Handheld pneumatic sludge scraping device and using method thereof

A hand-held, air-sourced technology, which is applied in earthwork drilling, wellbore/well parts, cleaning equipment, etc., can solve the problems of heavy labor, poor mud scraping effect, and inability to realize mud scraping, and achieve high mud scraping efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

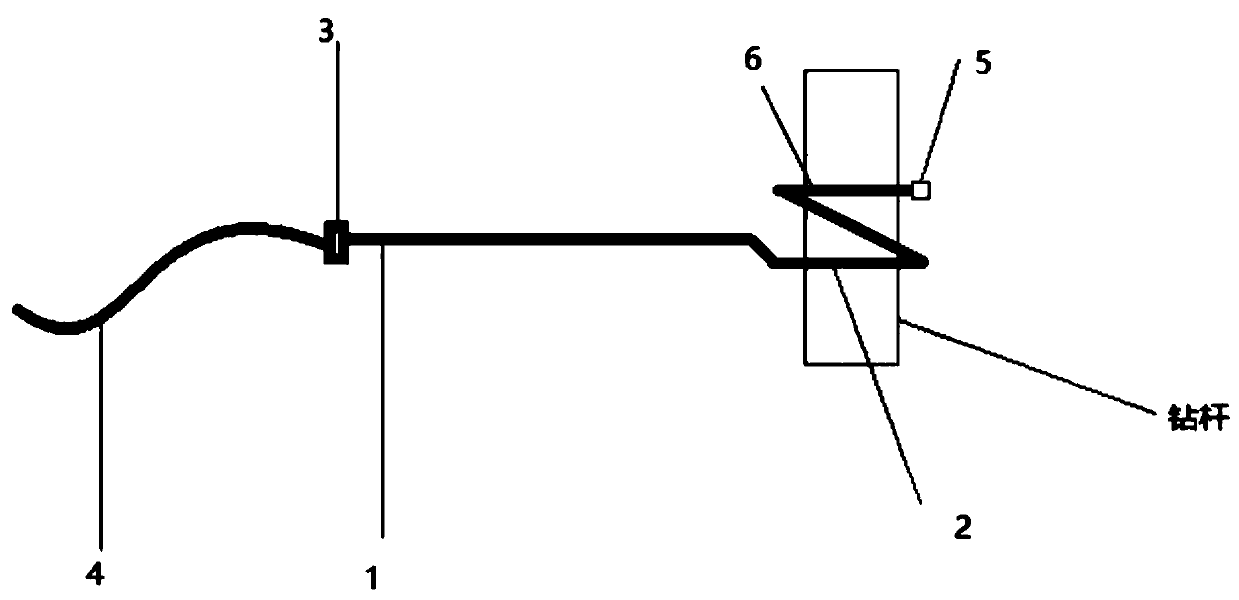

[0026] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a hand-held pneumatic mud scraping device, including a main body 2, one end of the main body 2 is a handle part 1, the other end of the main body 2 is a pneumatic mud scraping part, and the pneumatic scraper on the main body 2 The mud part is a spiral structure formed by setting the other end of the body 2 itself, and the other end of the body 2 is located on the top of the spiral structure. The handle part 1 at one end of the body 2 is connected to the gas source pipeline 4. The body 2 of the spiral structure Air blowing holes 6 are arranged on it.

[0027] In actual use: Hold the handle part 1 at one end of the body 2, and connect the spiral structure formed by the other end of the body 2 to the drilling tool to be scraped. The air blowing hole 6 set on the body 2 of the shape structure is used to scrape mud for the drilling tool to be scraped. The pneumatic mud scraping d...

Embodiment 2

[0029] Compared with Embodiment 1, the difference of this embodiment is that: the main body 2 is a pipeline of metal structure, and one end of the pipeline body 2 of metal structure is set into a pneumatic mud scraper in a spiral structure through its own deformation, and the spiral The helical surface of the pneumatic mud scraper with the shape structure is a 360-degree circle.

[0030] In actual use: the main body 2 is a pipeline with a metal structure, and the pipeline of the metal structure adopts a metal pipeline that is easily deformed. Through deformation, one end of the main body 2 is set into a spiral structure through its own deformation, forming a pneumatic mud scraper, so that the spiral structure The helical surface of the pneumatic mud scraping part is a 360-degree circle, and the diameter of the circular pneumatic mud scraping part helical surface is larger than the diameter of the drilling tool to be scraped, and the drilling tool to be scraped is on the helical...

Embodiment 3

[0032] Compared with Embodiment 2, the difference of this embodiment is that: the body 2 is also connected with a support frame along the outside of the body 2 itself, and the support frame is detachably connected with the body 2 .

[0033] In actual use: the body 2 is connected with a support frame along the outside of the body 2 itself, and the support frame is detachably connected to the body 2, because the body 2 is a metal structure pipeline that is easily damaged during the mud scraping process, so setting the support frame increases the overall Service life of pneumatic mud scraper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com