Device for removing slurry on outer wall of drilling rig

A technology for cleaning devices and drilling tools, used in earth-moving drilling, cleaning tools, wellbore/well components, etc., can solve the problems of fast consumption, large elongation at break, complicated installation process, etc., to improve the mud scraping efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

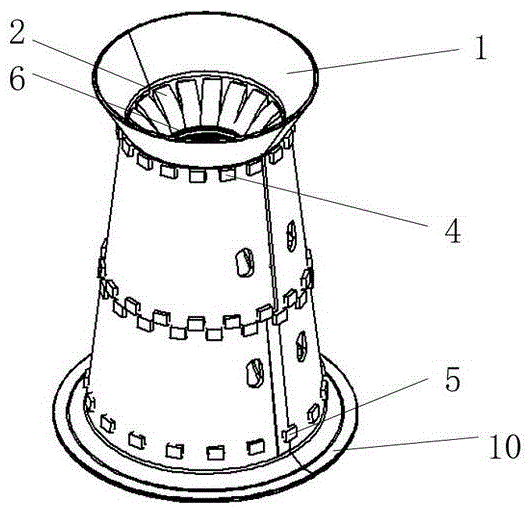

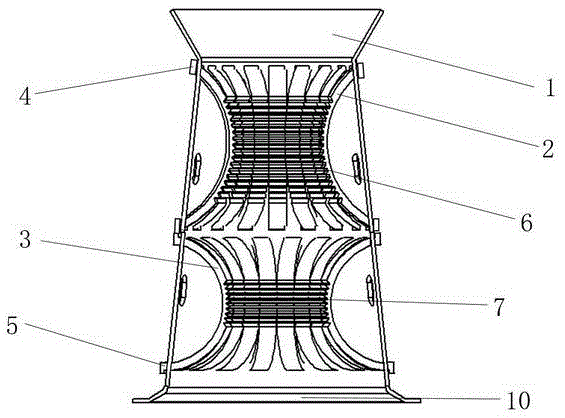

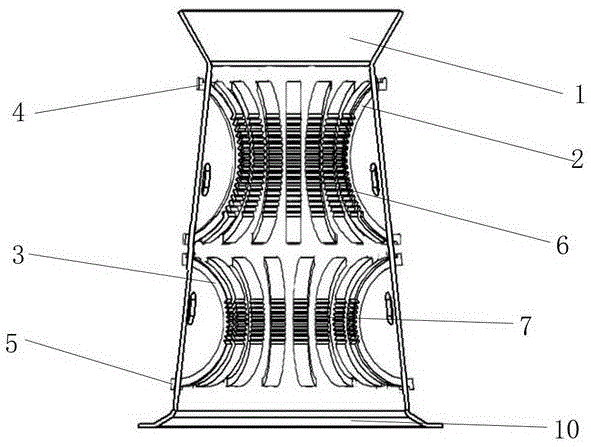

[0022] Such as Figure 1 to Figure 9 As shown, the present invention is composed of a supporting outer cylinder 1, several upper mud scraping units 2 and several lower mud scraping units 3. The upper part of the supporting outer cylinder 1 is an inverted truncated cone shape, and the lower part 10 of the supporting outer cylinder 1 is a circular ring shape. The upper part and the lower part of the support outer cylinder 1 are of truncated cone shape; the upper mud scraping unit 2 and the lower mud scraping unit 3 are bow-shaped; several upper mud scraping units 2 and several lower mud scraping units 3 are arranged in the supporting outer cylinder 1 Among them, the upper mud scraping unit 2 and the lower mud scraping unit 3 are located at the upper and lower parts of the supporting outer cylinder 1, respectively; the upper mud scraping section 6 of the upper mud scraping unit 2 and the lower mud scraping section 7 of the lower mud scraping unit 3 are gear-shaped , And the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com