Patents

Literature

286results about "Sedimentation device making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

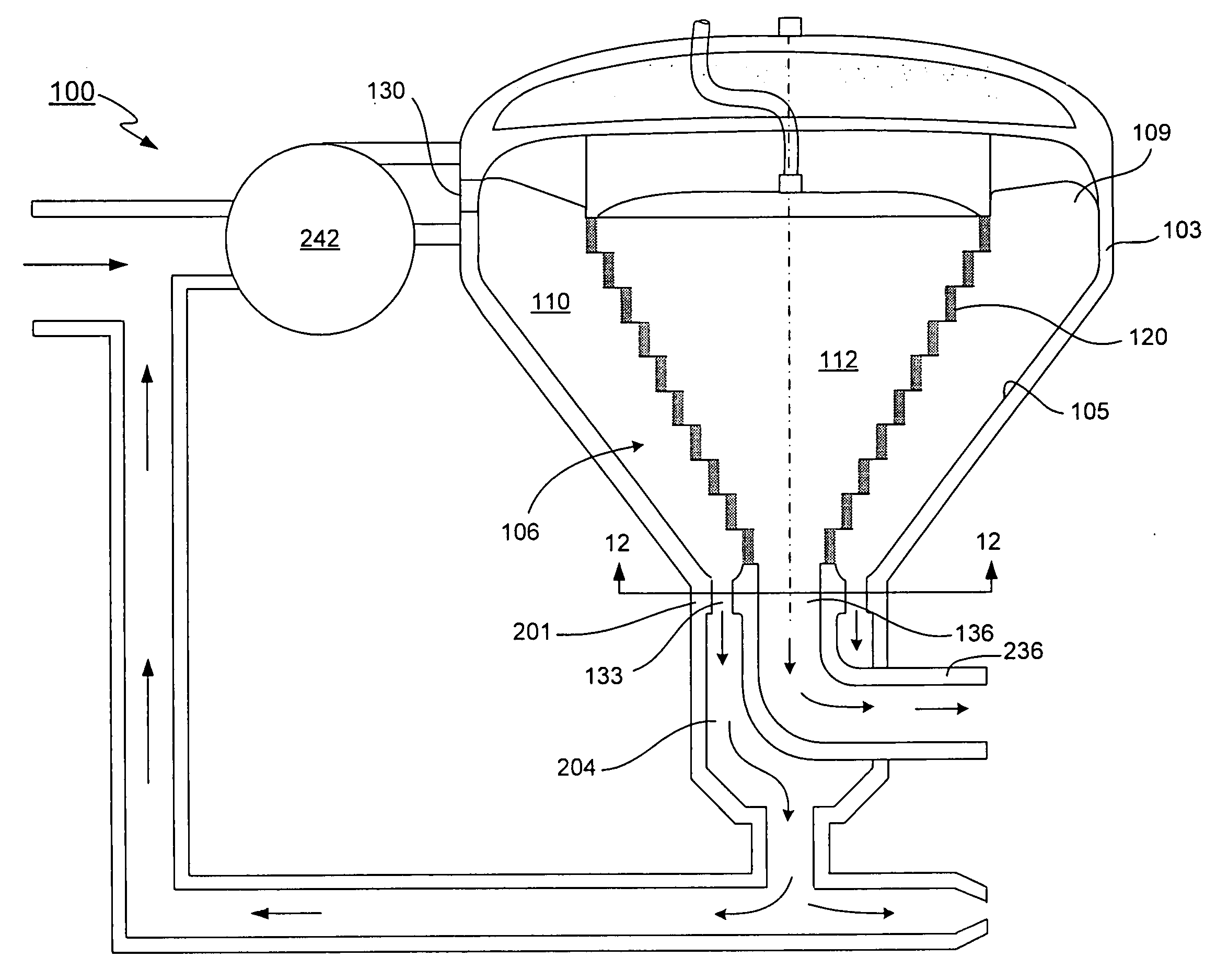

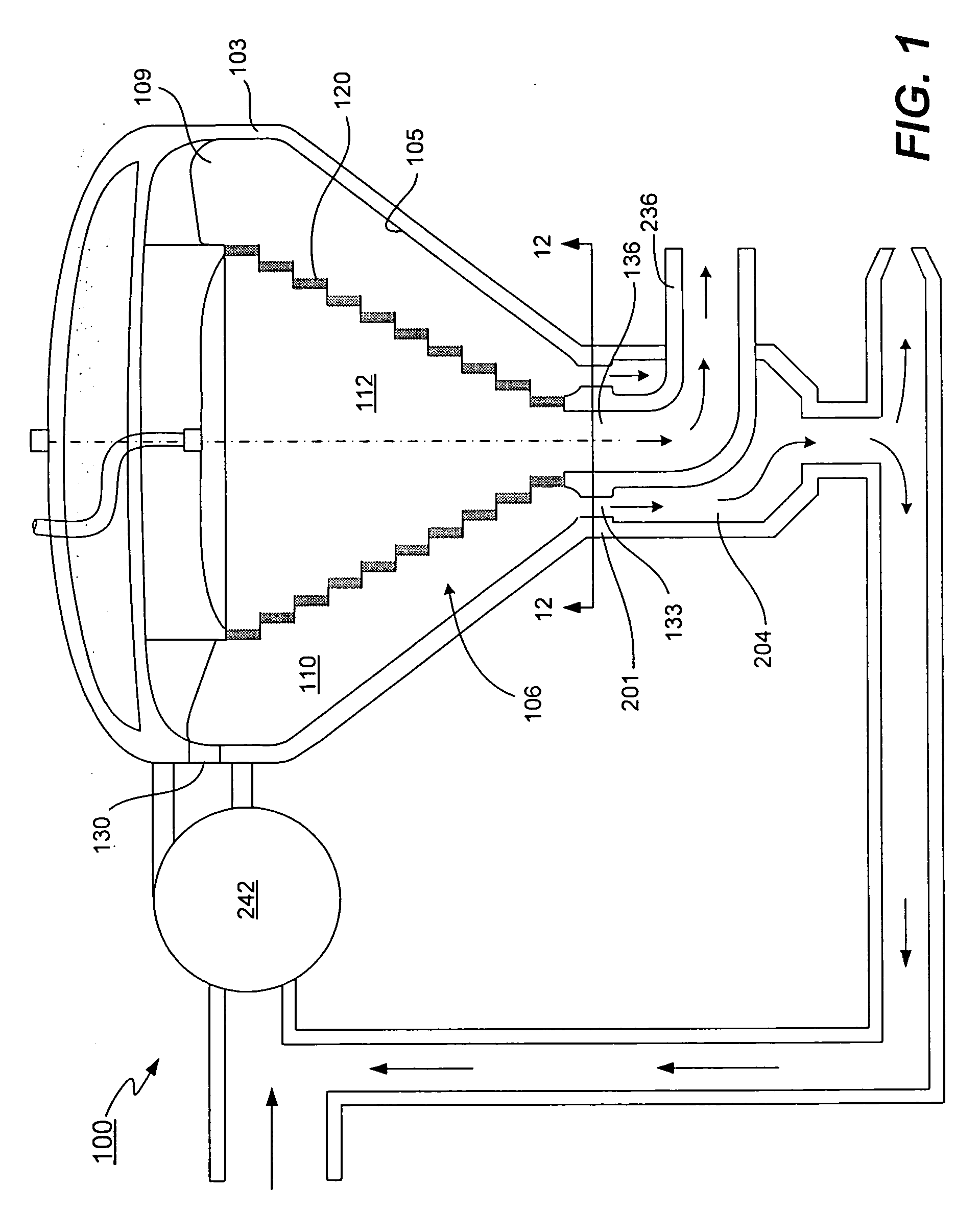

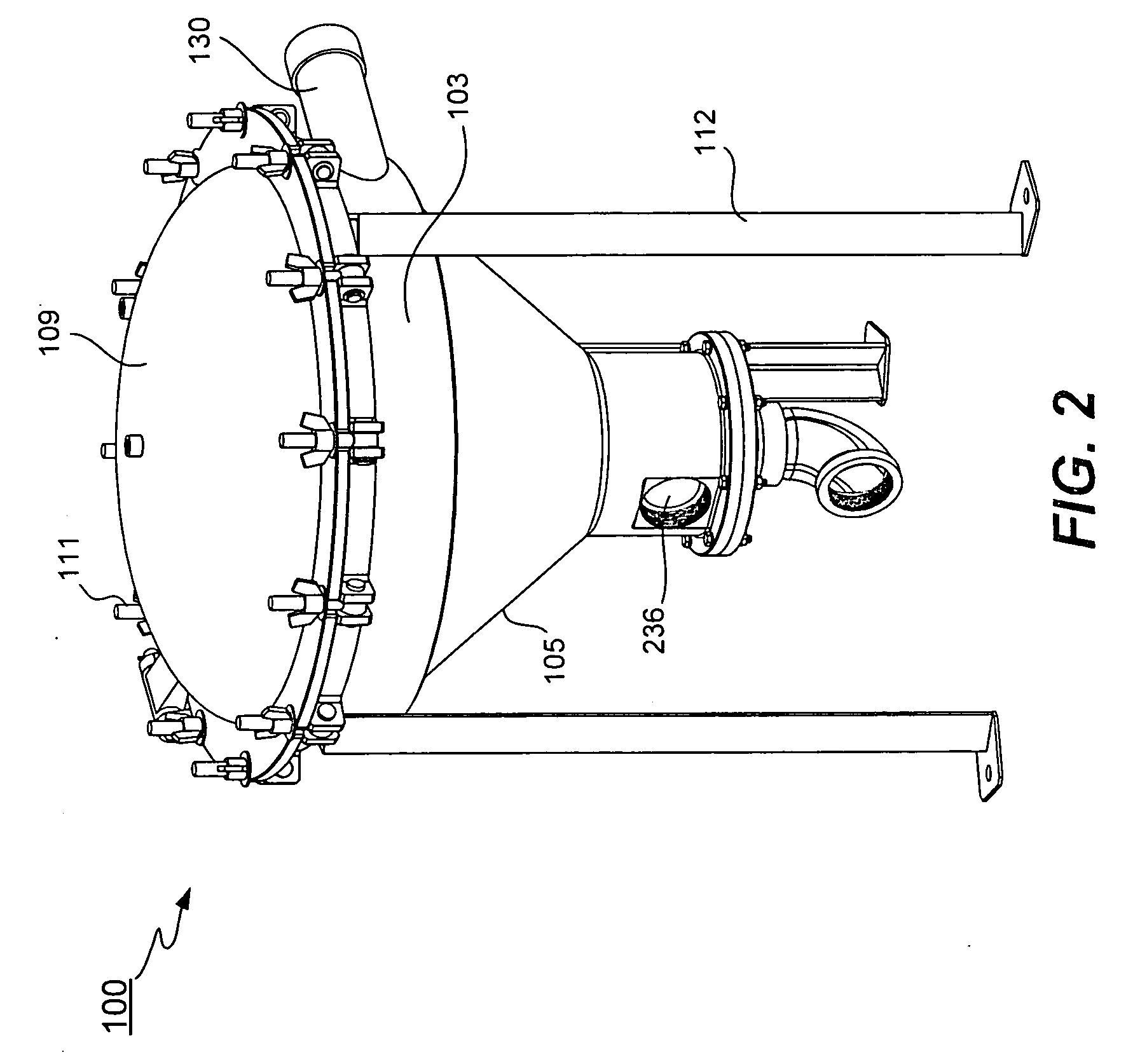

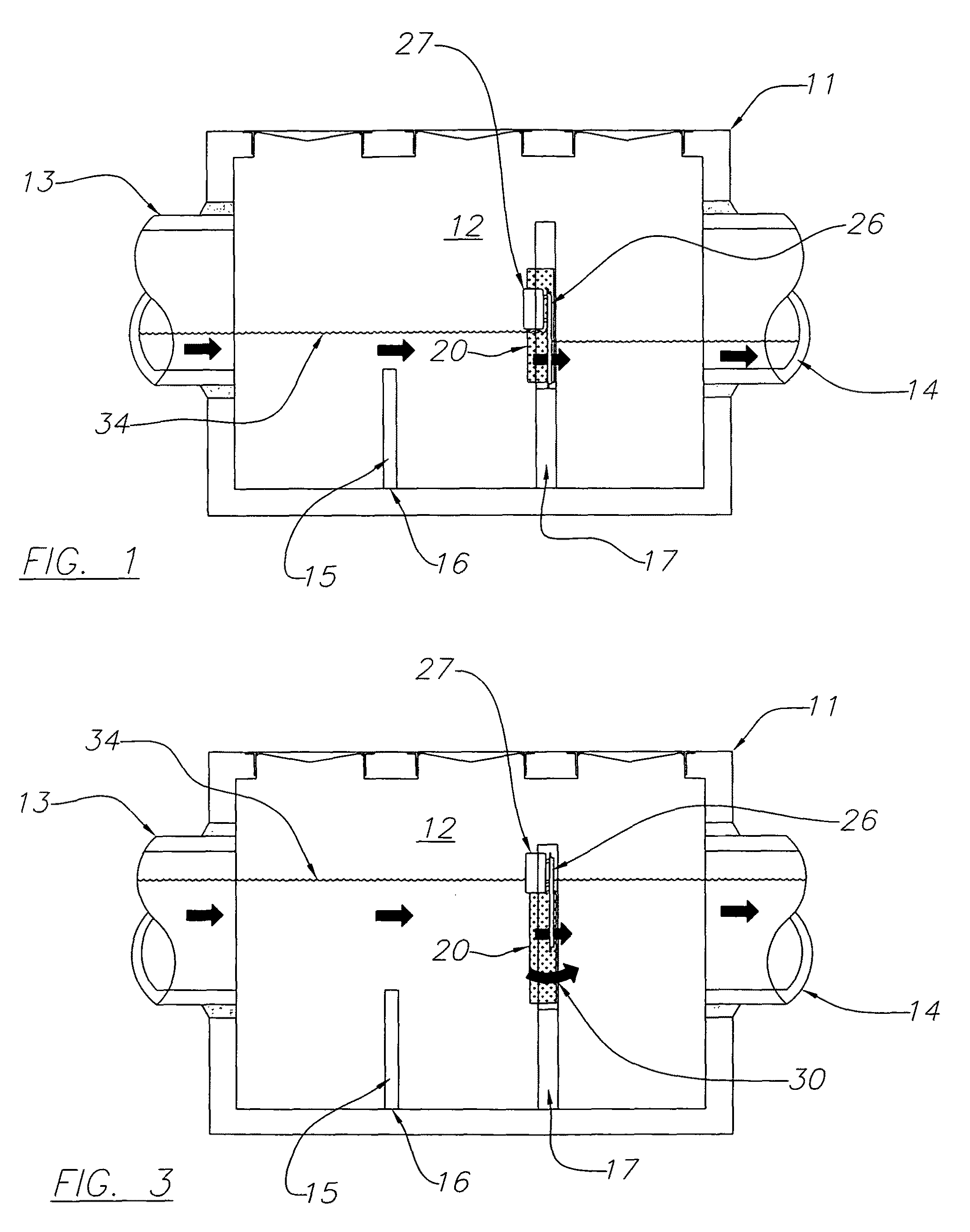

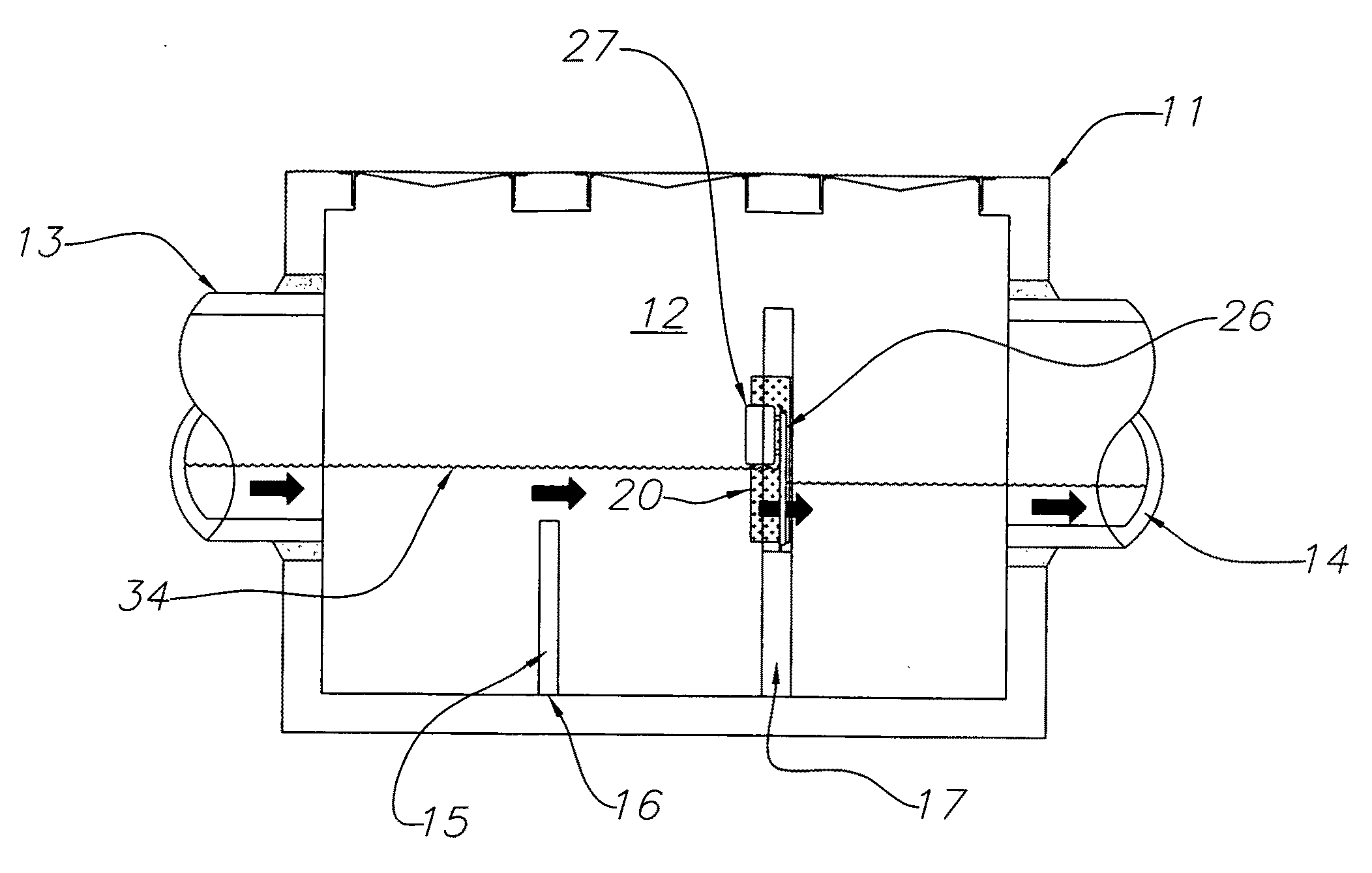

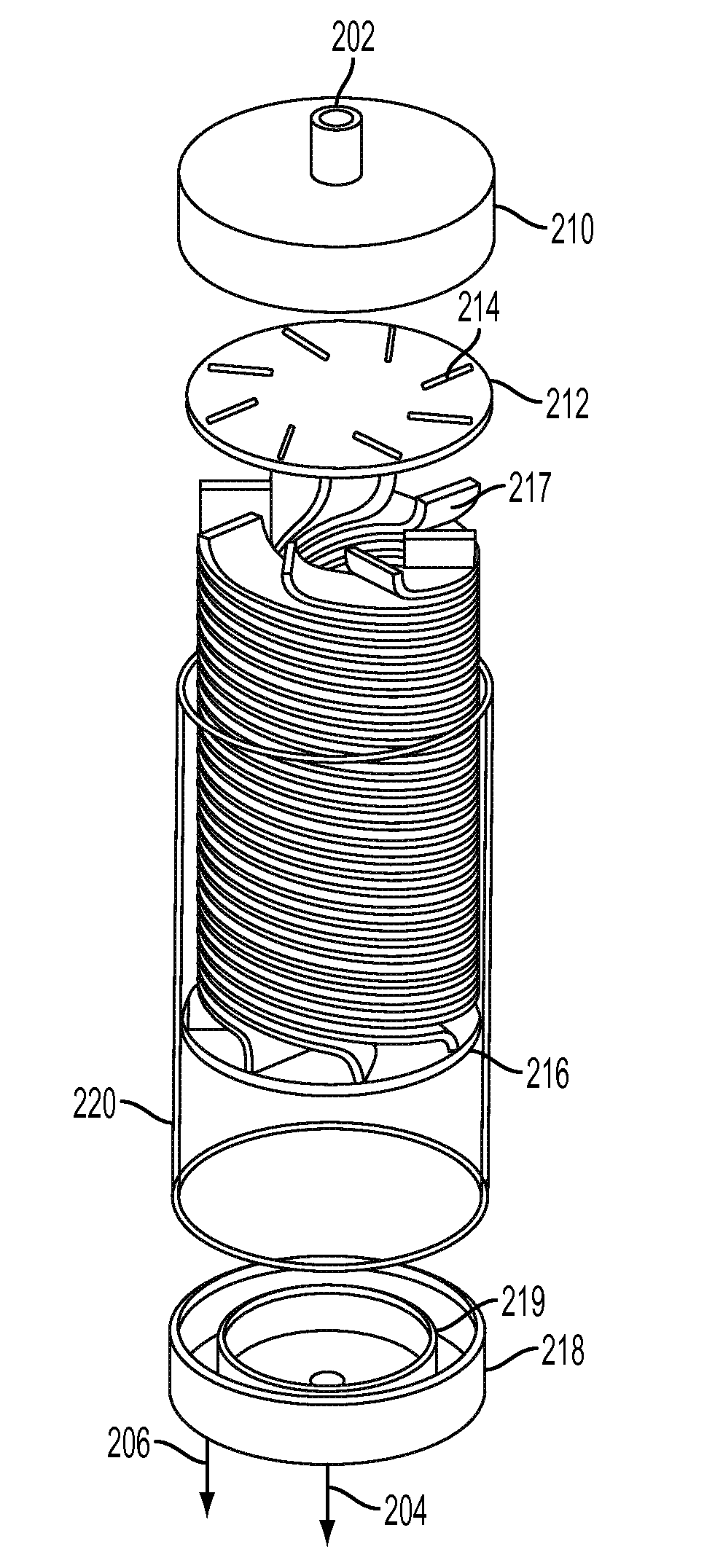

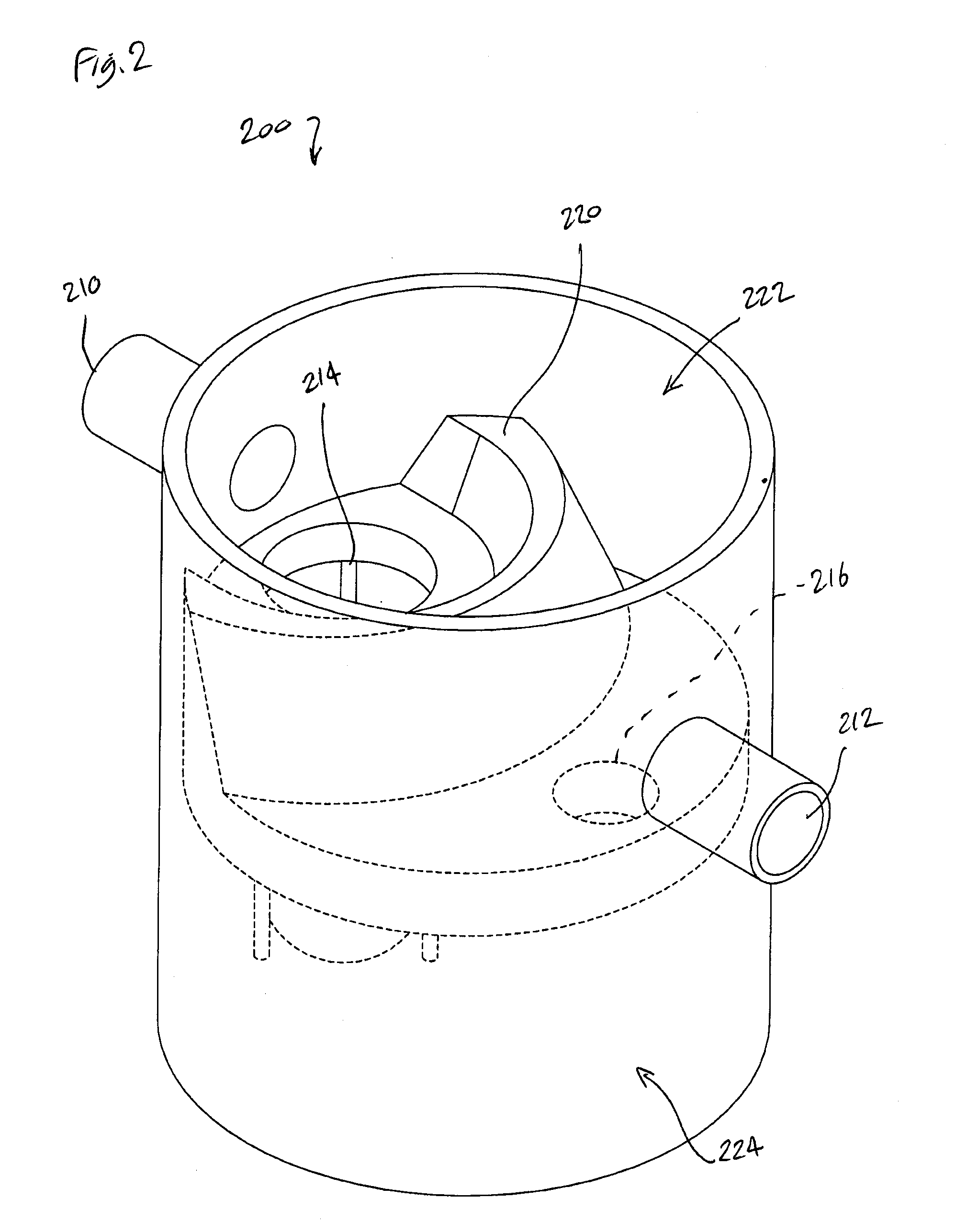

Hydroclone based fluid filtration system

ActiveUS20070039900A1Reduce morbiditySmall diameterLiquid separation auxillary apparatusReversed direction vortexCross-flow filtrationFluid filtration

