High-speed mud cutting equipment

A mud cutting, high-speed technology, applied in grain processing, ceramic molding machines, manufacturing tools, etc., can solve problems such as excessive motor load, easy adhesion of mud to the inner wall of the mud cutting silo, and decreased trowel speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

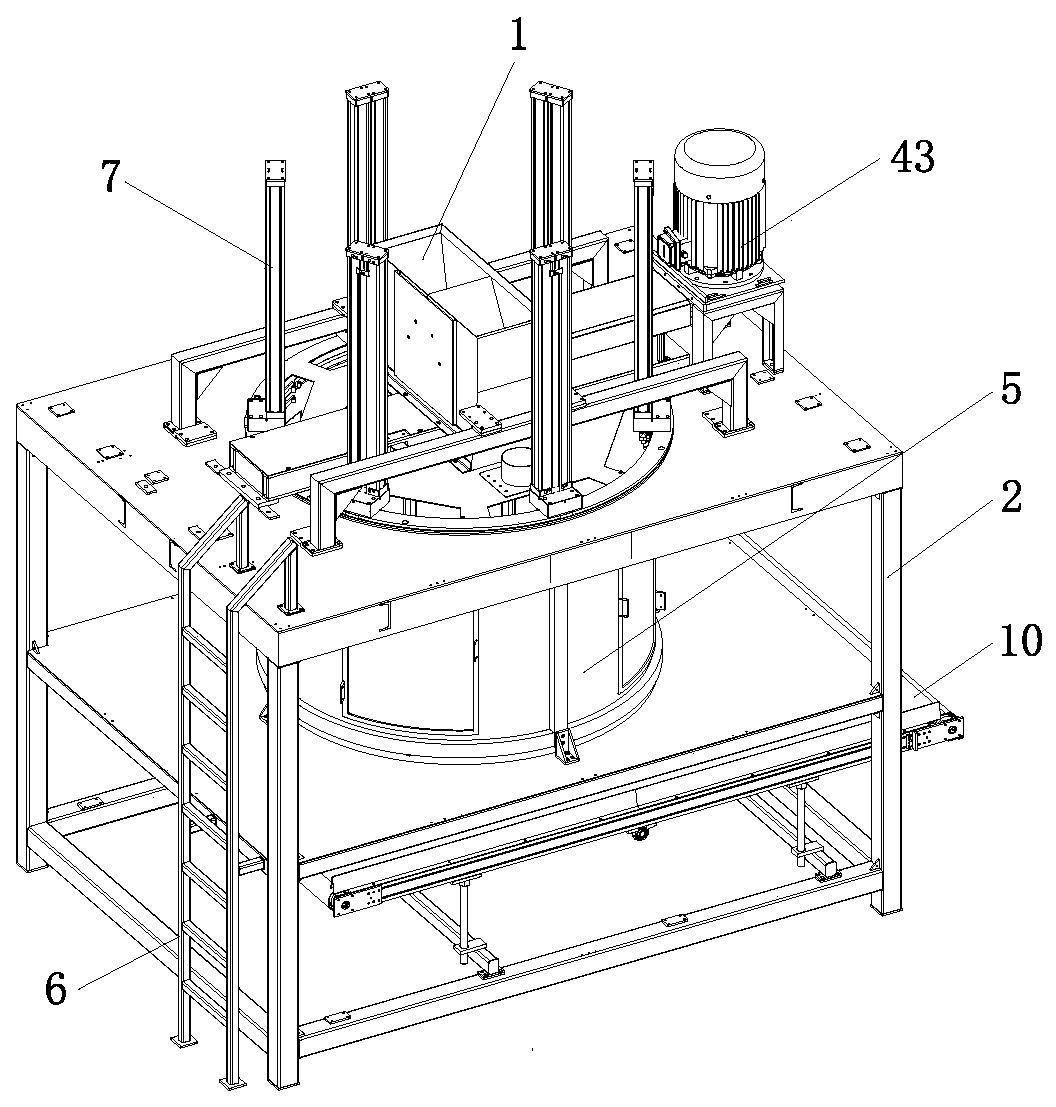

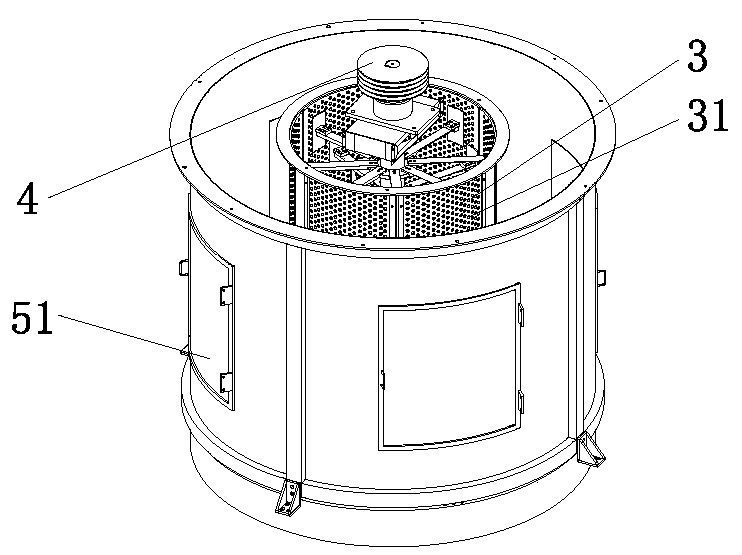

[0037] Such as figure 1 and figure 2 The high-speed mud cutting equipment shown includes a feed hopper 1, a mounting frame 2, a mud cutting bin 3, a mud cutting mechanism 4, and a mud retaining bin 5; the mud cutting bin 3 is cylindrical, and is fixedly installed on the mounting frame 2, the side wall of the mud cutting bin 3 is provided with some through holes 31, and the through holes 31 can be in shapes such as circle, ellipse or rhombus. The shape of the mud-shielding bin 5 is the same as that of the mud-cutting bin 3 and is cylindrical; In the present embodiment, the through holes 31 are circular holes and are evenly distributed on the side wall of the mud cutting bin 3. The diameter of the circular holes is about 3 cm. Of course, the diameter of the circular holes can also be selected according to the actual situation. Generally speaking When the diameter of the round hole is 1cm to 5cm, the effect is better.

