Grab bucket and sludge scraper thereof

A mud scraper and grab technology, applied to mechanically driven excavators/dredgers, etc., can solve problems such as low working efficiency of grabs, waste of resources, and increased construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

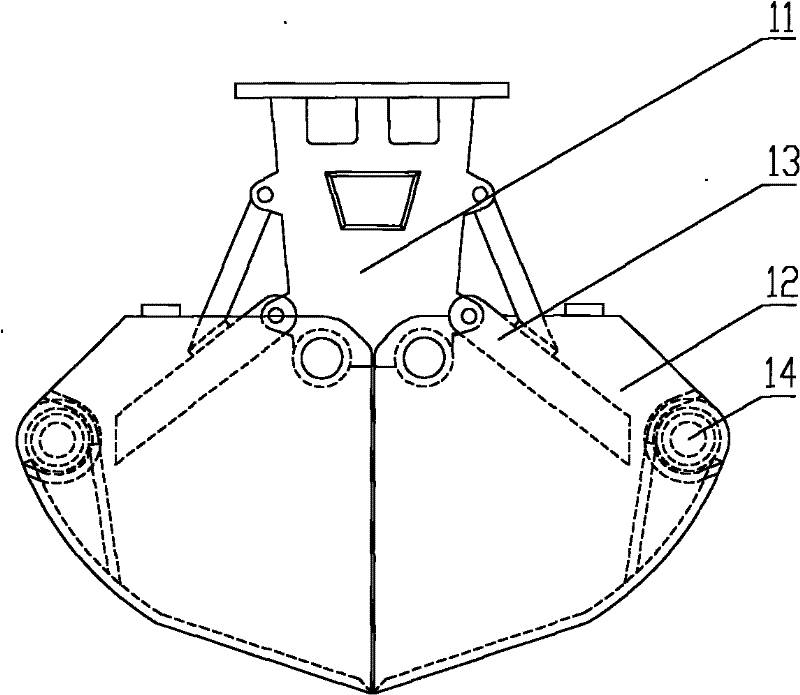

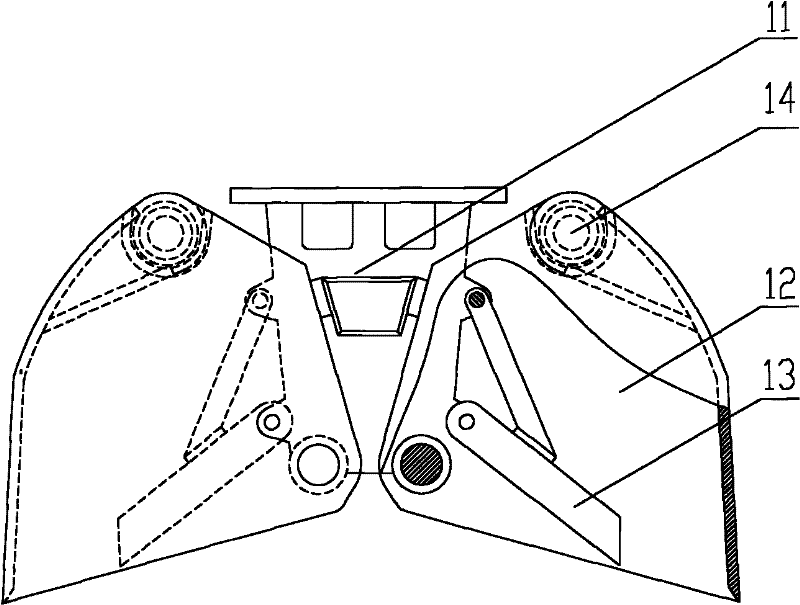

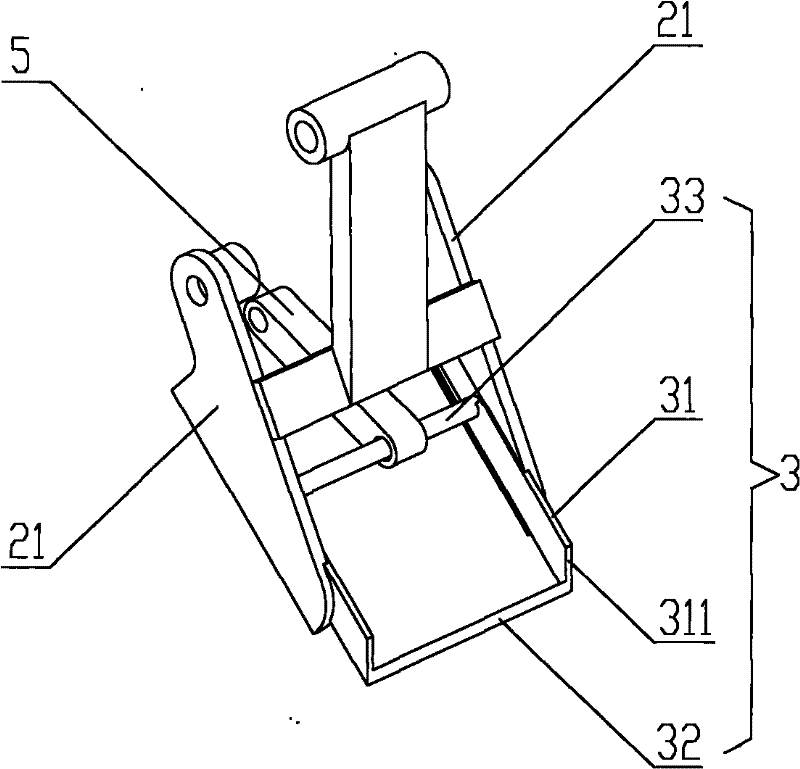

[0028] The core of the present invention is to provide a mud scraper for a grab, which has a high mud scraping rate, which is beneficial to improving the working efficiency of the grab and improving the construction progress. Another core of the present invention is to provide a grab bucket comprising the above mud scraper.

[0029] The basic concept of the present invention is: on the basis of the original static mud scraping device, install a dynamic mud scraping device that can slide along the extension direction of the static mud scraping device, so that the overall length of the mud scraper can be adjusted according to the opening degree of the grab body. It grows as it increases, and shortens as the closure of the grab body increases, so as to improve the mud scraping efficiency of the grab bucket and improve the working efficiency of the grab bucket without affecting the normal operation of the grab bucket body.

[0030] In order to enable those skilled in the art to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com