Mud-scraping mechanism for press wheel

A technology of pressing wheels and racks, applied in the direction of suppressors, agricultural machinery and implements, shovels, etc., can solve the problems of increasing thickness, unsatisfactory effect, easy to adhere to the scraper or scraper, etc., to achieve the mud scraping efficiency High, novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

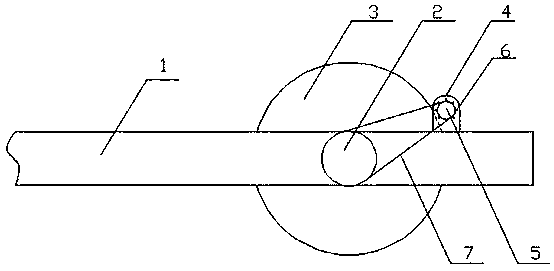

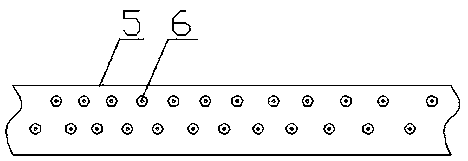

[0013] Such as figure 1 , 2 As shown, the present invention discloses a mud-scraping mechanism for the suppression wheel, comprising: a frame 1, a suppression shaft 2, a suppression wheel 3, a mounting seat 4, a mud-scraping shaft 5, a conical protrusion 6, and a transmission belt 7. The shaft 2 is installed on the right side of the frame 1 through a bearing, the pressing wheel 3 is installed on the pressing shaft 2, and the mounting seats 4 are two mounted on the inner and outer sides of the frame 1 respectively, and the two mounting seats 4 The connecting line between them is parallel to the suppressing shaft 2. The mud scraping shaft 5 is installed between the two mounting seats 4 through bearings. The outer peripheral surface of the mud scraping shaft 5 is fixed with a tapered protrusion 6, so The outer ends of the suppression shaft 2 and the mud scraping shaft 5 are fixedly connected to a turntable, and the suppression shaft 2 and the mud scraping shaft 5 are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com