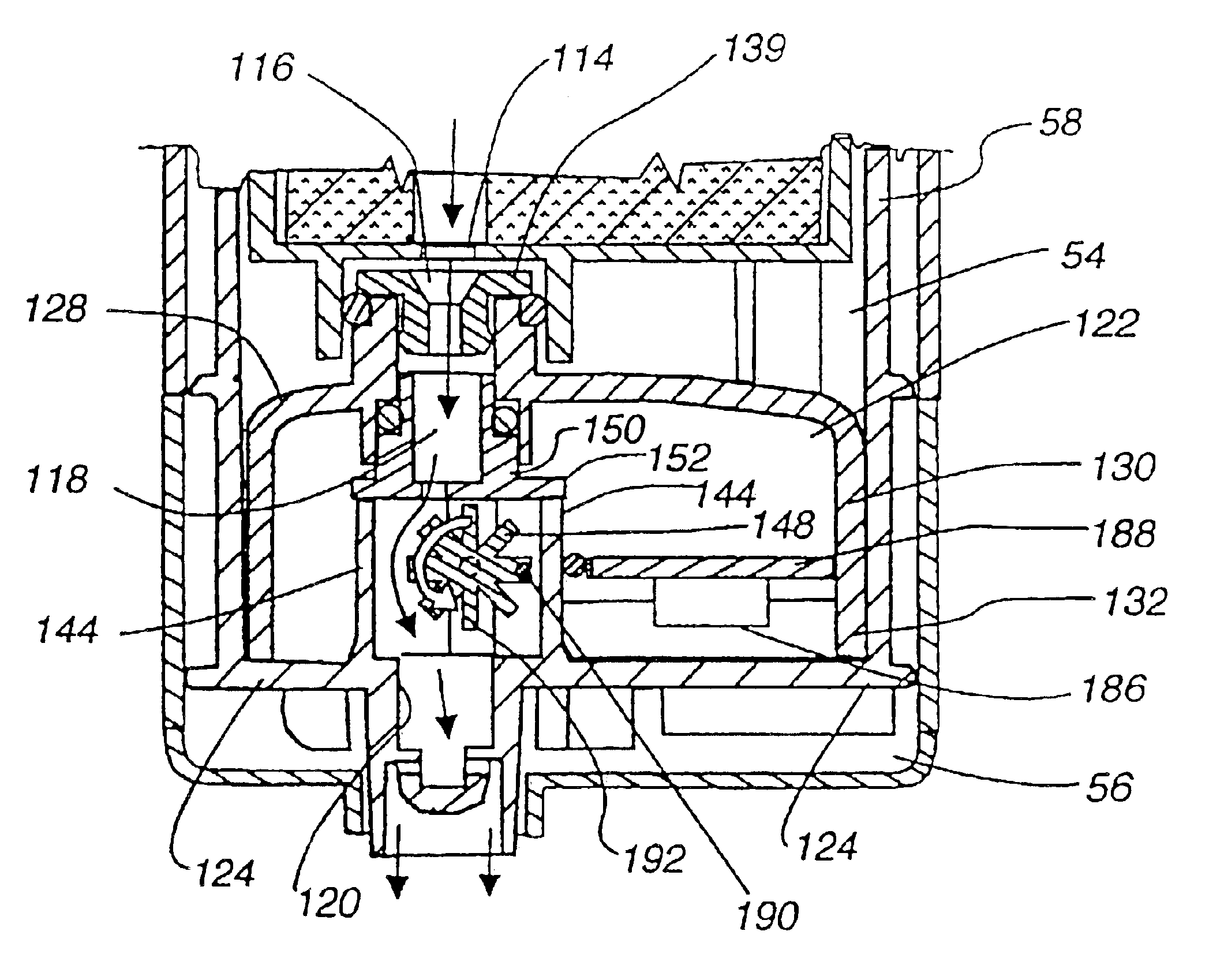

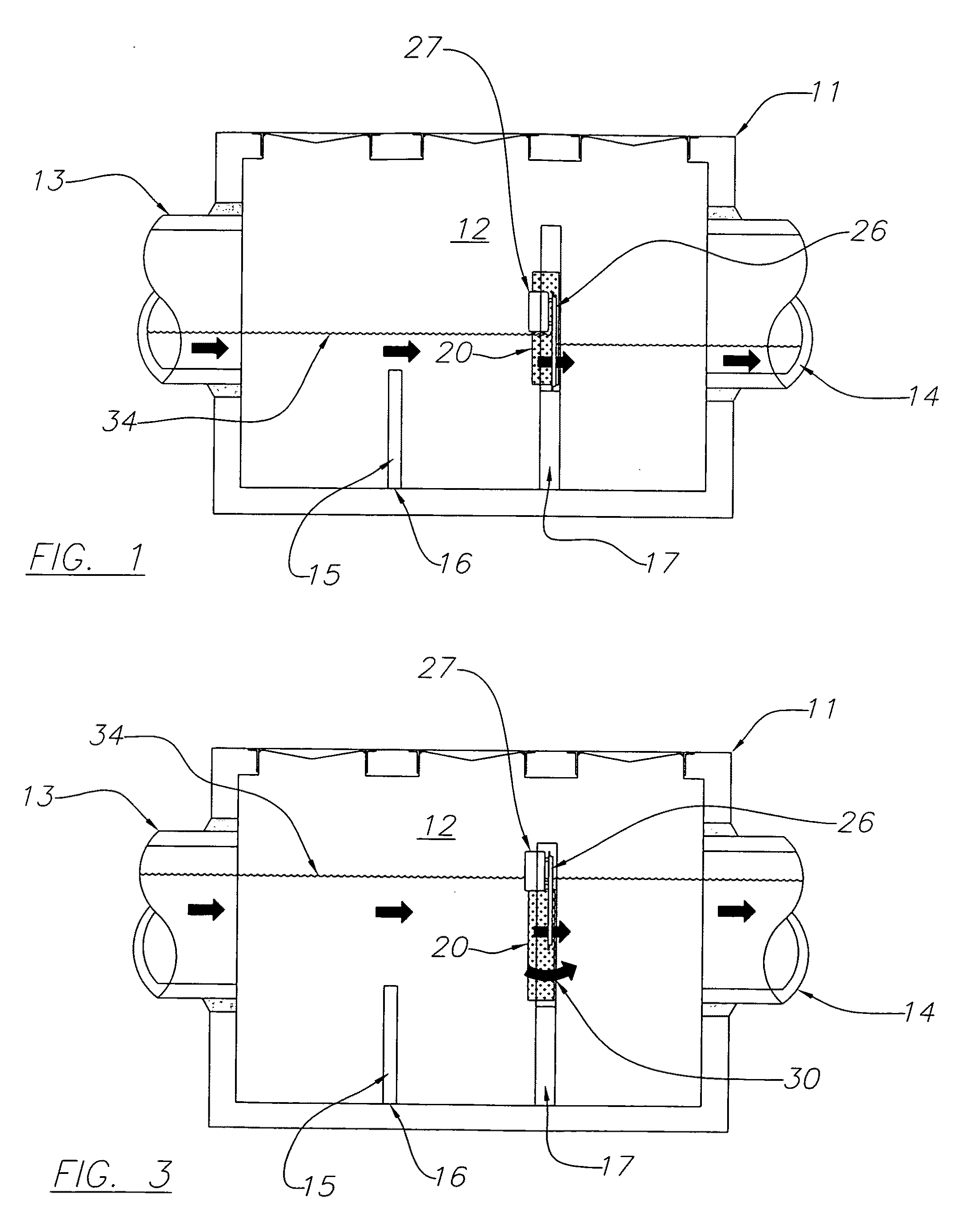

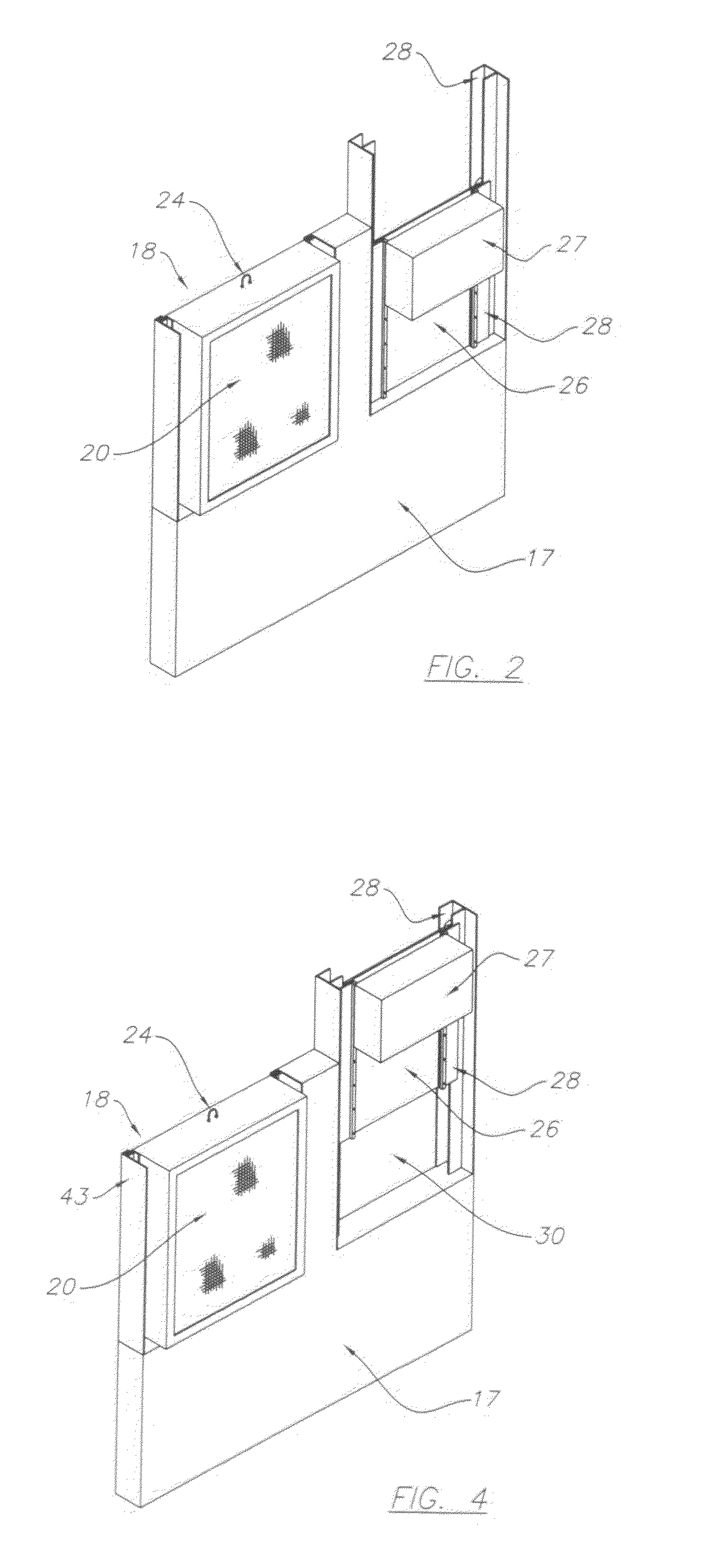

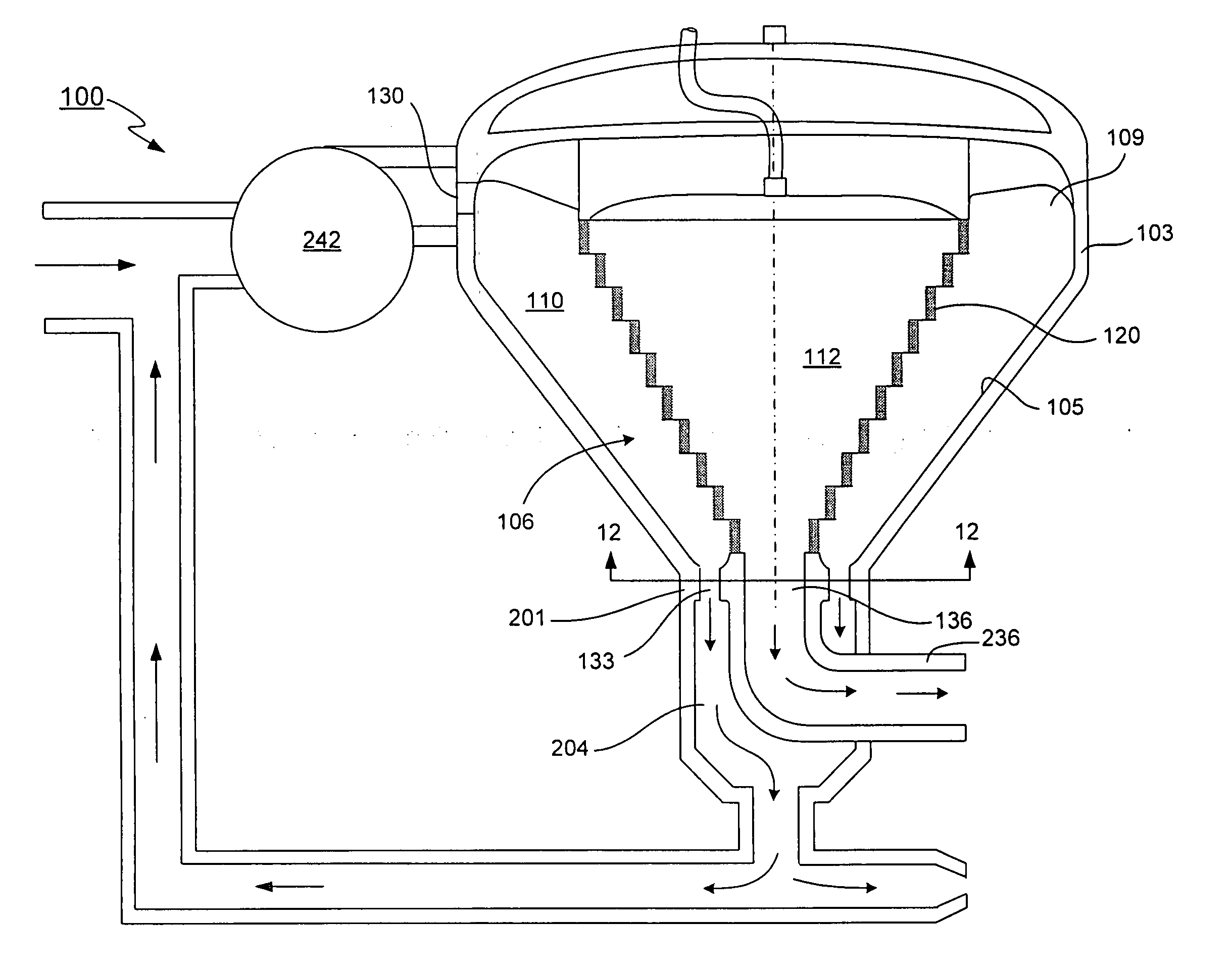

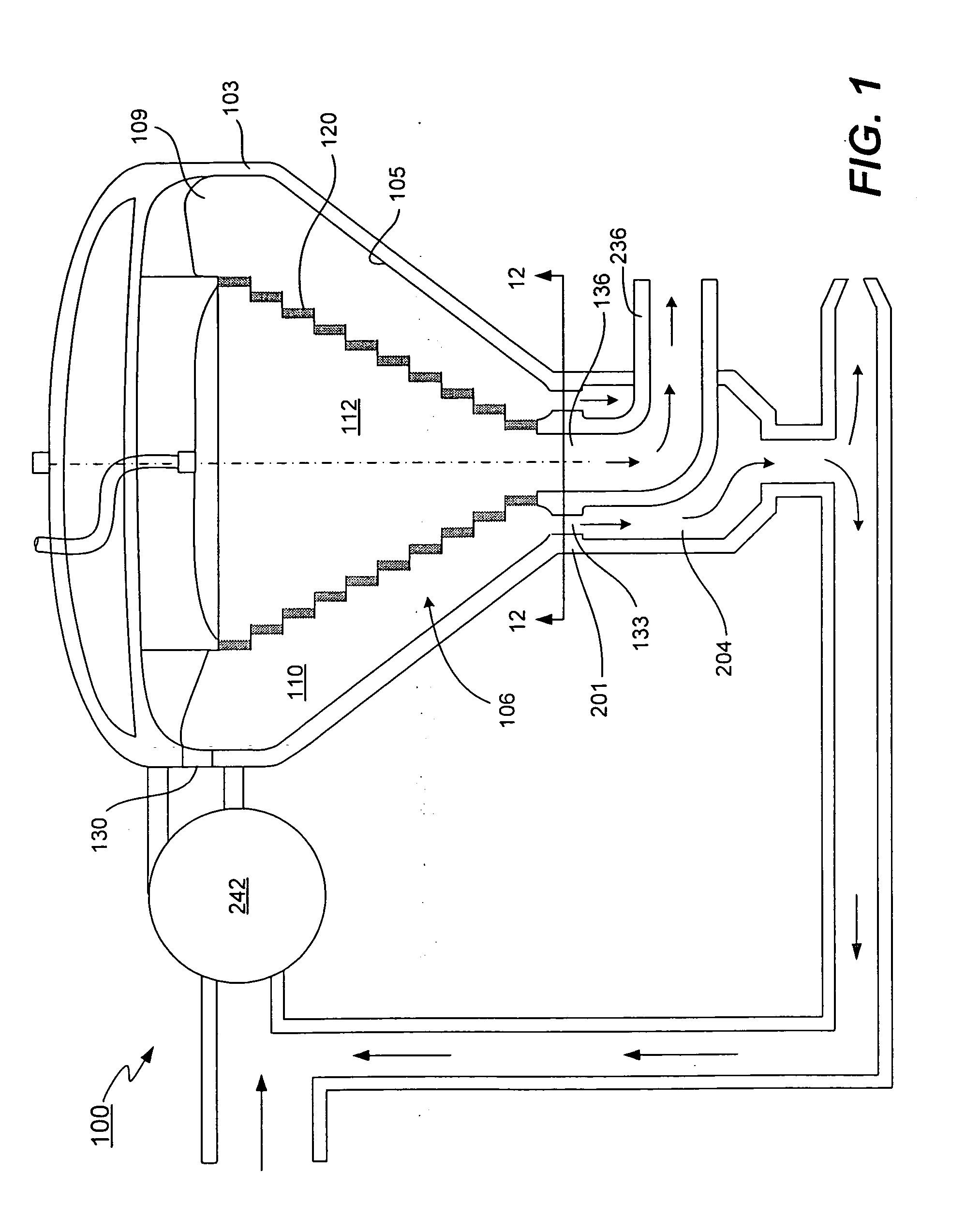

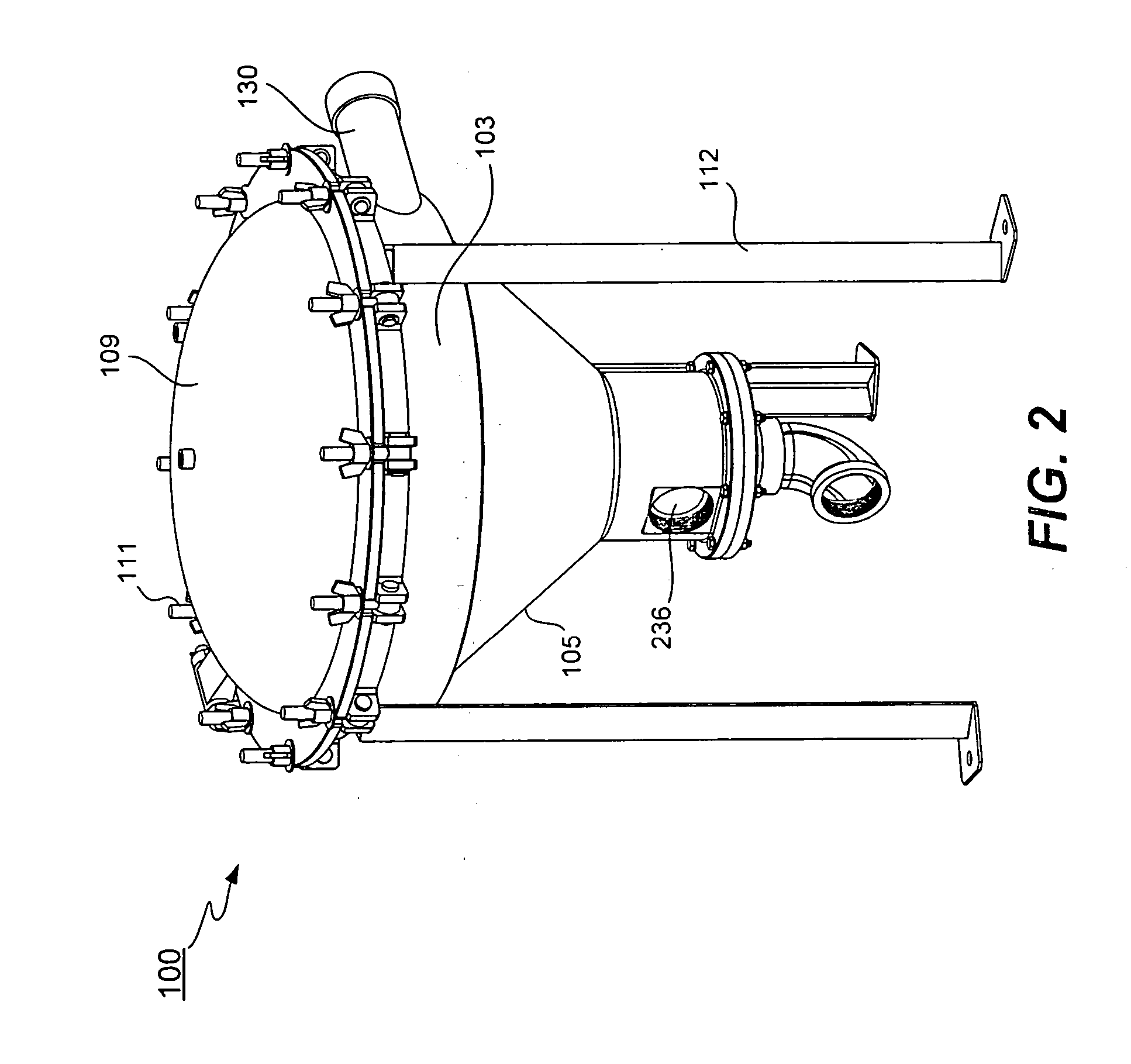

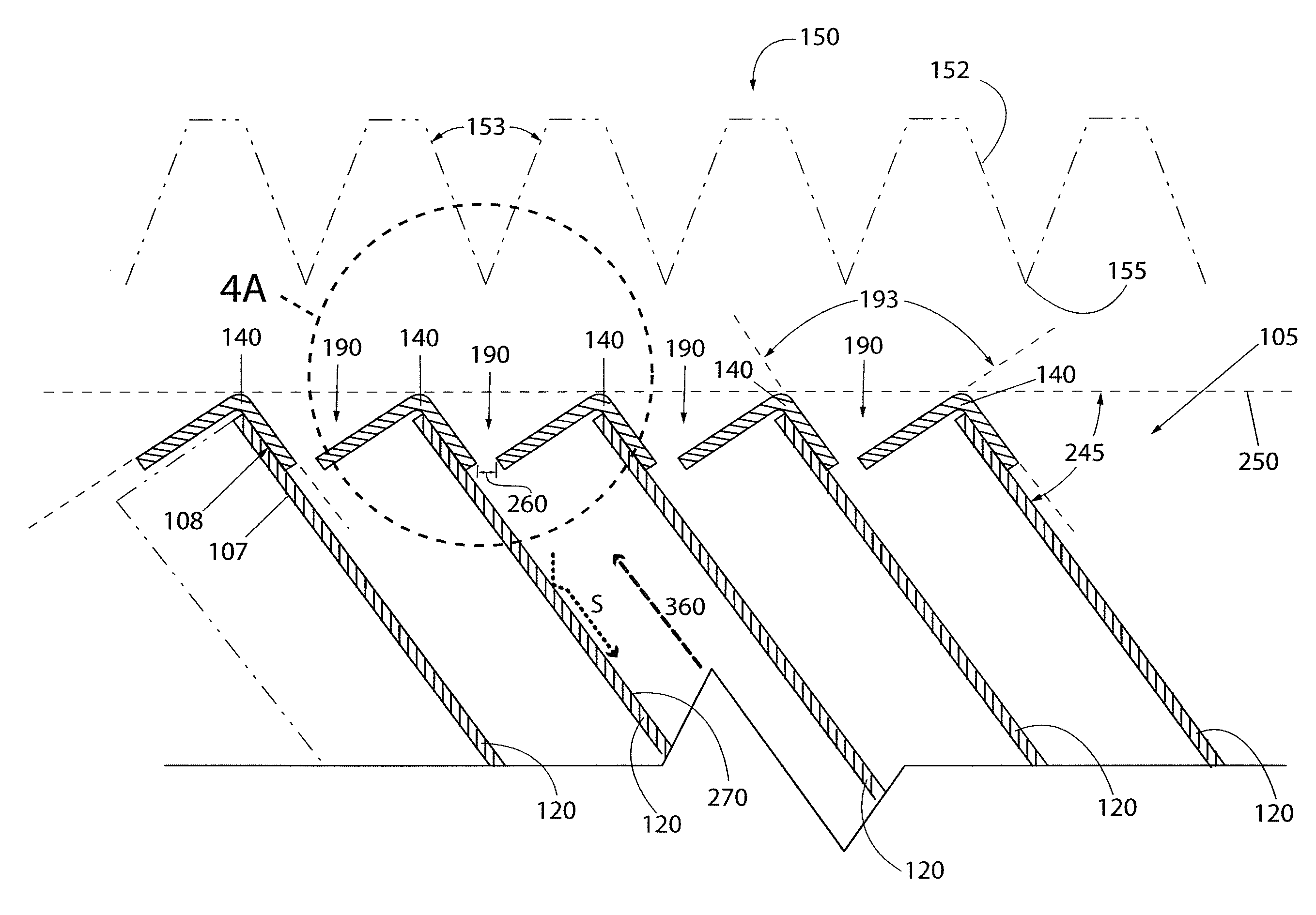

A variety of improved hydroclone based fluid filtering systems are described. The hydroclones generally include a tank having an internal chamber and a filter (preferably a surface filter) that is positioned within the internal chamber. The filter defines a filtered fluid chamber within the internal chamber of the tank. The hydroclone may be operated such that a vortex of flowing fluid is formed between the chamber wall and the filter with the filter being located in the center of the vortex. With this arrangement, the filter acts as a cross-flow filter. In one aspect of the invention, the filter is a stepped filter. In another aspect of the invention, the filter is an surface filter, as for example, an electroformed metal surface filter. In some preferred embodiments, the openings in the filter are arranged as slots that extend substantially vertically so that they are oriented substantially perpendicular to the flow path of fluid flowing in the adjacent portion of the vortex. In another aspect of the invention, a circulating cleaning assembly is provided in the hydroclone region. The cleaning assembly is arranged to help clean the filter and is driven by the vortex of flowing fluid formed in the hydroclone region of the internal chamber. In yet another aspect of the invention, improved hydroclone intake structures are described. The described hydroclones may be used to filter water and other fluids in a wide variety of applications.

Owner:ACCELERATED FILTRATION INC

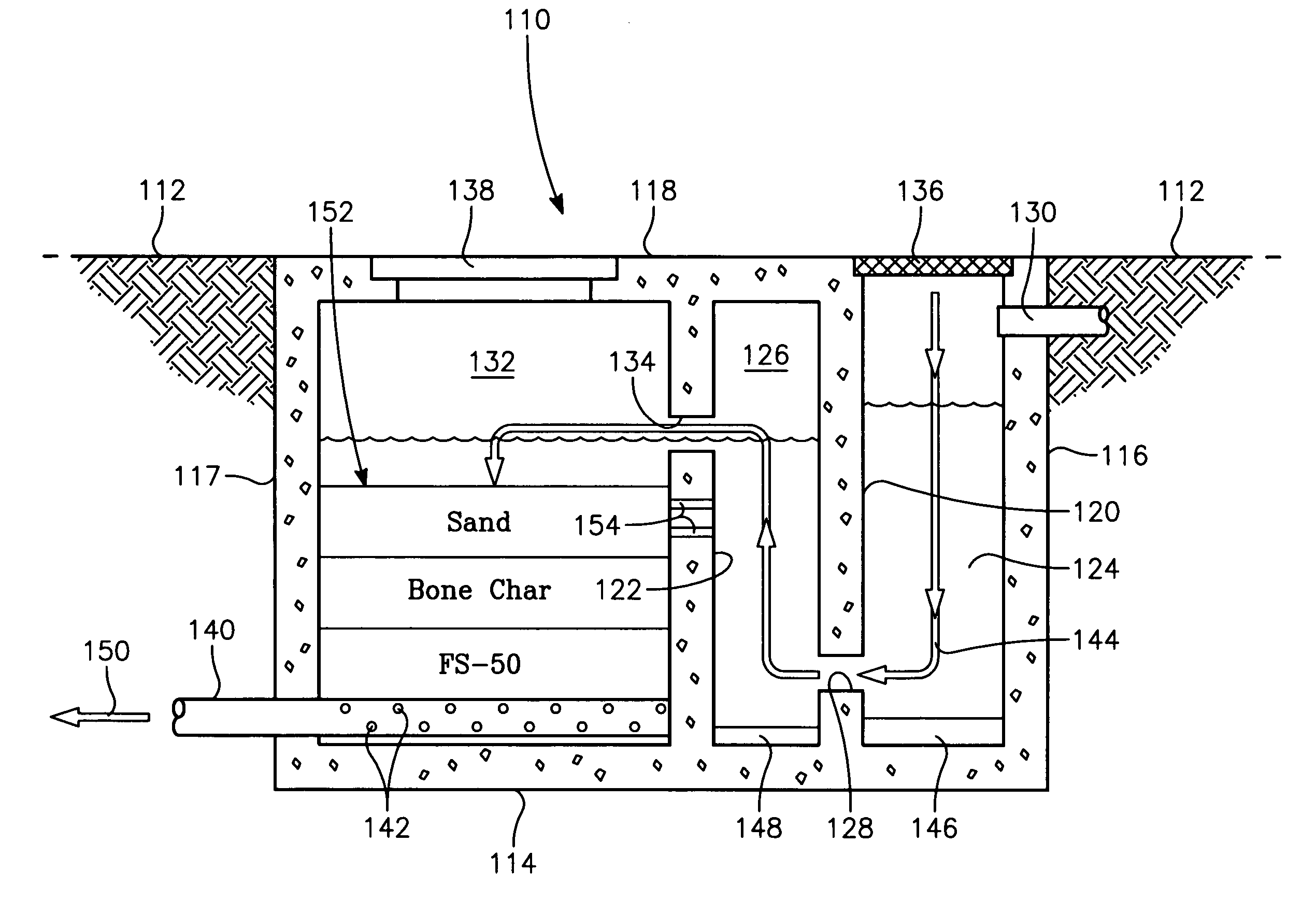

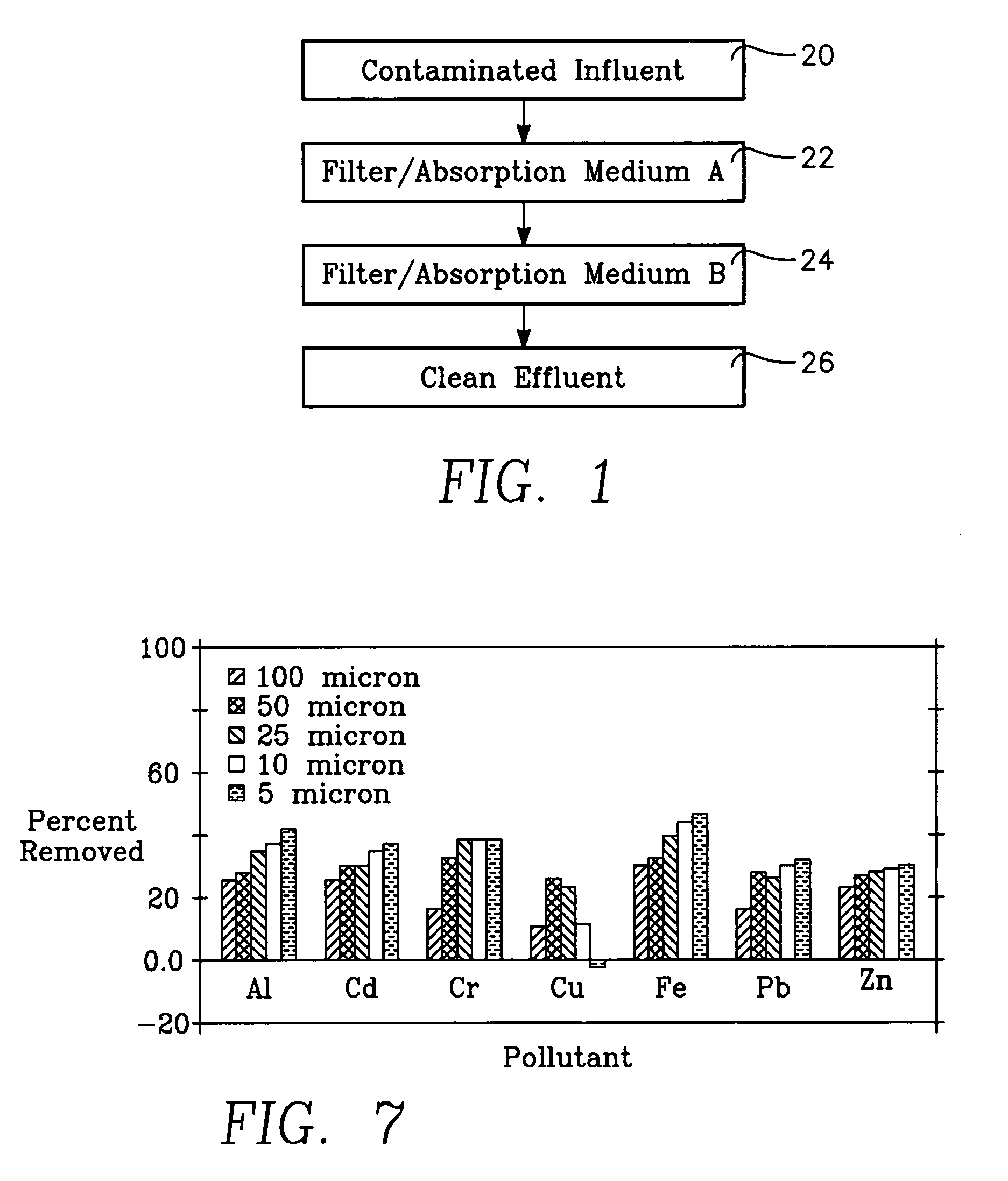

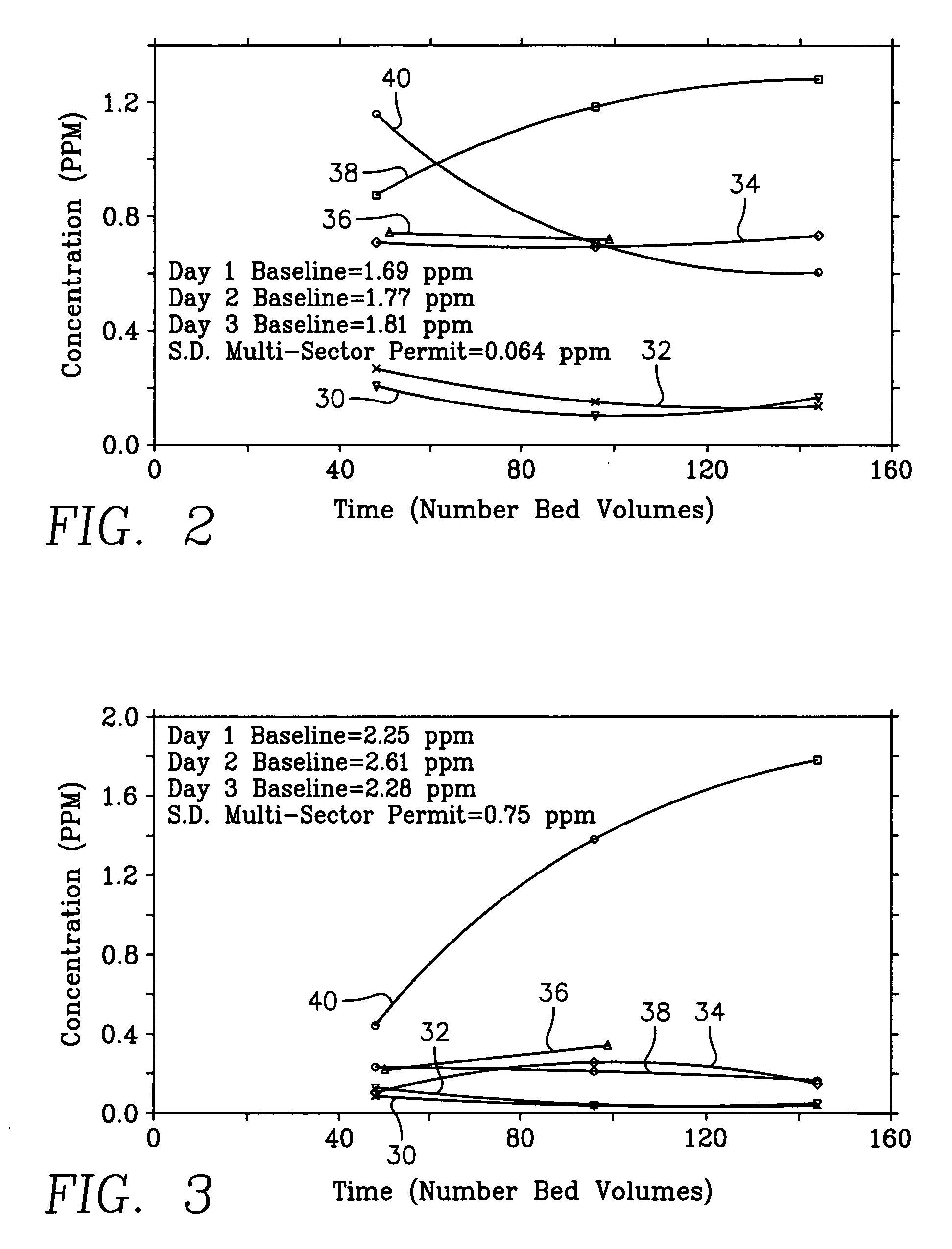

Materials for removing toxic metals from wastewater

ActiveUS7160465B2Simple designTreatment involving filtrationEnergy based wastewater treatmentWastewaterAbsorbent material

A treatment facility for removing toxic metals from storm water runoff to provide clean water. The treatment facility includes a pretreatment chamber for removing large toxic particles from the storm water runoff and absorbent chamber for removing fine particles of toxic metals from the storm water runoff. The absorption chamber has an absorption bed of three absorptive materials for removing the fine particles of toxic metals from the storm water runoff.

Owner:NAVY UNITED STATES OF AMERICA AS REPRESTENTED BY THE SEC OF THE

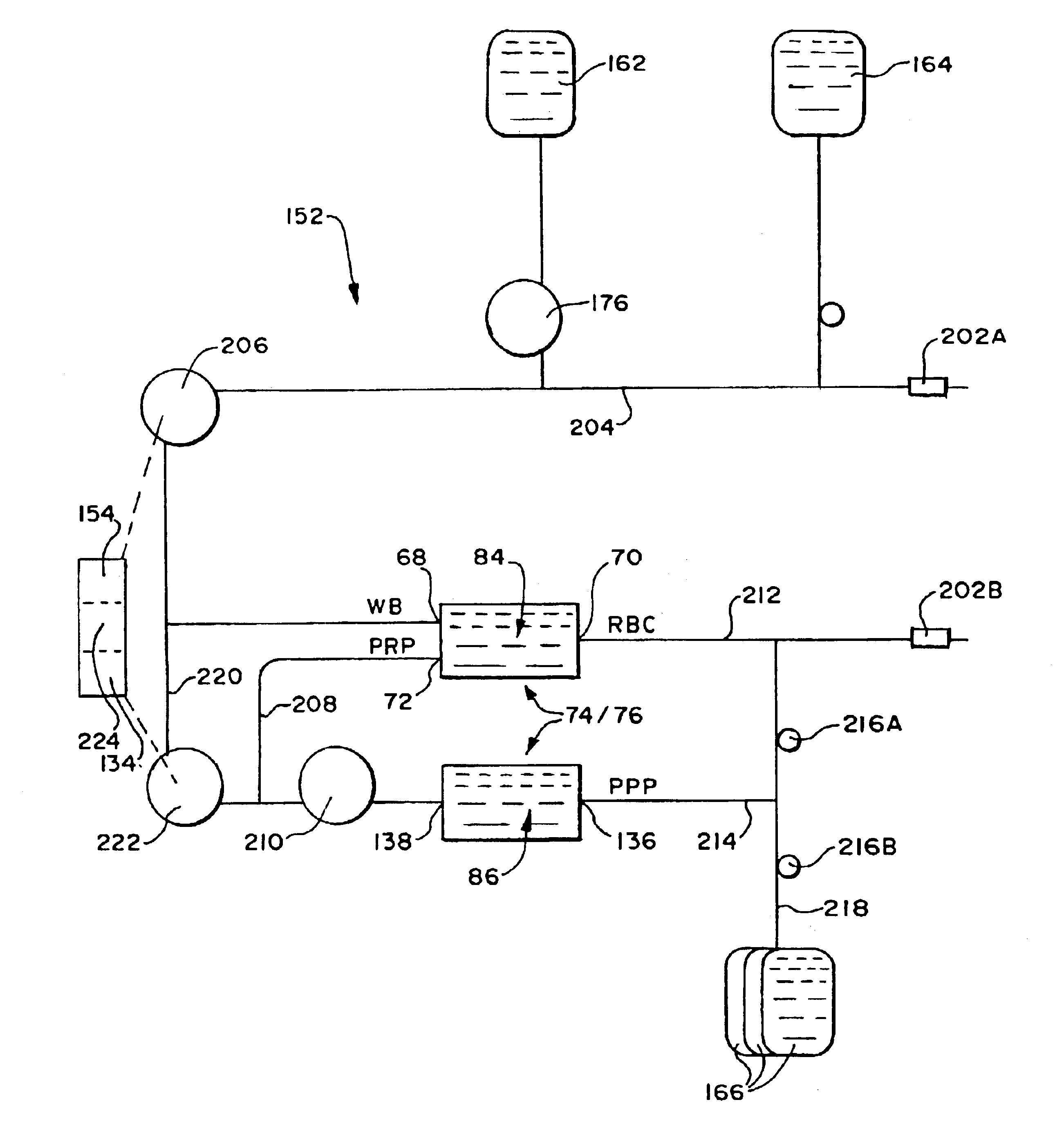

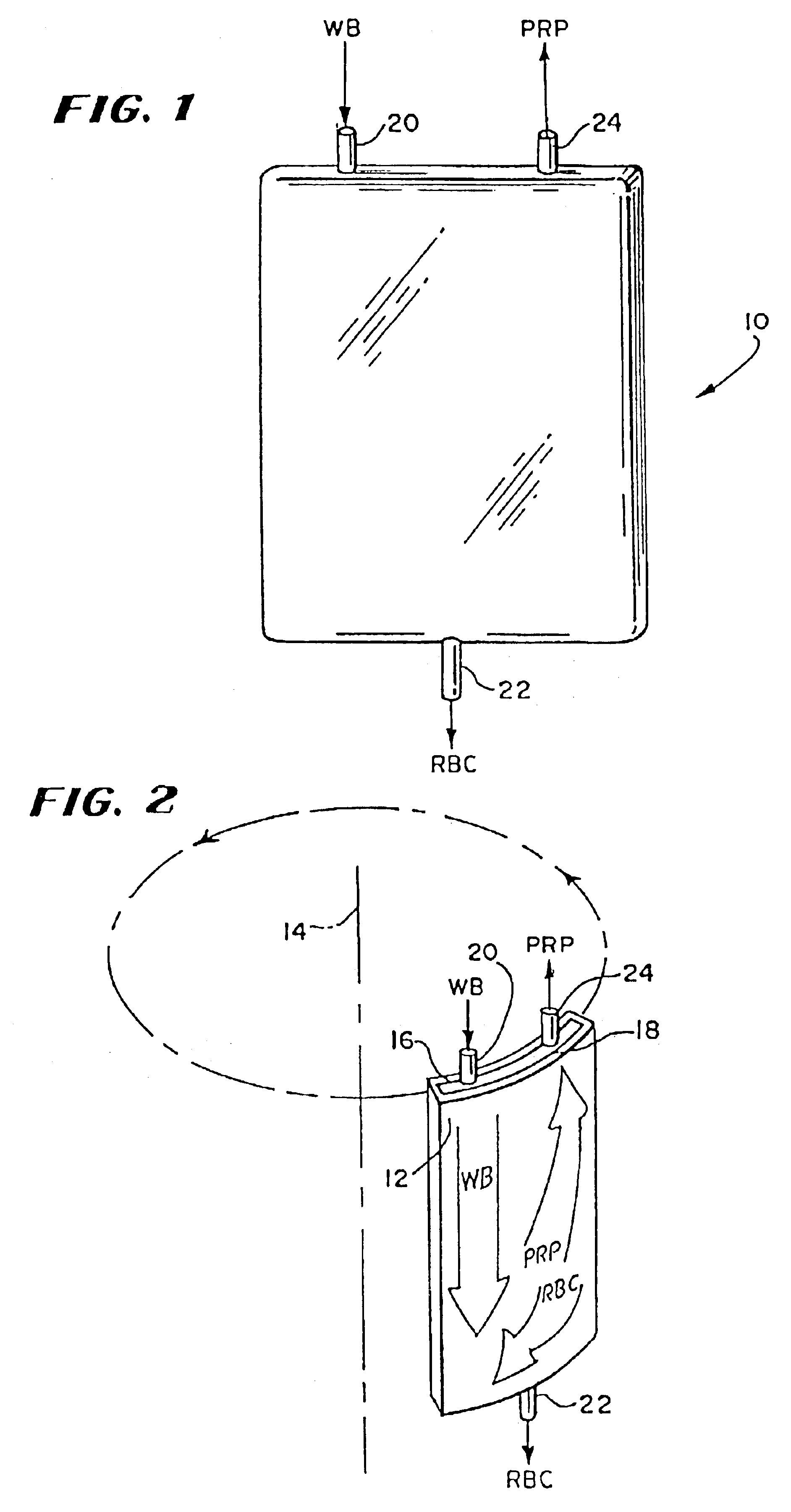

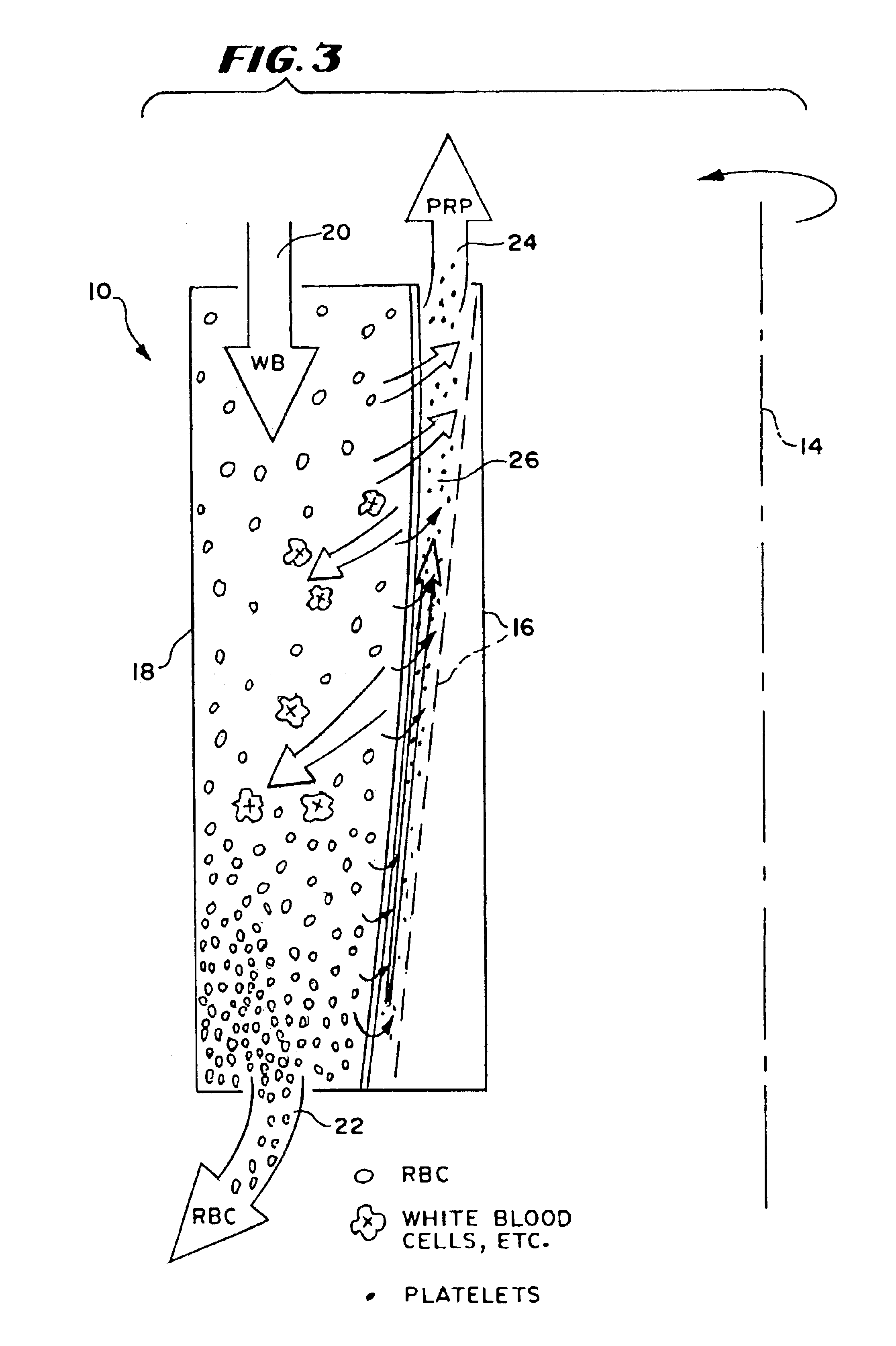

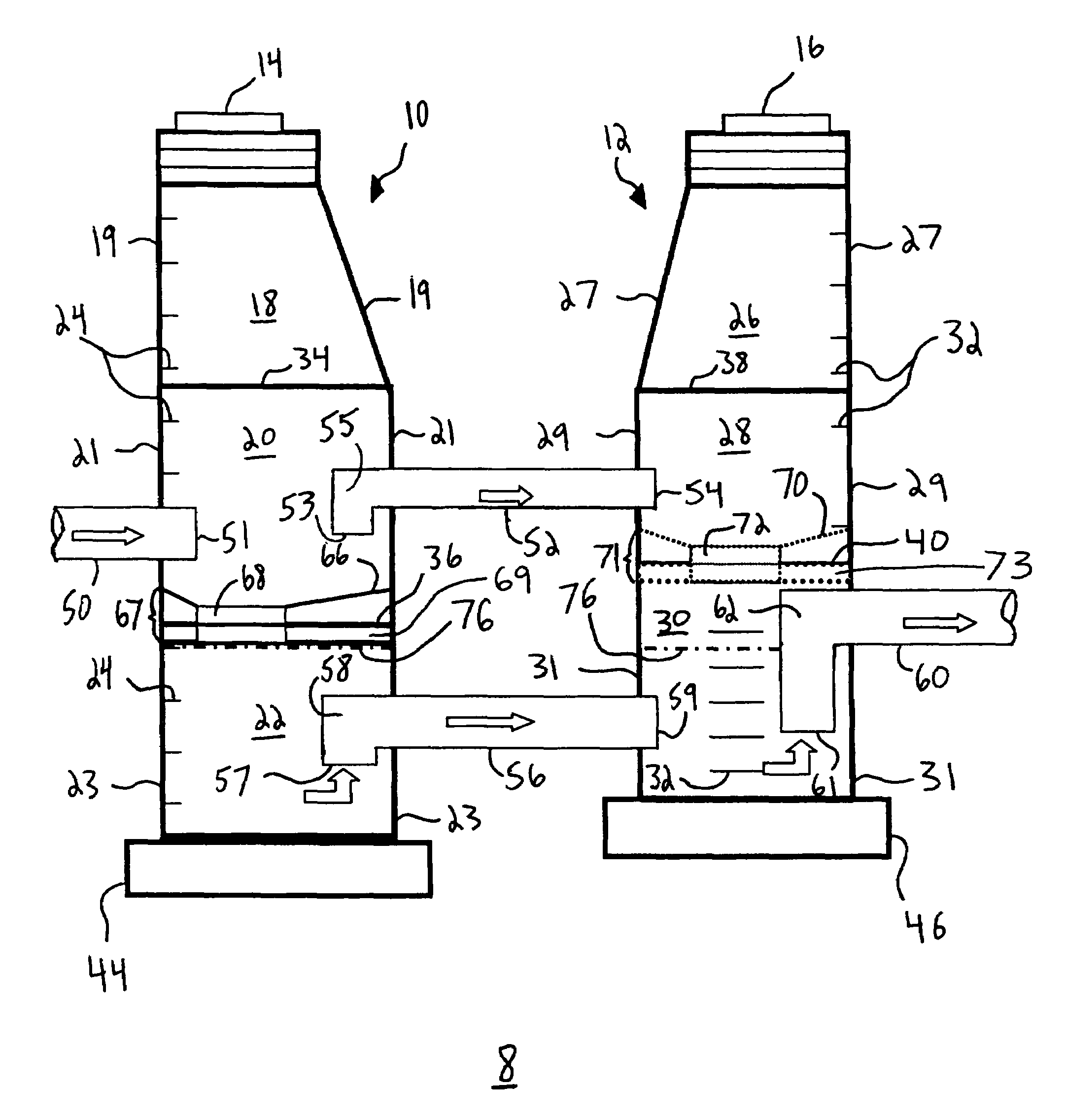

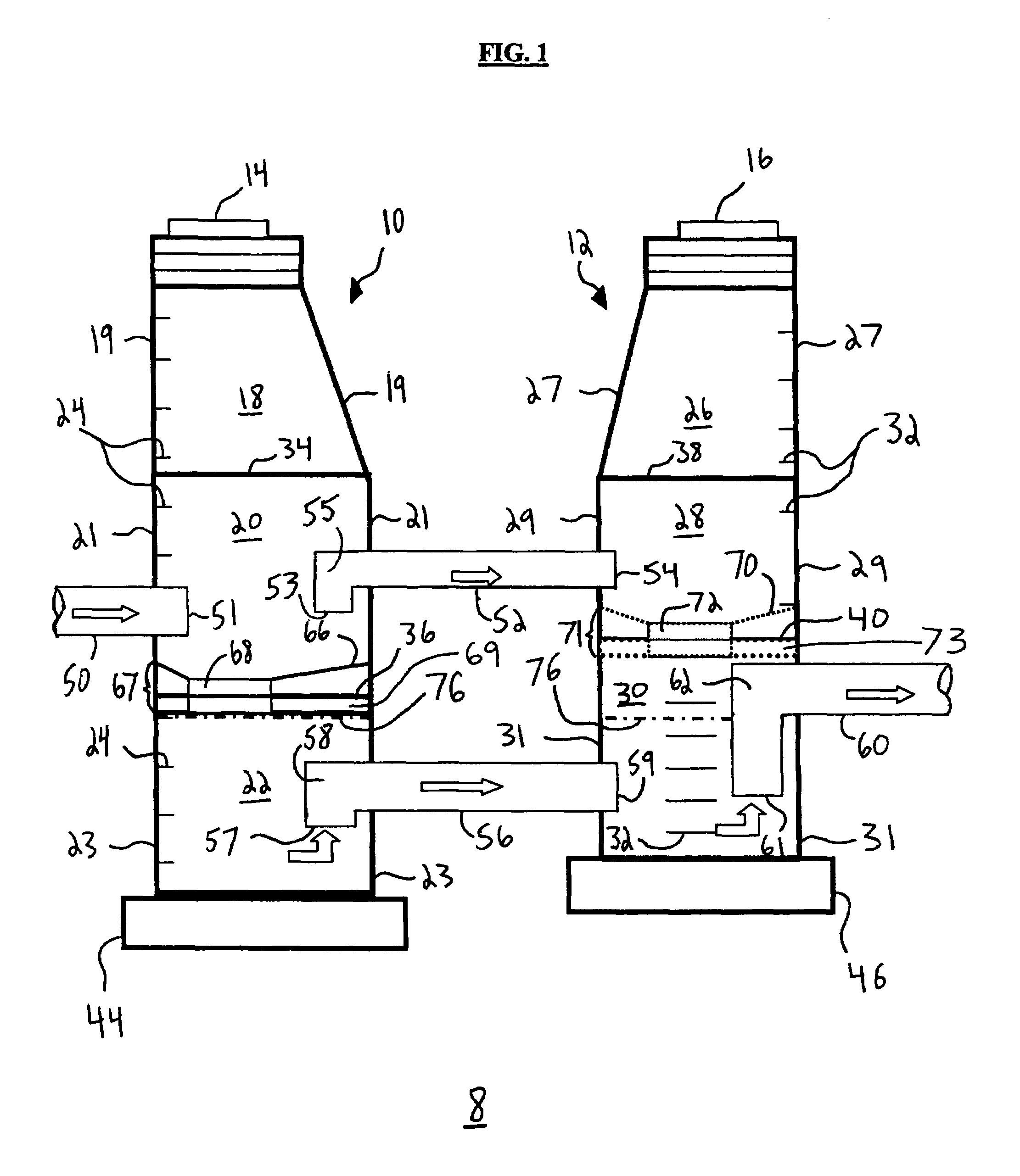

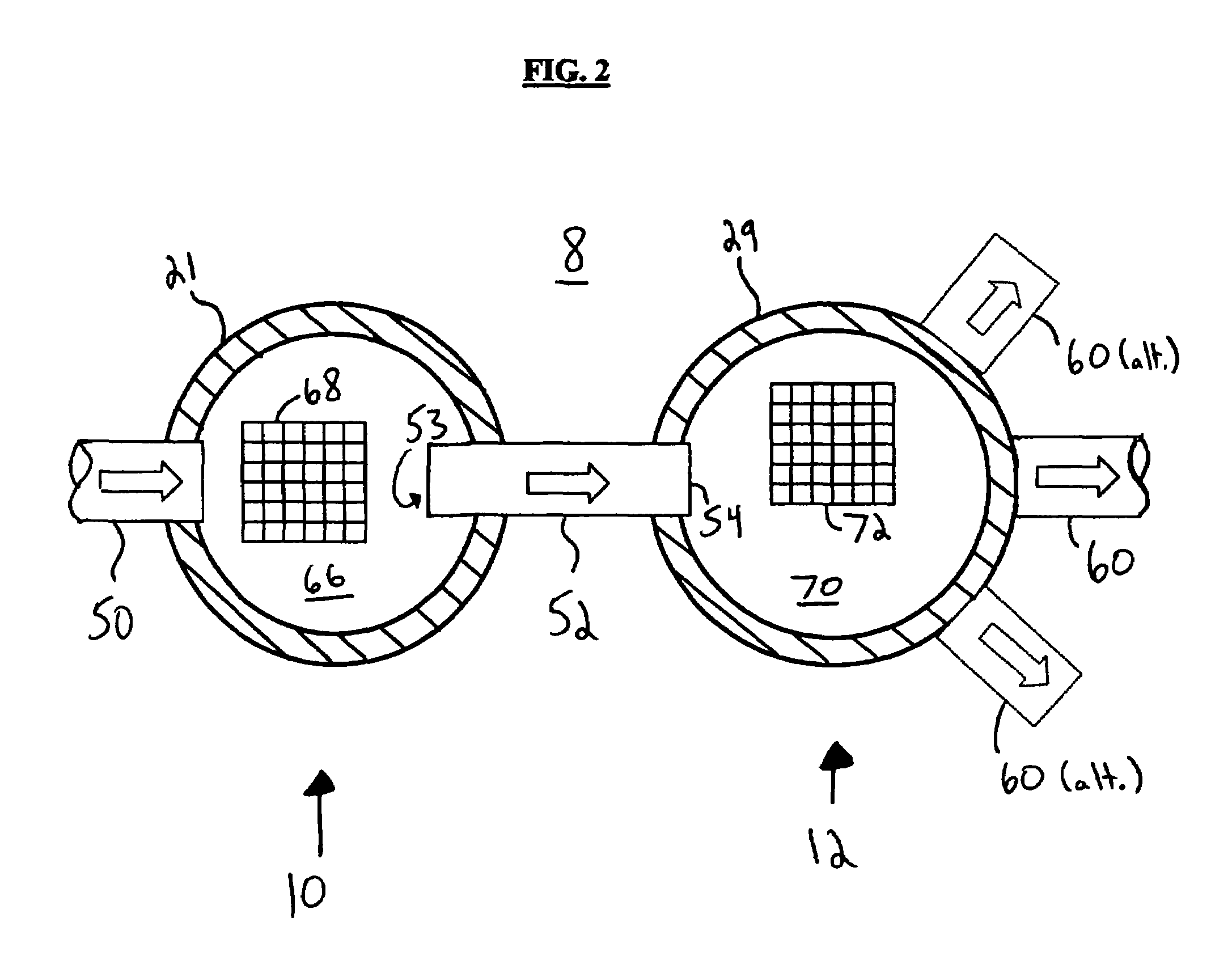

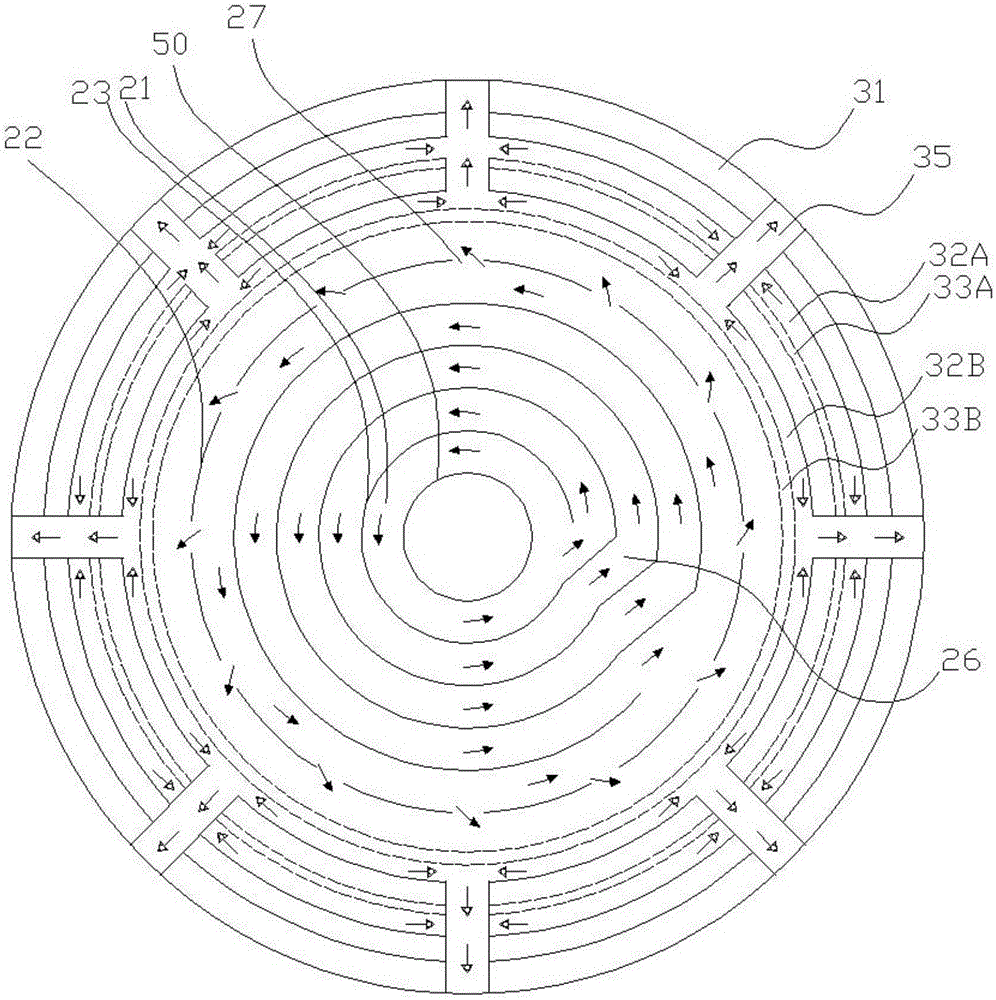

Blood processing systems and methods

InactiveUS6899666B2Easy to handleLiquid separation auxillary apparatusOther blood circulation devicesRotational axisMedicine

Systems and methods centrifugally separate whole blood into red blood cells, plasma, and a platelet concentrate. The systems and methods rotate a first rotating separation zone about a rotational axis, to separate whole blood into red blood cells and plasma constituent carrying platelets. Red blood cells separated are directed in a first circumferential flow direction toward a terminal wall, where blood flow is halted. Surface hematocrit is successively increased in the first circumferential flow direction by separating the plasma constituent from the red blood cells. Separated red blood cells are directed from the first rotating separation zone through a path where the surface hematocrit is the most. Plasma constituent separated is directed in a second circumferential flow direction opposite to the first circumferential flow direction toward a different region in the first rotating separation zone, where the surface hematocrit is the least. The systems and methods separate the plasma constituent into platelet concentrate and plasma in a second rotating separation zone.

