Bridge crane mud/sludge scraper for efficiently degrading industrial wastewater with high salt content

An industrial wastewater, refractory technology, applied in sedimentation tanks, liquid separation, chemical instruments and methods, etc., can solve problems such as unsatisfactory development of environmental protection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

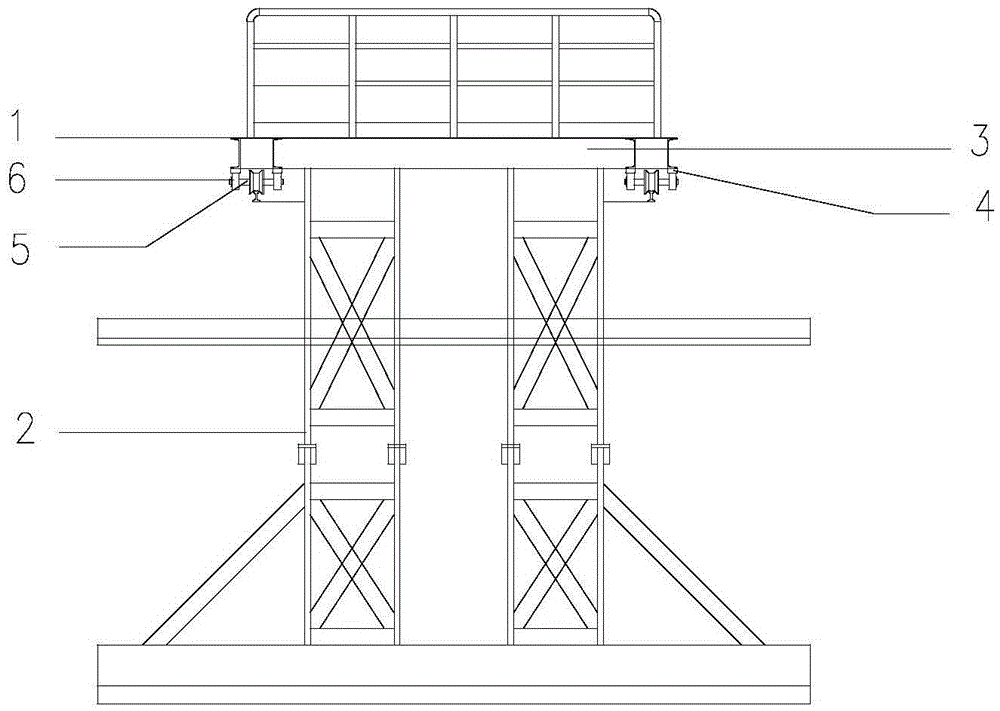

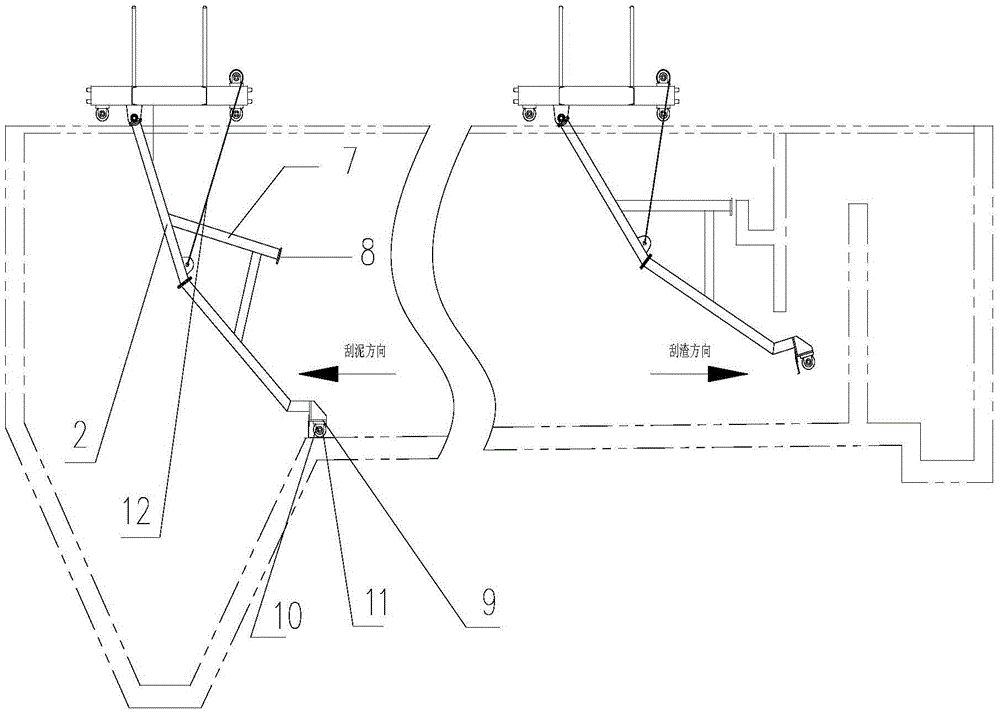

[0010] Such as Figure 1~2 A driving mud and slag scraper for high-efficiency and refractory high-salt industrial wastewater is shown, including an upper truss 1 and a scraper 2, the upper truss 1 and the scraper 2 are movably linked, and the bottom of the upper truss 1 is welded with Bearing 3, the bearing seat 4 at the bottom of both ends of bearing 3 is provided with a transmission shaft 5, and a sliding wheel 6 is arranged on the transmission shaft 5; The section scraping frame is fixedly connected from the middle by the slag scraping bar 7, and the slag scraping plate 8 is provided at the end of the slag scraping bar 7, and the end of the scraping frame 2 is connected with a roller 11 through a bearing seat 9 and a roller shaft 10, and the scraping frame 2 passes through The cable 12 is connected to the bearing 3 on the upper truss 1 , and the cable 12 is controlled by the power supply of the upper truss 2 and can be stretched. The scraper bar 7 is T-shaped and can be ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com