge desilting treatment equipment, the mud scraping cavity and a filtering belt can be cleaned without dismounting the equipment, so that the cleaning of the equipment is more convenient, and meanwhile, the time cost for cleaning the equipment is saved; and sludge in a sludge inlet pipe is optimized and stirred through a bidirectional motor, the stirring efficiency of the sludge isensured while the use number of stirring blades is reduced, the manufacturing cost of the equipment is saved, and fine sand in the sludge can be effectively prevented from being adsorbed on the surface of the filtering belt so as to affect the water filtering efficiency of the filtering belt.

Owner:SHANGHAI RUIHUI ENVIRONMENTAL PROTECTION TECH

Grab, continuous wall hydraulic grab grooving machine and grab operation method

ActiveCN103572791BImprove mud scraping efficiencyImprove work efficiencySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention provides a grab bucket, a continuous wall hydraulic grab bucket grooving machine and a grab bucket working method. The grab bucket comprises a grab bucket base, a grab bucket shell and a scraper, wherein the grab bucket shell is connected to the grab bucket base in a pivot mode, and the scraper is located in the grab bucket shell; the scraper includes a scraper body which is of a platy structure; when the grab bucket shell is in a fully open state, the scraper body is connected to the grab bucket base in a pivot mode in the form of at least covering a part of a soil inlet of the grab bucket shell, so that the scraper can rotate freely when the grab bucket grabs soil; in this way, the scraper will not cover the soil inlet of the grab bucket shell, and therefore the soil feeding amount of the grab bucket shell is not affected; furthermore, the scraper body is of the platy structure, so that the scraping area of the scraper is greatly increased when the grab bucket discharges the soil, and working efficiency of the grab bucket can be improved. Besides, in the working process of the grab bucket, the scraper can further compress ground for squeezing and draining, so that accumulated water in the grab bucket does not need to be drained by utilizing extra tools and time, the working efficiency of the grab bucket can be further improved, and the use cost of the grab bucket is saved.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

A kind of mud scraping equipment for sedimentation tank

ActiveCN110575686BImprove mud scraping efficiencyTimely lubricationSedimentation settling tanksSedimentation device makingSludgeMachine building

The invention relates to the technical field of mechanical manufacturing, and discloses a mud scraping equipment for a sedimentation tank, comprising a working bridge, the middle part of the working bridge is fixedly connected with a driving traveling device, and the left side of the driving traveling device is fixedly connected with an electric control The cabinet, the bottom of the drive traveling device is fixedly connected with a transverse bar. The mud scraping equipment for the sedimentation tank, through the fixed connection of the left end of the elastic expansion part and the right side of the circular plate, the elastic force stored in the elastic expansion part in the compressed state provides a constant outward thrust to the horizontal bar, avoiding the expansion of the expansion plate. The outer side is not tightly closed at the corner of the sedimentation tank, resulting in the consequence that it cannot be completely scraped off, which is conducive to improving the efficiency of the mud scraping equipment used in the sedimentation tank, and is conducive to timely lubrication of the equipment at the card to avoid excessive wear of related equipment , effectively prolong the service life of the corresponding equipment, and at the same time facilitate the rapid self-regulation of the wear and tear, without manual inspection step by step.