Owner:FENWAL

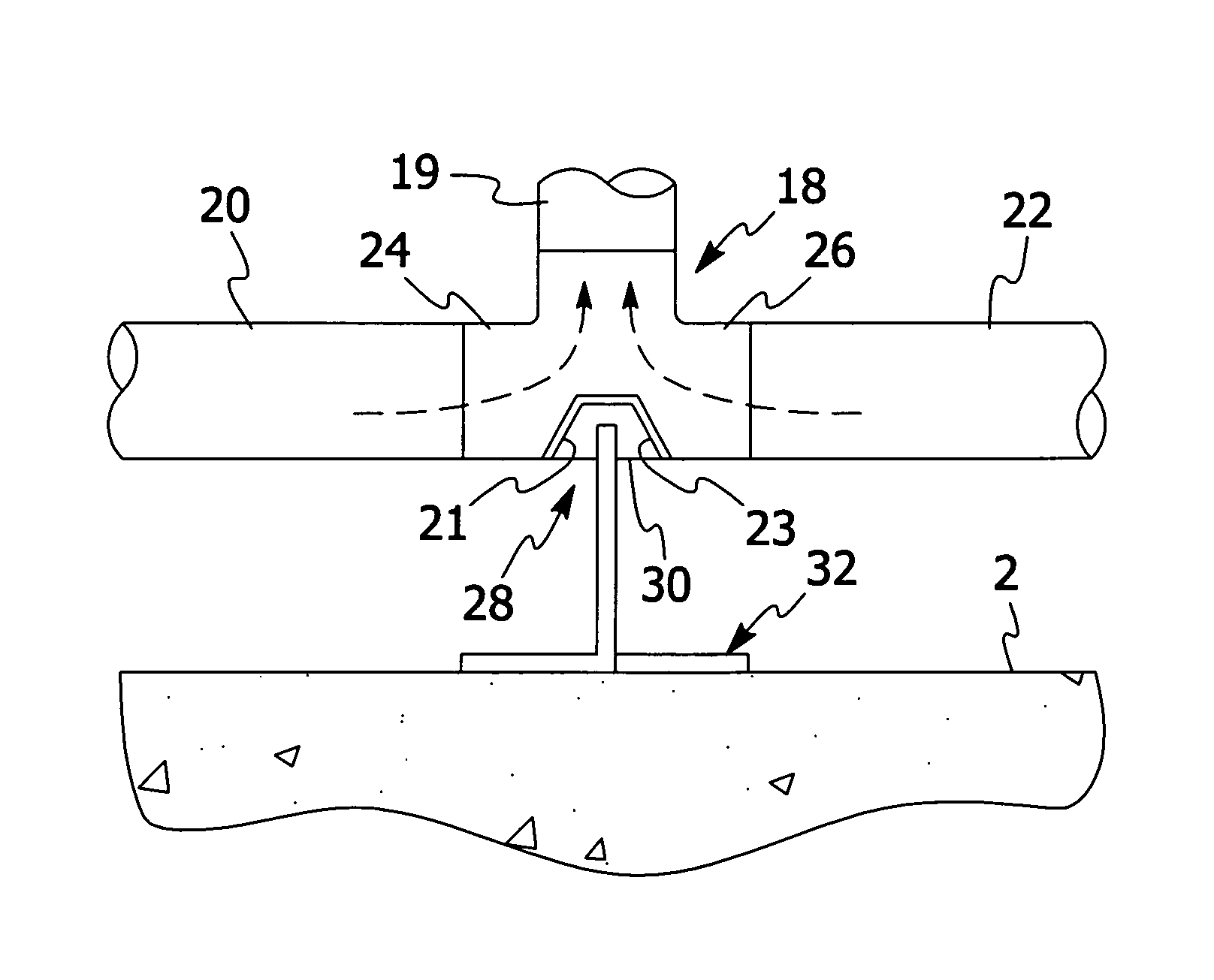

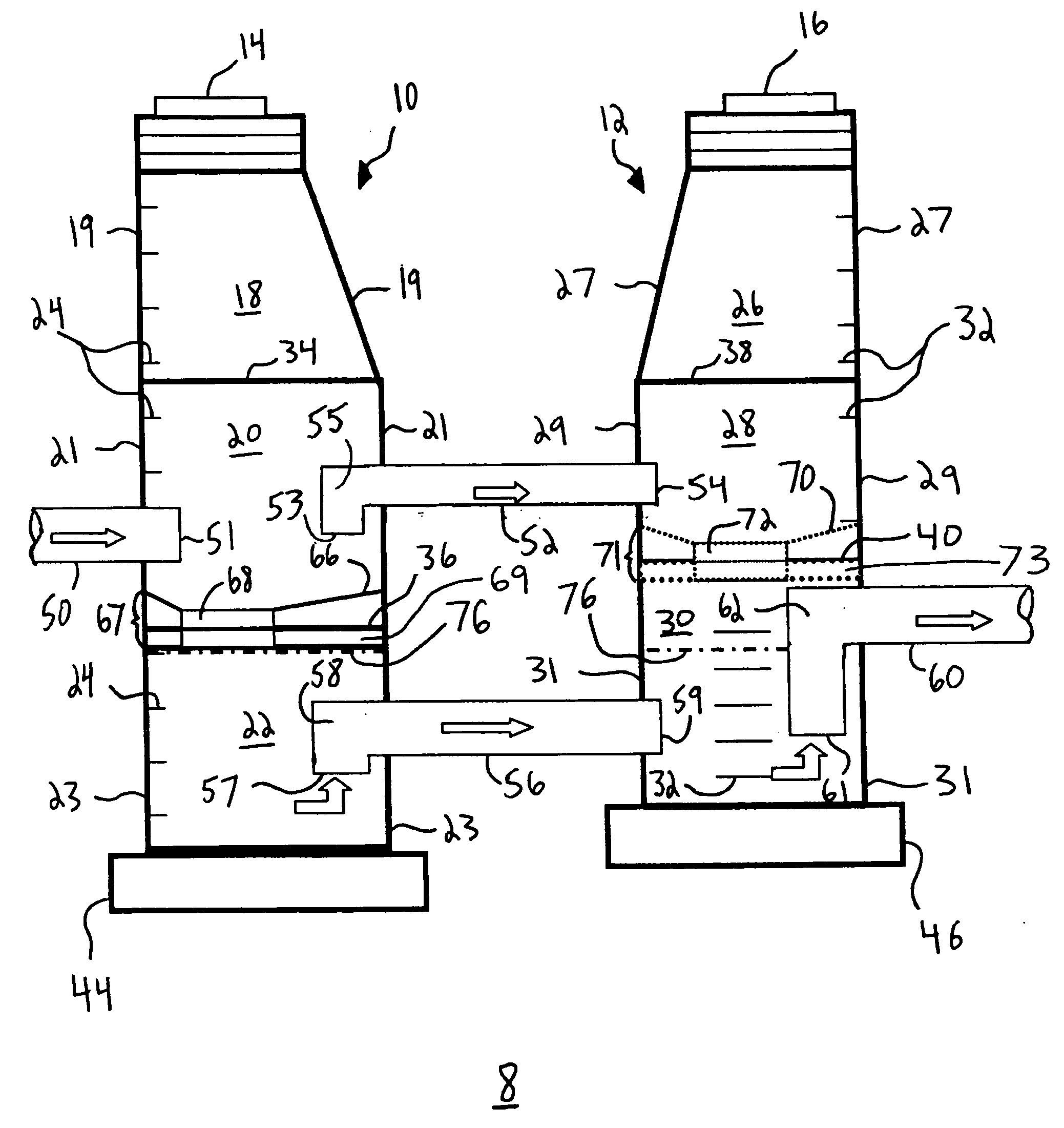

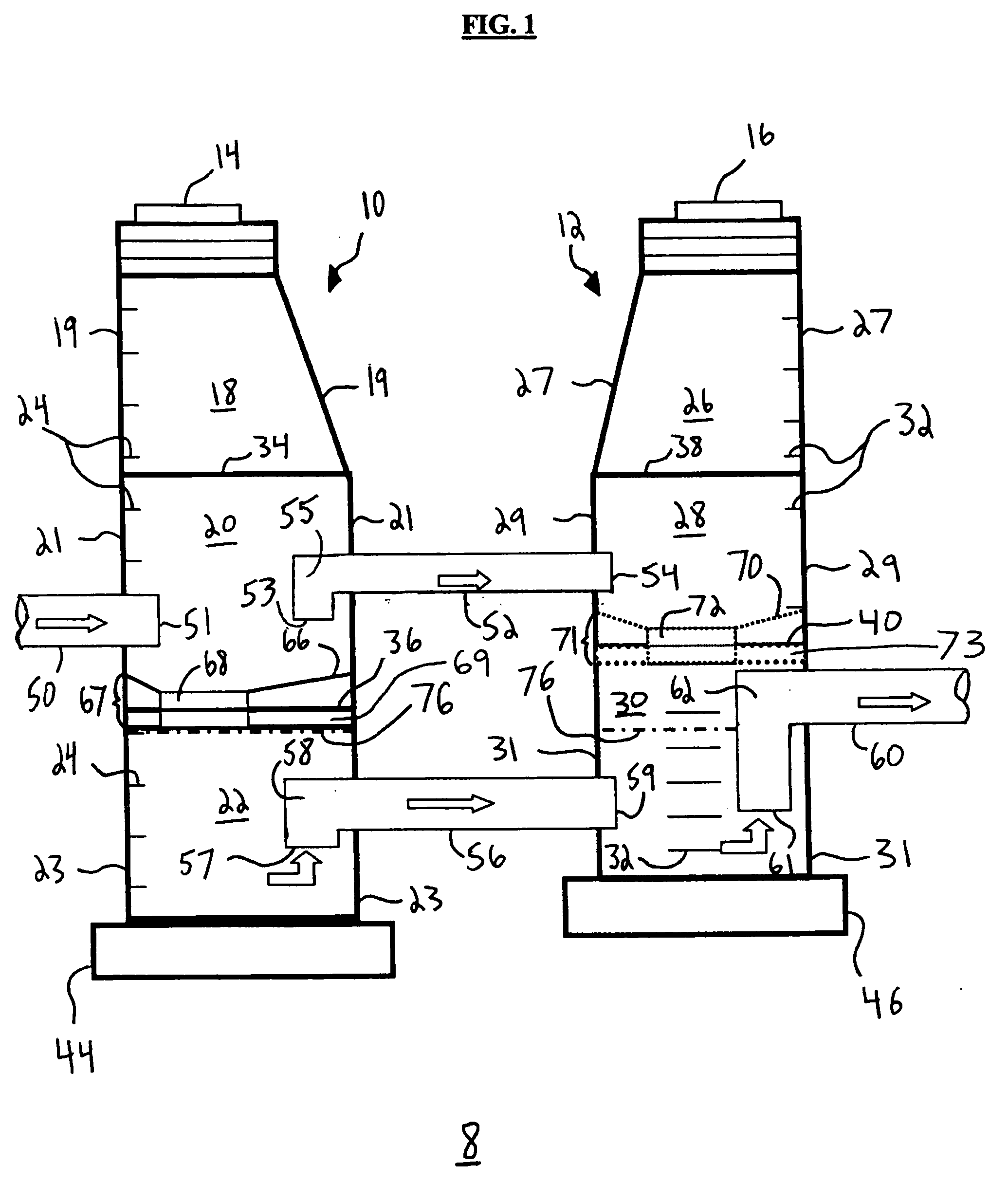

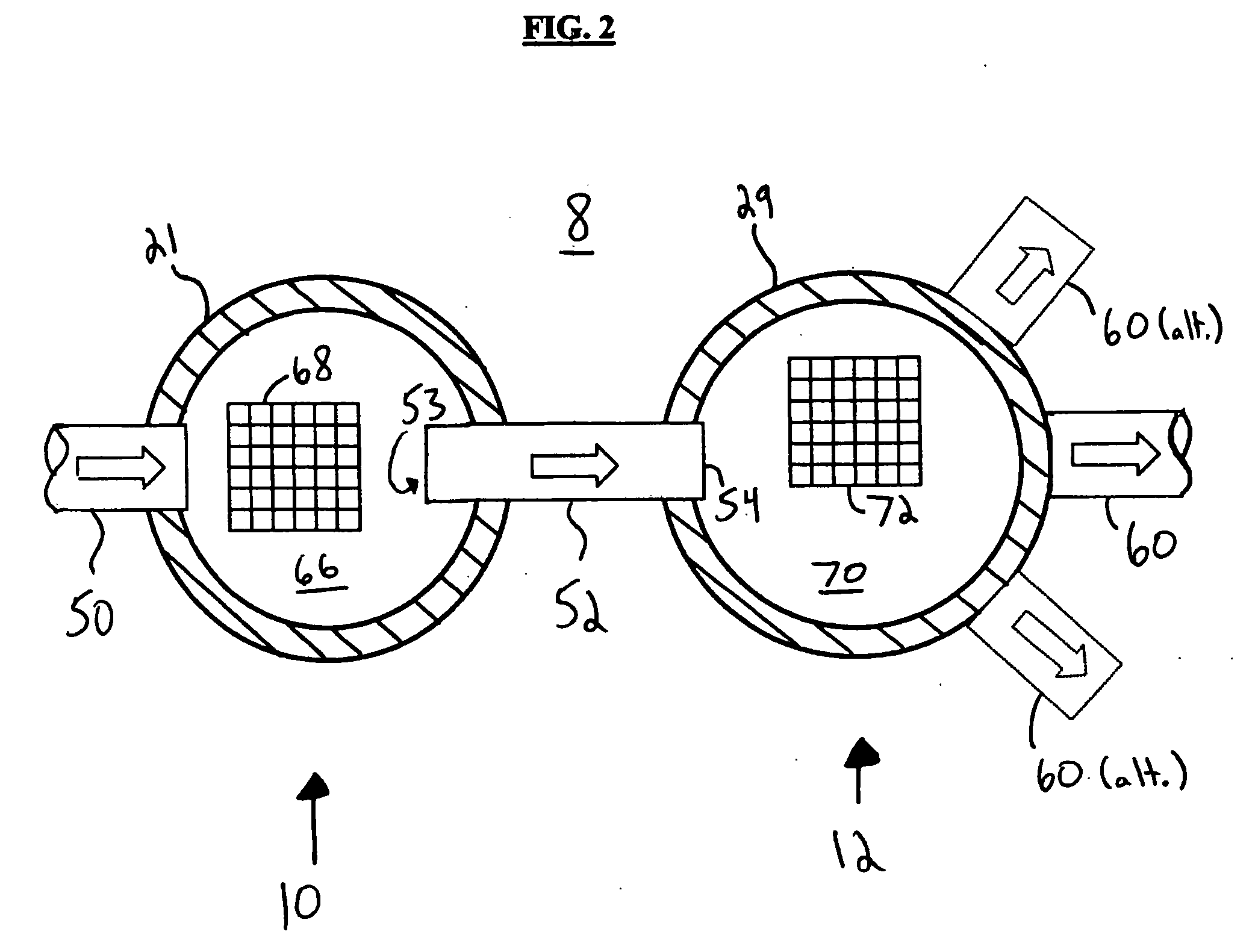

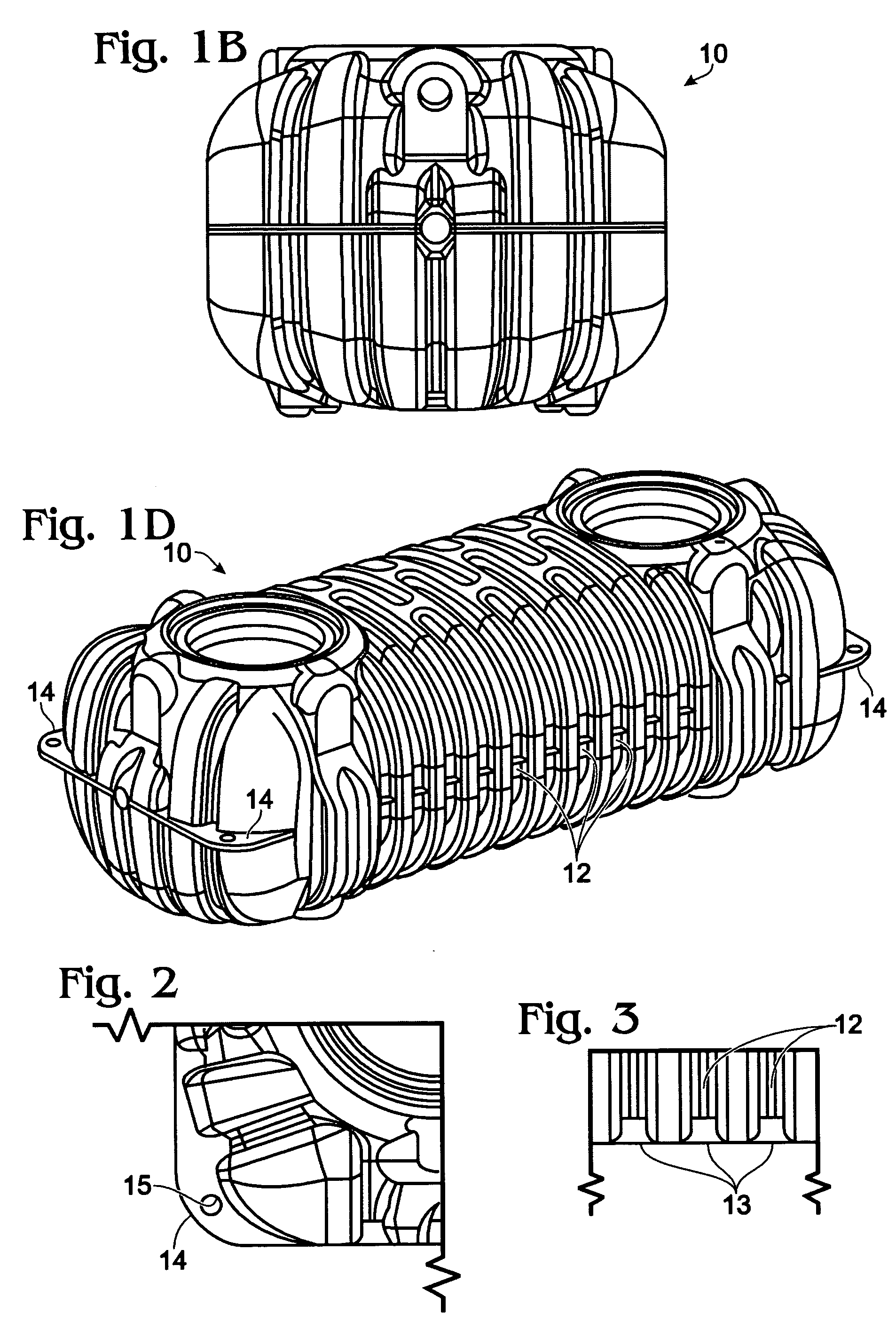

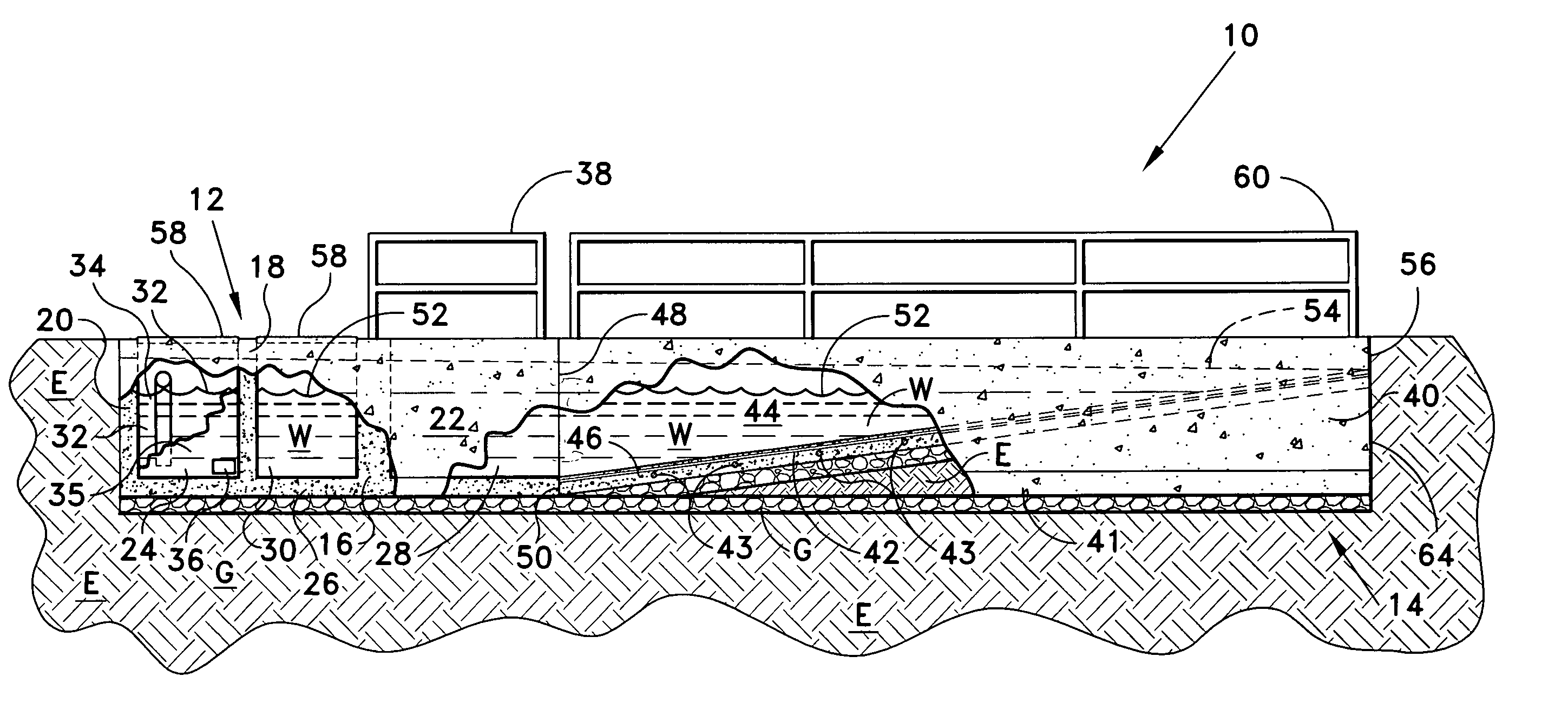

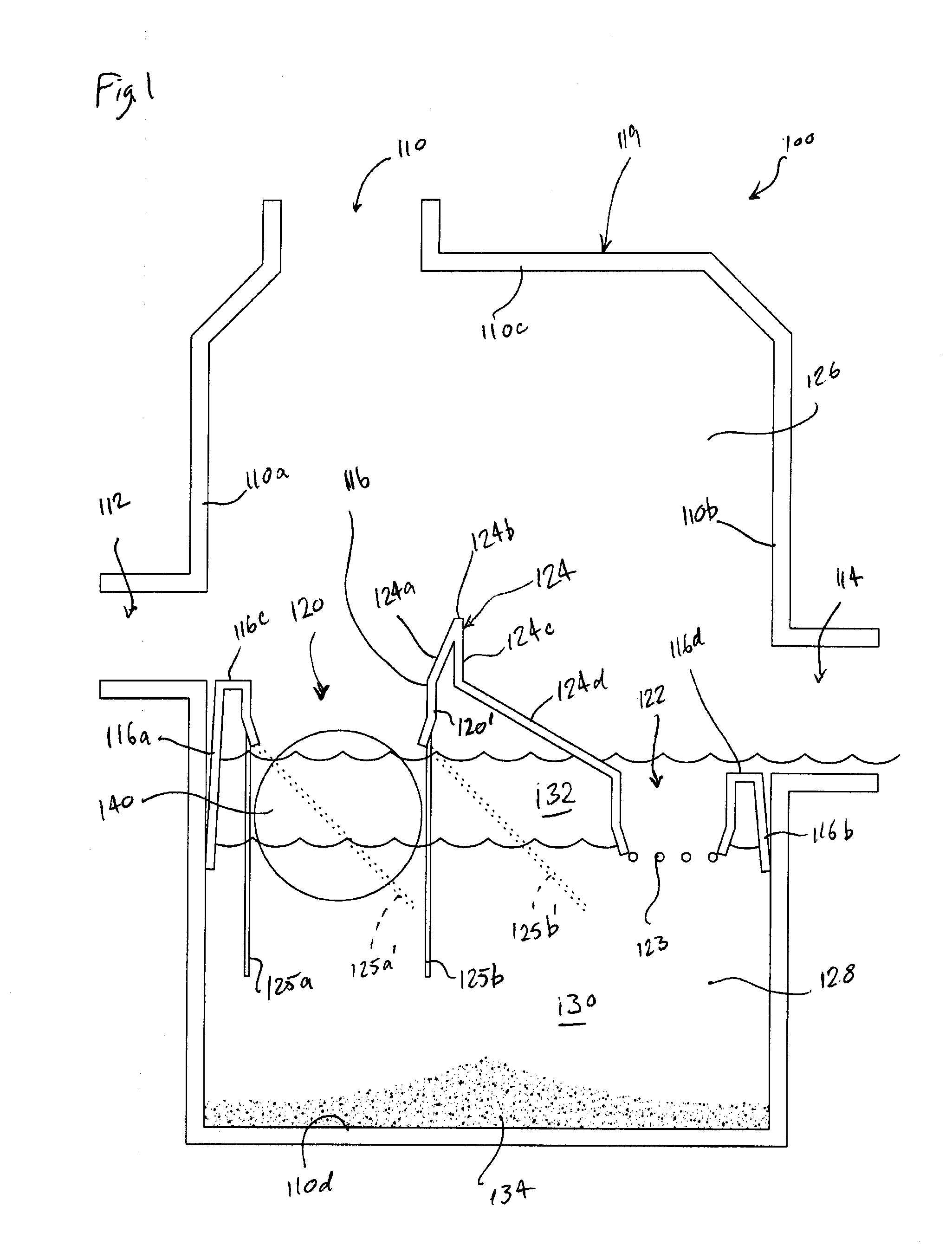

Storm water interceptor

ActiveUS7314549B2Quality improvementLess-expensive constructionWater cleaningSewerage structuresStormwaterGuide tube

A storm water interceptor comprises an input conduit connected to a first treatment tank for delivering storm water to the first treatment tank and having an obvert elevation. Also, the interceptor comprises a lower conduit having an invert elevation, a substantially horizontal orifice at a first end connected to the first treatment tank and an exit orifice at an opposite end connected to a second treatment tank, whereby the substantially horizontal orifice at the first end of the lower conduit is below the invert elevation of the lower conduit. The interceptor further comprises an overflow conduit connecting the first treatment tank to the second treatment tank, whereby the overflow conduit is connected to the first treatment tank at a location above the obvert elevation of the input conduit. As well, there is an output conduit having a substantially horizontal orifice at a first end connected to the second treatment tank and an exit portion extending away from the second treatment tank, whereby an invert elevation of the output conduit is above an obvert elevation of the lower conduit, and whereby the substantially horizontal orifice at the first end of the output conduit is below the invert elevation of the output conduit. More than two treatment tanks may be connected in a cascading manner using the same general components and principles as an interceptor having two treatment tanks.

Owner:STORM PAL CORP

Water treatment device with volumetric and time monitoring features

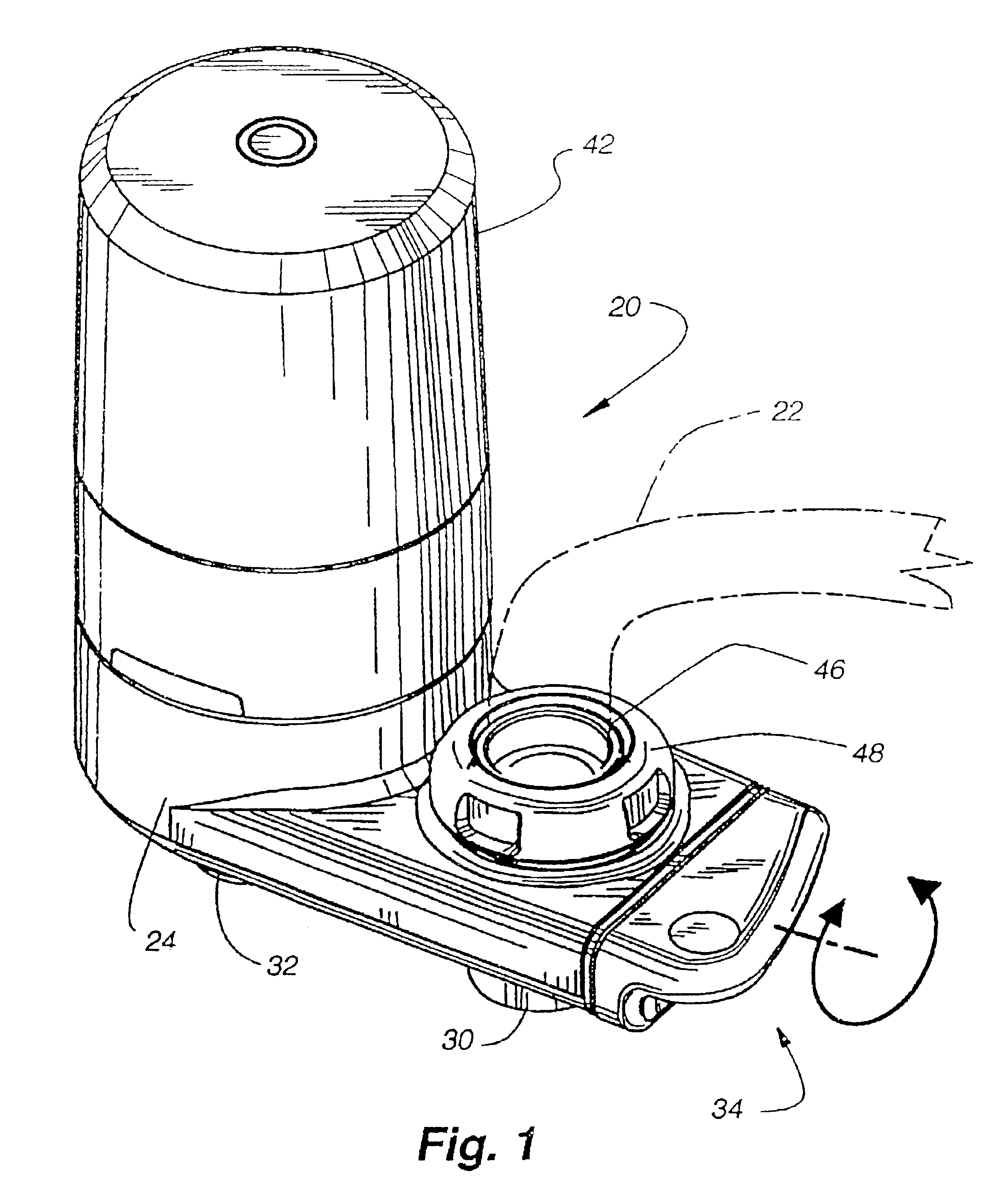

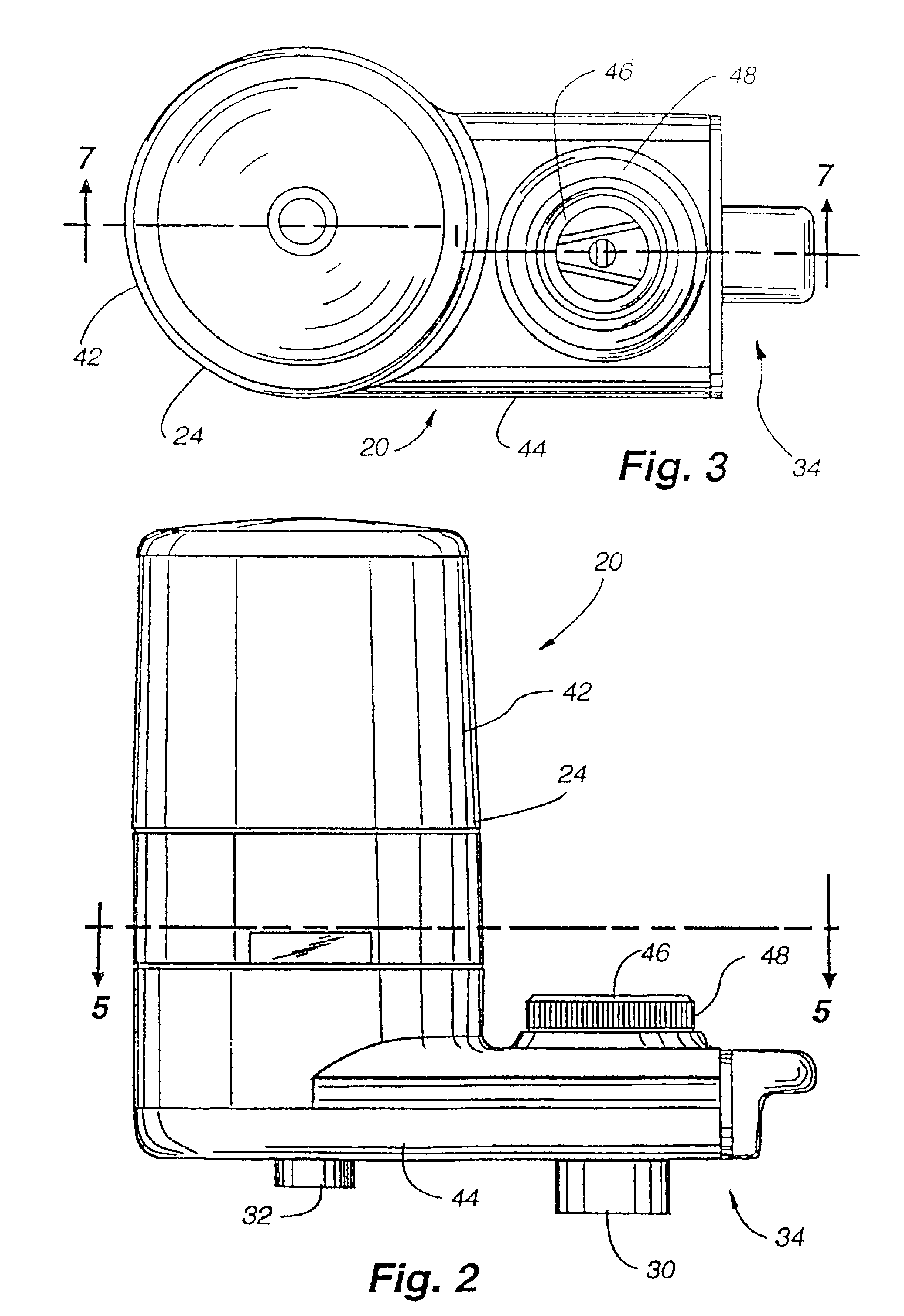

InactiveUS6926821B2Less palatableEnhanced flushingTreatment involving filtrationCartridge filtersMicrocontrollerOutput device

A totalization meter system for a water treatment device, the device having an inlet aperture and an outlet aperture, and a channel for channeling water between the inlet and outlet apertures. A flow reactive device is positioned in the channel and is exposed to the flowing water, and a signal generating member is positioned on the flow reactive device. A switch is positioned proximately to the flow reactive device, and is sensitive to the proximity of the signal generating member. The switch is able to communicate electric signals indicative of the motion of the signal generating member. A resettable processor having a performance threshold programmed therein and an output device is included. The microcontroller is in electrical communication with the switch for receiving electrical signals from the switch. The switch is capable of sensing the characteristics of the flow reactive device and communicates electrical signals representative of the characteristics to the microcontroller. The microcontroller interprets the signals as a first performance data. The microcontroller compares the first performance data against the respective performance threshold in the microcontroller to determine if the performance threshold has been surpassed, and if surpassed actuates the output device.

