Mud scraping device of static pile pressing machine

A technology of static pressure pile driver and rotary drive device, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems that square or other special-shaped pipe piles cannot be applied, so as to improve the mud scraping efficiency and pile pressing efficiency, Strong applicability and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

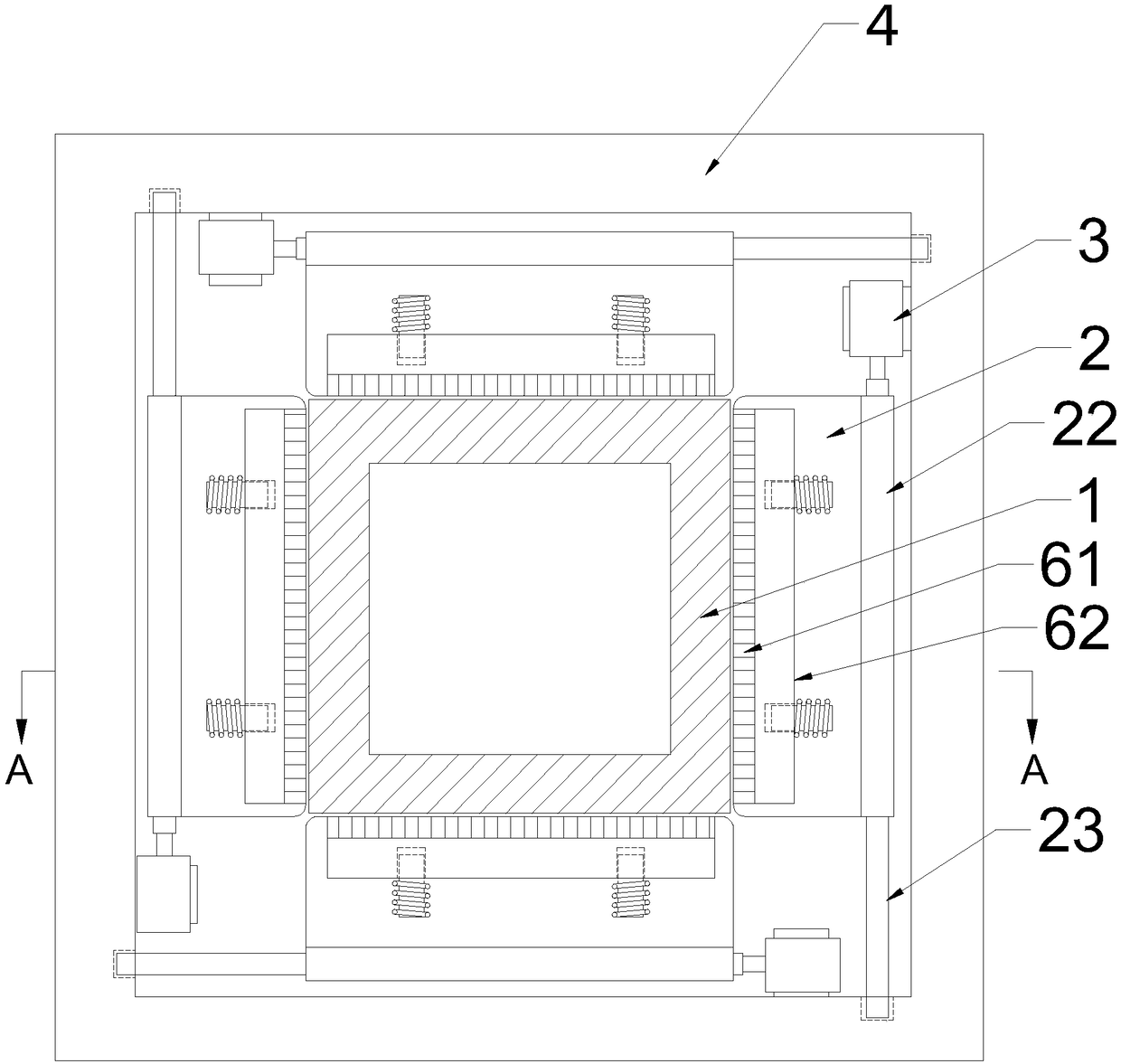

