A kind of sludge thickening equipment based on sbr treatment process

A sludge concentration and treatment process technology, applied in sludge treatment, water/sludge/sewage treatment, feed/discharge device of settling tank, etc., can solve waste, affect sludge treatment timeliness, scraper rake Rack damage, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

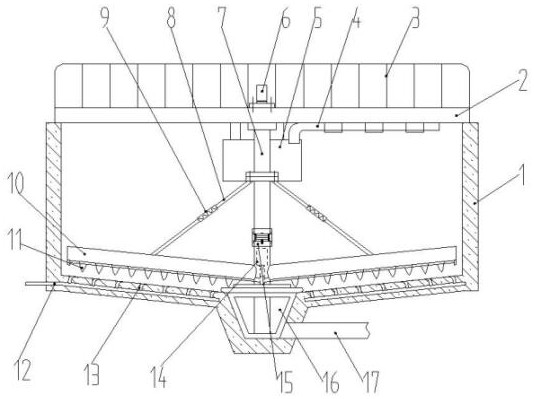

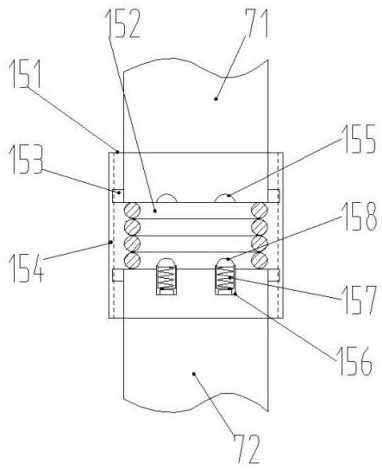

[0031] Such as figure 1 with figure 2As shown, a sludge concentration equipment based on SBR treatment process includes a sedimentation tank 1, a mud scraping mechanism and an aeration mechanism; the mud scraping mechanism is installed in the center of the sedimentation tank 1 through a working bridge 2, and the aeration mechanism is installed in The bottom of the sedimentation tank 1; the mud scraping mechanism includes a driving device one 6, a rotating main shaft 7, a screw auger 11 and a driving device two 14; the driving device is installed on the working bridge 2 and is connected with the rotating main shaft 7 to drive the The main shaft 7 rotates; the screw auger 11 is parallel to the bottom of the sedimentation tank 1 and is connected with the rotating main shaft 7, and with the rotation of the main shaft 7, the screw auger 11 is also separately connected with a driving device 2 14 that drives its rotation; The bottom end of the rotating main shaft 7 is also connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com