Owner:INSTAPURE BRANDS

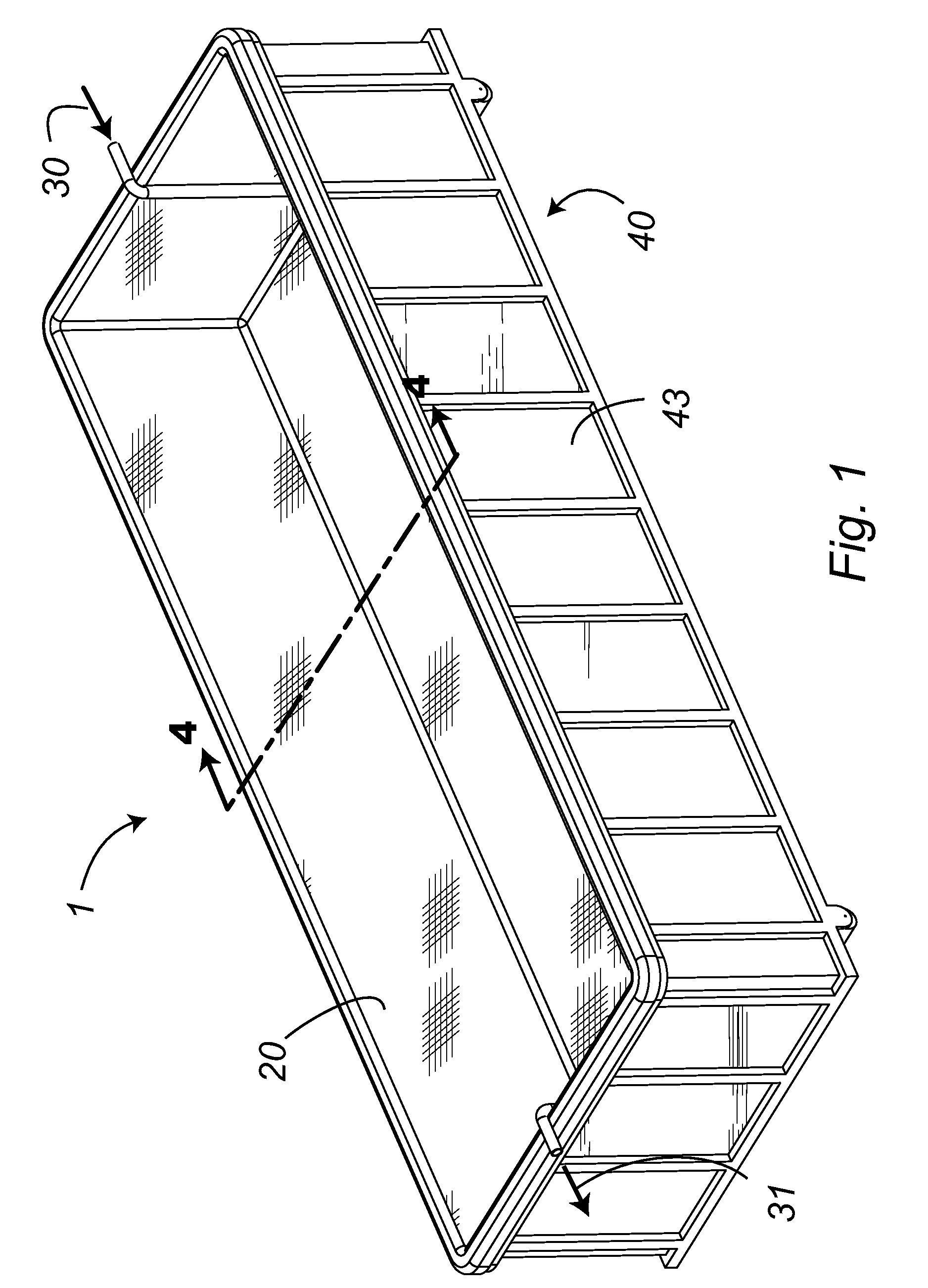

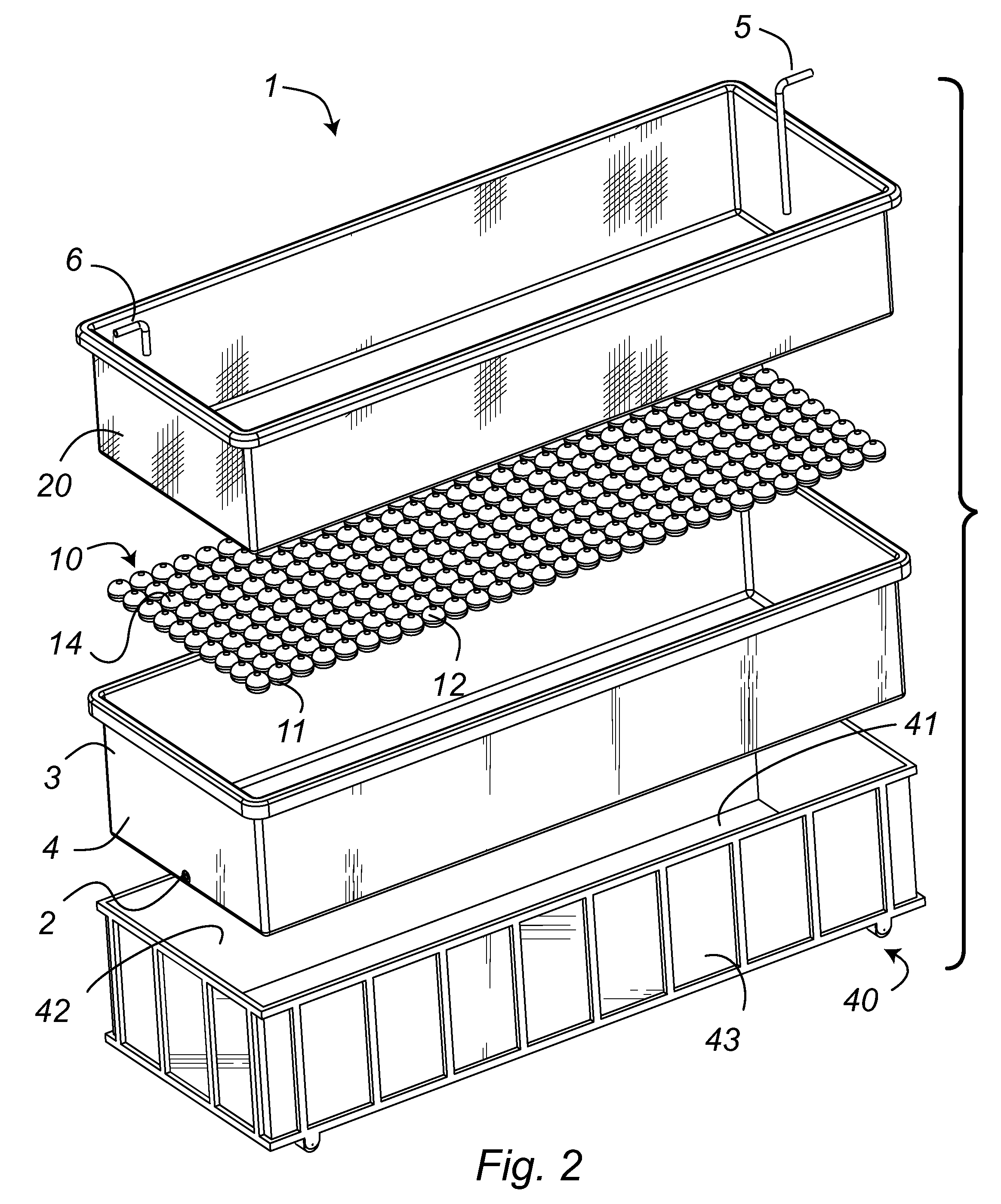

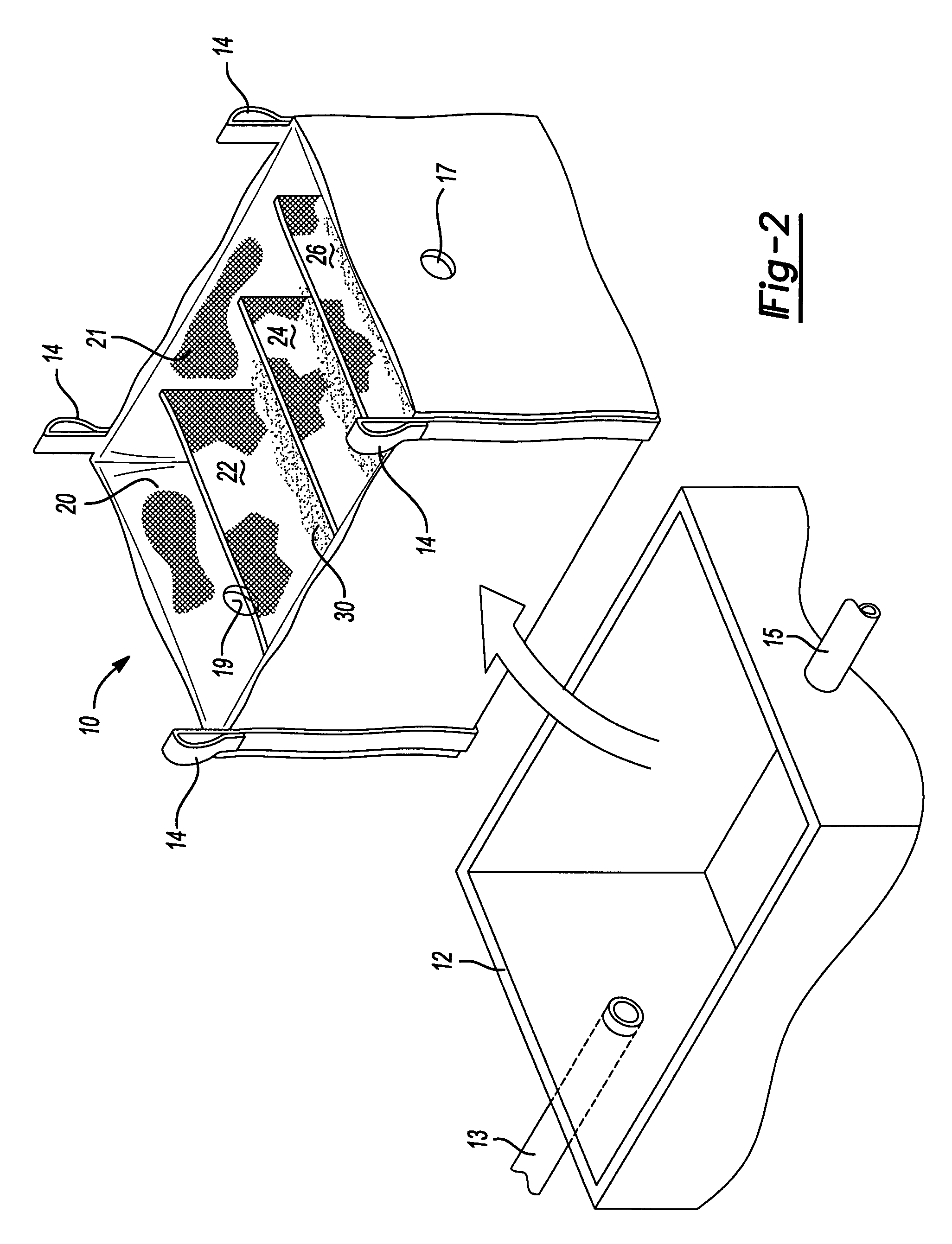

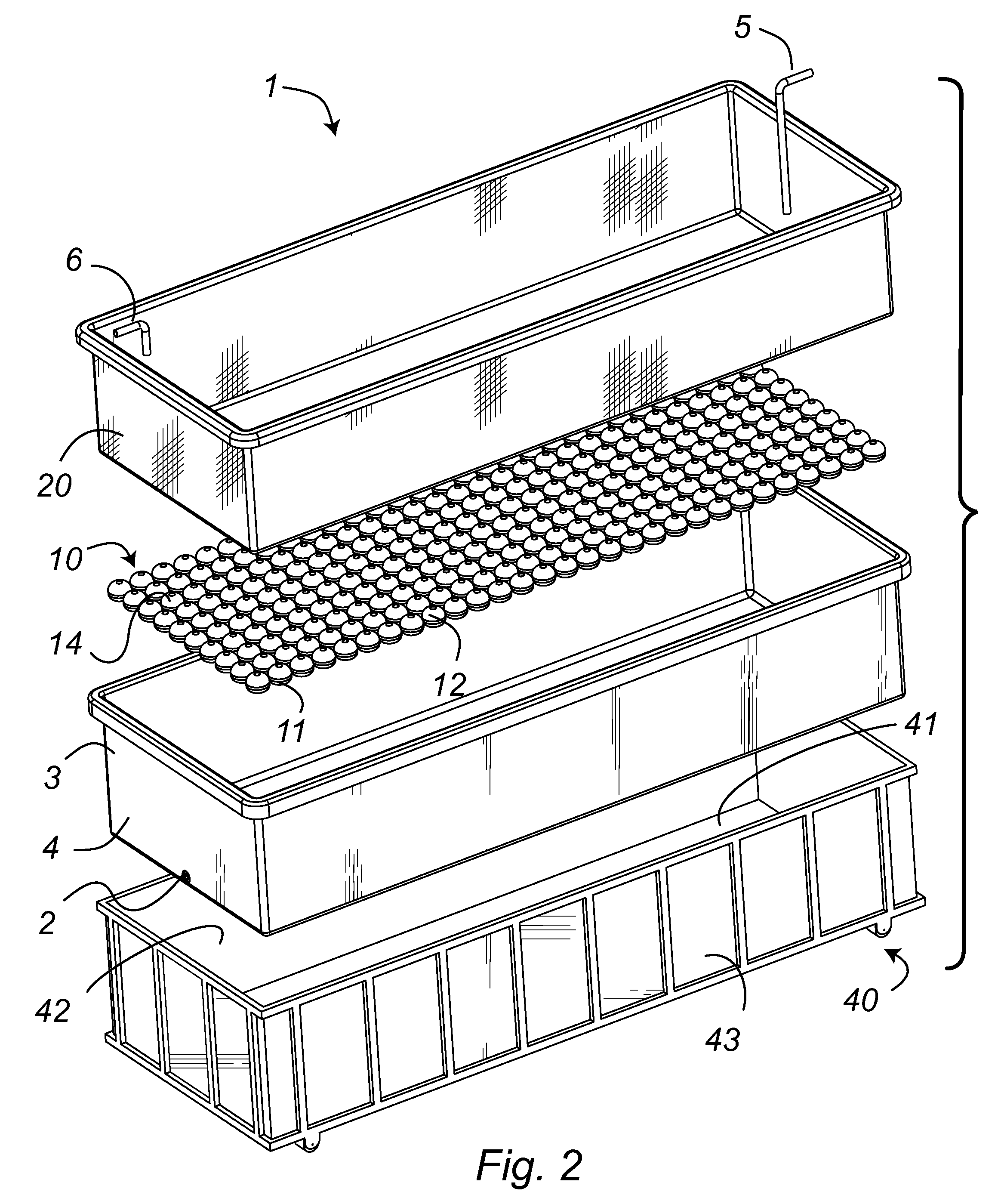

Portable settling and dewatering tank

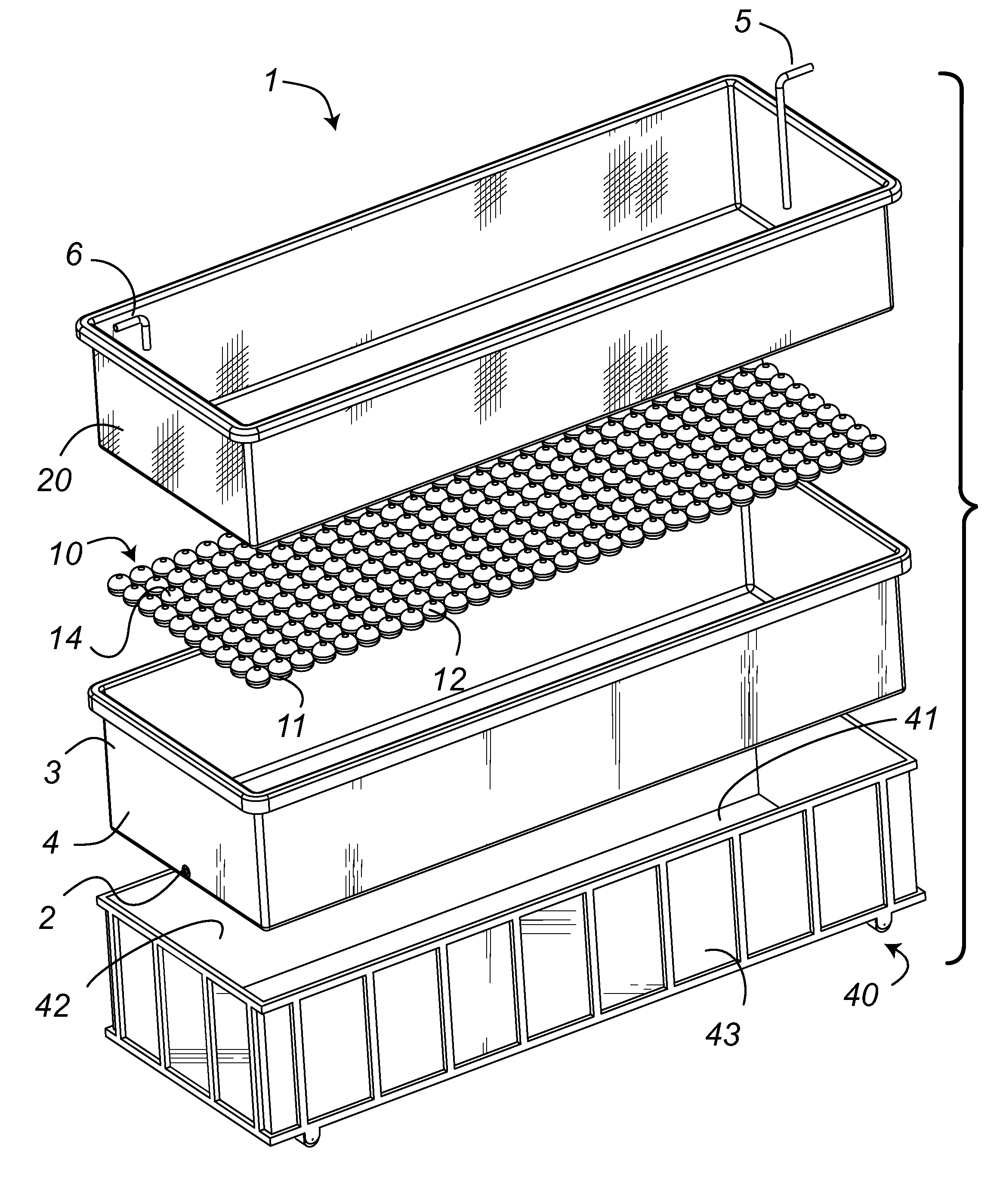

InactiveUS7943051B2Avoids any terminal cleanupAvoid cloggingMachines/enginesLoose filtering material filtersSludgeSlurry

A settling tank for dewatering a thin slurry is provided in a lined portable container and with a disposable filtering means. A novel method of processing the slurry by settlement of the solid phase and removal of the liquid phase in cycles avoids the clogging of the filtering means. The settling tank can be easily transported and dumped without requiring the transferring of residue sludge or the cleaning of equipment.

Owner:DIEZIGER HELEN IRENE

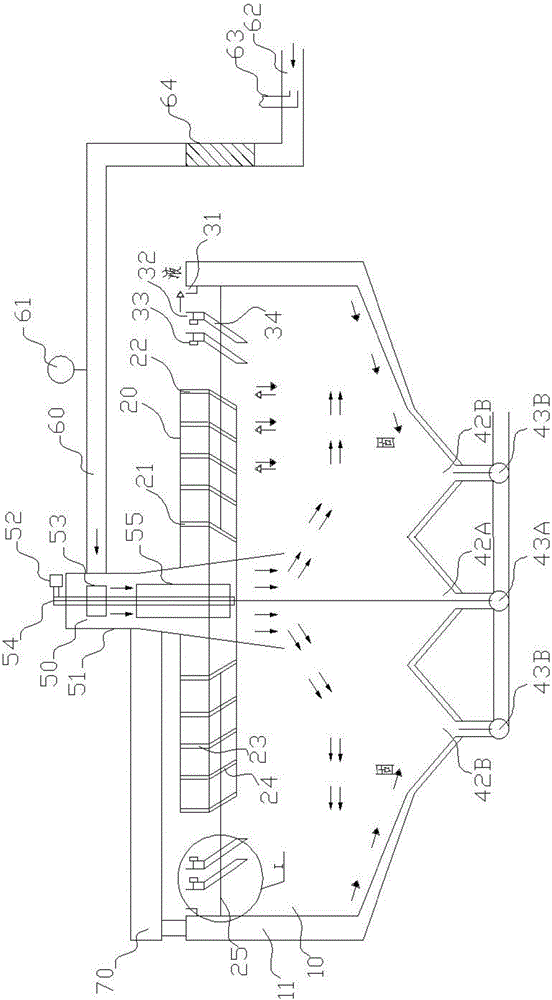

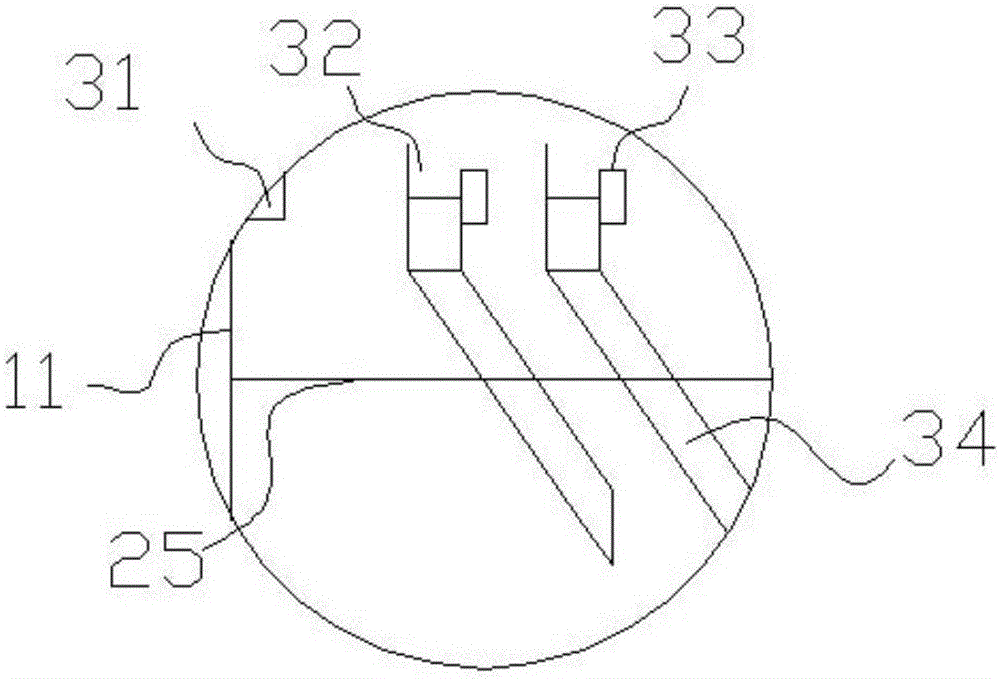

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

Refuse/oil removing device and refuse/oil recovery bag

InactiveUS7815800B2Improve rate of settling downPromote recoveryLiquid suspension thickening by filtrationLiquid displacementOil and greaseEngineering

A refuse / oil removing device and a refuse / oil recovery bag are provided which can remove refuse and oil contained in drainage discharged from a restaurant in a simple manner without contact with the refuse and oil. A support base of a support unit is disposed in the interior of a grease trap at a position higher than the water level. A recovery bag is attached to the support unit and plural layers of bag portions of the recovery bag are put on the support base. The bag portions are each formed of a material which permits the adhesion of oil thereto and a large number of water passing holes are formed in each of the bag portions. Drainage is introduced inside the innermost one of the plural layers of bag portions and is passed through the bag portions, allowing refuse and oil to adhere to the bag portions. In this way, the job of replacing the recovery bag can be simplified and the amount of oil accumulated within the grease trap can be decreased.