Owner:东阳市横店自来水有限公司

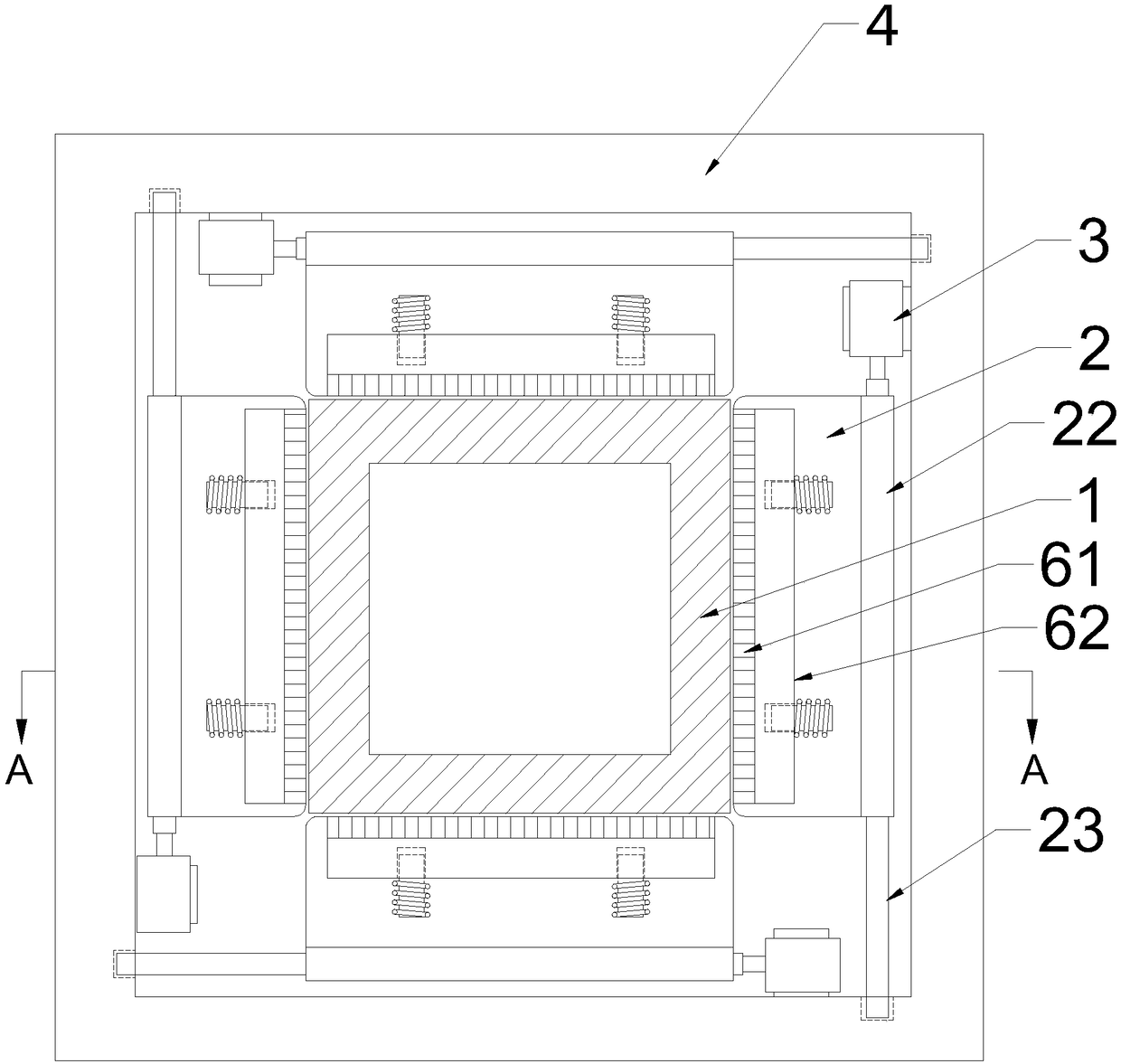

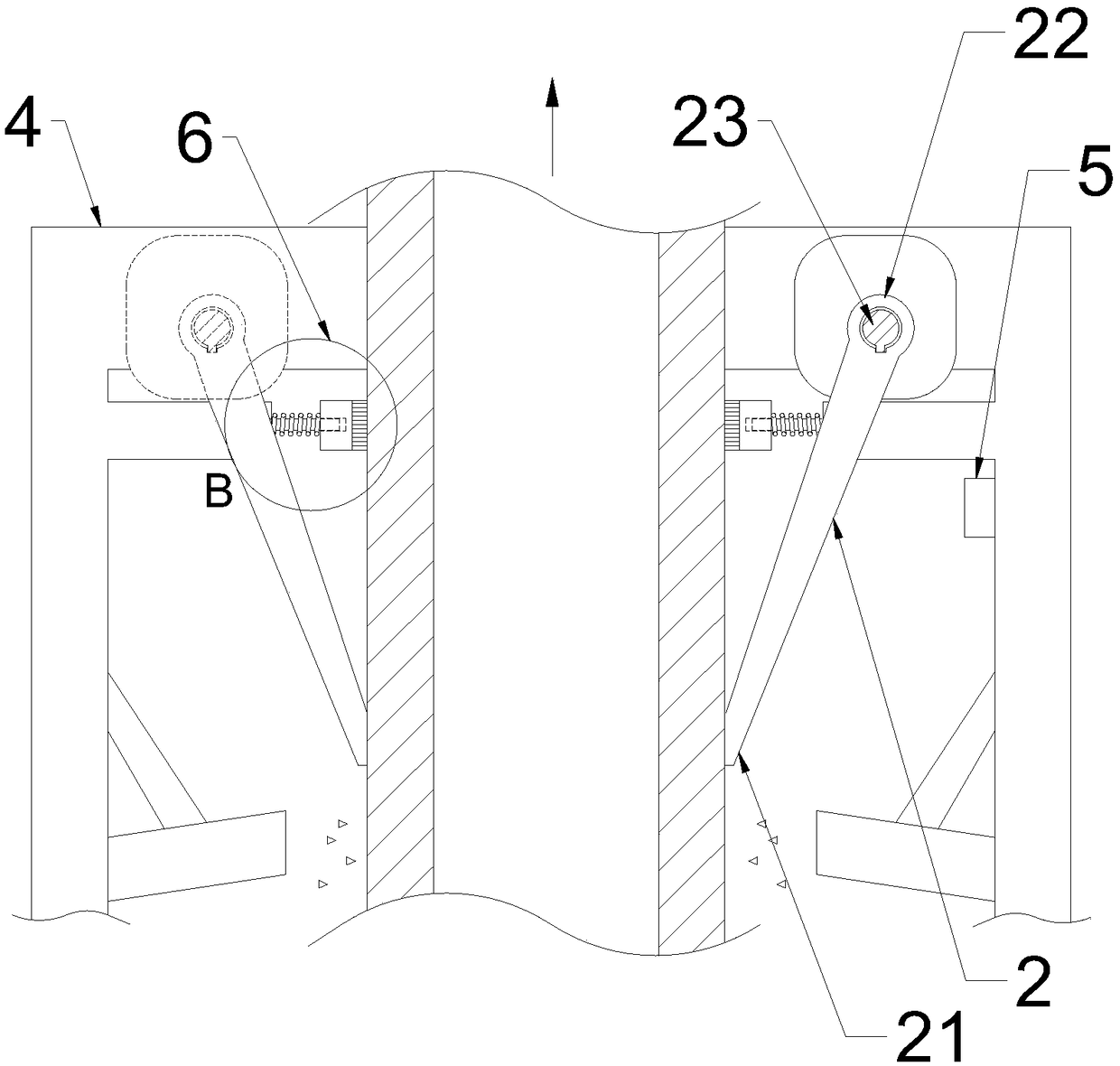

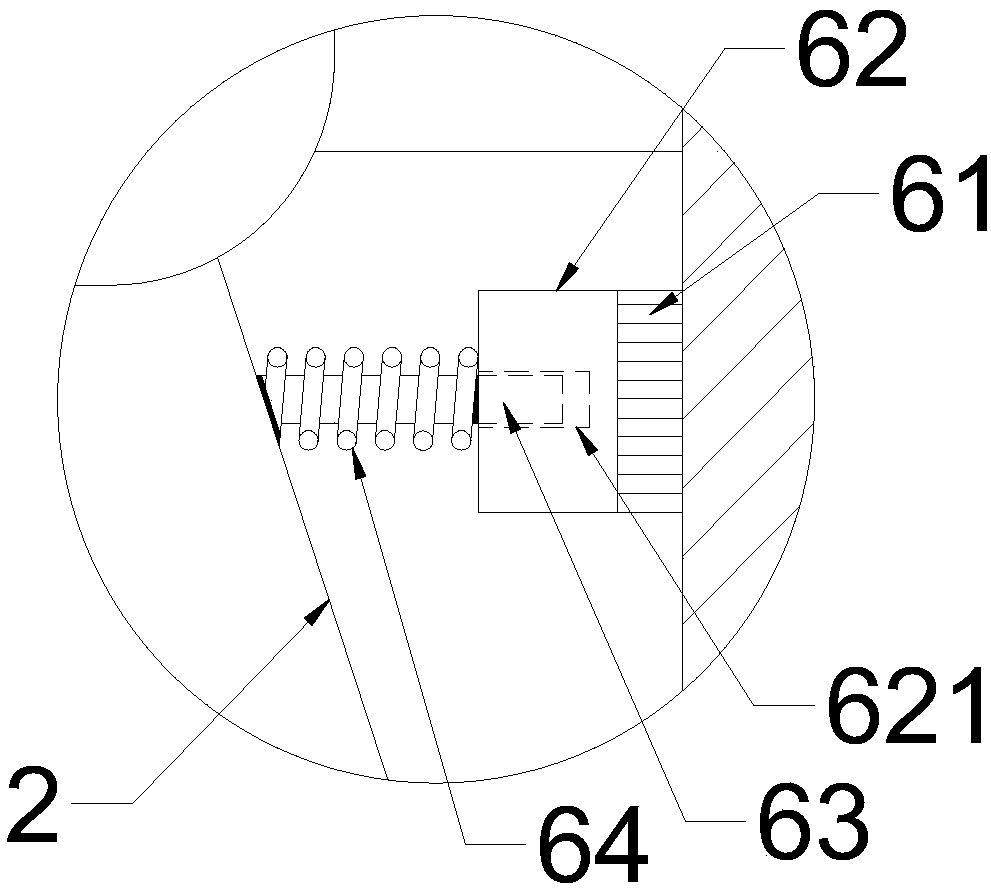

Mud scraping equipment for sedimentation tank

ActiveCN110575686AImprove mud scraping efficiencyAvoid wearing out fastSedimentation settling tanksSedimentation device makingEngineeringElectric control

The invention relates to the technical field of machine manufacturing, and discloses mud scraping equipment for a sedimentation tank. The mud scraping equipment comprises a working bridge, wherein a driven walking device is fixedly connected to the middle of the working bridge; an electric control cabinet is fixedly connected to the left side of the driven walking device; and a transverse rod is fixedly connected to the bottom of the driven walking device. According to the mud scraping equipment for the sedimentation tank, the left end of an elastic telescopic part is fixedly connected with the right side of a circular plate, so elastic force stored in the elastic telescopic part in a compressed state provides always outward thrust for the transverse rod; the consequence of incapable thorough scraping caused by the fact that the outer side of a telescopic plate is not tightly closed at the corner of the sedimentation tank is overcome; the mud scraping efficiency of the mud scraping equipment for the sedimentation tank can be improved; the equipment at a clamping position can be lubricated in time; related equipment is prevented from being abraded too fast; the service life of the corresponding equipment is effectively prolonged; and an abraded position can be conveniently and quickly self-conditioned, and manual step-by-step checking is not needed.

