Double-chain driven sludge scraper

A technology of double chain and mud scraper, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank, which can solve the problem of low separation efficiency of sludge and clarified water and the structure of reciprocating mud scraper Complicated, affecting sludge treatment efficiency and other issues, to achieve the effect of simple structure, convenient safety and maintenance, stable wear-resistant service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

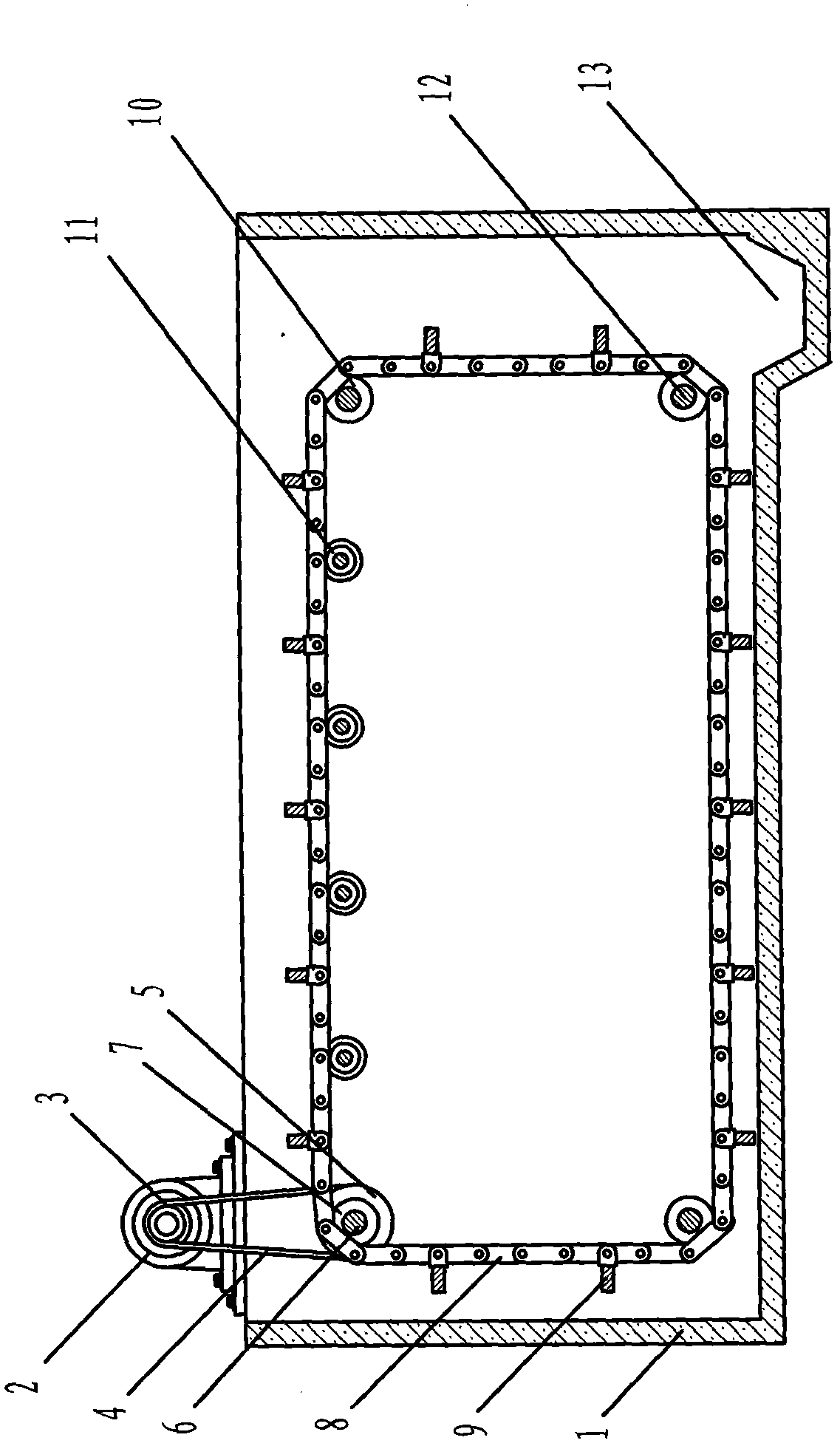