Owner:KOMATSU KIYOSHI

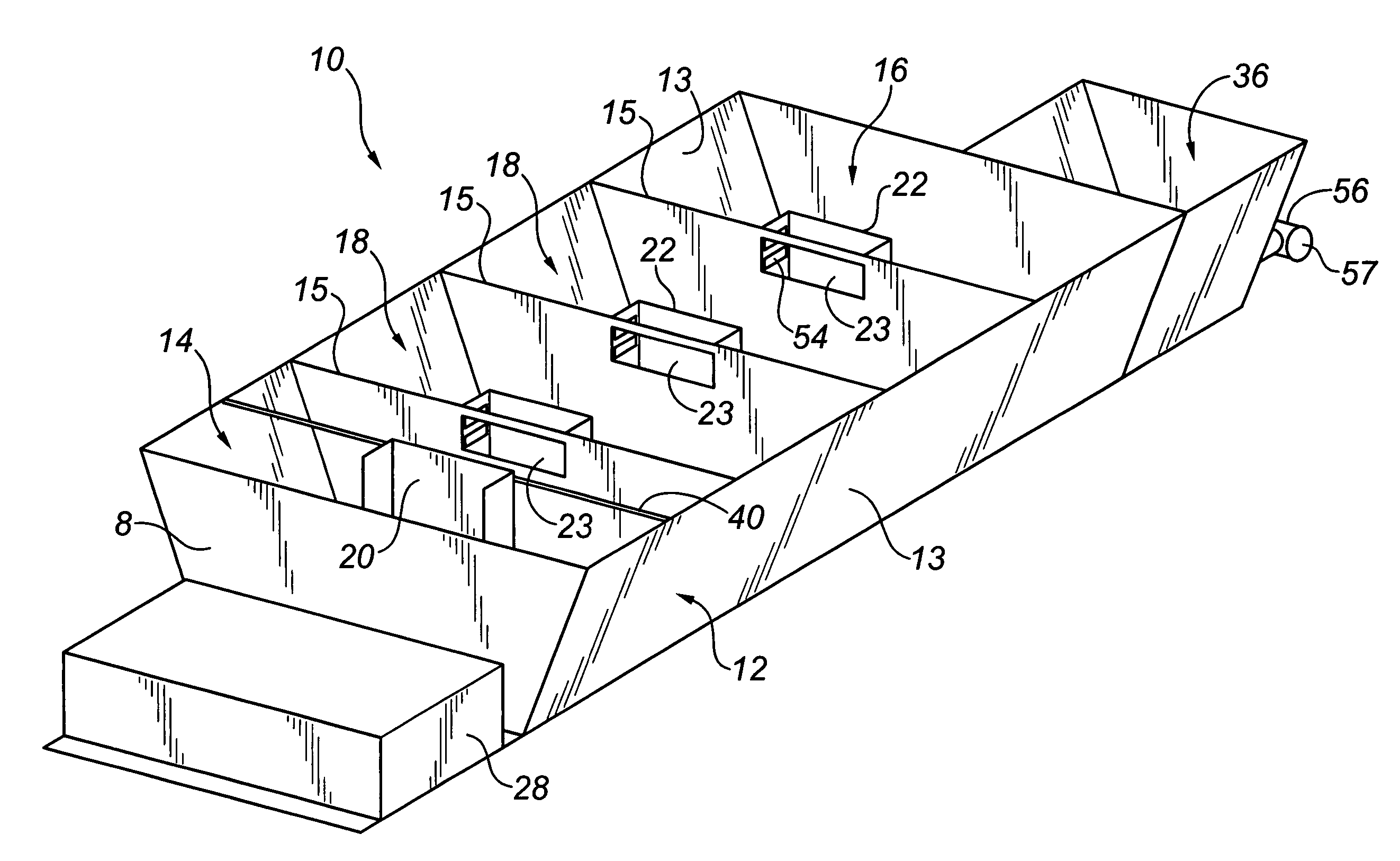

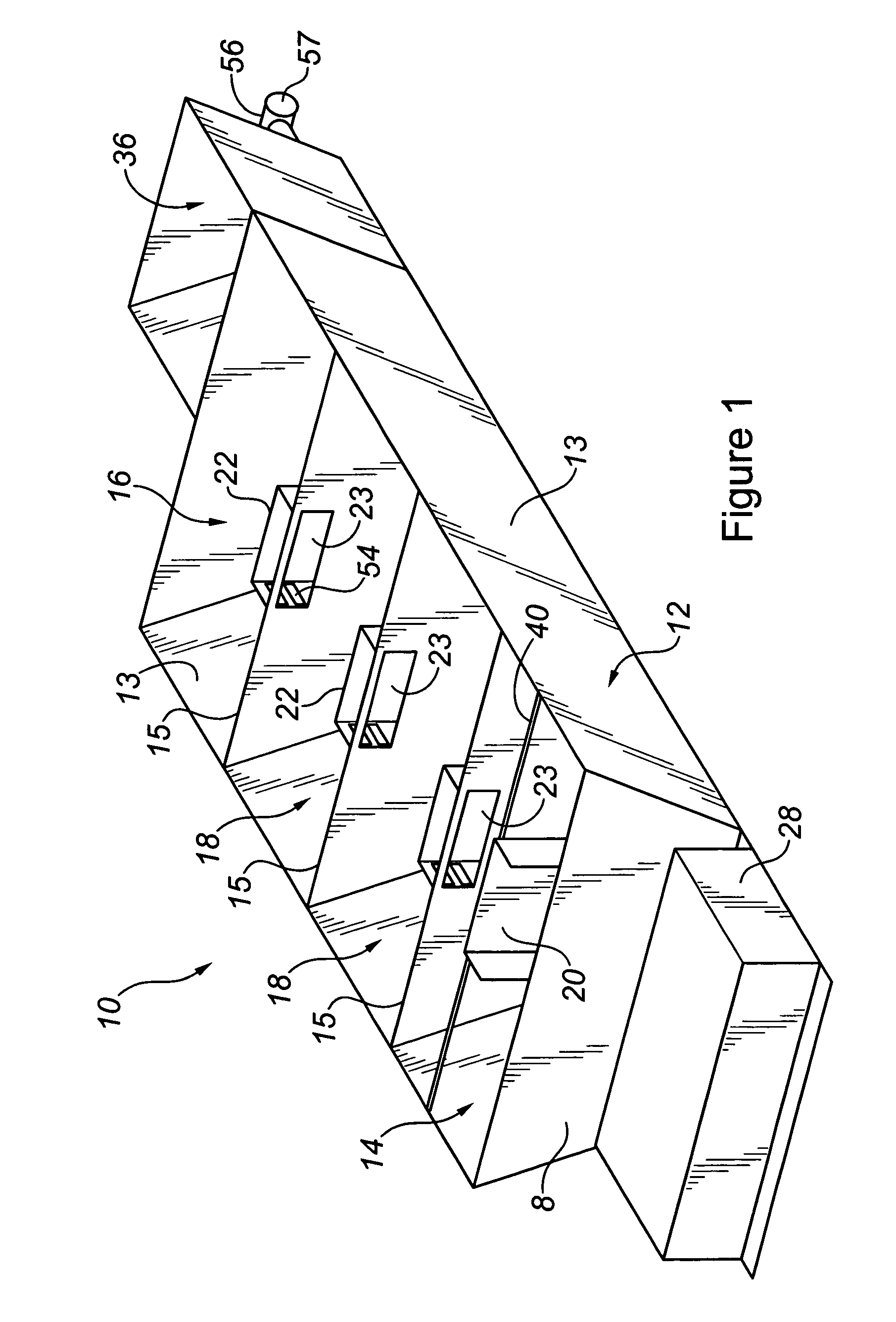

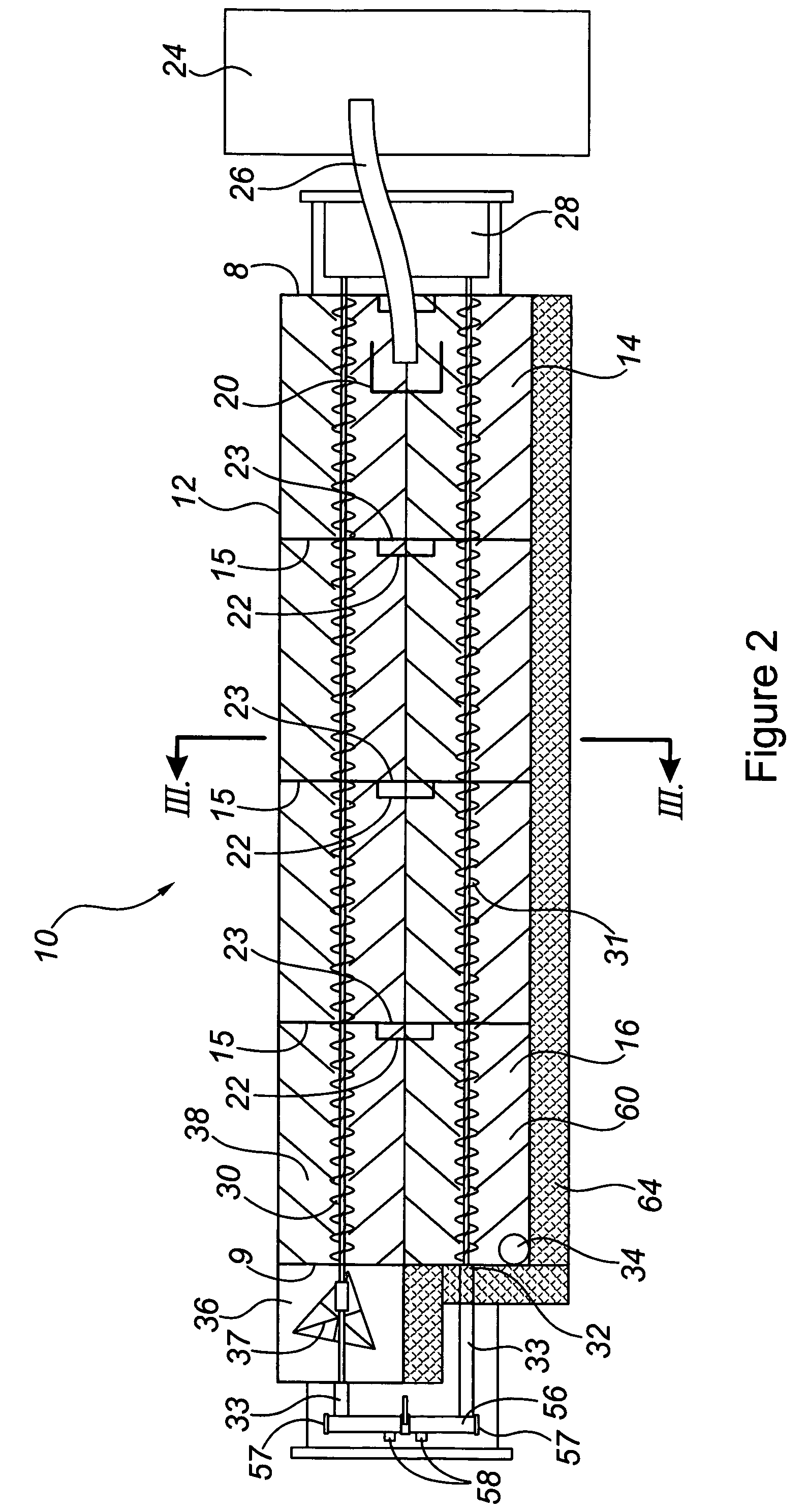

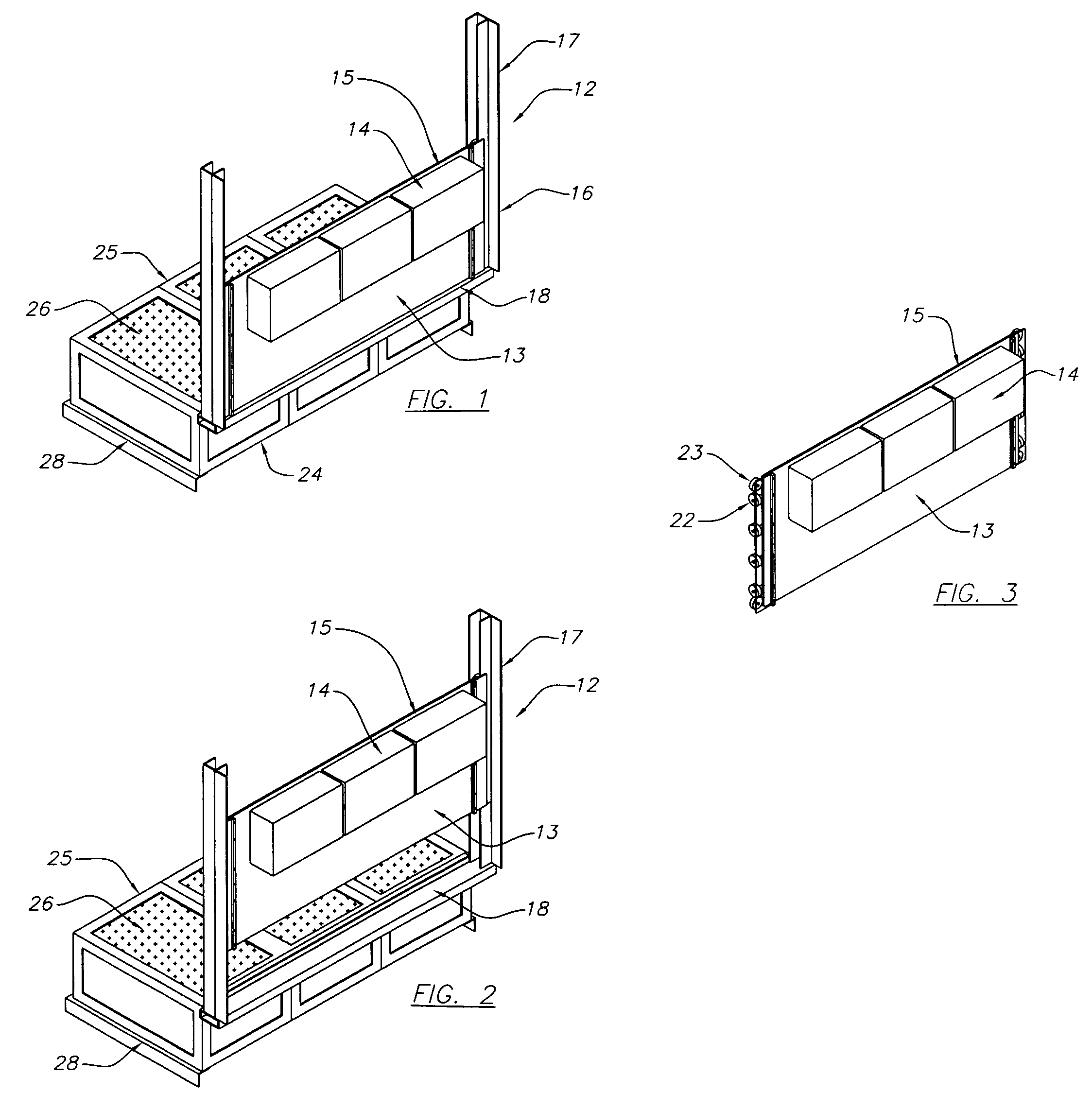

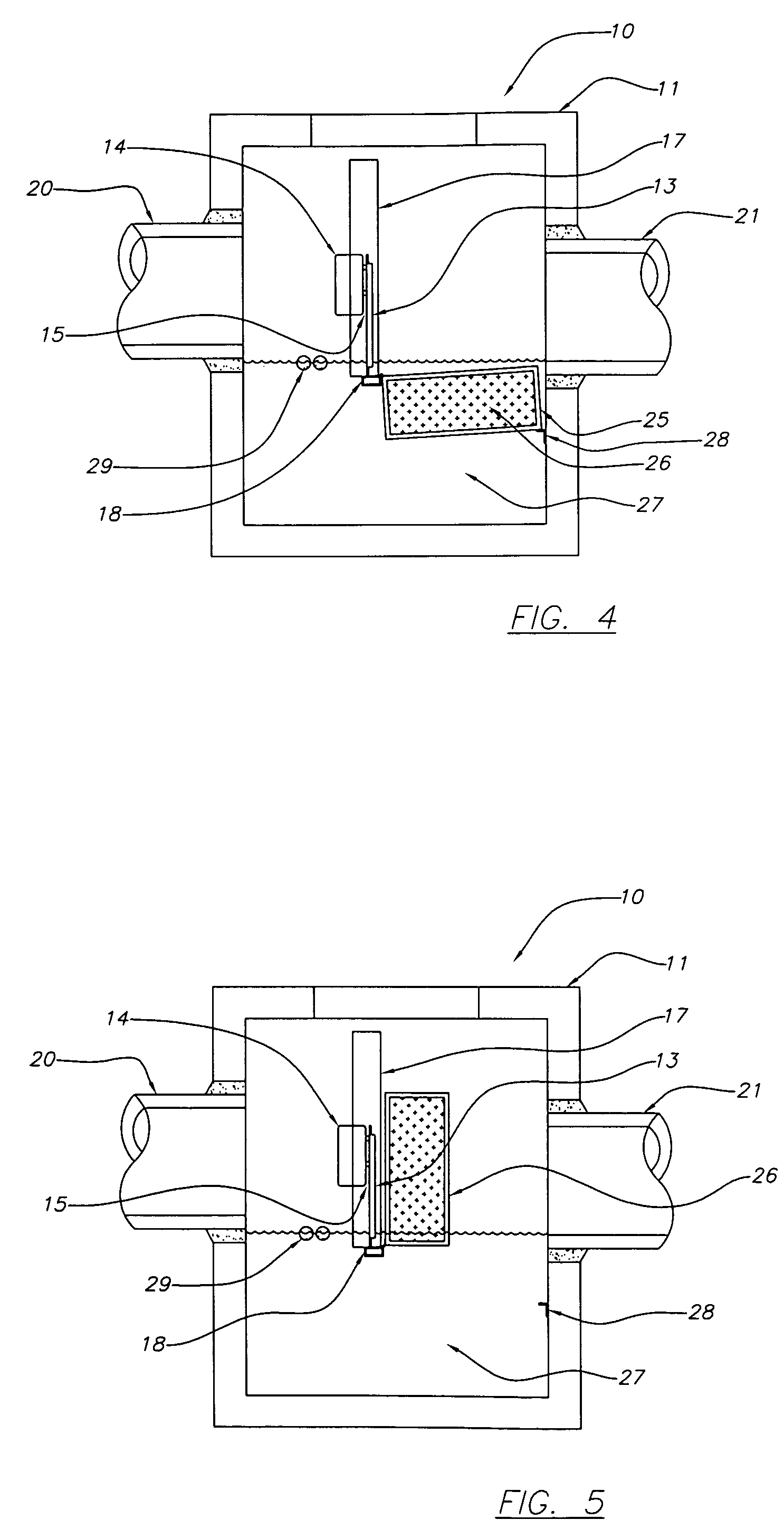

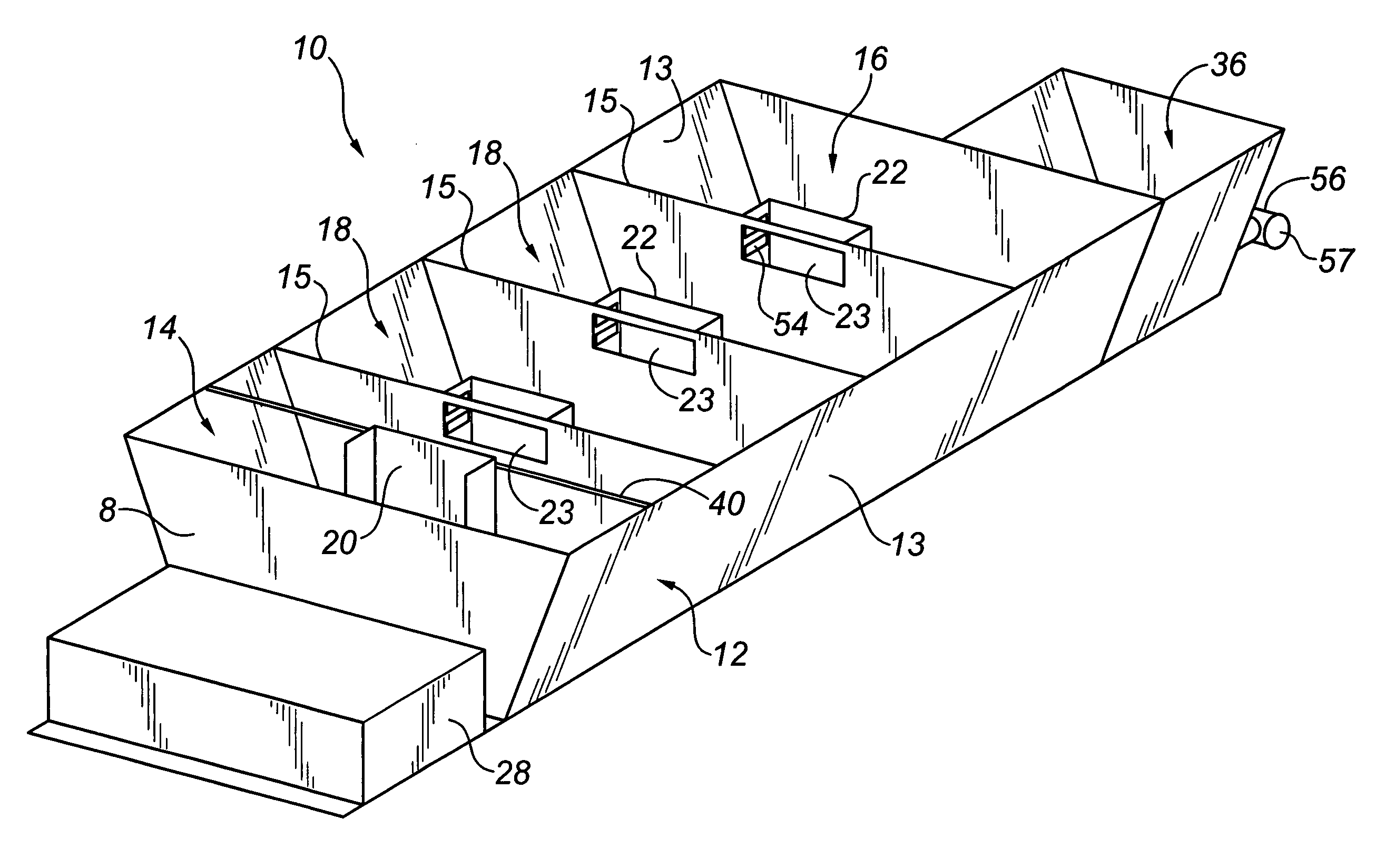

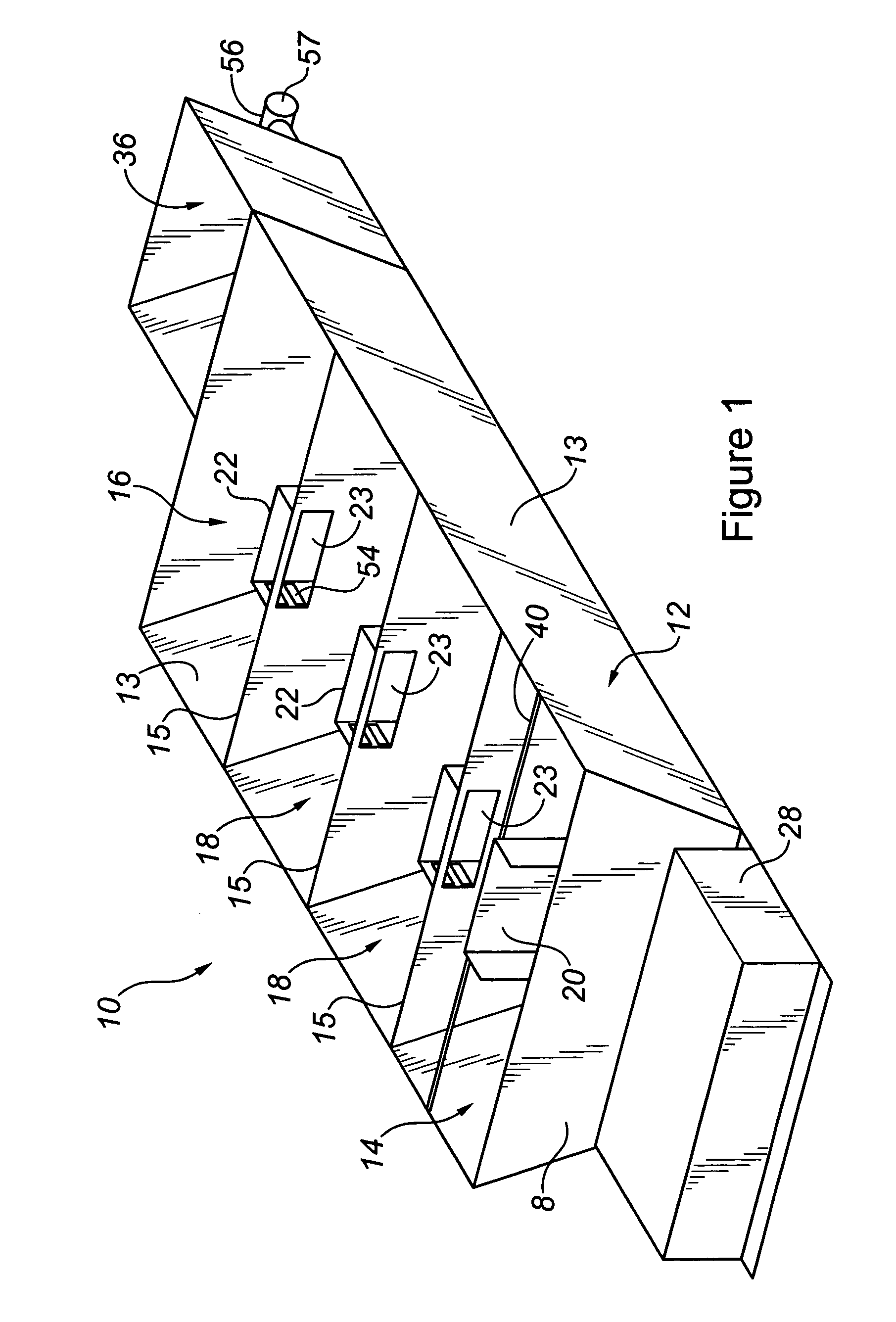

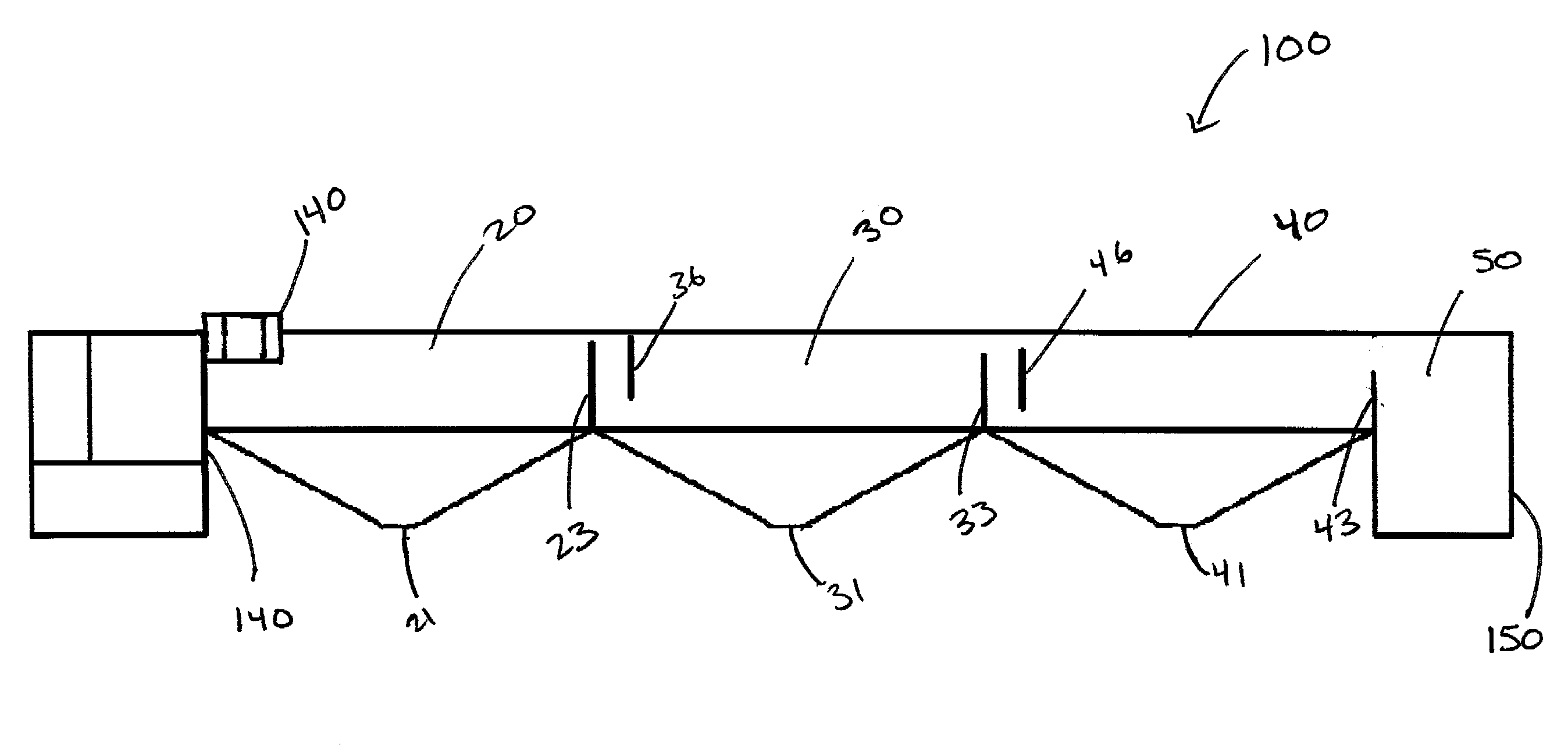

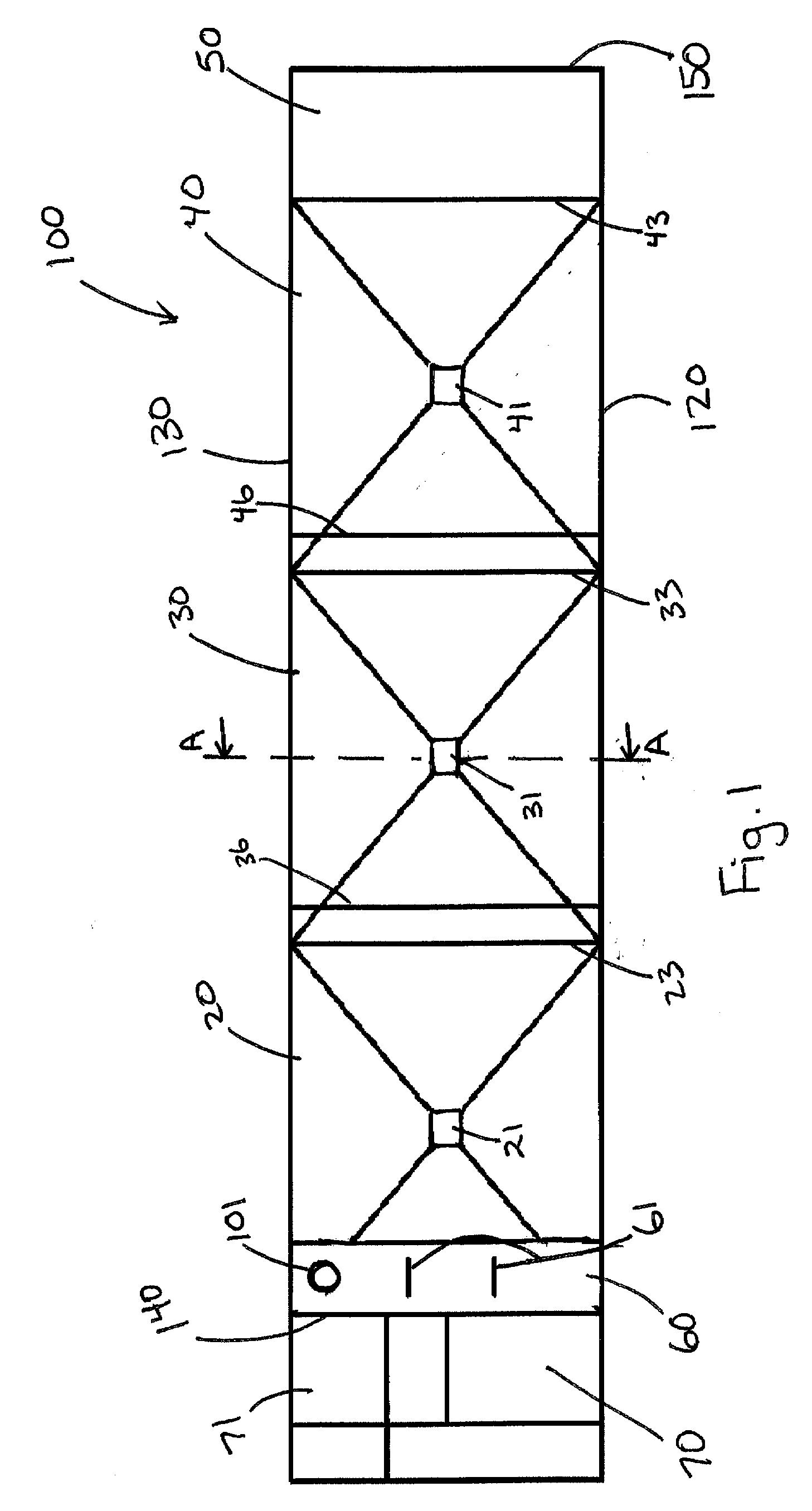

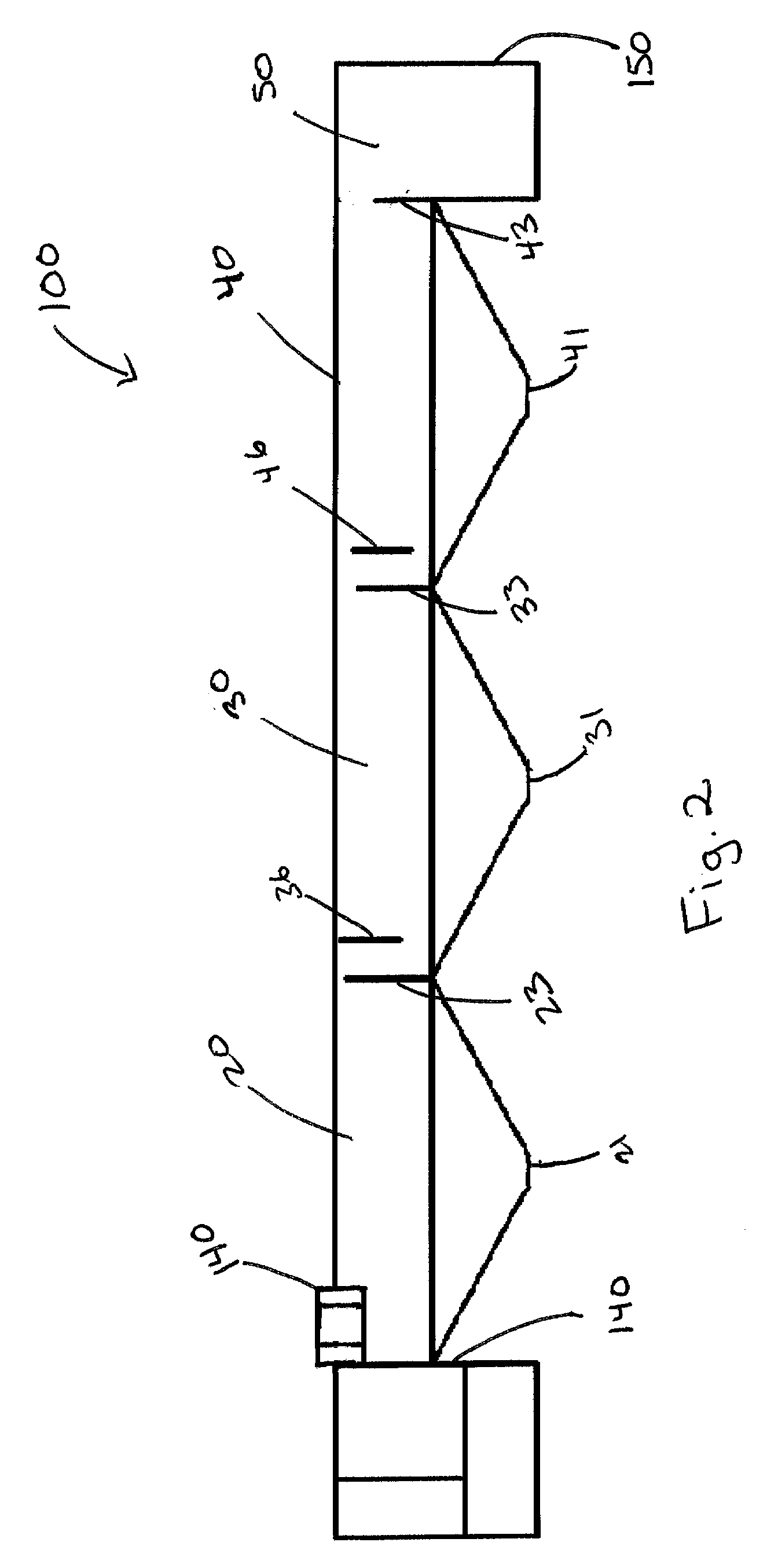

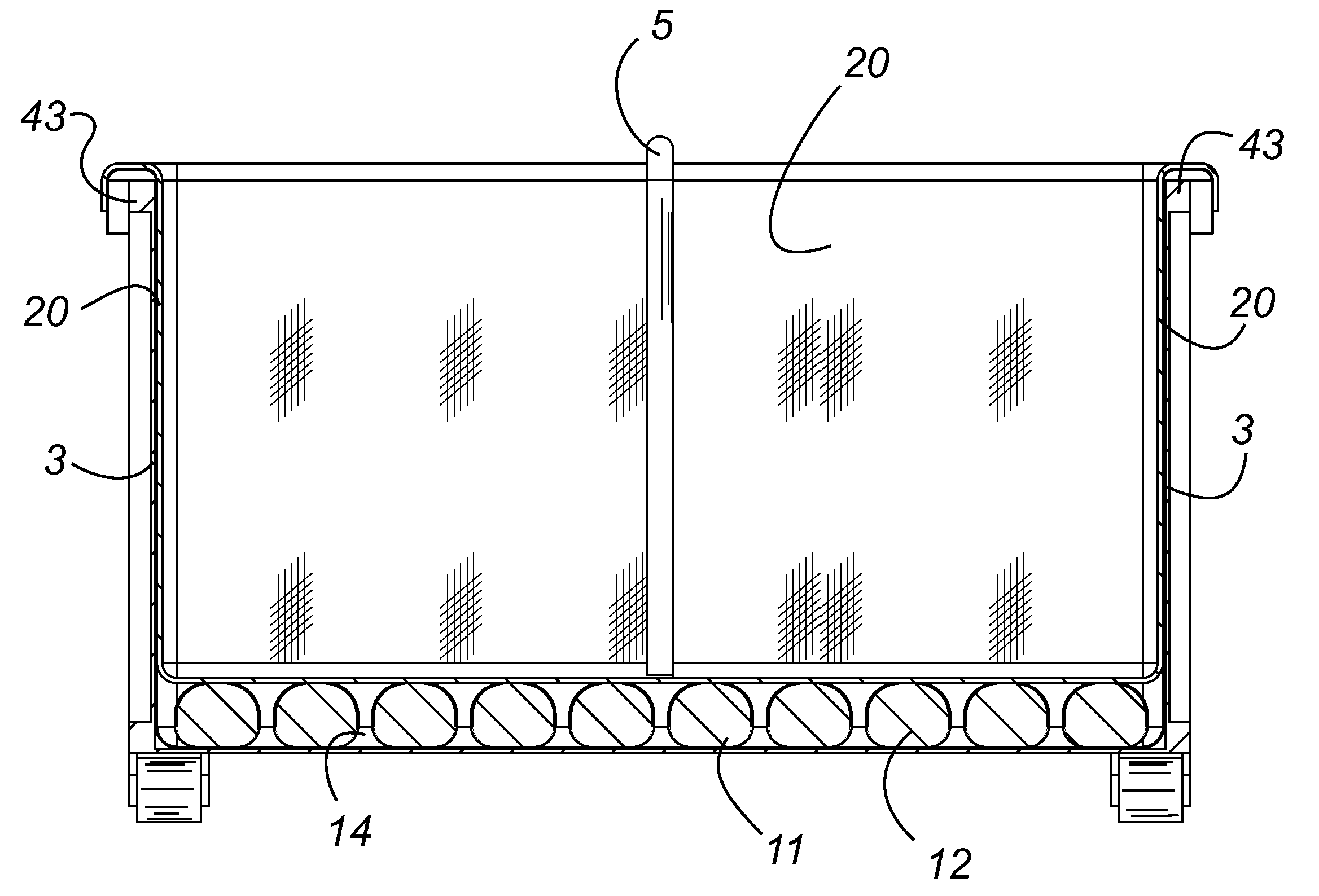

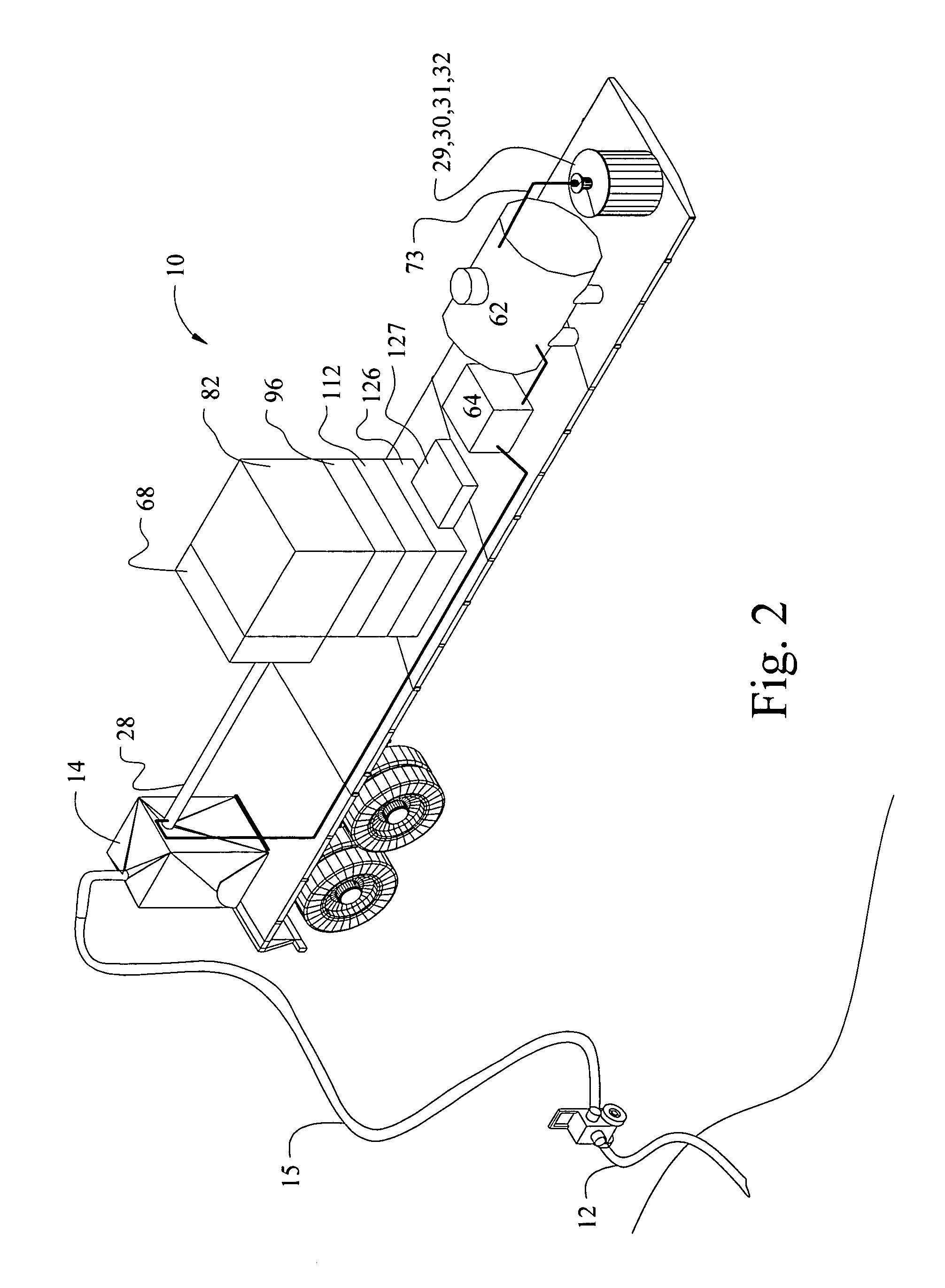

Method and apparatus for removing cuttings from drilling fluids

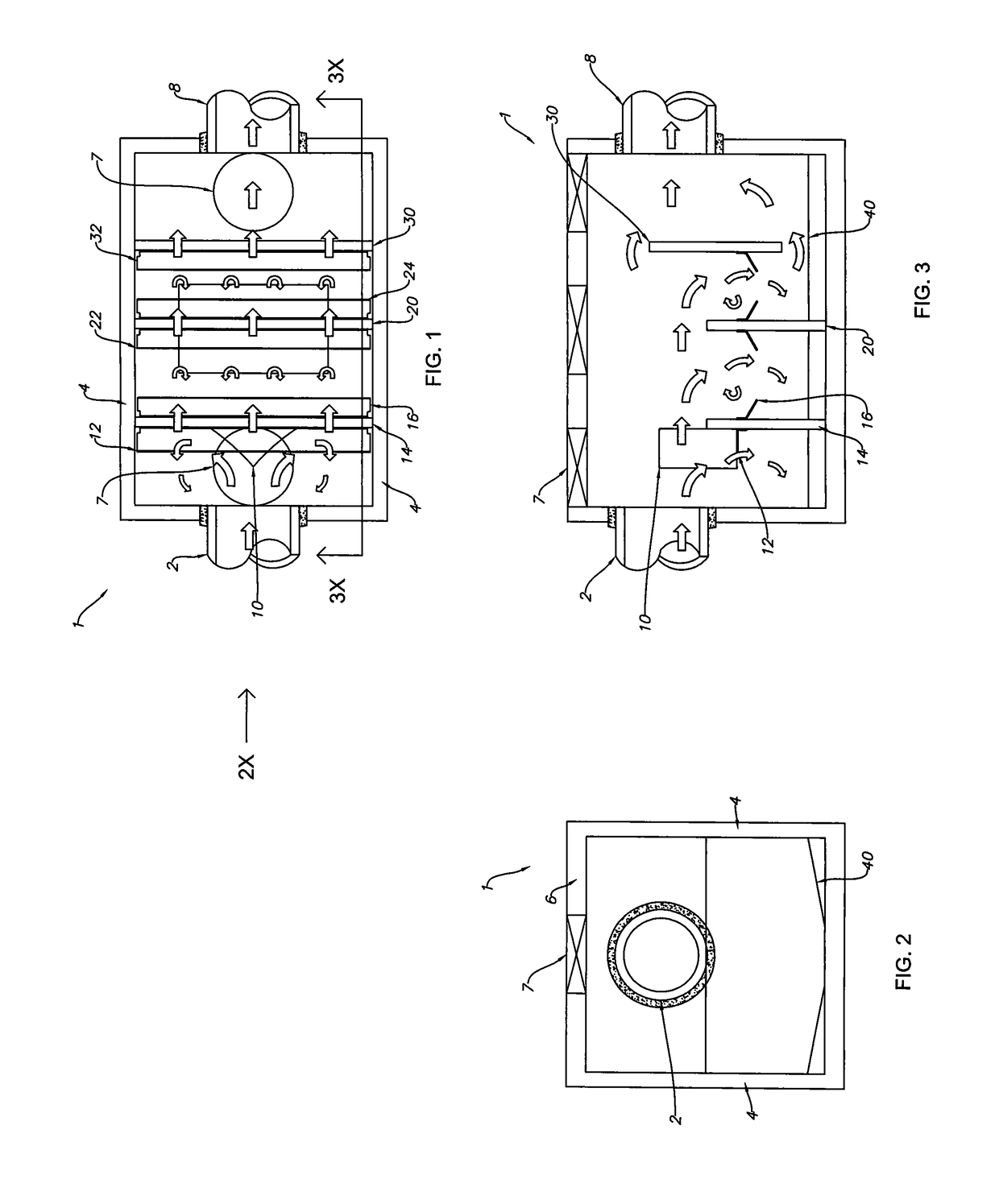

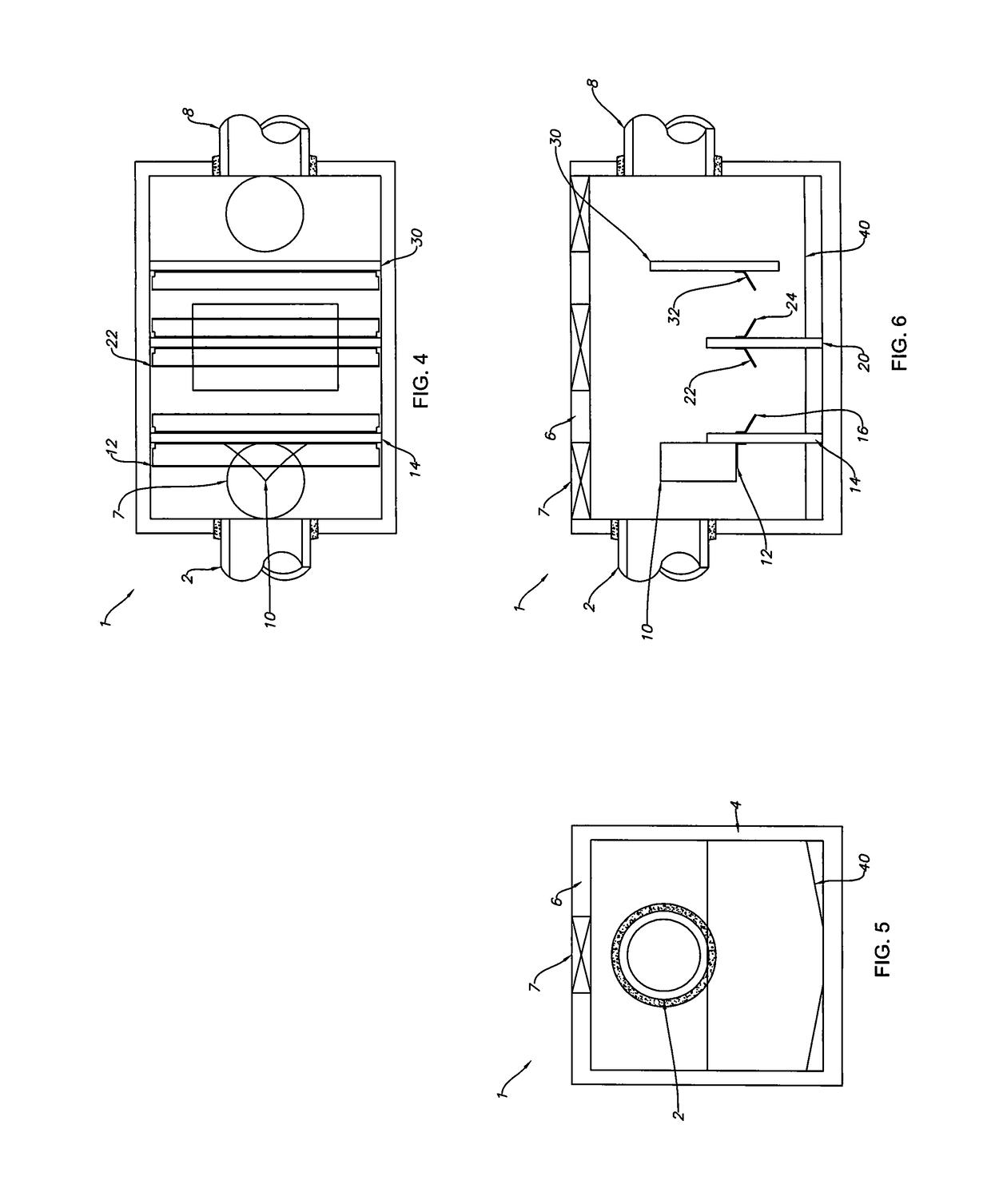

The present invention is concerned with a method and apparatus for recycling drilling fluids used in the drilling of wells. The apparatus comprises a tank with a plurality of compartments. Used drilling fluid containing well cuttings or “solids” is pumped into a receiving compartment of the tank and directed towards a flow-reversing barrier. Reversal of the flow causes heavier solids to settle to the bottom of the tank. As fluid fills the receiving compartment, it flows downstream into an adjacent compartment by passing through a flow-restricting baffle that causes more solids to settle to the bottom of the tank. As fluid overflows from compartment to compartment in the tank, it passes through successive flow-restricting baffles causing further solids to settle to the bottom of the tank. When the fluid reaches the collecting compartment of the tank, it is removed to be used again in drilling operations. A conveyor extending along the bottom of the tank is used to move the settled solids to the collecting compartment, from which they are removed and pumped through a centrifuge to recover residual fluids.

Owner:HARDING DARIN MERLE

Floating skimmer apparatus with up-flow filter

InactiveUS8034234B2General water supply conservationTreatment involving filtrationWater filterFiltration

The present invention is a storm water filter system for filtering floatable debris and non-floating pollutants from storm water passing through a storm water drain system. The storm water filtering system has a floatable skimmer therein for capturing floatable debris and trash from the storm water and a separate filtration system to filter non-floatable pollutants from water passing therethrough.

Owner:OLDCASTLE INFRASTRUCTURE INC

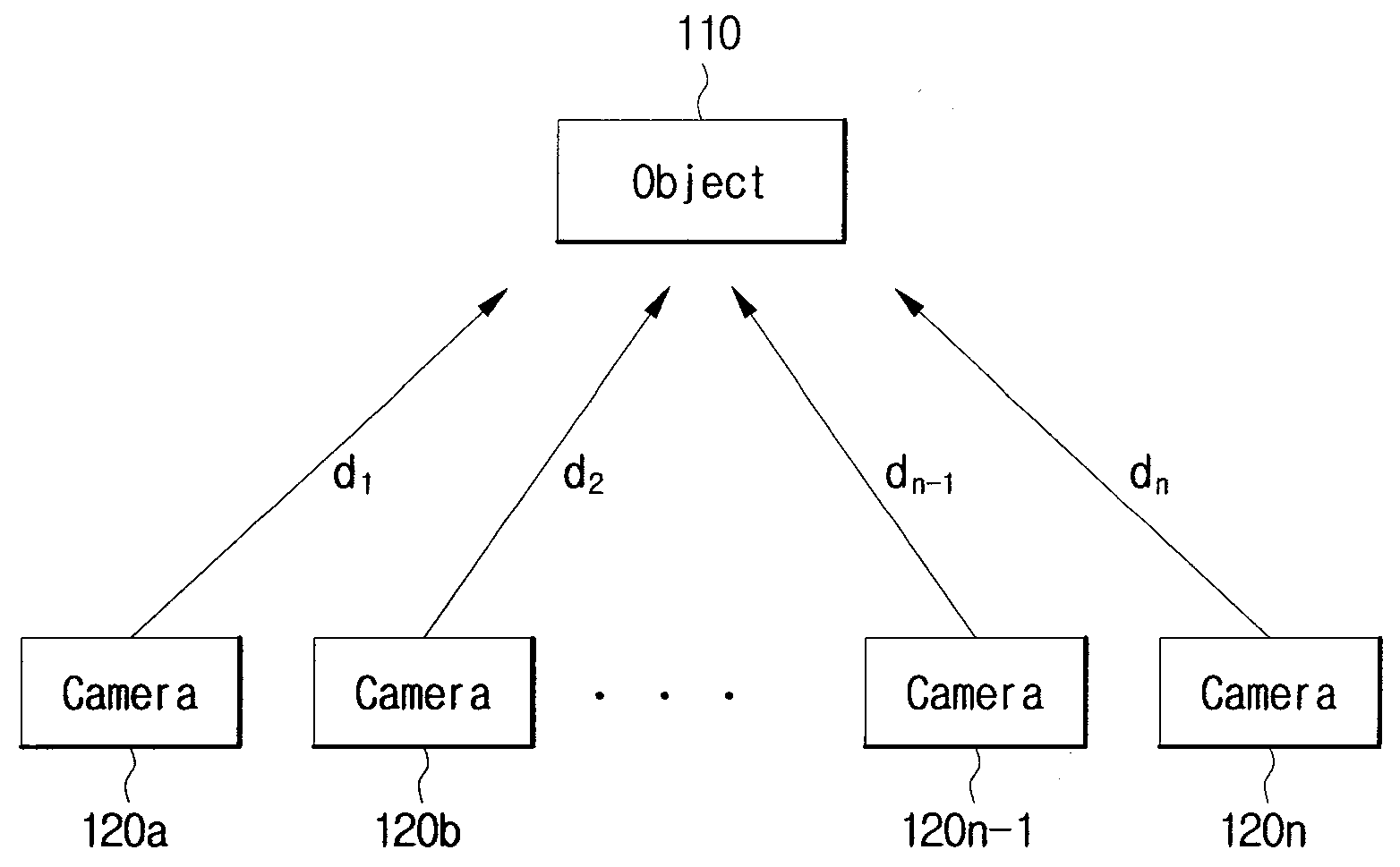

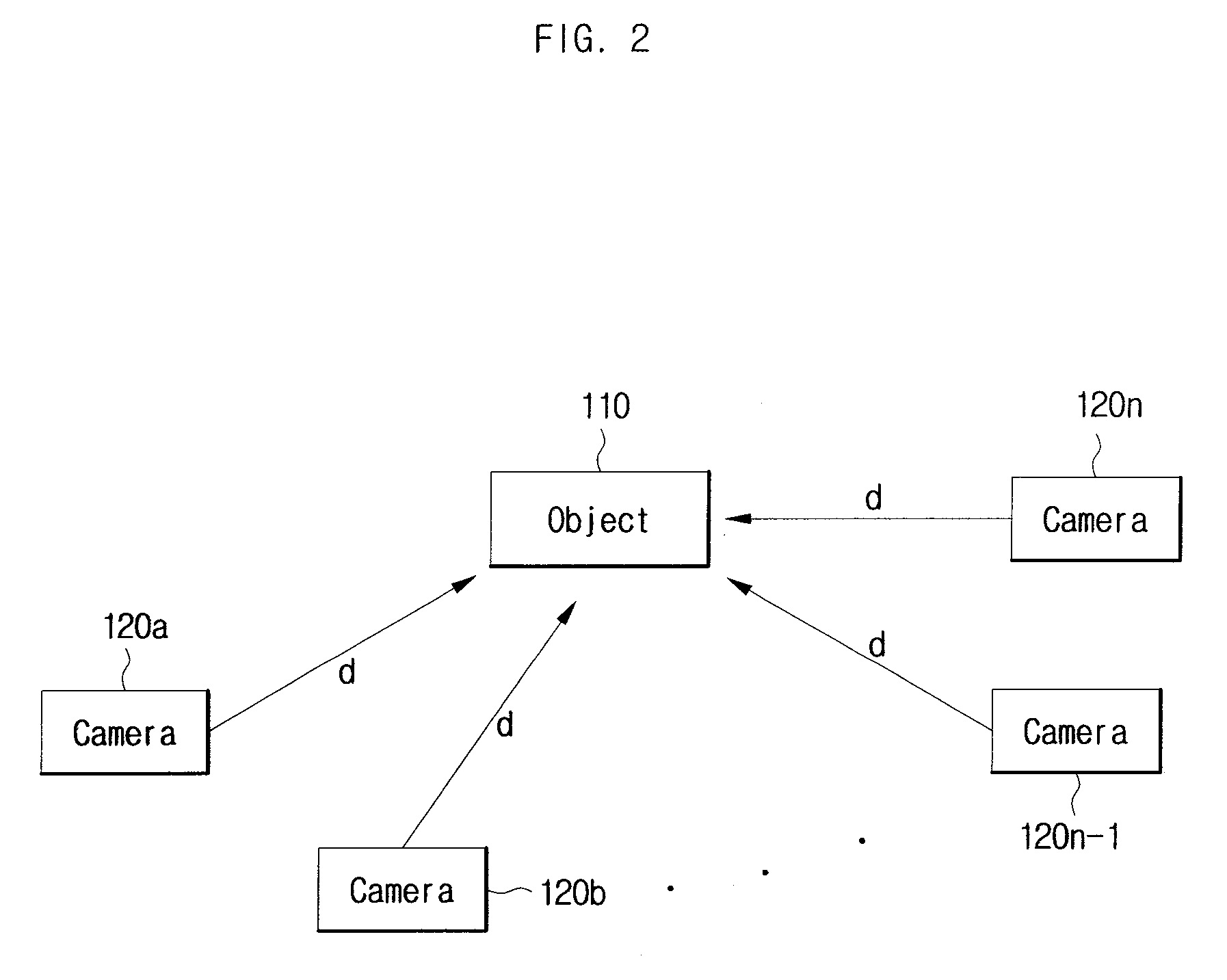

Reference Frame Ordering For Multi-View Coding

InactiveUS20080130738A1Improve picture qualityAvoid delayPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningThree dimensionalityComputer science

A method for setting the order of reference frames for multi-view coding and a recorded medium recording the method are disclosed. The method of setting the order of reference frames, in accordance with an embodiment of the present invention, comprises the steps of selecting the n (integer) number of frames of the same kind that have a same-view relation with said current frame and are encoded or decoded prior to said current frame as a first reference frame, selecting the m (integer) number of frames of the same kind that have a same-view relation with said current frame and have an inter-view relation with a frame of the same kind, which is encoded or decoded immediately before, as a second reference frame, wherein the frame of the same kind has a same-view relation with said current frame, and encoding or decoding said current frame by making reference to the frames of the same kind included in said first reference frame and said second reference frame. With the present invention, an improved picture quality and three-dimensionality can be provided, and the delay in processing time can be prevented when using the reference frame.