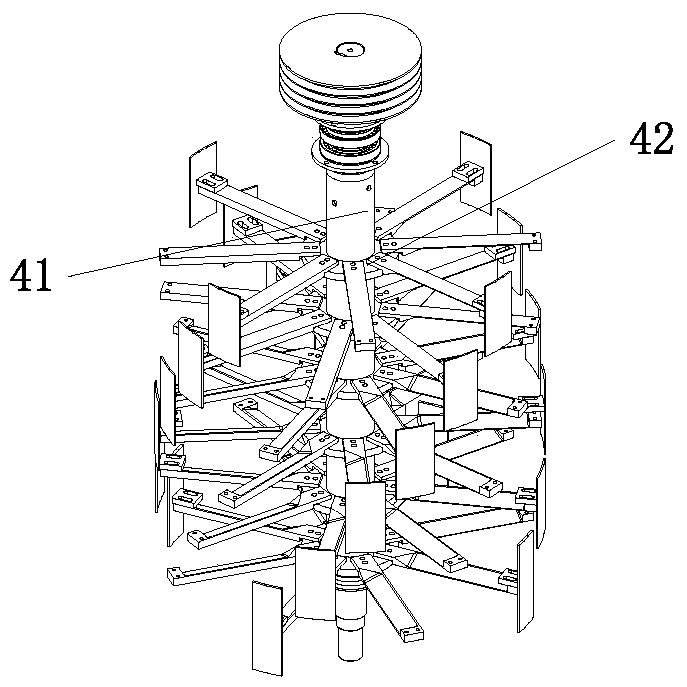

[0038] Such as figure 2 and image 3 As shown, the mu...

Embodiment 2

[0050] Some mud material to be cut has a large volume and heavy weight, so when it falls into the mud cutting bin 3 from the feed hopper 1, it will hit the mud cutting knife 421 rotating at a high speed, which will cause great damage to the mud cutting knife 421 and the rotating shaft 41. Big impact seriously affects the service life of the present invention. In order to solve this problem, this embodiment adds a crushing device 8 on the basis of Embodiment 1, and pre-crushes the mud entering the feed hopper 1 to reduce the volume of the large mud, so that it enters the mud cutting bin 3 The volume of the mud inside is relatively uniform.

[0051] The crushing device 8 is fixedly installed on the installation frame 2 and is located directly above the feed hopper 1 .

[0052] Such as Figure 8 As shown, the crushing device 8 includes a mounting bracket 81, a crushing bin 82, a screen 83, a breaking hammer assembly 84 and a motor A85. The crushing bin 82 is fixedly mounted on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com