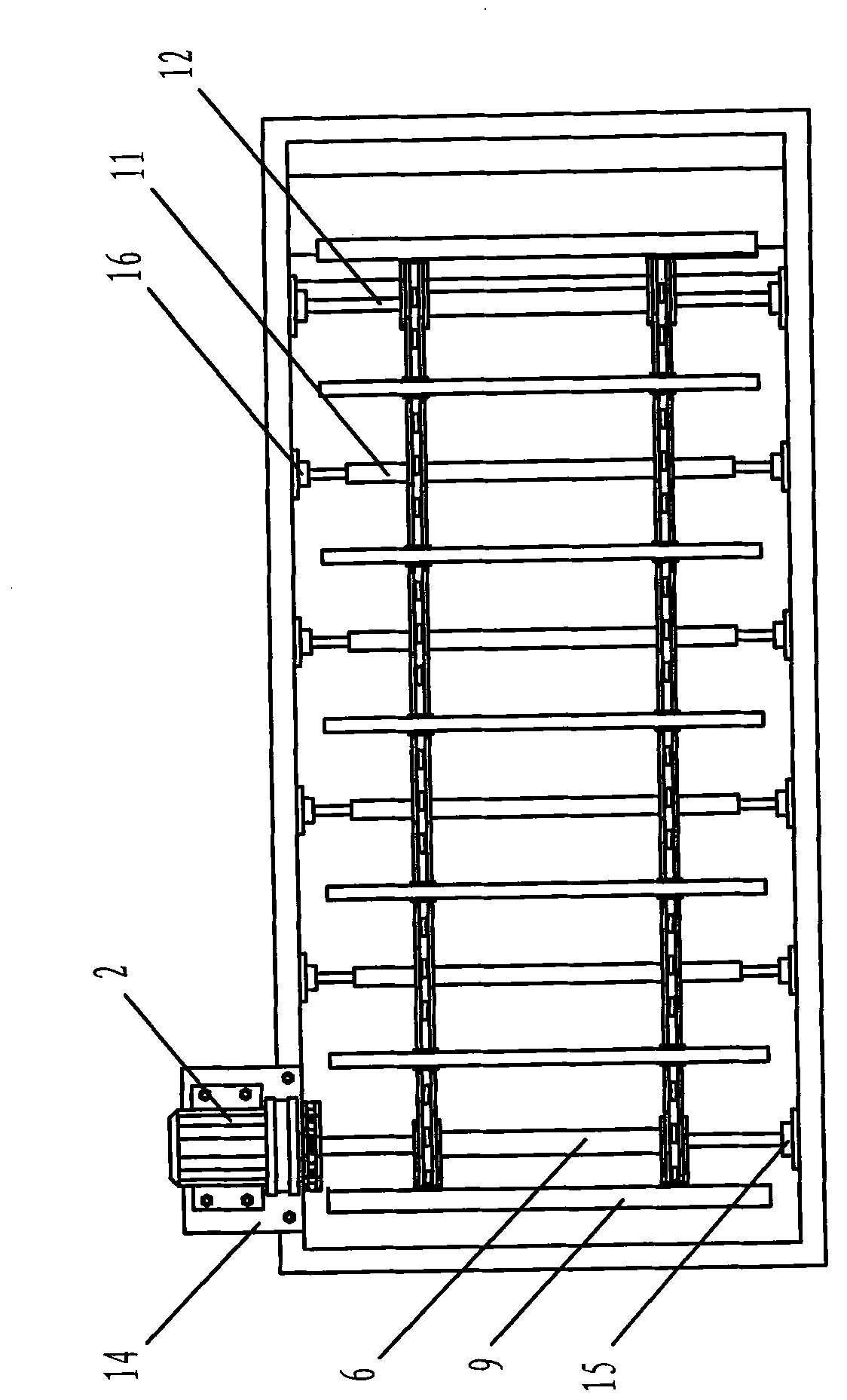

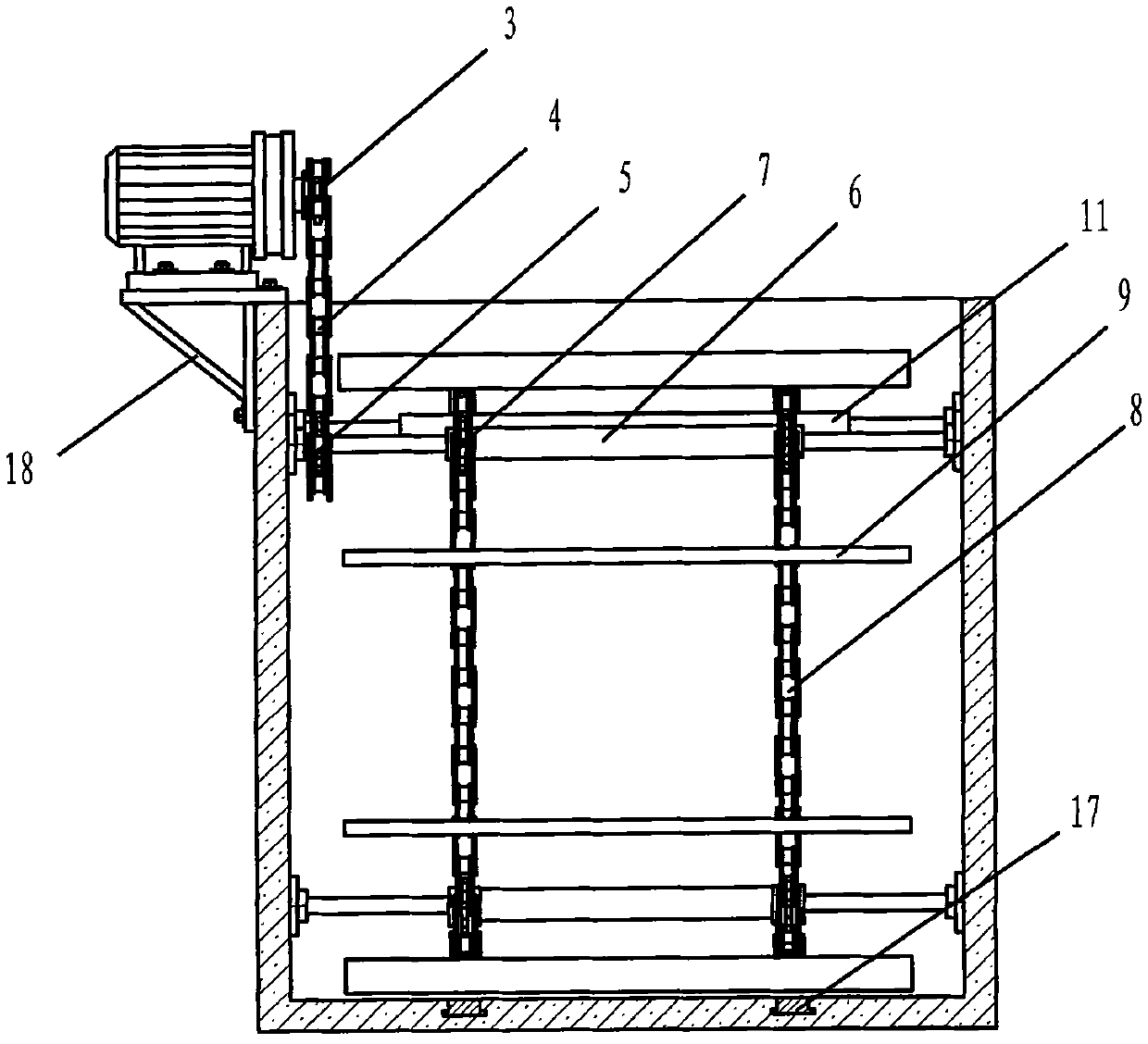

[0016] See Figure 1 to Figure 5 As shown, the present invention provides a double-chain driven mud scraper. A motor base 14 is installed at the upper end of the sedimentation tank 1. The motor base 14 is provided with a tripod 18 and is installed on the wall of the sedimentation tank 1 made of concrete using expansion bolts. The material used to make the motor base 14 and the tripod 18 is carbon structural steel, which is formed by welding. The geared motor 2 is installed on the motor base 14. The control cabinet of the geared motor 2 is equipped with an overload self-stop safety device. The sprocket 3 is provided with a driving shaft 6 on the upper side of the sedimentation tank 1, and the driving shaft 6 and the driven shaft 12 are made as a welding combination, which is machined after welding. The two ends of the driving shaft 6 and the driven shaft 12 are welded for use The material is carbon structural steel, and the material used in the middle welding is seamless steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com