Owner:东阳市横店自来水有限公司

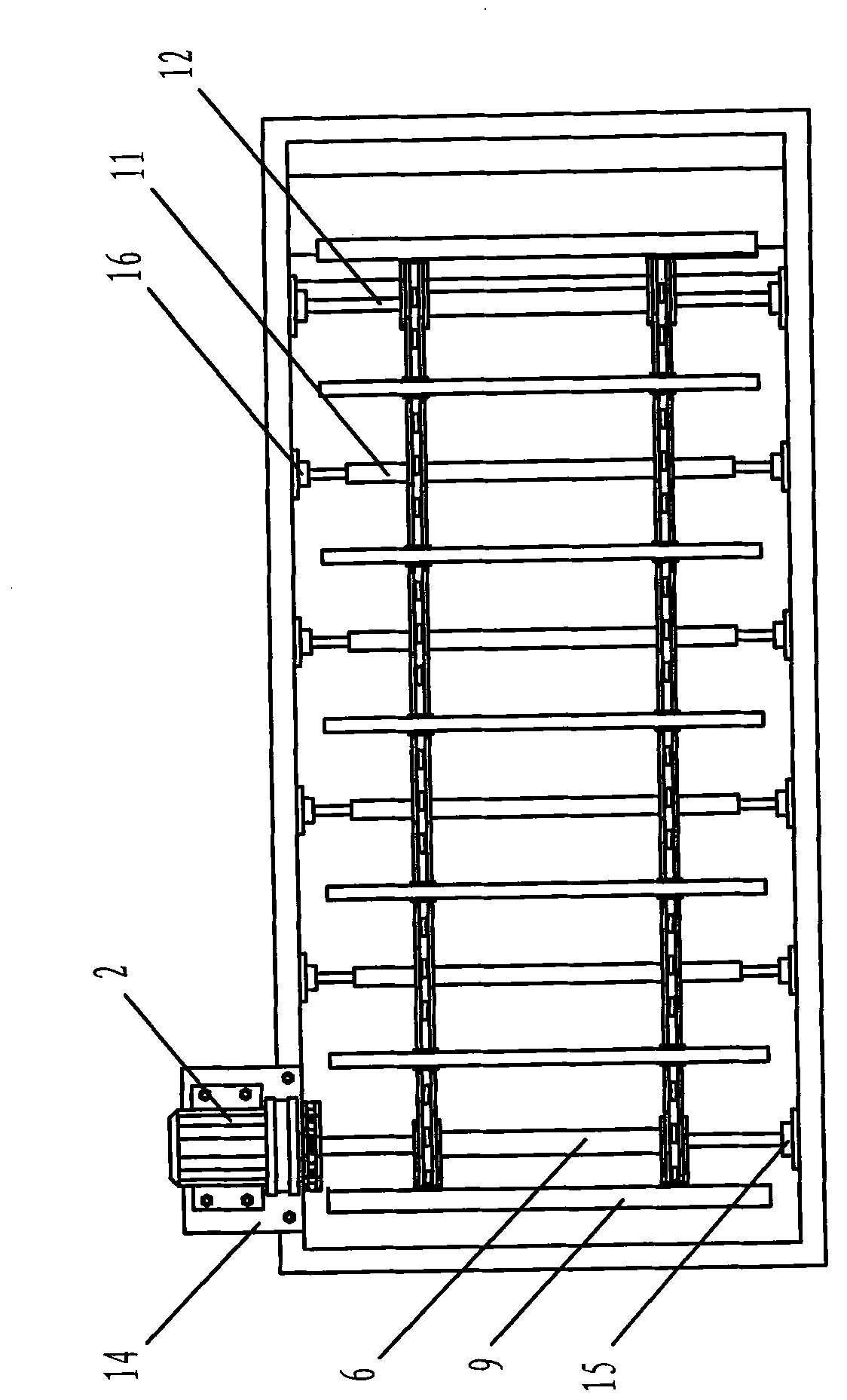

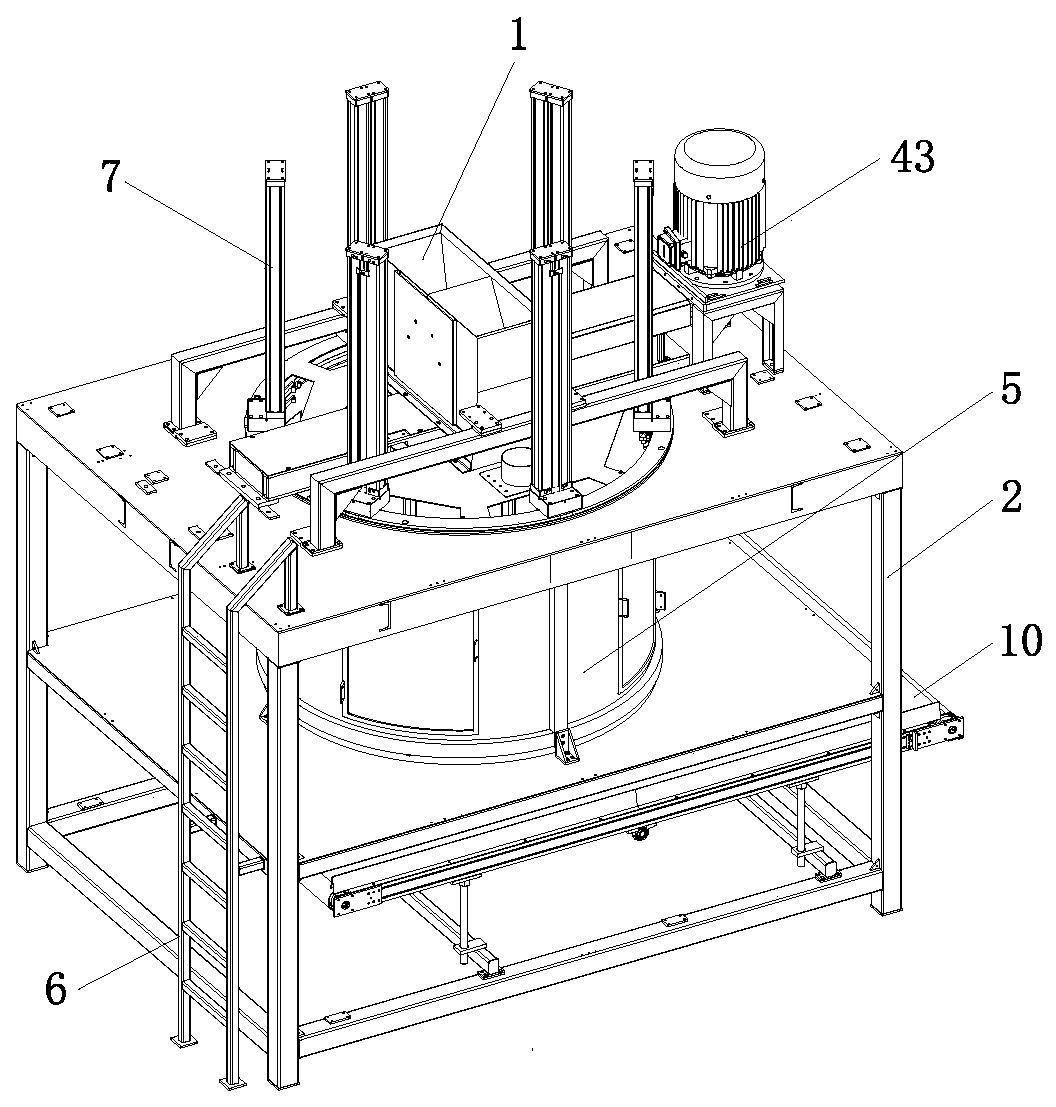

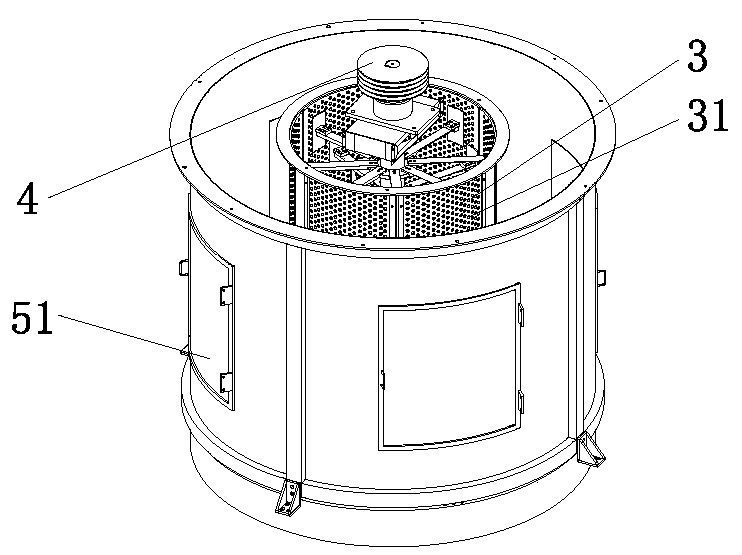

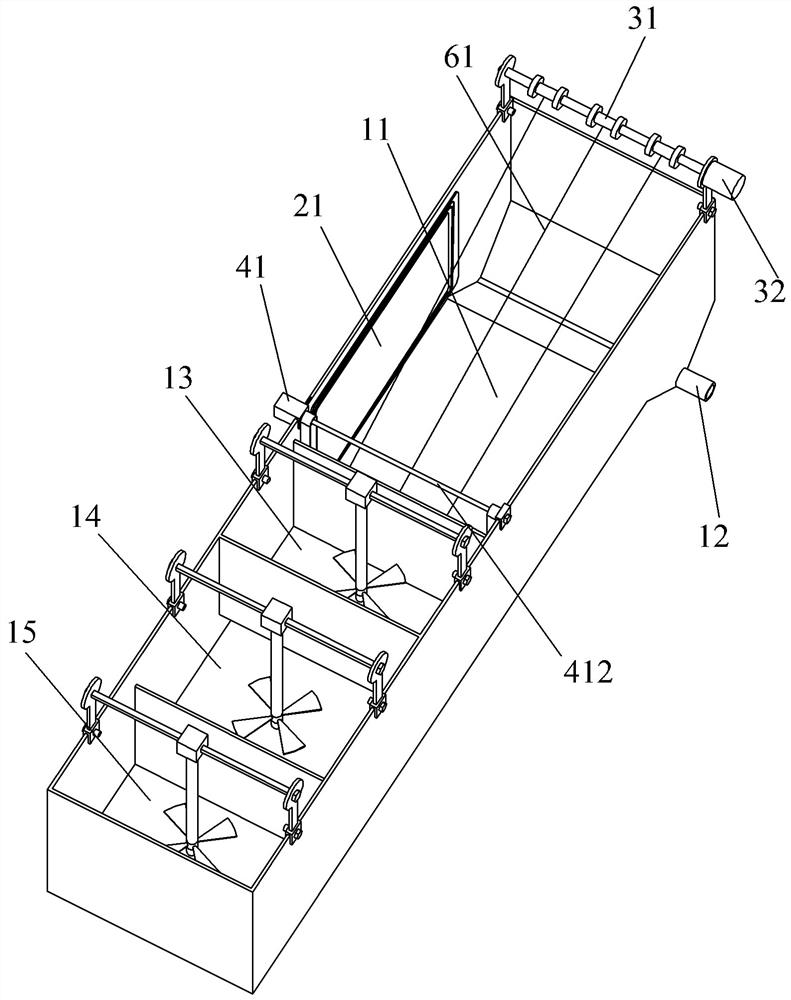

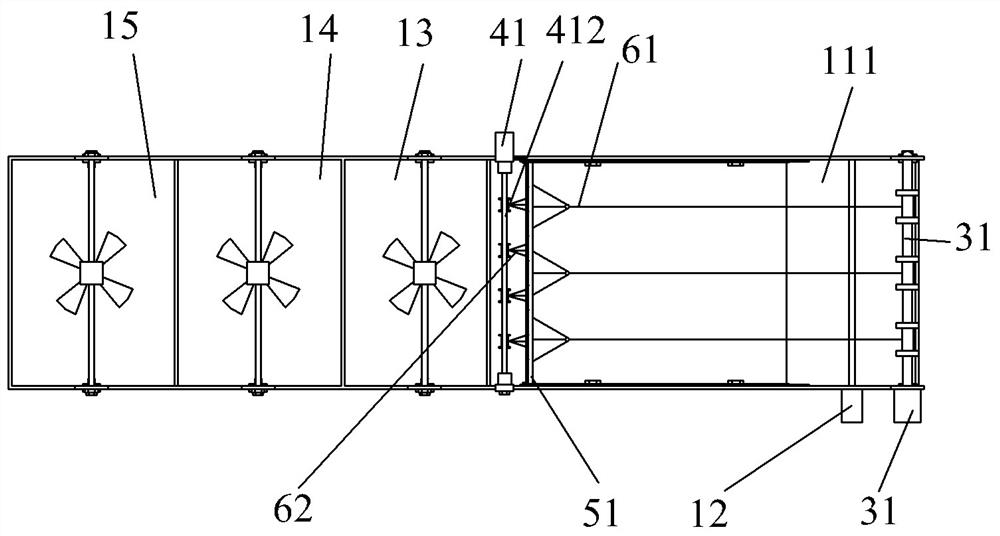

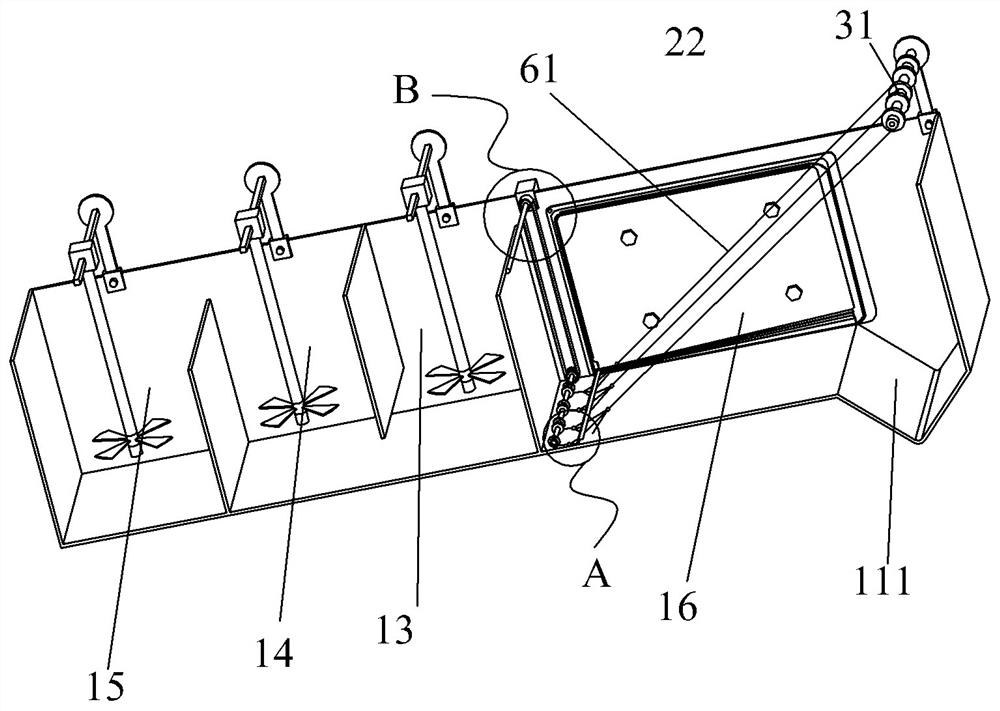

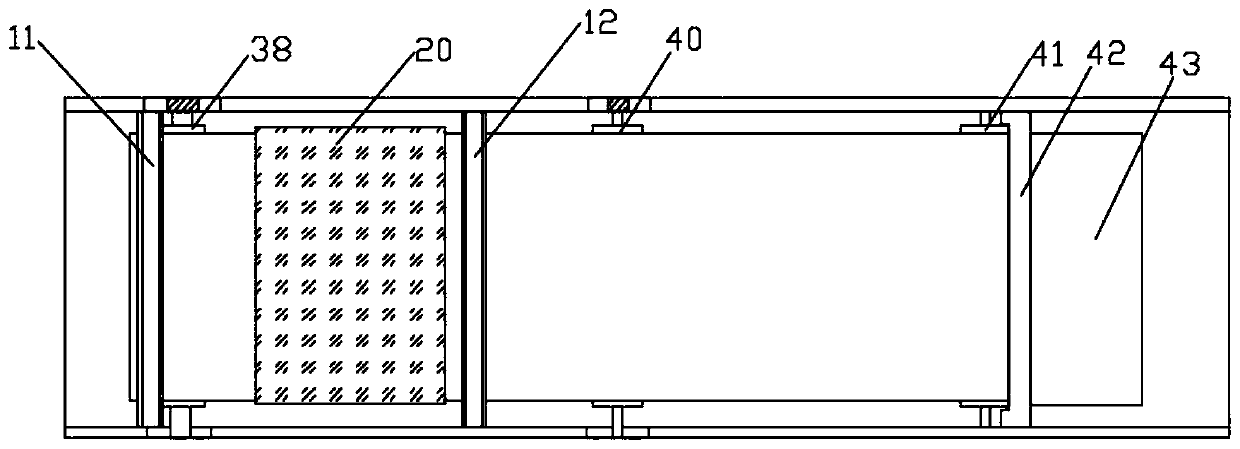

Portable magnetic coagulation sedimentation device

InactiveCN109574363AImprove concentrationImprove mud scraping efficiencyMultistage water/sewage treatmentTreatment involving sedimentationEngineeringMechanical engineering

The invention discloses a portable magnetic coagulation sedimentation device. The portable magnetic coagulation sedimentation device comprises a machine body. The interior of the machine body is successively provided with a driving chain wheel and a driven chain wheel along a horizontal direction. The driving chain wheel and the driven chain wheel are rotatably connected in the machine body. A mudscraper chain is connected between the driving chain wheel and the driven chain wheel. The outer wall of the mud scraper chain is uniformly and fixedly provided with a plurality of scraping plates. The machine body is provided with a motor. A transmission chain is connected between the motor and the driving chain wheel. The interior of the machine body is fixedly provided with an inclined plate.The inclined plate and an effluent weir are successively installed above the mud scraper chain. The water outlet end of the inclined plate is communicated with the water inlet end of the effluent weir. The top end of the machine body is provided with a water distributing hole. The portable magnetic coagulation sedimentation device is capable of integrating a mud scraper and an efficient inclined plate sedimentation basin, has the characteristics of large wetted perimeter, small hydraulic radius, good laminar conditions, and no flocculant flow interference to particle sedimentation, and has thecharacteristics of strong overload capacity and large transmission power through chain transmission, and is convenient for maintaining and skid-mounting.

