Environment-friendly self-adaptive adjustment type sedimentation tank mud scraper

An adaptive adjustment and sedimentation tank technology, which is applied in the direction of sedimentation separation, settling tank, feeding/discharging device of the settling tank, etc., can solve the problem that there is no lifting mechanism, no telescopic mechanism, and the sedimentation that cannot adapt to different widths Pool and other problems, to achieve the effect of increasing efficiency, reducing labor costs, and preventing device deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

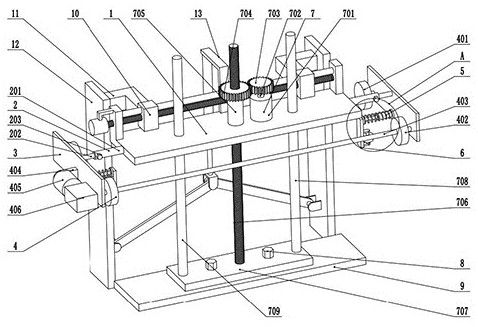

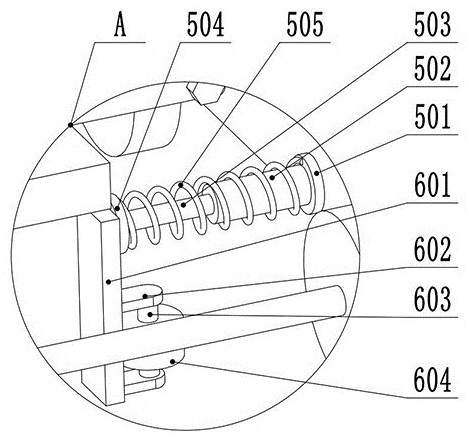

[0027] see Figure 1-8 , an environment-friendly self-adaptive adjustment sludge scraper for sedimentation tanks, comprising a mounting base 1, the side of the mounting base 1 is fixedly connected to a telescopic mechanism 2, two telescopic mechanisms 2 are provided, and the telescopic mechanism 2 is fixedly connected to a side plate 3, Side plate 3 rotates and connects mobile mechanism 4, and side plate 3 inner sides are fixedly connected with limit mechanism 5, and limit mechanism 5 is fixedly connected with limit wheel mechanism 6, and the upper surface of mounting seat 1 is fixedly connected with lifting mechanism 7, and lifting mechanism 7 is provided with a A bolt 8, the first bolt 8 is threaded to connect the bottom mud scraper 9, the upper surface of the mounting seat 1 is fixedly connected to the adjustment mechanism 10, the adjustment mechanism 10 is fixedly connected to two connecting rods 11, and the connecting rod 11 is fixedly connected to the side mud scraper 12,...

Embodiment 2

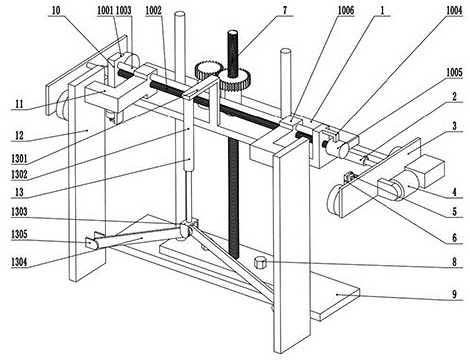

[0035] see Figure 1-8 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the pressing mechanism 13 includes an electric telescopic rod mounting frame 1301, the lower surface of the electric telescopic rod mounting frame 1301 is fixedly connected to the electric telescopic rod 1302, and the electric telescopic rod The lower end of 1302 is fixedly connected to the first rotating seat 1303, and the first rotating seat 1303 is rotatably connected to the pressing rod 1304. There are two pressing rods 1304, and the end of the pressing rod 1304 away from the first rotating seat 1303 is rotatably connected to the second rotating seat 1305 , the second rotating seat 1305 is fixedly connected with the side mud scraper 12 .

[0036] During the implementation of the present invention, the device is first placed on the upper part of the sedimentation tank, then the telescopic mechanism and the telescopic shaft 403 are adjusted to adapt to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com