Owner:HUMAX CO LTD

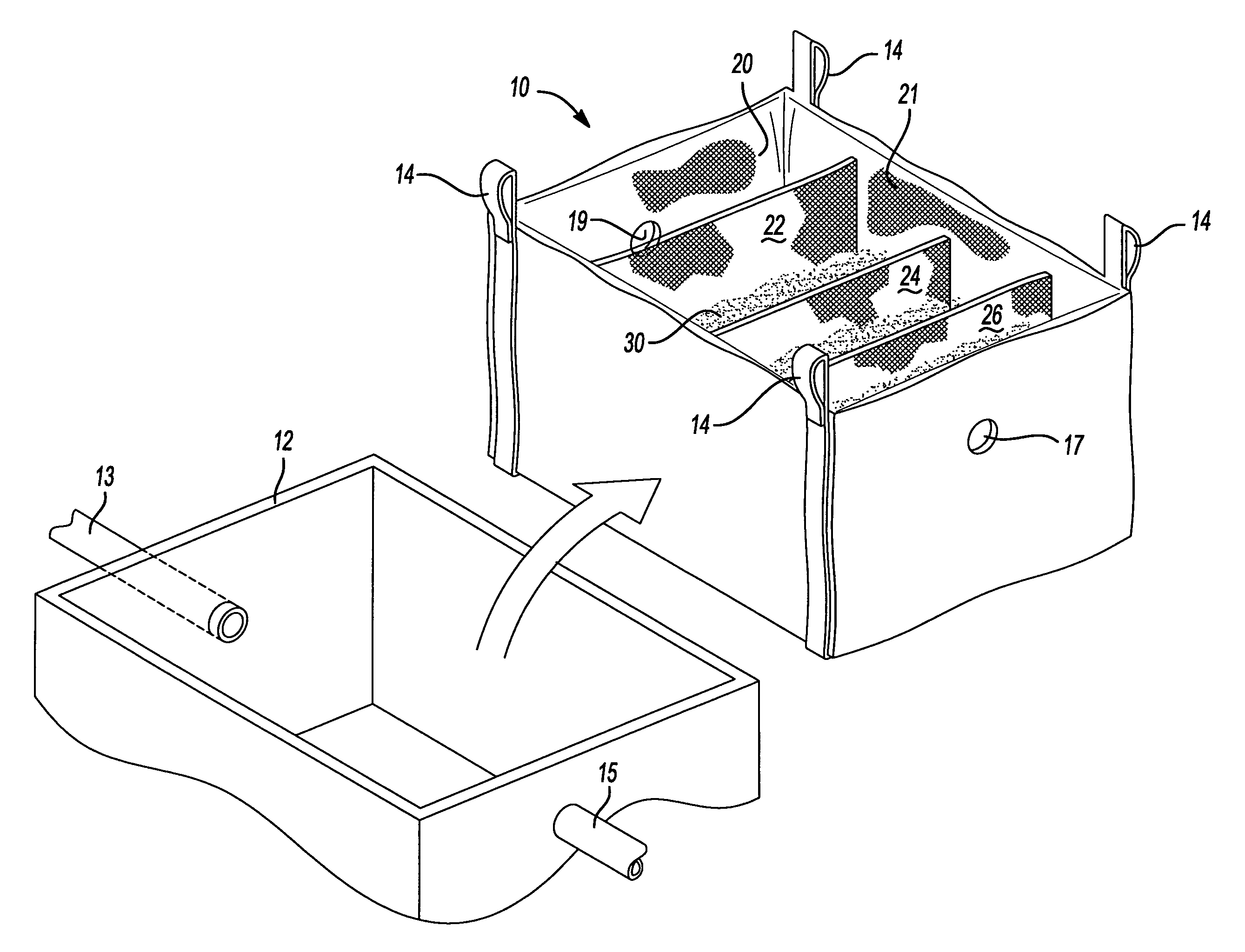

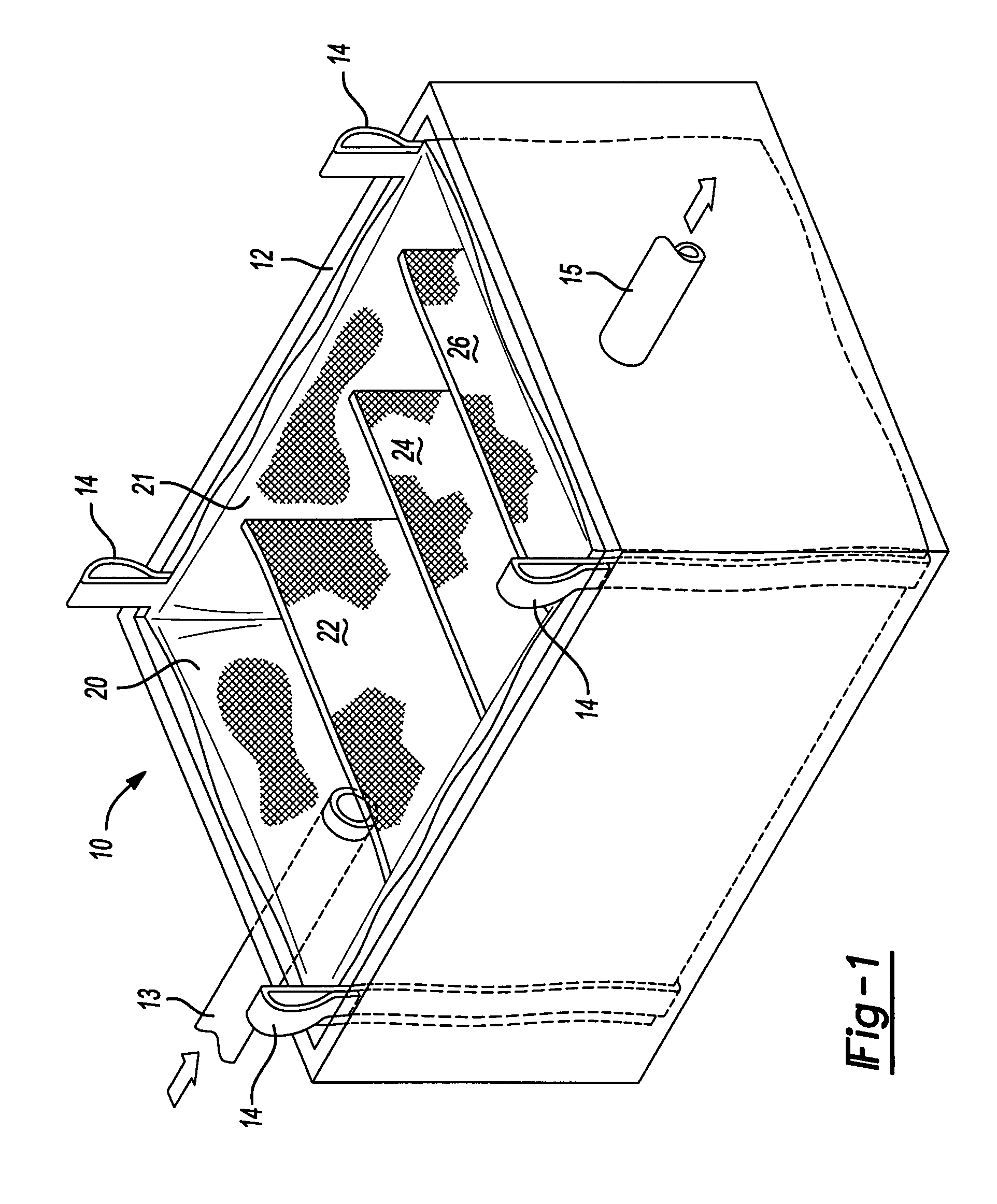

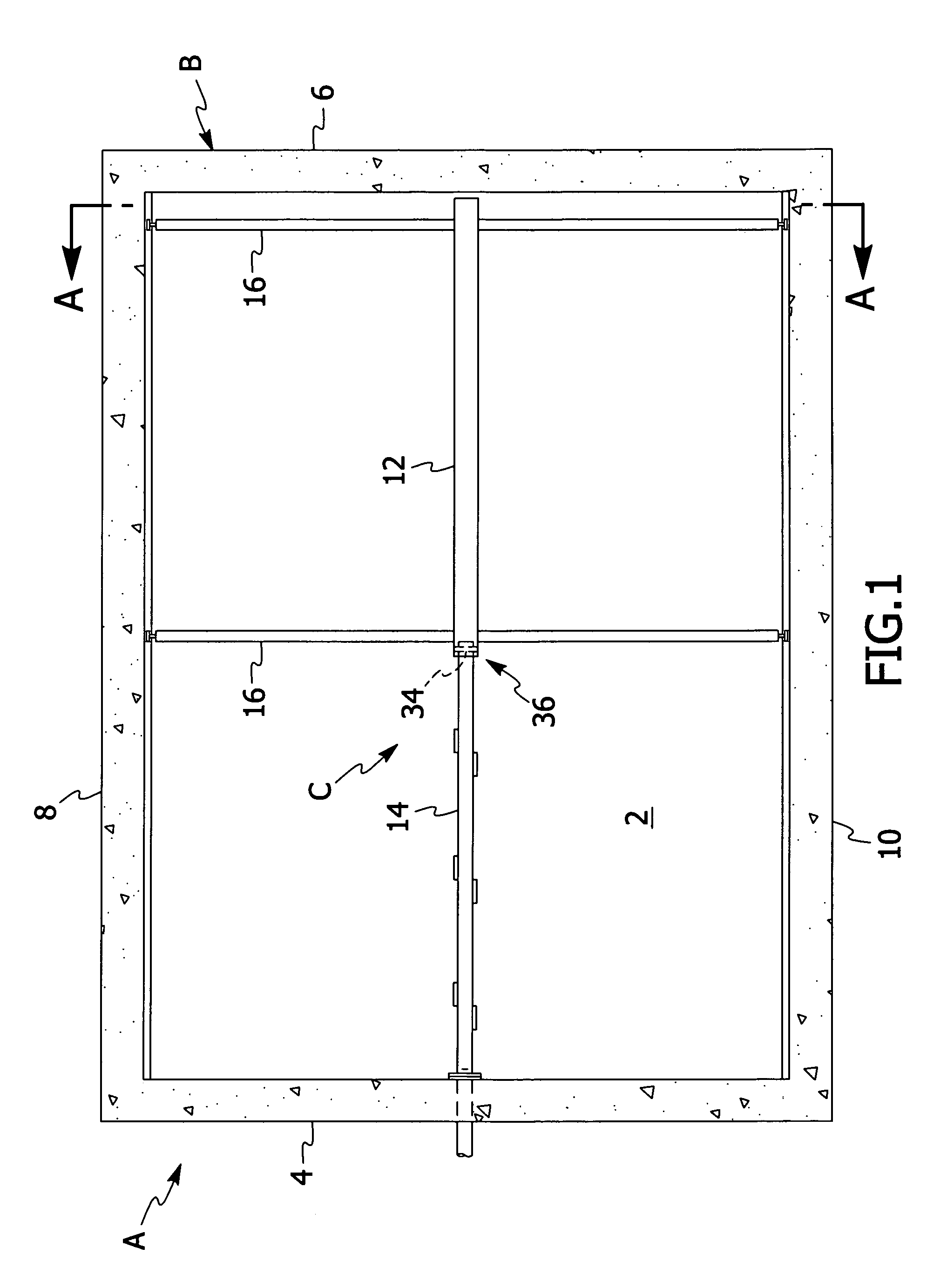

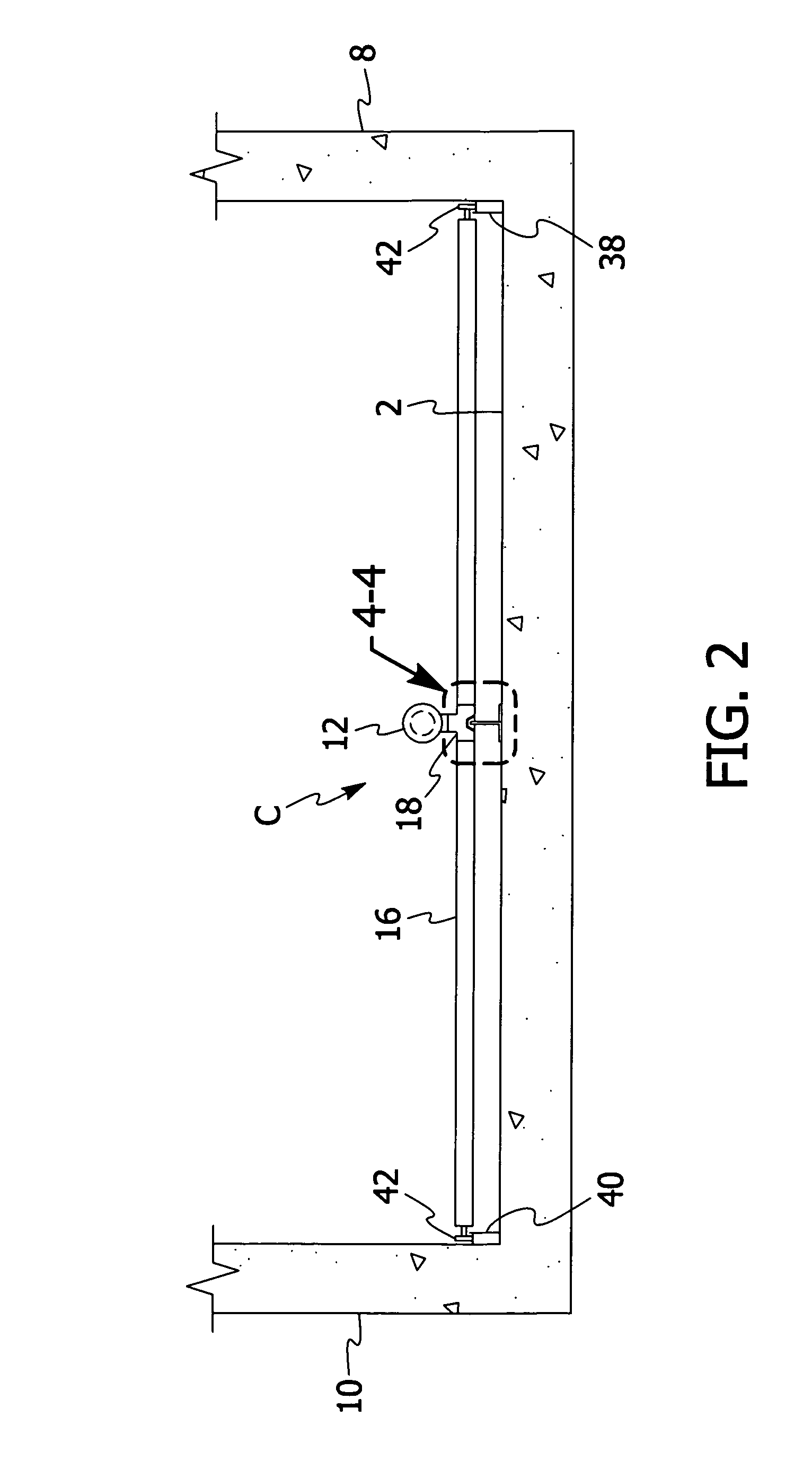

Disposable weir liner

InactiveUS7438803B1Reduce downtimeThe process is convenient and fastSedimentation tanksWater/sewage treatmentParticulatesFiltration

A garnet settling / filtration system for use with a plurality of machine tools such as a water jet cutting machine is described. The garnet settling / filtration system comprises a settling tank, which utilizes a removable, disposable settling weir, which is received therein. The settling weir drops into the settling tank and provides an over-under flow system through which the garnet slurry must travel. As the flow of the slurry travels over and under the incorporated series of baffles, the garnet particulate settles out on the bottom of the liner. Once the liner has reached its maximum holding capacity, a series of incorporated, reinforced removal loops located near the top of the liner allow for the easy and quick removal of the liner and the settled-out particulate from the settling tank. The liner can then be discarded and a new one replaced in a matter of minutes, thereby reducing downtime of the machine.

Owner:EBBSO

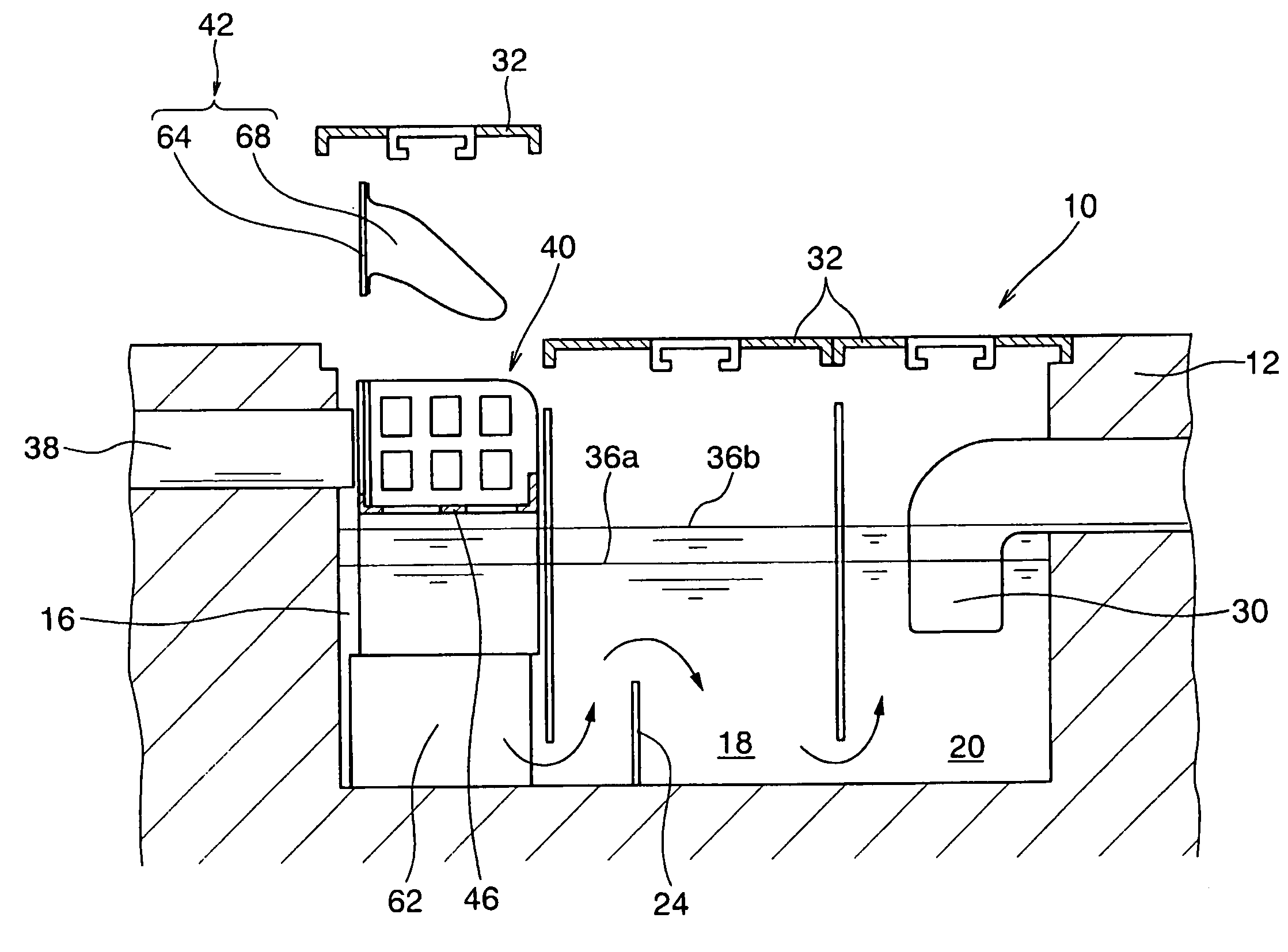

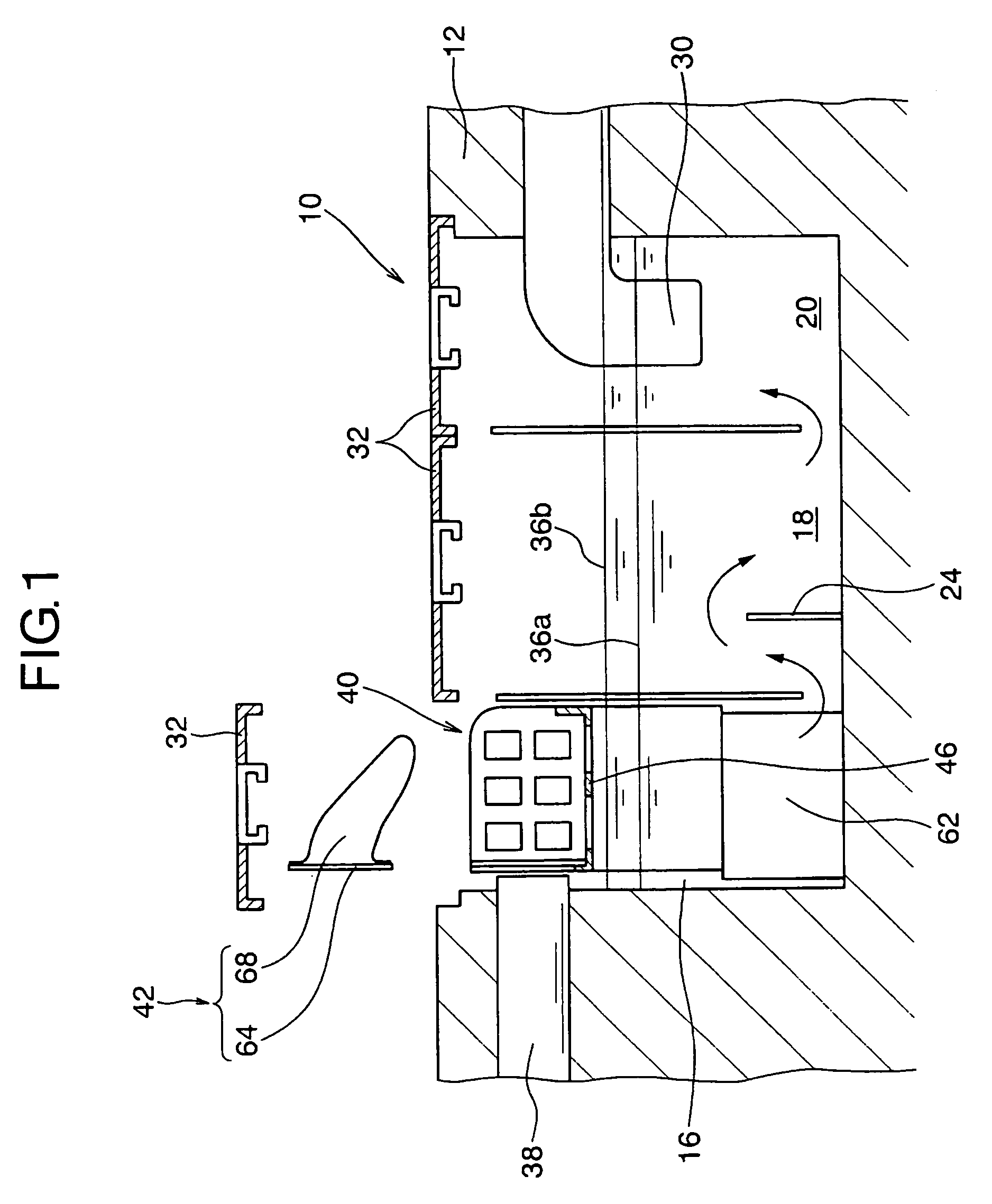

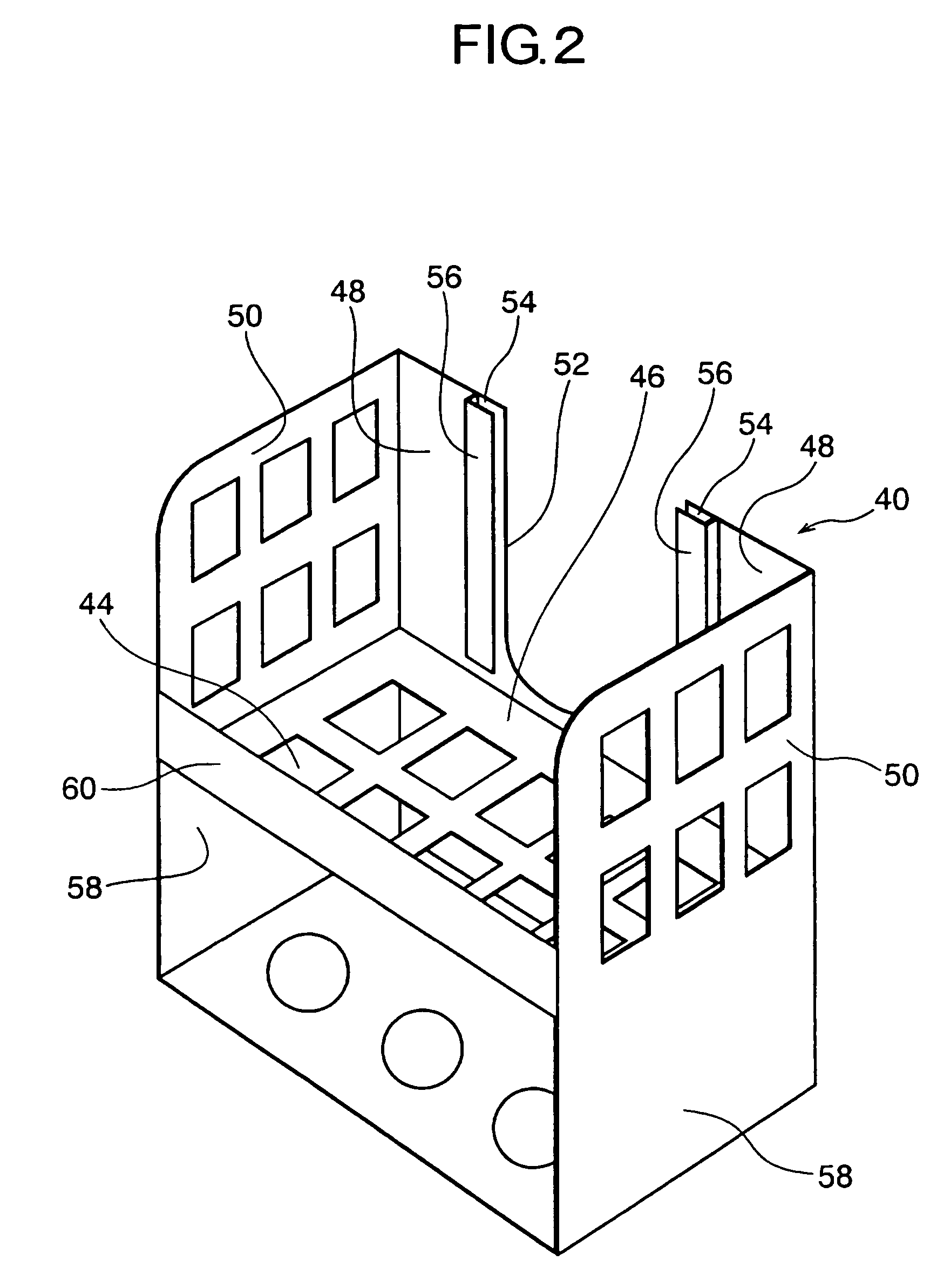

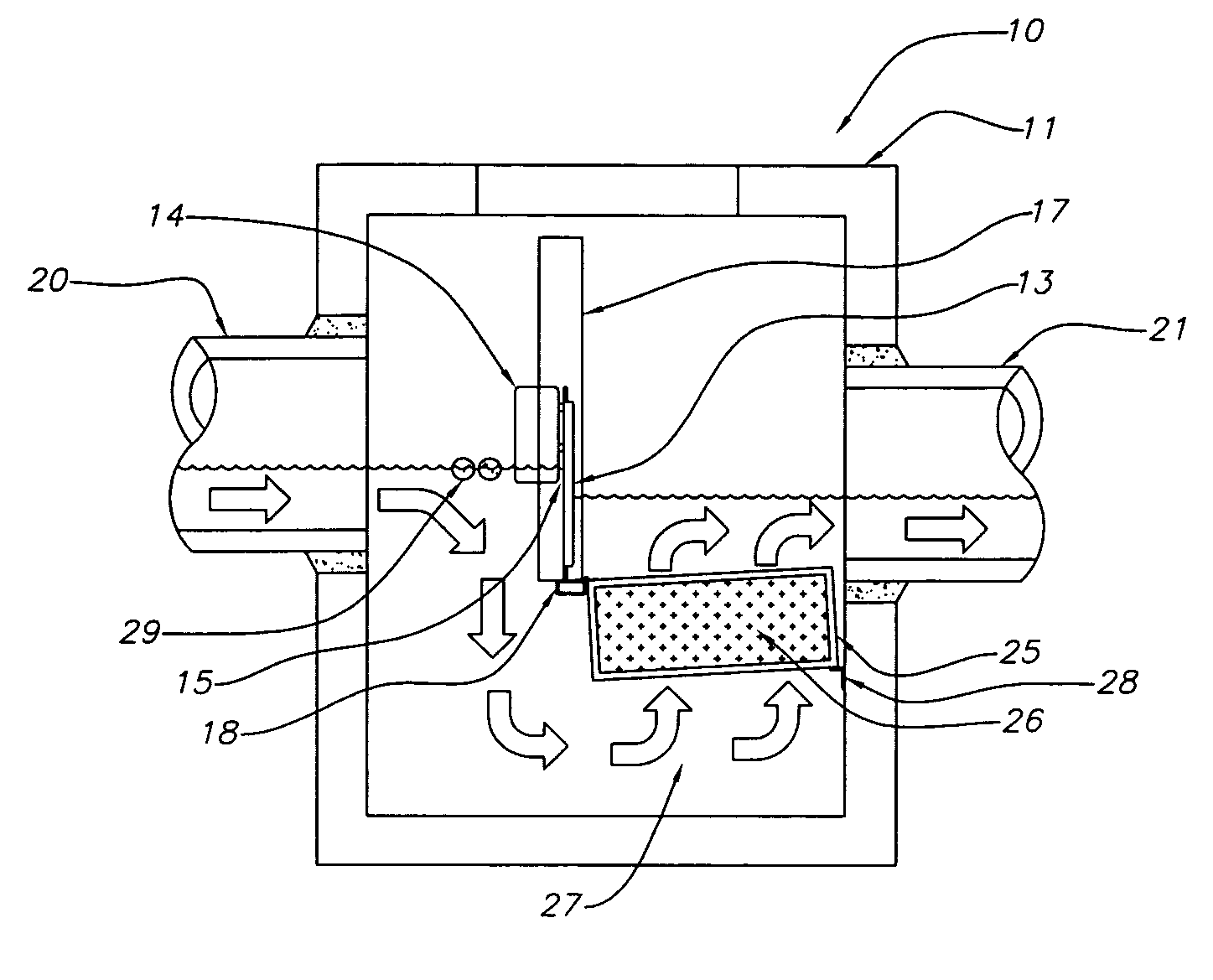

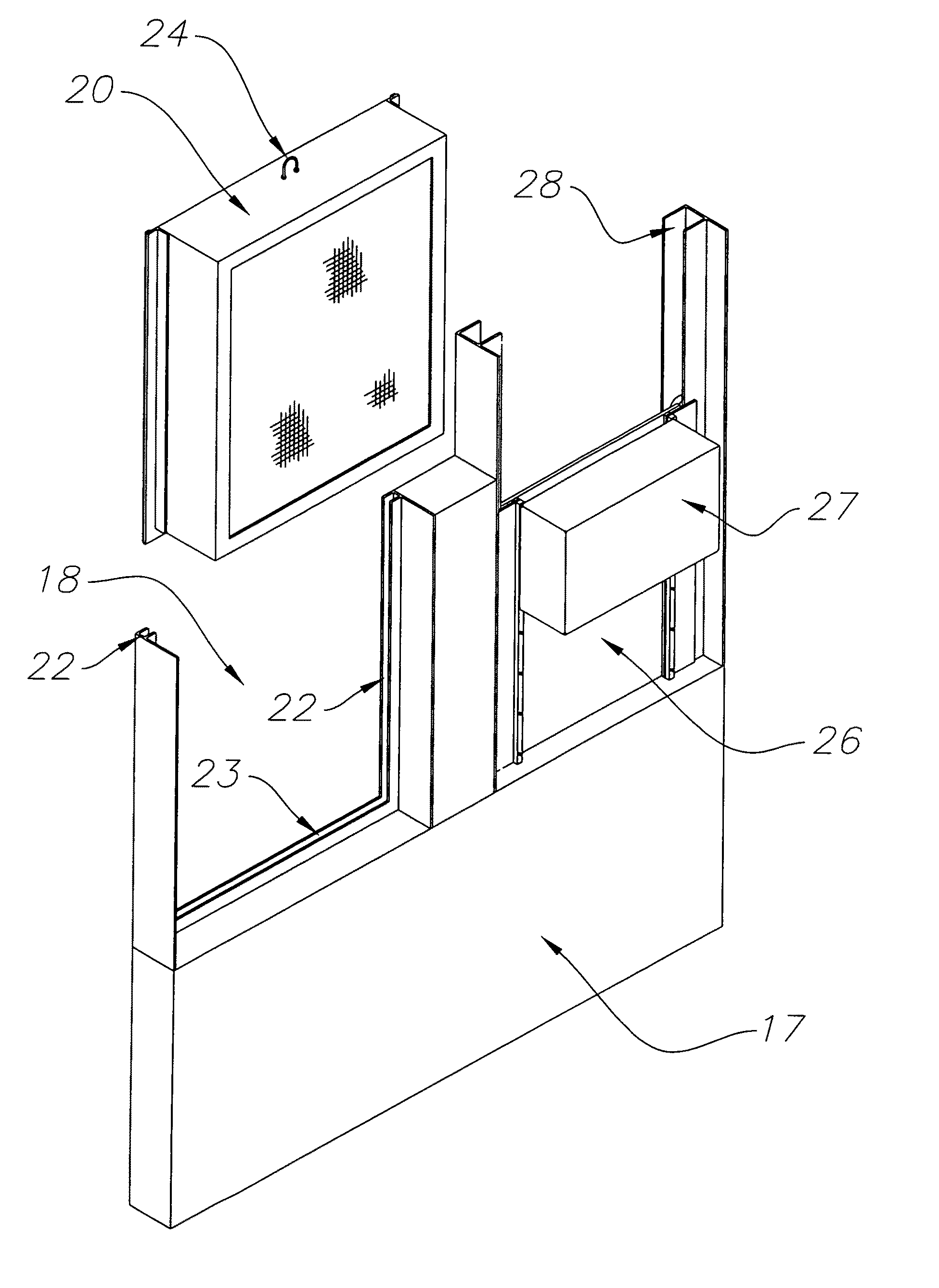

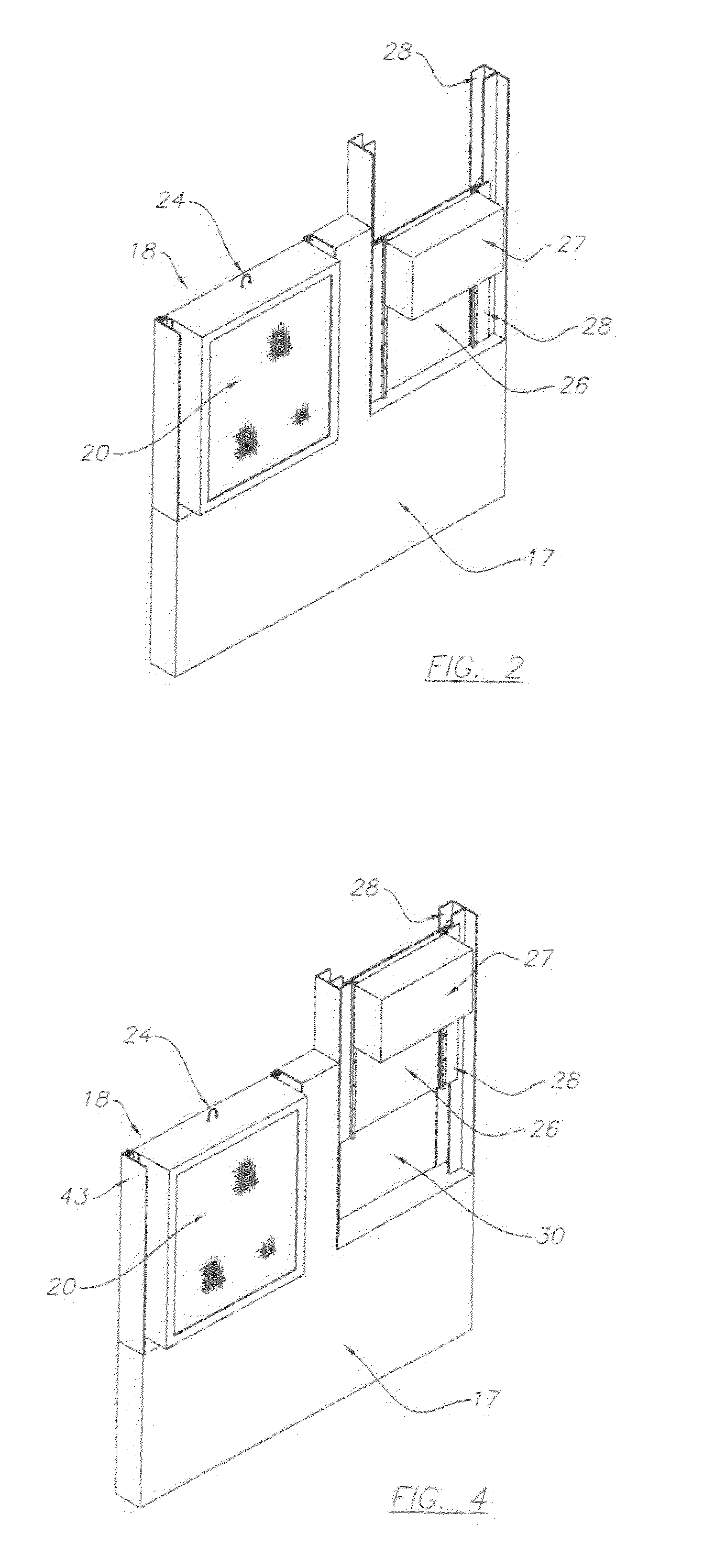

Floating baffle panel and filter apparatus

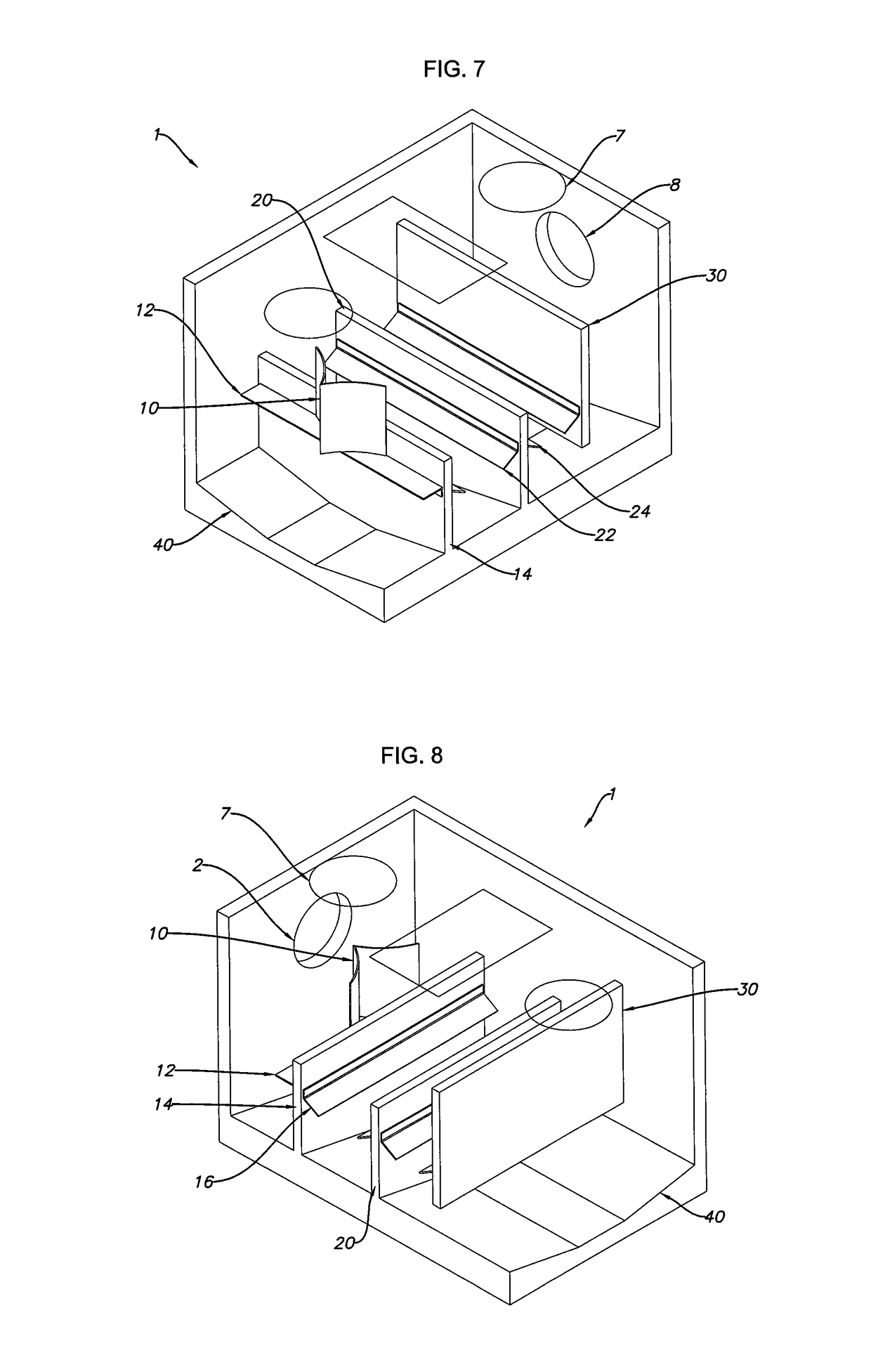

ActiveUS8083937B2Avoid accumulationAvoid passingGeneral water supply conservationTreatment involving filtrationWater filterFilter element

The present invention is a storm water filter system for filtering floatable debris and non-floating pollutants from storm water passing through a storm water drain system vault. The storm water filtering system has a vault having chamber having a wall between the inlet thereto and the outlet therefrom. The wall has a filter passageway therethrough for filtering the storm water and a floatable baffle panel covering a second passageway therethrough for capturing floatable debris and trash from the storm water. Storm water entering the vault inlet passes through a filter element and out the outlet and also can pass under the floating baffle panel when the floatable baffle panel is floated to a raised position to thereby prevent storm water from accumulating on the inlet side of the wall.

Owner:OLDCASTLE INFRASTRUCTURE INC

Floating baffle panel and filter apparatus

ActiveUS20100078370A1Avoid accumulationAvoid passingGeneral water supply conservationTreatment involving filtrationWater filterStormwater

The present invention is a storm water filter system for filtering floatable debris and non-floating pollutants from storm water passing through a storm water drain system vault. The storm water filtering system has a vault having chamber having a wall between the inlet thereto and the outlet therefrom. The wall has a filter passageway therethrough for filtering the storm water and a floatable baffle panel covering a second passageway therethrough for capturing floatable debris and trash from the storm water. Storm water entering the vault inlet passes through a filter element and out the outlet and also can pass under the floating baffle panel when the floatable baffle panel is floated to a raised position to thereby prevent storm water from accumulating on the inlet side of the wall.

Owner:OLDCASTLE INFRASTRUCTURE INC

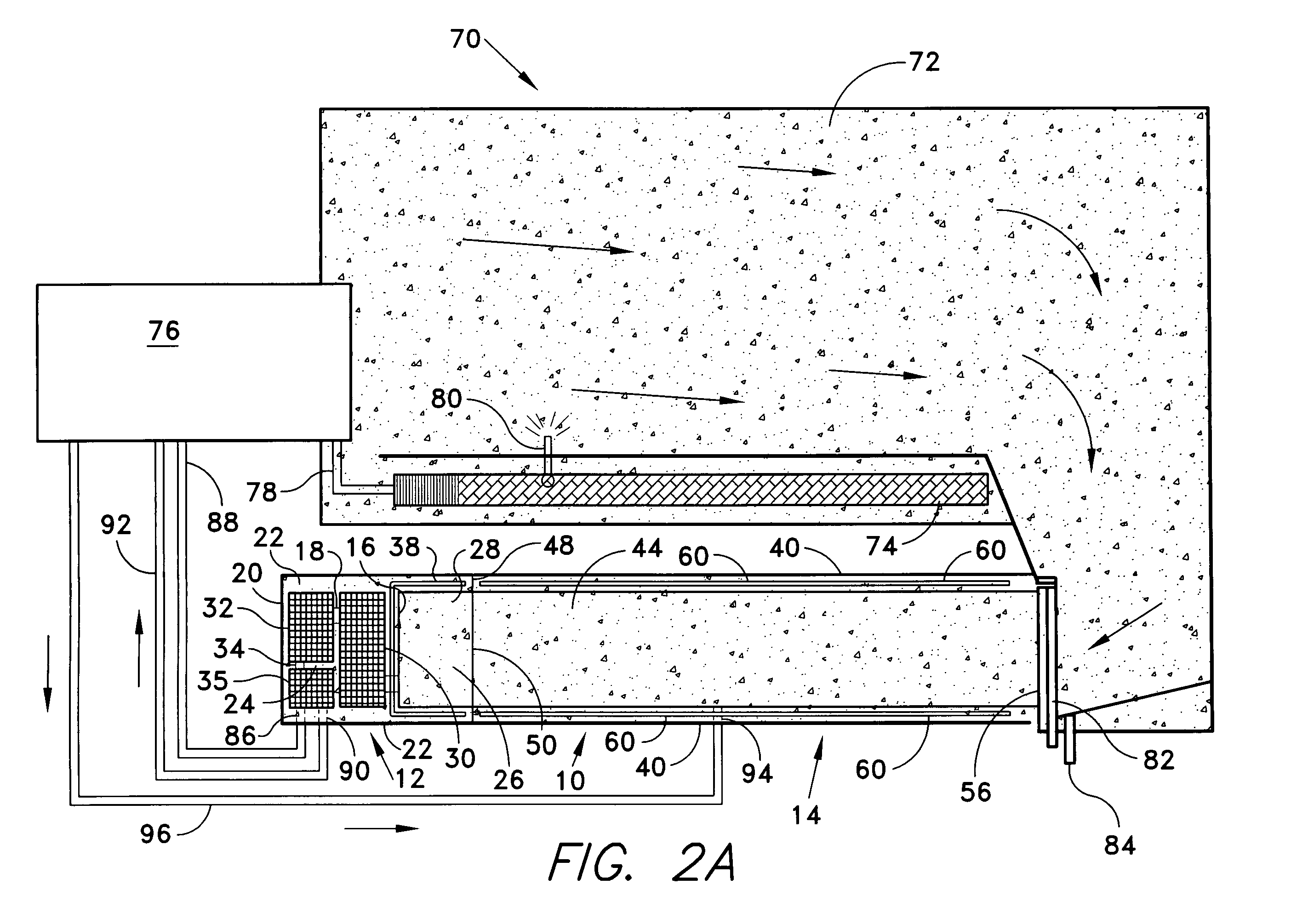

Dual screen treatment system

InactiveUS10202285B1Easy and inexpensiveAvoid areaFatty/oily/floating substances removal devicesSedimentation tanksFiltrationStorm water runoff

Vaults, boxes, systems, and methods of treatment systems to capture pollutants from storm water runoff and prevent the conveyance of these pollutants from entering a receiving water body or landscape area, which is designed to be a part of a local permanent storm water drainage infrastructure. A single treatment box, vault and system combines both drainage conveyance, multi-level treatment techniques, variable hydraulic capabilities, and easy and inexpensive methods for servicing the system. A flow spreader can split incoming water to pass into dual screen filtration systems. The system can include components selected from a shelf beneath the spreader, at least one baffle, skimmer, deflectors, media filtration and water pressure lines with spray heads for cleaning debris on a sloped floor.

Owner:OLDCASTLE INFRASTRUCTURE INC

Method and apparatus for removing cuttings from drilling fluids

The present invention is concerned with a method and apparatus for recycling drilling fluids used in the drilling of wells. The apparatus comprises a tank with a plurality of compartments. Used drilling fluid containing well cuttings or “solids” is pumped into a receiving compartment of the tank and directed towards a flow-reversing barrier. Reversal of the flow causes heavier solids to settle to the bottom of the tank. As fluid fills the receiving compartment, it flows downstream into an adjacent compartment by passing through a flow-restricting baffle that causes more solids to settle to the bottom of the tank. As fluid overflows from compartment to compartment in the tank, it passes through successive flow-restricting baffles causing further solids to settle to the bottom of the tank. When the fluid reaches the collecting compartment of the tank, it is removed to be used again in drilling operations. A conveyor extending along the bottom of the tank is used to move the settled solids to the collecting compartment, from which they are removed and pumped through a centrifuge to recover residual fluids.