Owner:ANHUI PUSHI ECOLOGICAL ENVIRONMENT ENG

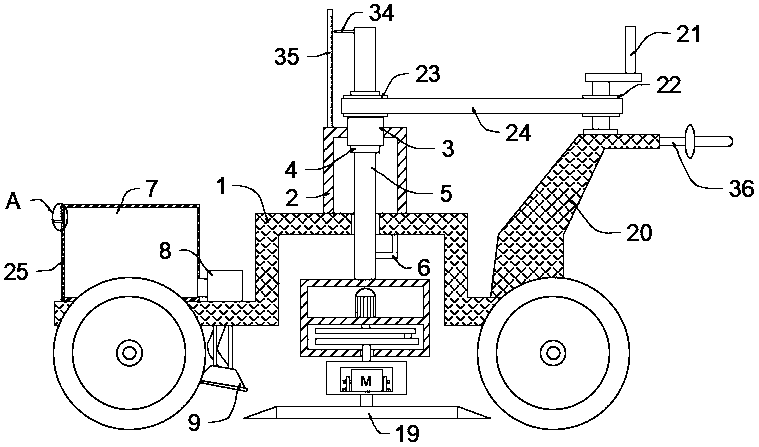

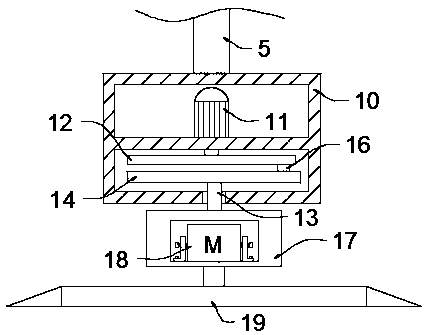

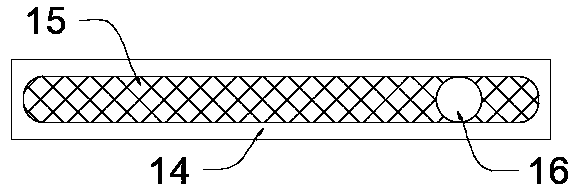

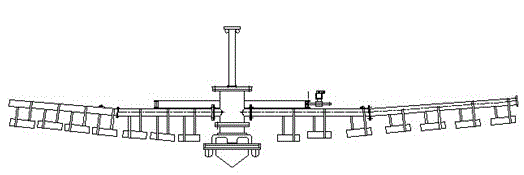

Peripheral transmission aspiration sludge scraper for sewage treatment

InactiveCN110975351AWide range of mud scrapingImprove mud scraping efficiencySettling tanks feed/dischargeSedimentation settling tanksSewage treatmentWater treatment

The invention discloses a peripheral transmission aspiration sludge scraper for sewage treatment. The peripheral transmission aspiration sludge scraper for sewage treatment comprises a vehicle body, the middle of the vehicle body is of an arched structure; the upper end of the arched structure is fixedly connected with a limiting seat; a bearing is fixedly connected to the upper end of the limiting seat in a penetrating manner; the inner ring of the bearing is fixedly connected with a rotating pipe in a sleeving manner; an internal thread is formed in the inner wall of the rotating pipe; a connecting column is in threaded sleeve connection with the interior of the rotating pipe; the lower end of the connecting column penetrates through and extends to the bottom of the vehicle body and is connected with a mud scraping mechanism, a vertically-arranged limiting groove is formed in the side wall of the connecting column, a limiting rod is further fixedly connected to the bottom of the vehicle body, and one end of the limiting rod is inserted into the limiting groove and is in sliding connection with the limiting groove. According to the peripheral transmission aspiration sludge scraper, the mud scraping range of a mud scraper in unit time can be larger, so that the mud scraping efficiency is higher; the sludge scraping depth can be adjusted according to the thickness of deposited sludge; and the scraped sludge can be collected in a centralized manner and quickly cleaned, so that the use is very convenient.

Owner:刘晓明

Novel scraper shallow-layer gas flotation machine

InactiveCN107055667AIncrease the number ofReduce disturbanceFatty/oily/floating substances removal devicesLiquid separationSlagEngineering

The invention discloses a novel scraper shallow air flotation machine, which comprises a pool body, a walking platform arranged on the side wall of the pool body, and a walking frame arranged on the upper end of the pool body. The sewage tank, the inside of the sewage tank is provided with a clear water tank, and the inside of the clean water tank is provided with a scum tank; The mud scraper is opened in the direction, and the mud scraper is fixedly connected with the walking frame through a vertical connecting rod. The beneficial effect of the present invention is that the mud scraping efficiency is improved, and the disturbance of the mud scraper to sewage is reduced at the same time.

Owner:山东中科贝特环保装备股份有限公司

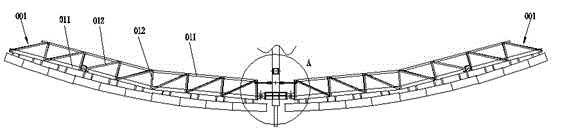

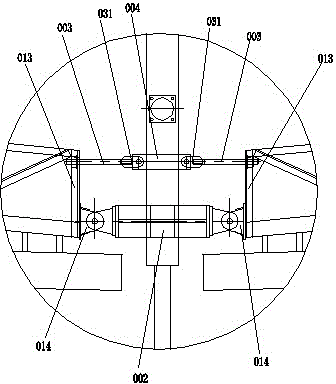

Adjustable mud-scraping truss for mud scraper

ActiveCN103816701AImprove mud scraping efficiencyExtended service lifeSedimentation separationStructural engineeringMechanical engineering

Owner:JIANGSU YIHUAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com