Adjustable mud-scraping truss for mud scraper

A mud scraper and adjustable technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of inability to adjust up and down tilt, low mud scraping efficiency, low strength, etc., to reduce maintenance costs and improve scraping. The effect of mud efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

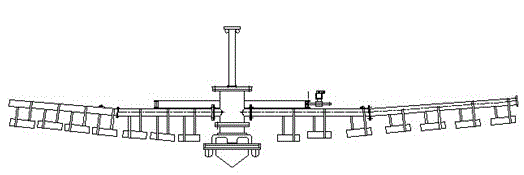

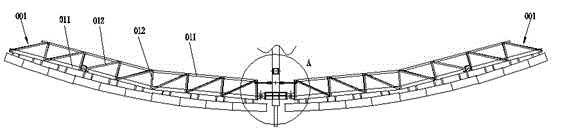

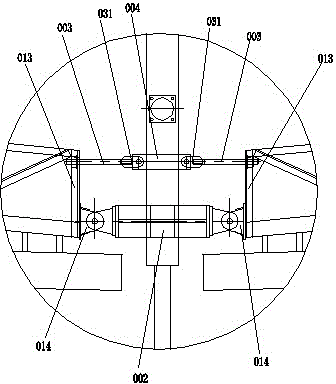

[0015] An adjustable mud scraper truss, the truss is divided into left and right two truss structures 001, the truss 001 is composed of upper and lower section steel 011 arranged in parallel, and connecting angle steel 012 is spliced between the upper and lower section steel 011, and the connecting angle steel 012 is installed obliquely or vertically to form a "Z" or "V" structure. The corresponding ends of the left and right two-section trusses 001 are provided with connecting plates 013, and the upper ends of the connecting plates 013 are provided with bolt holes. , the lower end of the connecting plate 013 is provided with a connecting ear plate 014, and the connecting ear plate 014 is correspondingly hinged with the ear plate support 002 arranged on the transmission shaft of the mud scraper; a U-shaped angle adjustment clip is arranged on the shaft of the mud scraper 004, the adjustment clip is provided with a screw rod 003 with a hole, one end of the screw rod 003 is scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com