Owner:HARDING DARIN MERLE

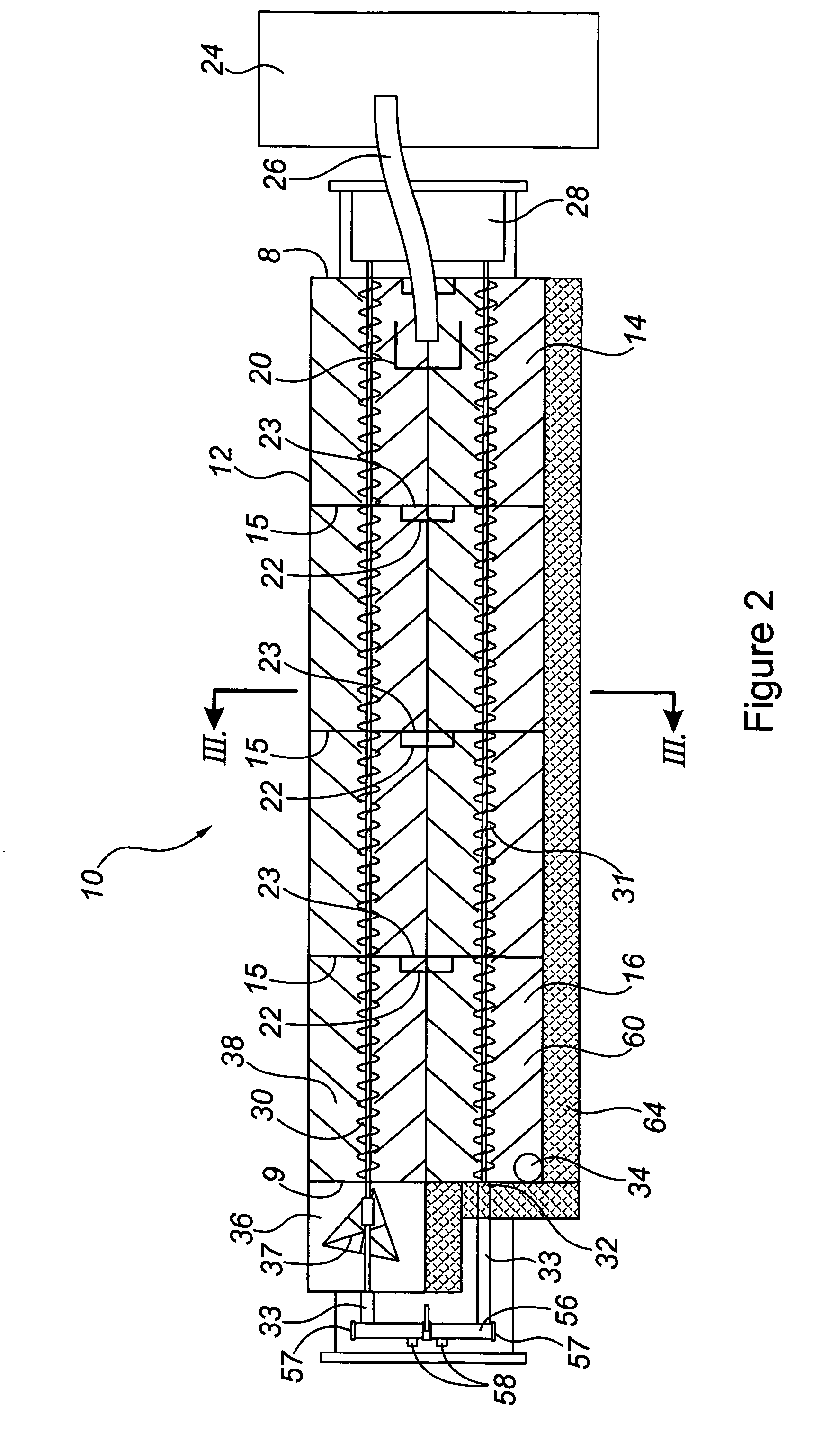

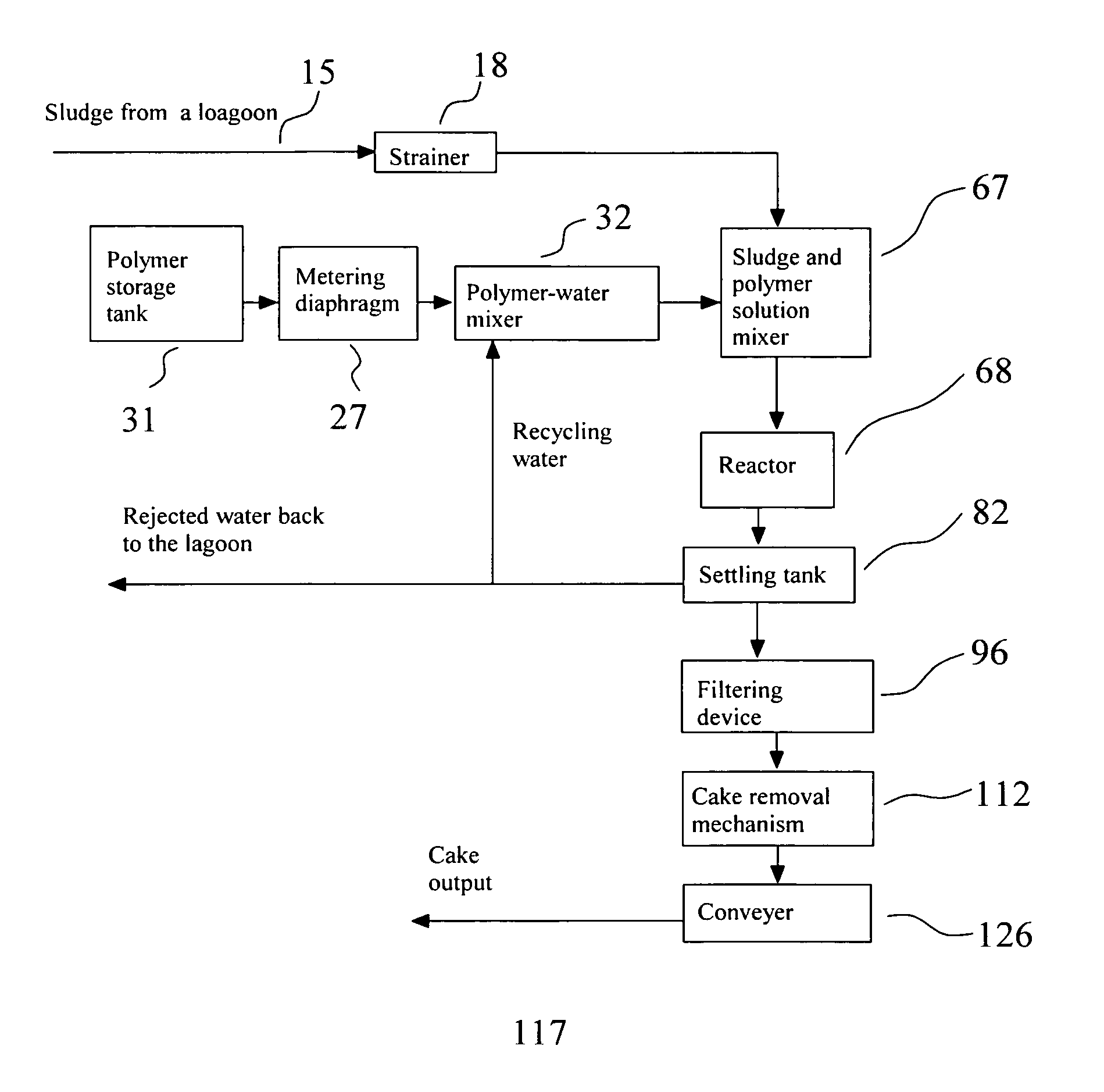

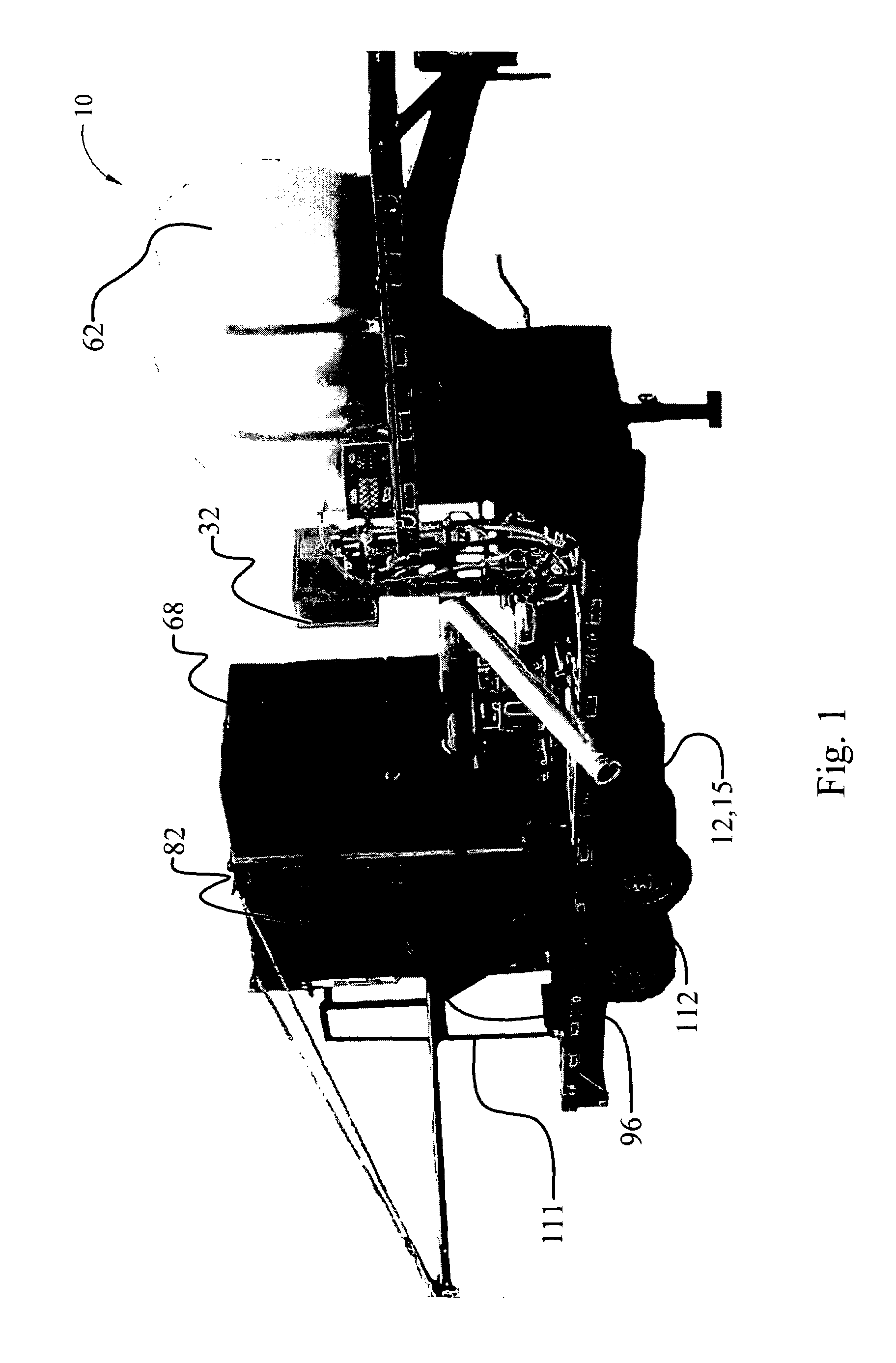

Fluid clarification system, method, and apparatus

InactiveUS20080121589A1Reduce load rateReduce the overall heightIon-exchanger regenerationSolid sorbent liquid separationEngineeringPolymer

A fluid clarification system and method is described in which fluid is passed through one or more settling compartments, each having a solids outlet at the base of the compartment. The base of each compartment includes inclined surfaces for guiding settled solids to the outlet. Also described is a polymer reaction trough including baffles to promote gentle mixing of inflow fluid with flocculant. The system is designed to reduce costs of transportation, flocculent, and solids handling. The system is preferably arranged to facilitate transport on a skid or trailer, while maximizing fluid handling capabilities and minimizing costs.

Owner:GODLIEN SCOTT BLAIR

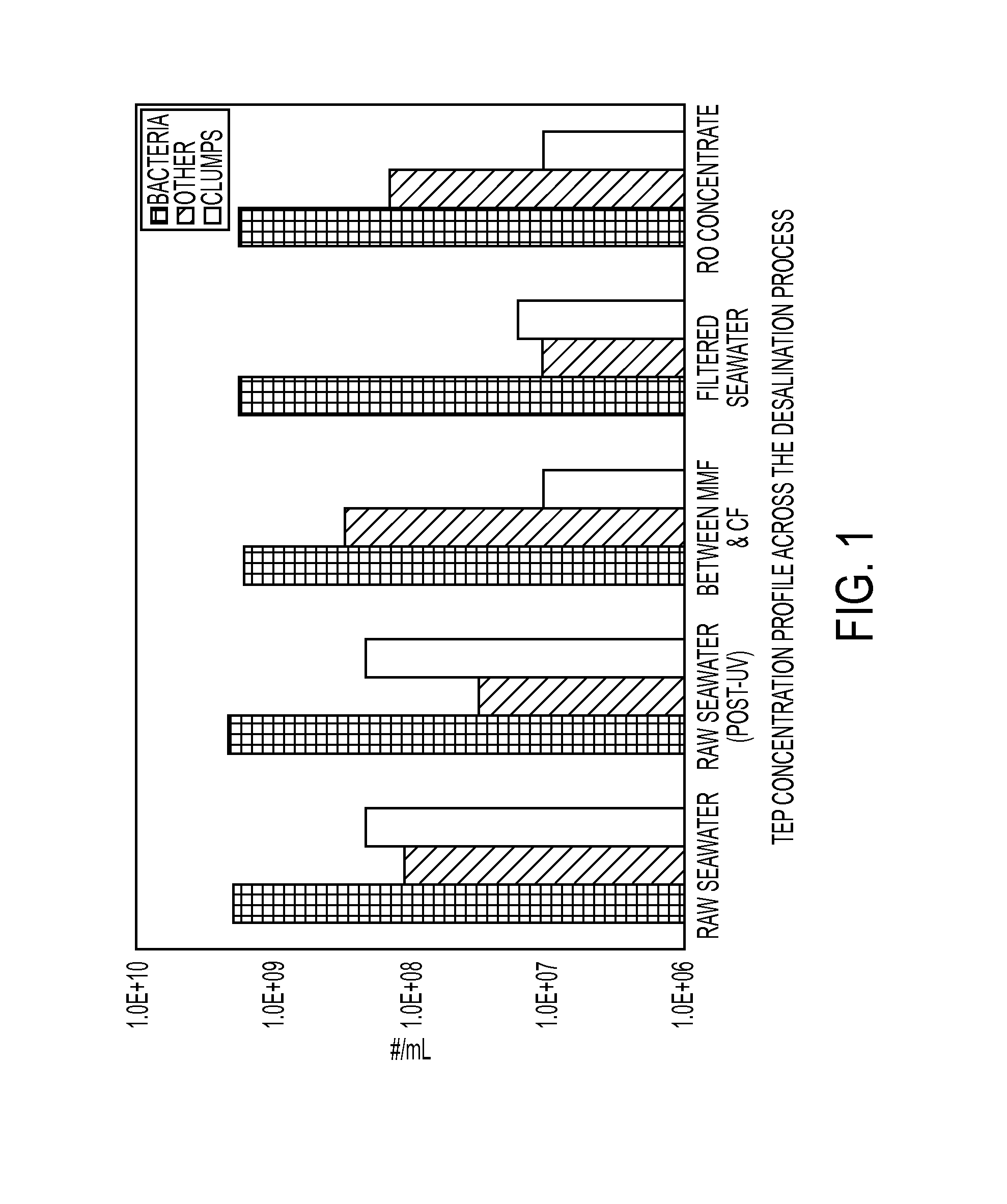

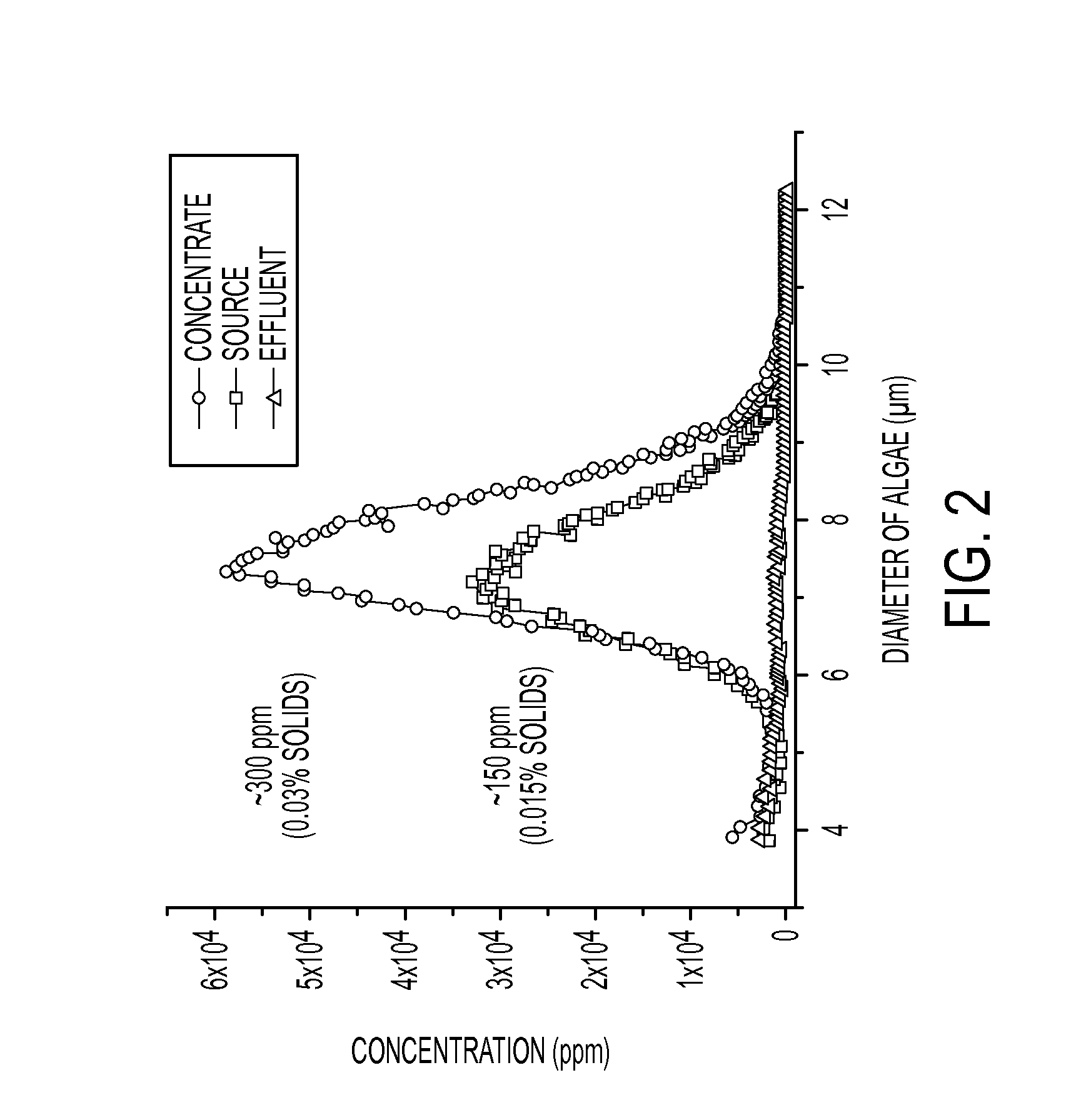

Systems and apparatus for seawater organics removal

InactiveUS20120152855A1Improve throughputPromote aggregationReversed direction vortexSeawater treatmentManufacturing technologyFiltration

A non-filtration pre-separation device and method for the removal of algae using the same, comprising a system having a hydrodynamic separator including at least one curved structure for the removal of bio-organisms from seawater, such structure having an inlet in operative connection with a source of raw seawater and a bifurcated outlet operative for passing pre-treated effluent fluid to a downstream filtration system and the removal of waste fluid. Various fluidic structures, implementations and selected fabrication techniques to realize such a device, whether singular or in stacked and / or packed parallel configuration are also provided.

Owner:PALO ALTO RES CENT INC

Portable settling and dewatering tank

InactiveUS20100206817A1Avoids any terminal cleanupAvoid cloggingMachines/enginesLoose filtering material filtersSludgeSlurry

A settling tank for dewatering a thin slurry is provided in a lined portable container and with a disposable filtering means. A novel method of processing the slurry by settlement of the solid phase and removal of the liquid phase in cycles avoids the clogging of the filtering means. The settling tank can be easily transported and dumped without requiring the transferring of residue sludge or the cleaning of equipment.

Owner:DIEZIGER HELEN IRENE

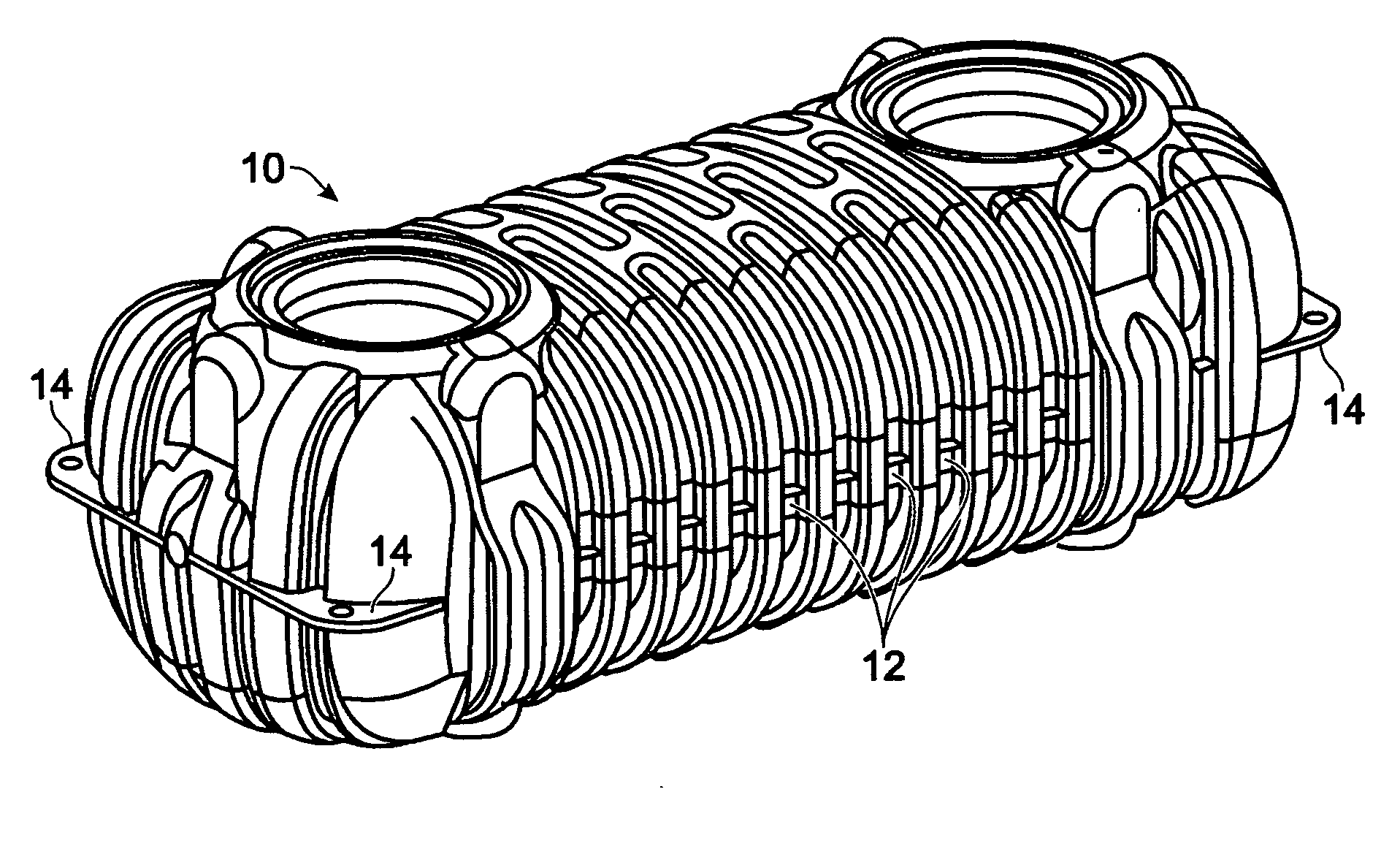

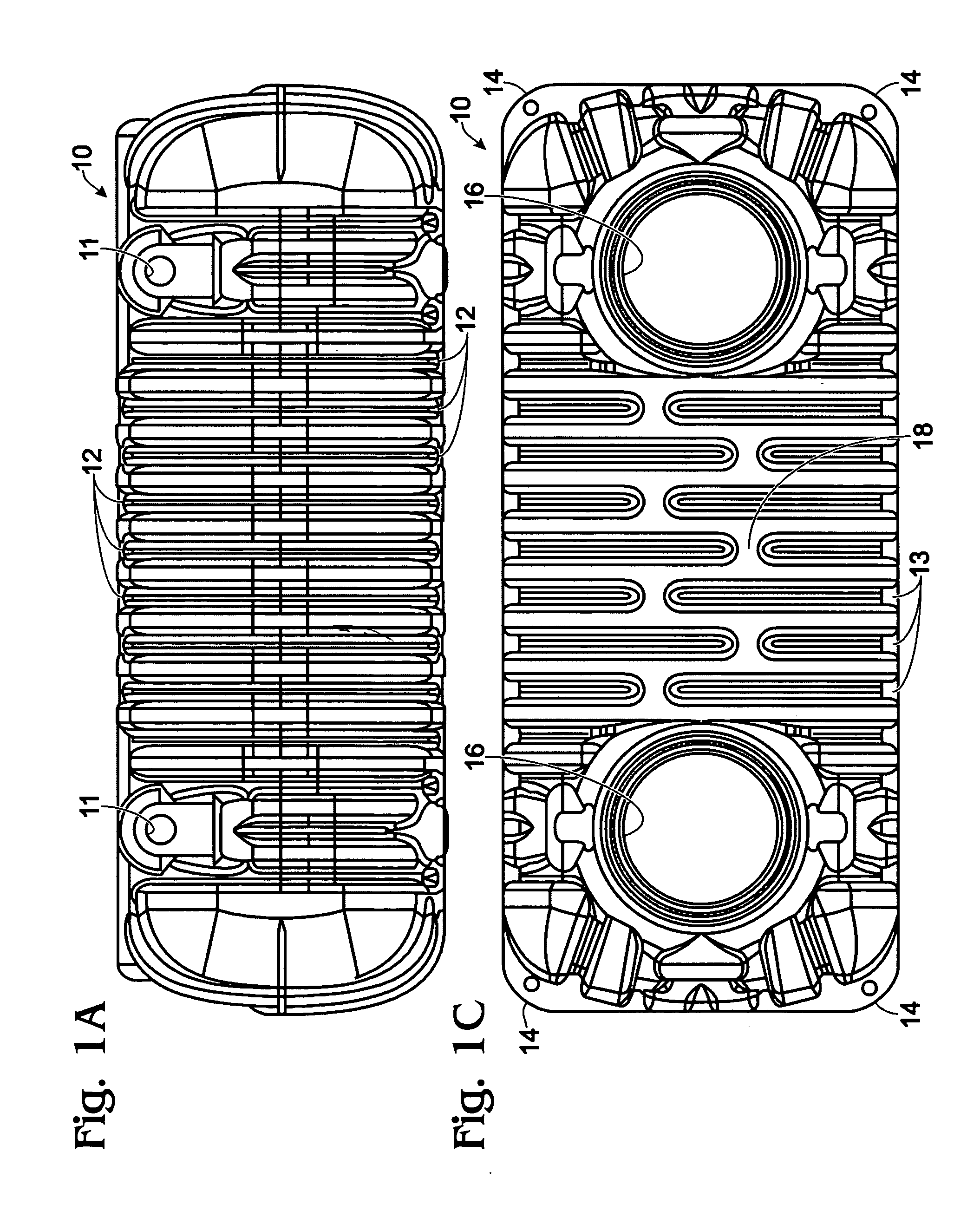

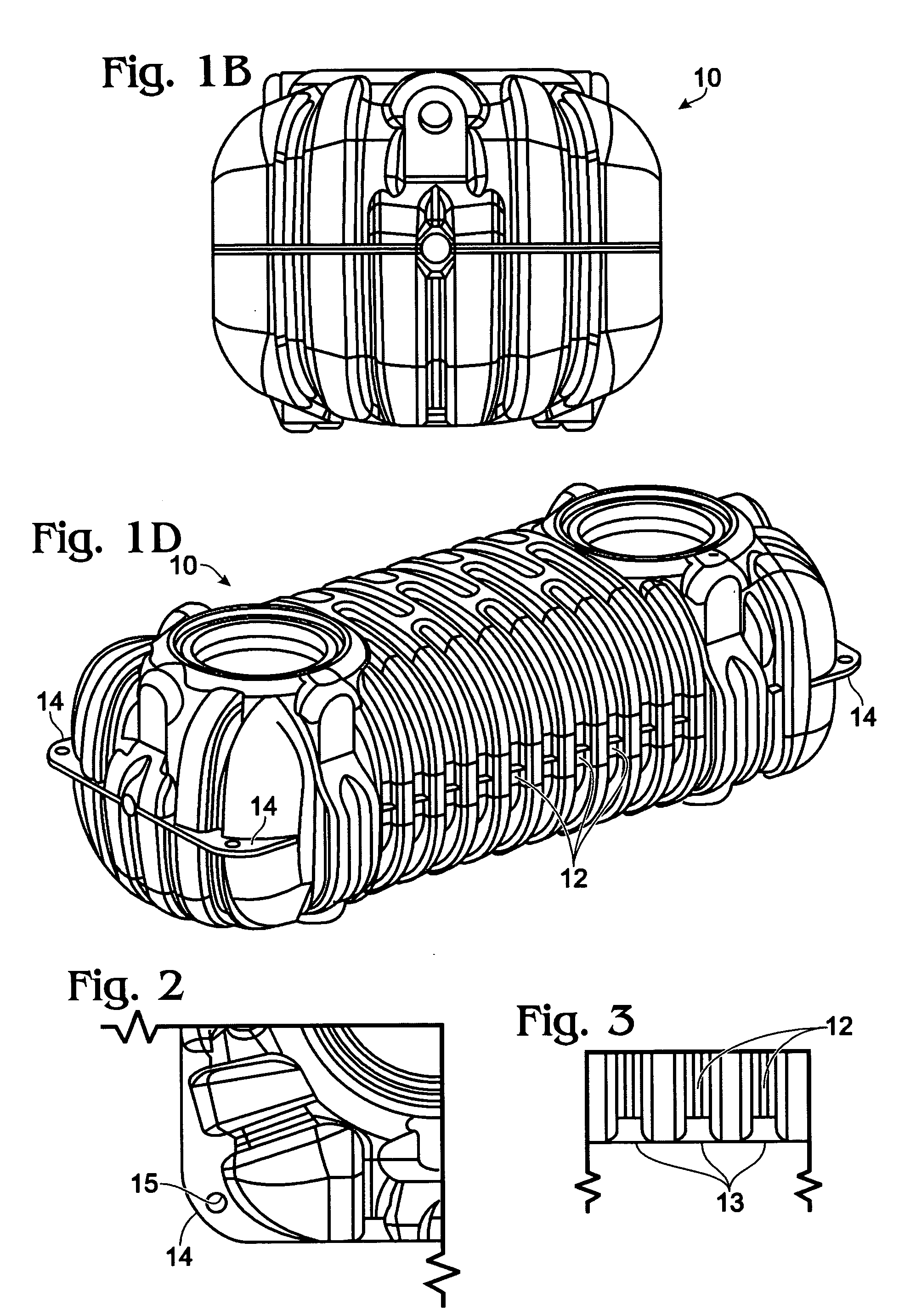

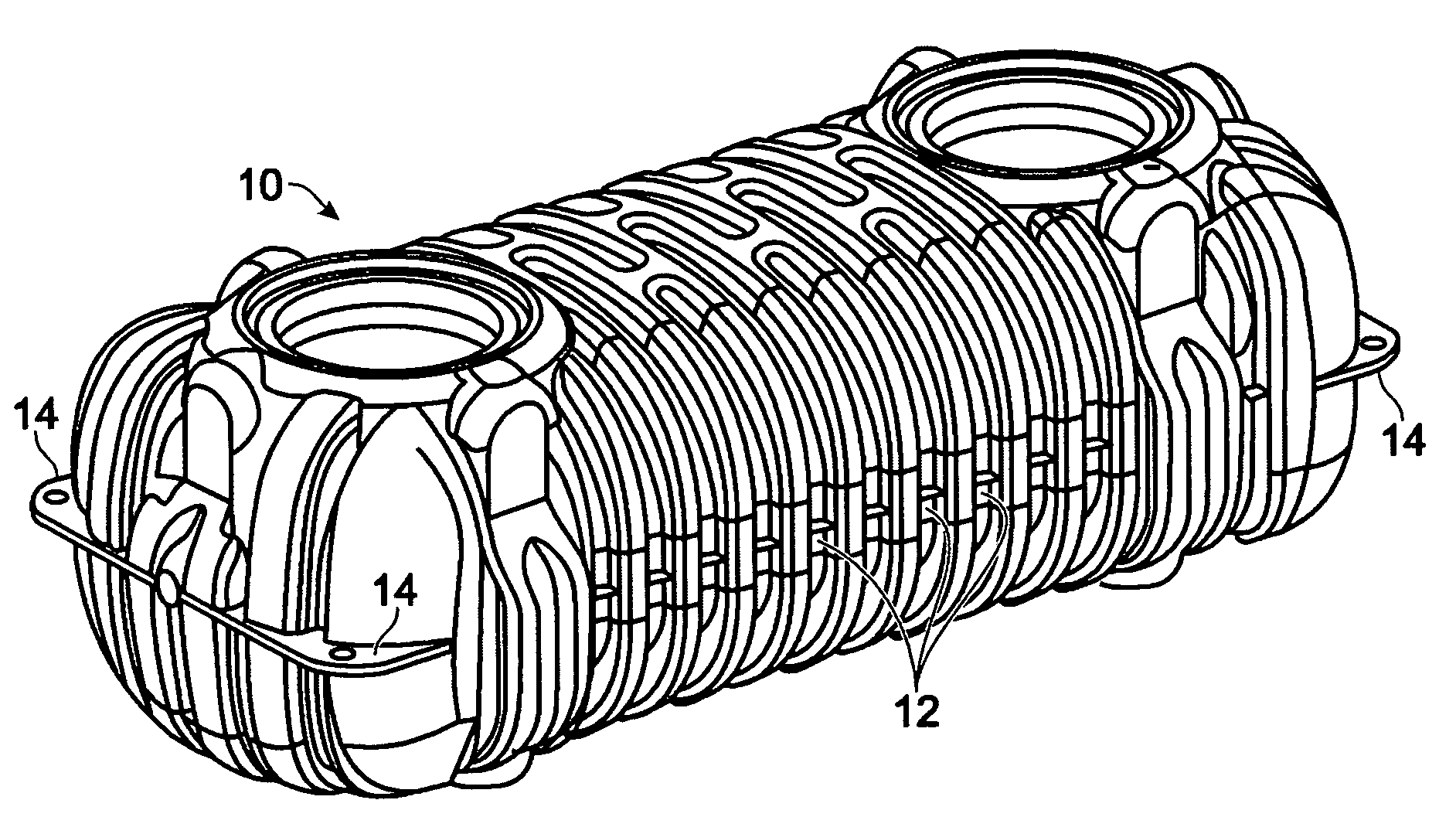

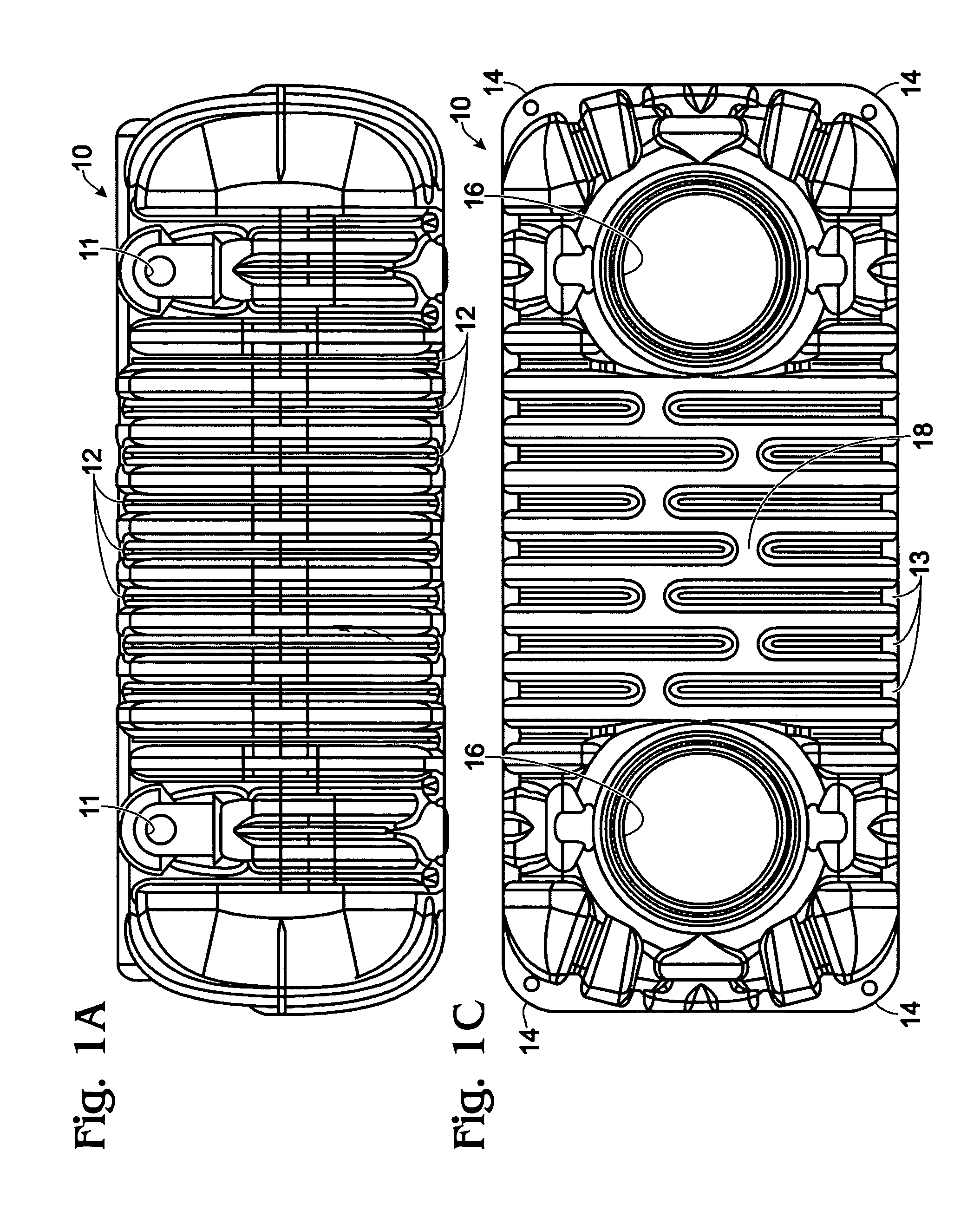

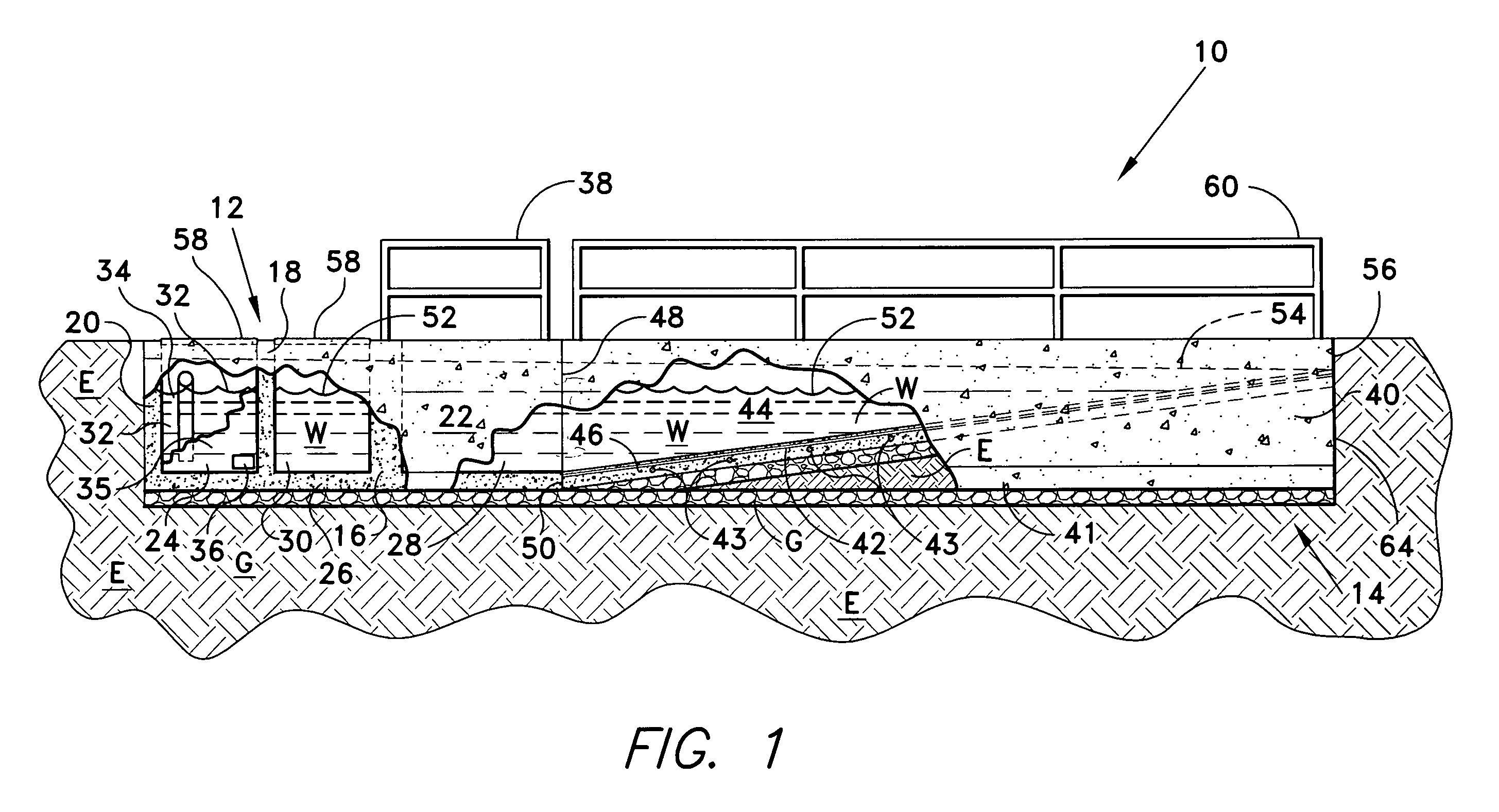

Blow Molded Septic Tank and Method of Manufacture

A septic tank formed of a blow molded body having an interior and an exterior. The septic tank body is formed from one or more layers of plastic material that are chosen for their chemical, mechanical or other properties. The septic tank body includes a plurality of integral ribs to provide circumferential structurally rigidity and also includes compression molded flange portions to provide axial structural rigidity. Additionally, septic tank covers and riser systems are provided.

Owner:ROTH GLOBAL PLASTICS

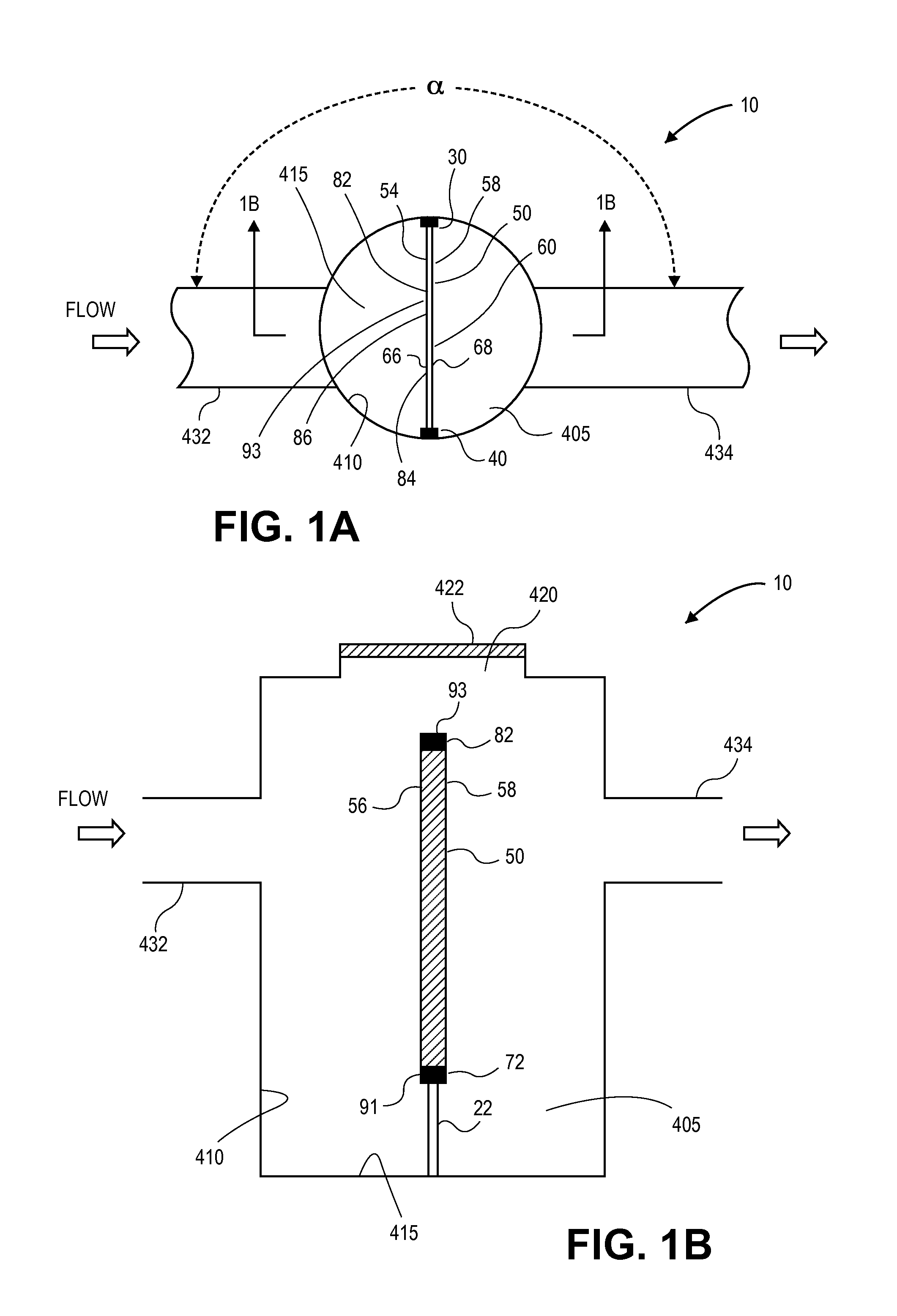

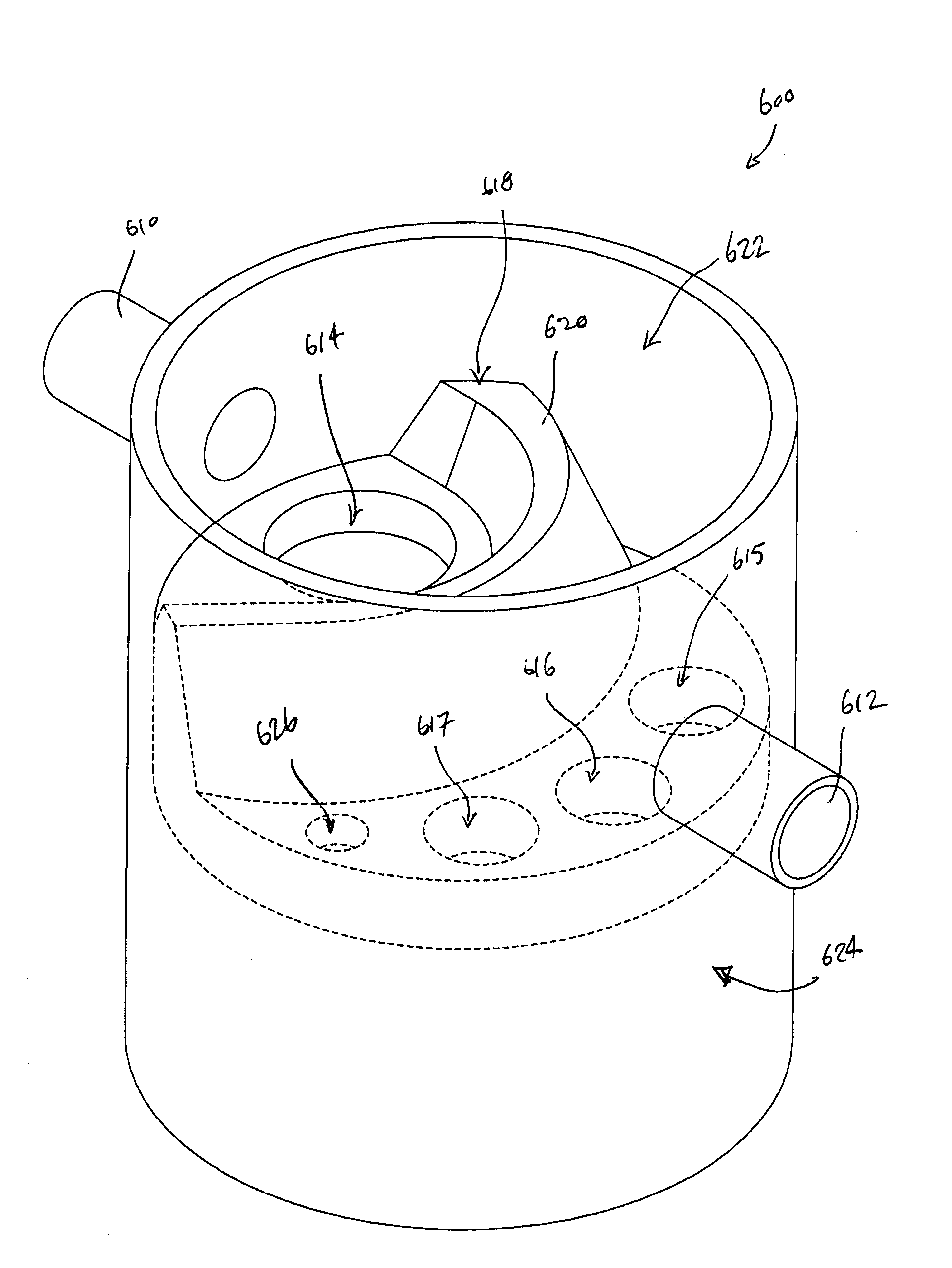

Hydroclone based fluid filtration system

InactiveUS20070045168A1Reduce morbiditySmall diameterLiquid separation auxillary apparatusReversed direction vortexCross-flow filtrationFluid filtration

A variety of improved hydroclone based fluid filtering systems are described. The hydroclones generally include a tank having an internal chamber and a filter (preferably a surface filter) that is positioned within the internal chamber. The filter defines a filtered fluid chamber within the internal chamber of the tank. The hydroclone may be operated such that a vortex of flowing fluid is formed between the chamber wall and the filter with the filter being located in the center of the vortex. With this arrangement, the filter acts as a cross-flow filter. In one aspect of the invention, the filter is a stepped filter. In another aspect of the invention, the filter is an surface filter, as for example, an electroformed metal surface filter. In some preferred embodiments, the openings in the filter are arranged as slots that extend substantially vertically so that they are oriented substantially perpendicular to the flow path of fluid flowing in the adjacent portion of the vortex. In another aspect of the invention, a circulating cleaning assembly is provided in the hydroclone region. The cleaning assembly is arranged to help clean the filter and is driven by the vortex of flowing fluid formed in the hydroclone region of the internal chamber. In yet another aspect of the invention, improved hydroclone intake structures are described. The described hydroclones may be used to filter water and other fluids in a wide variety of applications.

Owner:ACCELERATED FILTRATION INC

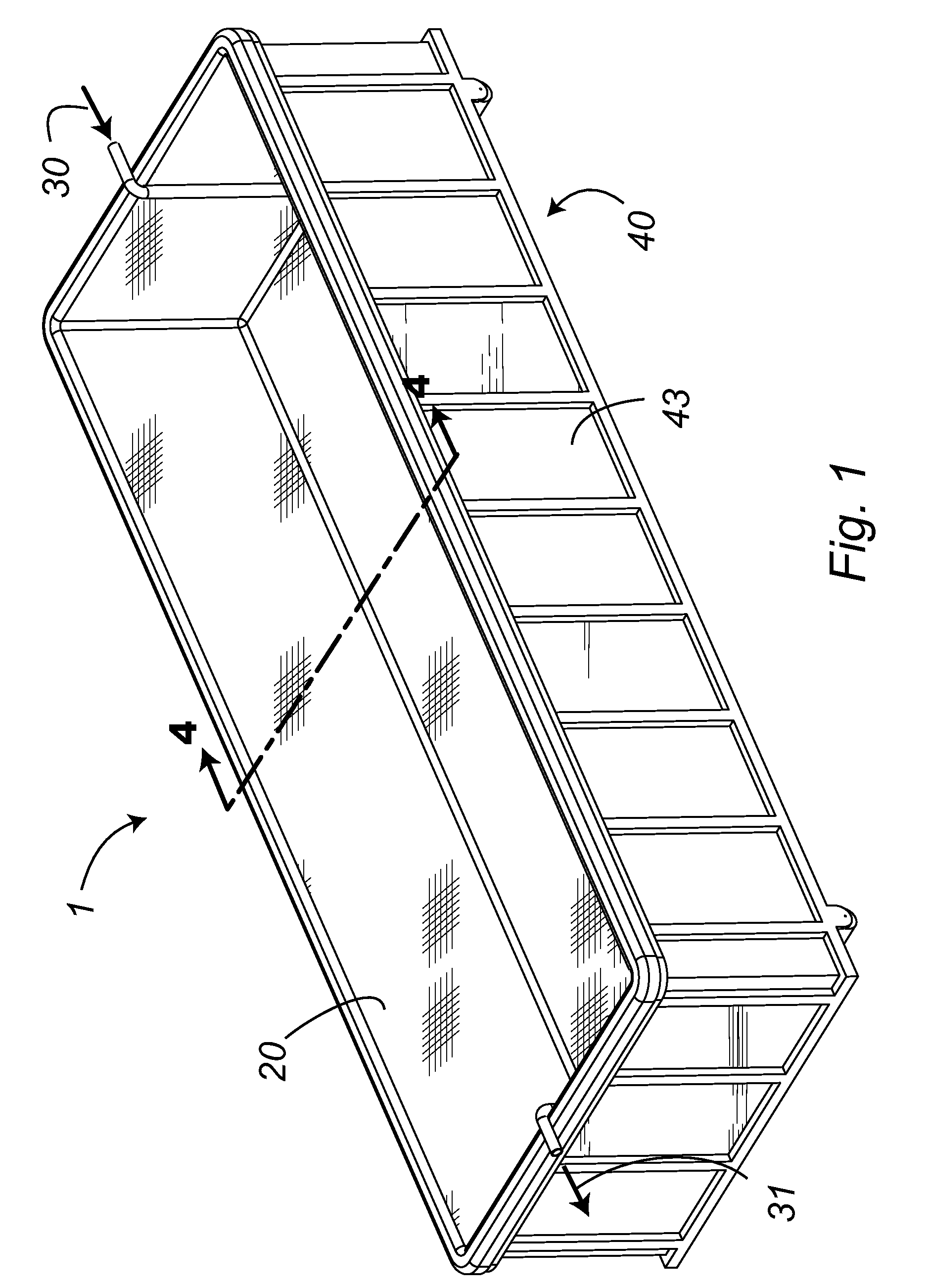

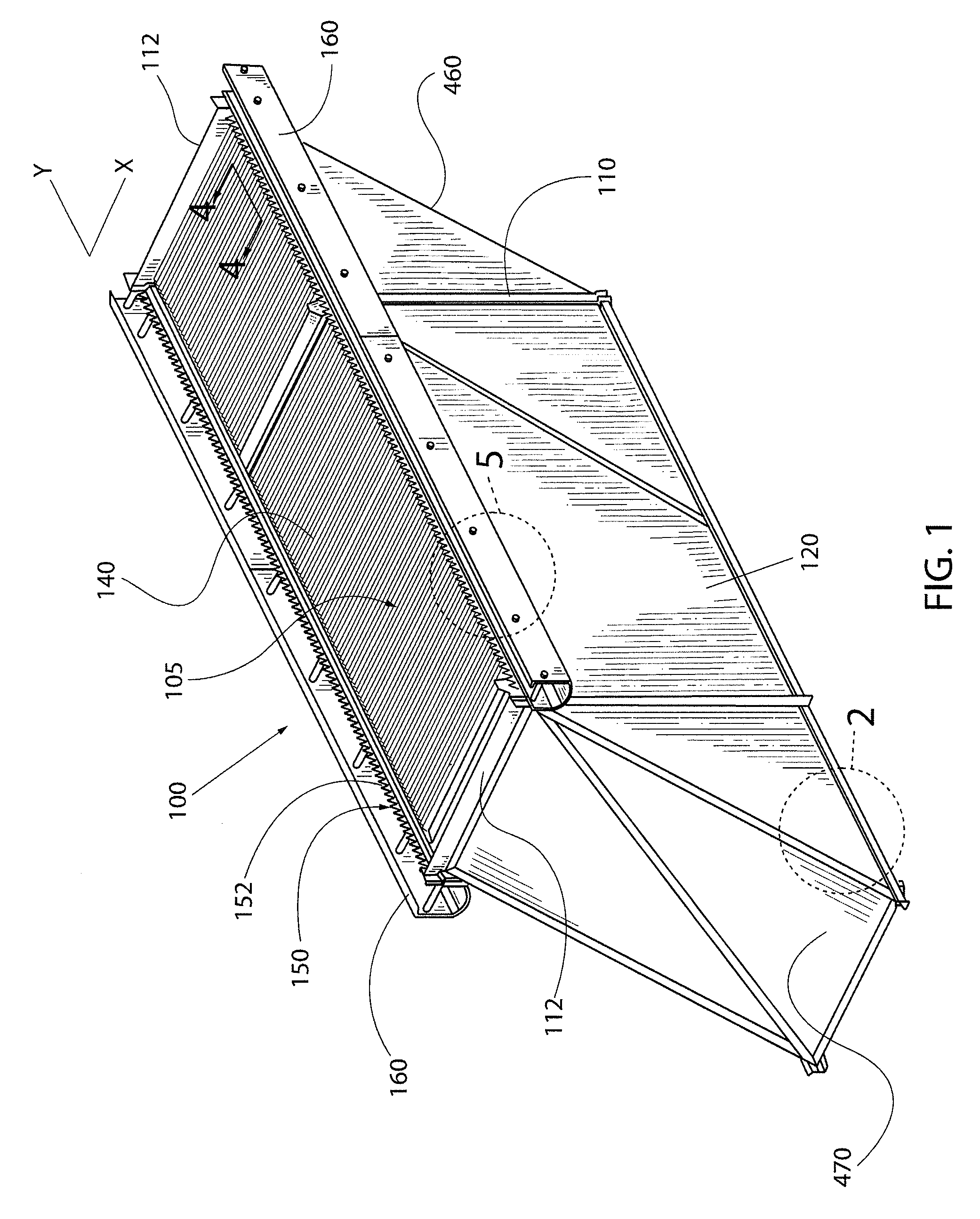

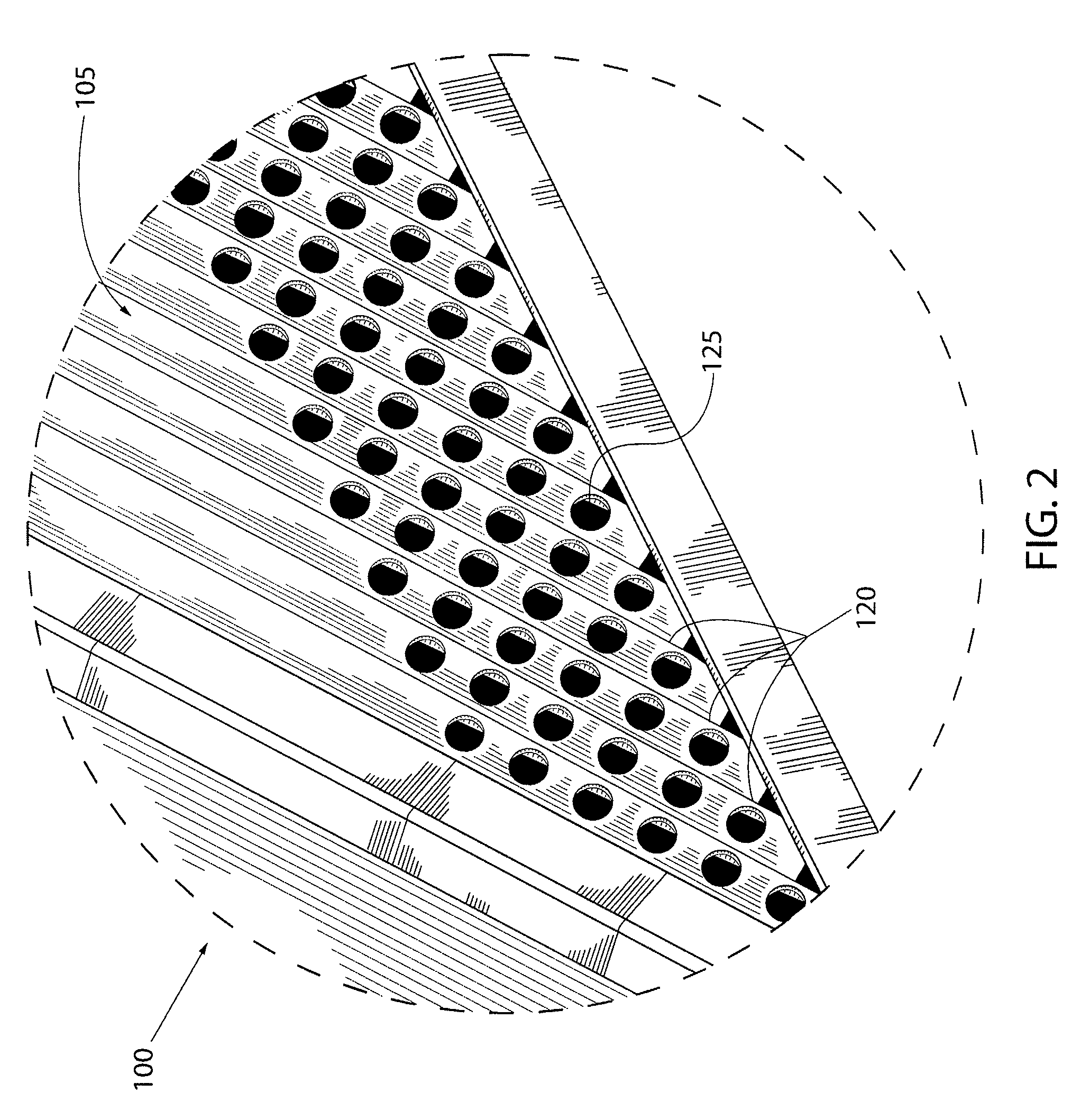

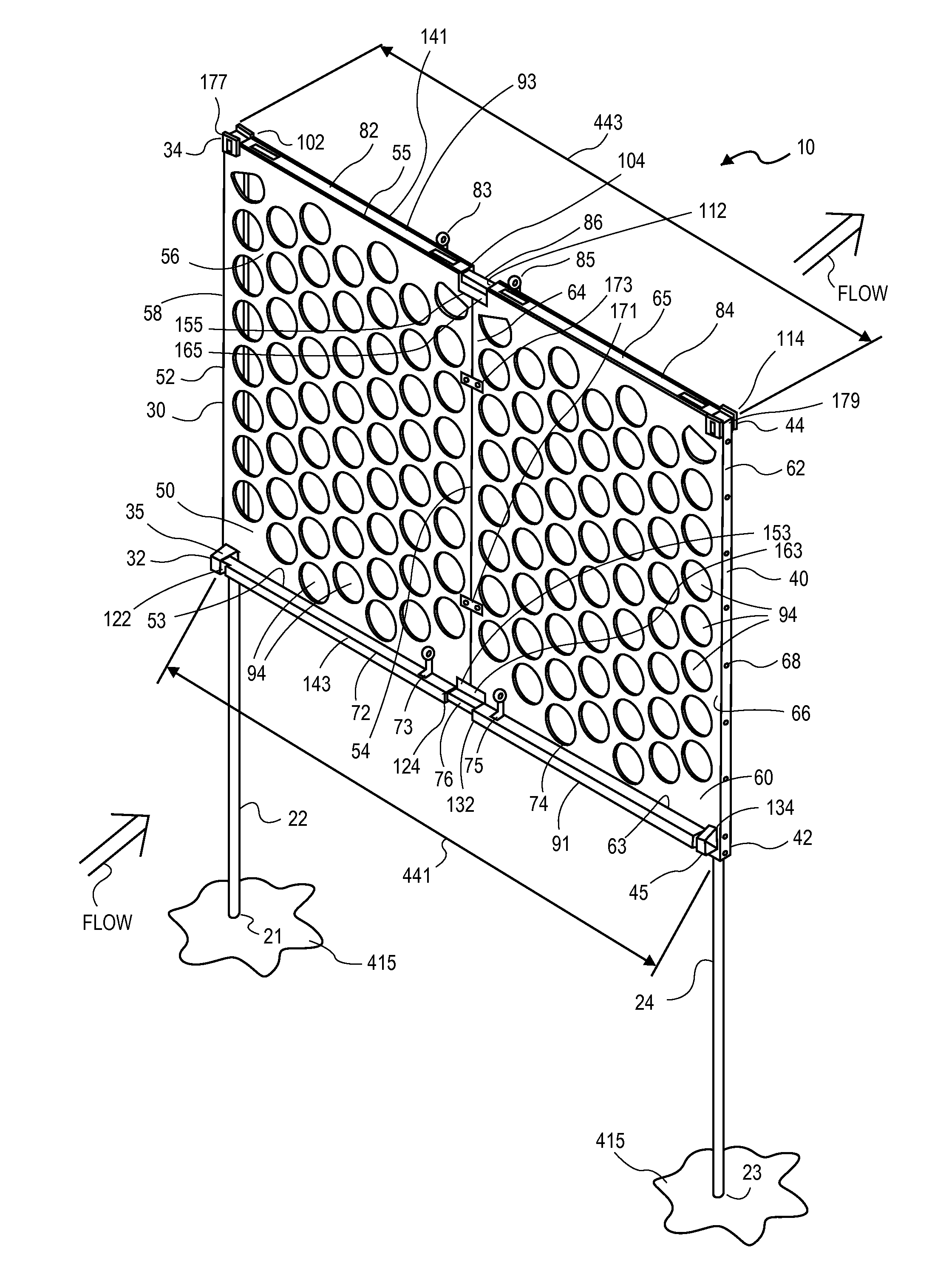

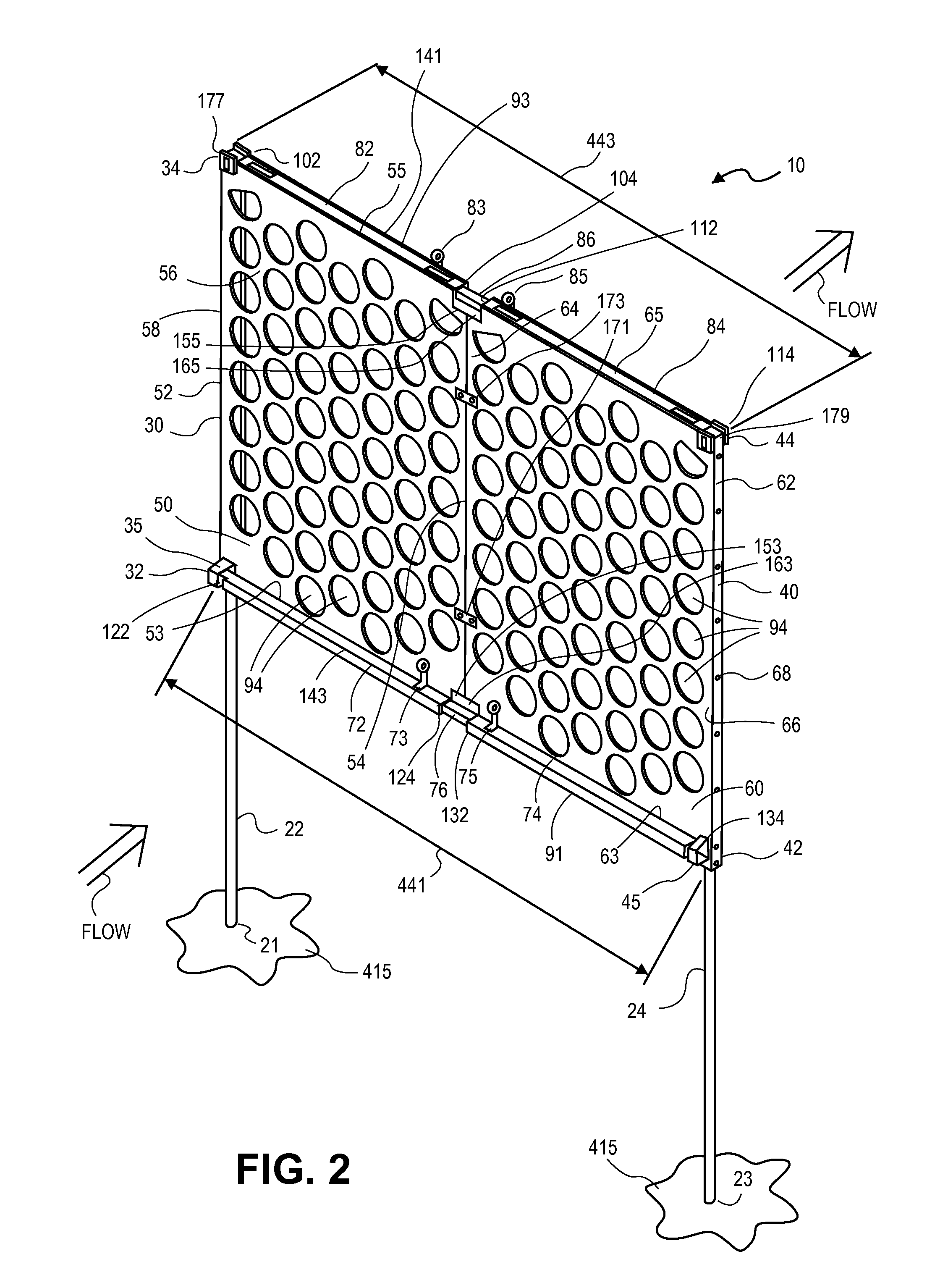

Plate settler with angular support members

Various embodiments of the present invention are directed to a plate settler comprising: a plurality of plates, each plate defining a first end, a second end, and a settling surface there between; a plurality of angular support members extending from and structurally supporting the first ends of respective ones of the plurality of plates, each angular support member defining a first lateral flow encouraging surface and a second lateral flow encouraging surface; and a plurality of headloss control gaps defined by the plurality of angular support members. The first lateral flow encouraging surface of each angular support member may combine with the second lateral flow encouraging surface of an adjacent angular support member to define a generally v-shaped lateral flow channel.

Owner:JIM MYERS & SONS

Settling grid separator

InactiveUS7276154B1Promote solid flocculationLimit transportabilityIon-exchanger regenerationSolid sorbent liquid separationFlocculationHigh density

A settling grid separator apparatus and method of use which provides deep dehydration of high flow rate sludge in an environmentally friendly and energy efficient manner. The apparatus and method comprise and utilize an efficient mixing of the sludge with a flocculating agent or polymer solution, and sludge flow quieting techniques to reduce disturbances and promote flocculation of clustered solids. Free surface liquid rejection, a series of traps, and pressurized filtering utilize gravimetric, hydrometric, and densimetric techniques to separate liquid from suspended solids. Gravitational forces are utilized throughout the apparatus and method to promote separation of higher density solids from the lower density liquid carrier. Upon separation, solids with a minimal liquid content are controllably discharged for proper disposal or recycling.

Owner:VAV TECH

Apparatus and method for removing materials from a material collection container

ActiveUS9067727B2Easy to installEasy to operateSedimentation regulating devicesSettling tanks feed/dischargeMaterial removalSludge

An apparatus for removing material collected in a material collection container having a floor and at least one substantially vertically extending wall. The apparatus includes a material removal assembly for removing material collected in the material collection container. The material removal assembly includes a first conduit and a second conduit. The first conduit is in telescoping relationship with the second conduit to permit the first conduit to move relative to the second conduit. The first conduit and the second conduit each have a longitudinal axis. The material removal assembly further includes at least one material removal header configured to receive material accumulating on the floor of the material collection container. The material removal assembly is preferably configured to enhance numerous aspects of the sludge removal process.

Owner:ROBERTS MARKETING DE

Storm water interceptor

ActiveUS20070241052A1Quality improvementDecreased storm water temperatureSewerage structuresSeparation devicesStormwaterWaste management

A storm water interceptor comprises an input conduit connected to a first treatment tank for delivering storm water to the first treatment tank and having an obvert elevation. Also, the interceptor comprises a lower conduit having an invert elevation, a substantially horizontal orifice at a first end connected to the first treatment tank and an exit orifice at an opposite end connected to a second treatment tank, whereby the substantially horizontal orifice at the first end of the lower conduit is below the invert elevation of the lower conduit. The interceptor further comprises an overflow conduit connecting the first treatment tank to the second treatment tank, whereby the overflow conduit is connected to the first treatment tank at a location above the obvert elevation of the input conduit. As well, there is an output conduit having a substantially horizontal orifice at a first end connected to the second treatment tank and an exit portion extending away from the second treatment tank, whereby an invert elevation of the output conduit is above an obvert elevation of the lower conduit, and whereby the substantially horizontal orifice at the first end of the output conduit is below the invert elevation of the output conduit. More than two treatment tanks may be connected in a cascading manner using the same general components and principles as an interceptor having two treatment tanks.

Owner:STORM PAL CORP

Blow molded septic tank and method of manufacture

A septic tank formed of a blow molded body having an interior and an exterior. The septic tank body is formed from one or more layers of plastic material that are chosen for their chemical, mechanical or other properties. The septic tank body includes a plurality of integral ribs to provide circumferential structurally rigidity and also includes compression molded flange portions to provide axial structural rigidity. Additionally, septic tank covers and riser systems are provided.

Owner:ROTH GLOBAL PLASTICS

Pre-cast drive-down water separation pit system

ActiveUS6966984B1Easy to assemblePositive sealLiquid displacementLoose filtering material filtersWater holdingTongue and groove

A unitary or modular, pre-cast, drive-down pit system suitable for use in a heavy equipment wash installation. The completed pit collects runoff generated by the washing of heavy equipment such as construction, industrial, farming, or road-building equipment. The pre-cast concrete separation unit and separate wall sections have tongue and groove mating ends that facilitate assembling the pit and provide for sealing against leakage of water. The wall sections have built-in rebar attachment and water block elements at an angle so as to provide for a strong and waterproof bond with the ramp floor. The ramp floor is concrete, poured after installation of the separation unit and the wall sections to complete the finished drive-down pit. The separation unit has up to four chambers: a primary solids collection section; a secondary solids settling chamber; a free oil separating section; and a pump water holding section.

Owner:SOLOMON MICHAEL L +1

Flow baffle installation methods and apparatus

A method of flow baffle installation is disclosed herein. The method, in various aspects includes the steps of orienting a side support at a specified elevation about a sidewall of a sump using a leveling support, bolting the side support to the sidewall of the sump following the step of orienting a side support at a specified elevation about a sidewall of a sump using a leveling support, orienting an opposing side support at the specified elevation about the sidewall of the sump using a corresponding leveling support, bolting the opposing side support to the sidewall of the sump following the step of orienting an opposing side support at the specified elevation about the sidewall of the sump using a corresponding leveling support, adjusting an adjustable cross-member to span between the side support and the opposing side support. This Abstract is presented to meet requirements of 37 C.F.R. §1.72(b) only. This Abstract is not intended to identify key elements of the apparatus and methods disclosed herein or to delineate the scope thereof.

Owner:UPSTREAM TECH

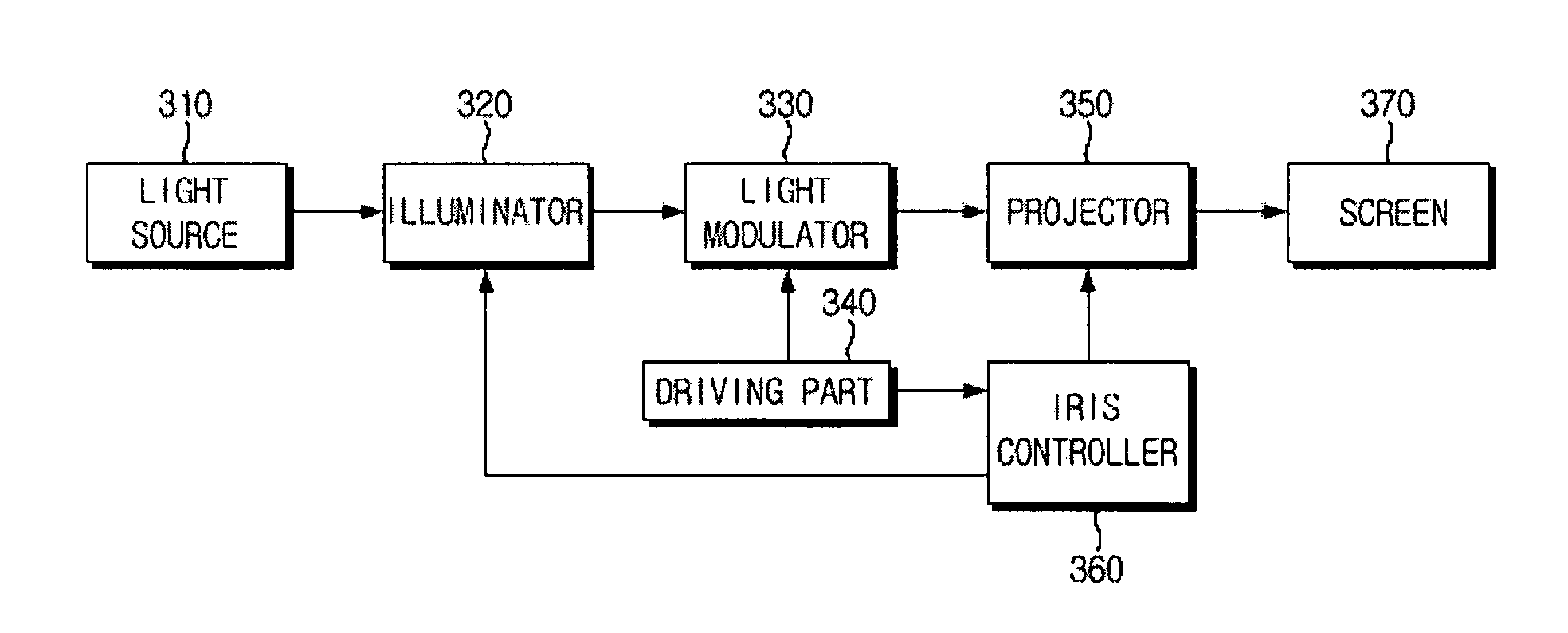

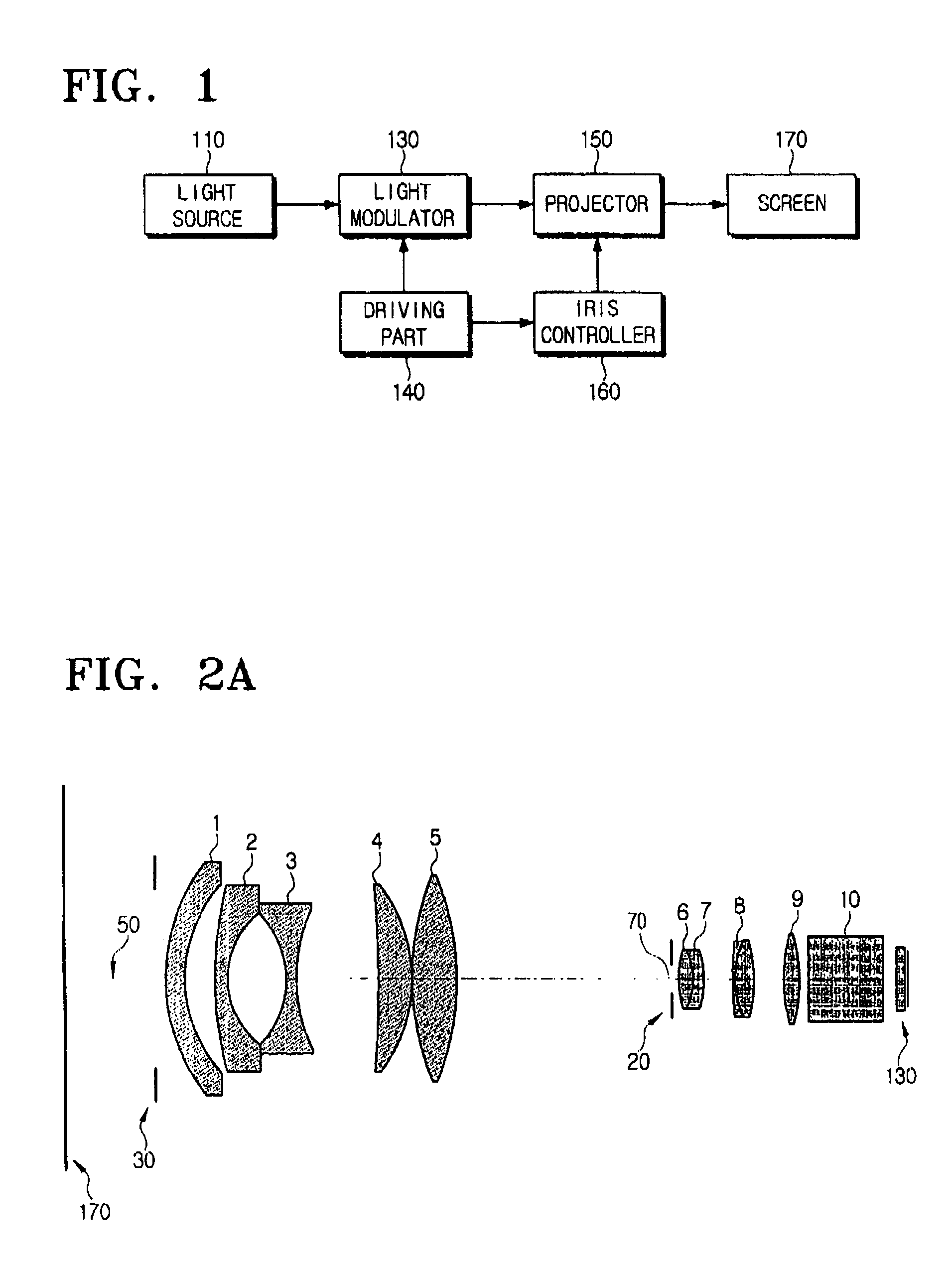

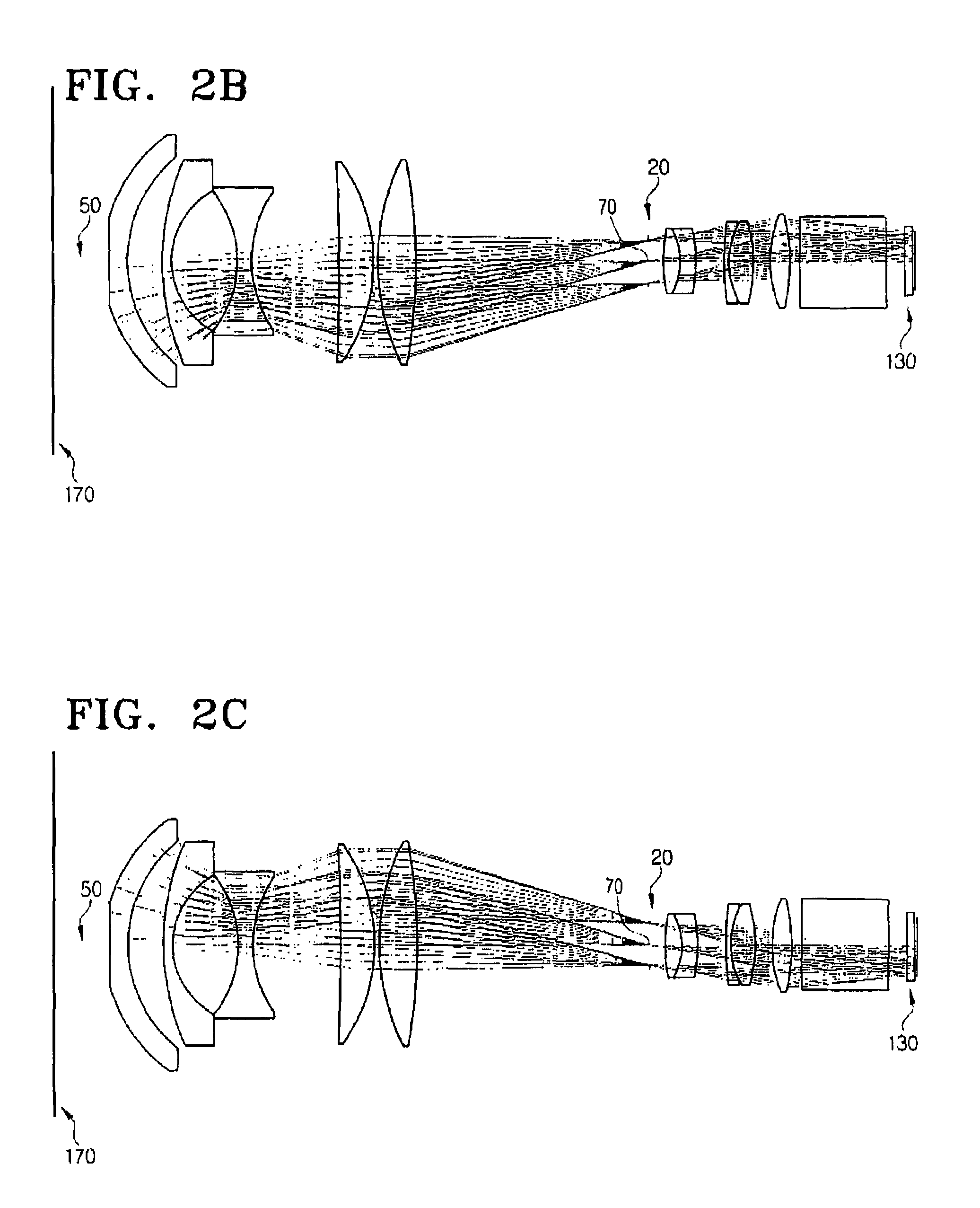

Optical system with iris controlled in real time

An optical system having an iris controlled in real time and a control method of amount of light thereof. The optical system includes a light source, a light modulator modulating a light emitted from the light source to a certain image, a driving part controlling the light modulator to produce the certain image and outputting luminance information of the certain image, a projector projecting the certain image, a screen on which the projected image is formed, a projection iris controlling an amount of light projected from the light modulator onto the screen, and a iris controller receiving the luminance information of the certain image from the driving part and controlling the projection iris corresponding to the luminance information of the certain image. Since the opening range of the iris is controlled in real time, the contrast ratio (C / R) is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Pollutant Trap

A system for removing pollutants from a liquid. The system has a tank with a bypass chamber, a treatment chamber, inlet and outlet ports. A dividing wall is located within the tank and defines the bypass chamber and the treatment chamber. The dividing wall has an inlet opening, one or more outlet openings, retaining rods forming a retention space at least partially below the inlet opening, and a vertically-extending weir between the inlet opening and the outlet opening(s). The inlet opening receives polluted liquid from the inlet port and the one or more outlet openings output a cleaned liquid to the outlet port. A float in the treatment chamber is adapted to float in a retention space formed by the retaining rods. The float is adapted to rise against the inlet opening when a fluid level in the treatment chamber reaches a predetermined level to substantially block the inlet opening.

Owner:IMBRIUM SYST

Popular searches

Single direction vortex Gravity filters Filter regeneration Stationary filtering element filters Biological water/sewage treatment Moving filtering element filters Water/sewage treatment by centrifugal separation Centrifugal force sediment separation Multistage water/sewage treatment Membrane filters

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com