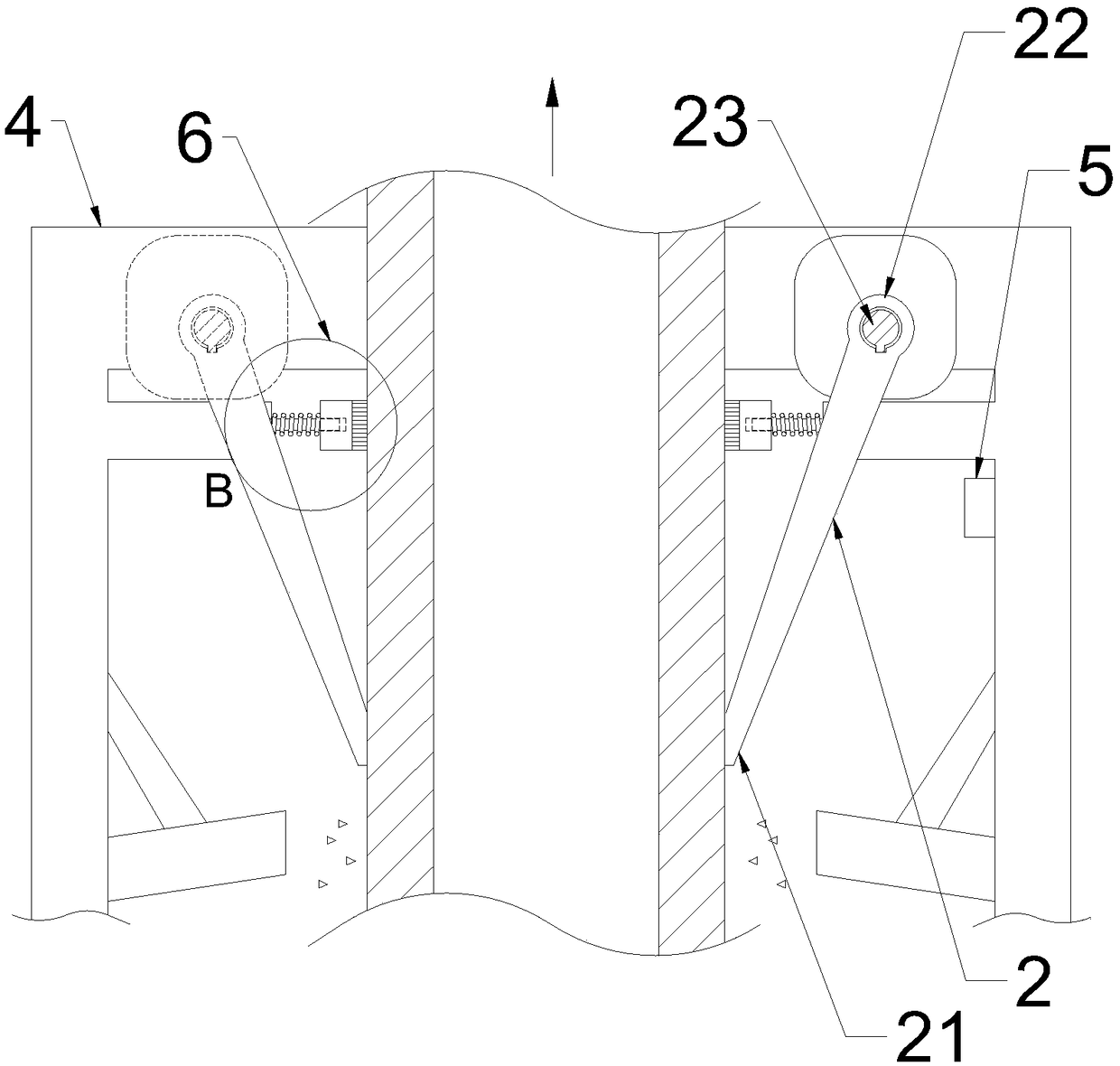

[0022] Such as figure 1 with figure 2 As shown, a mud scraping device of a static pile press is suitable for mud scraping of square pipe piles. It includes four movable scrapers 2 and the four scrapers 2 are arranged symmetrically in pairs. Enclosed into a square structure; the top of the scraper 2 is connected with a rotating drive device 3, which can be a rotating motor, and the bottom of the scraper 2 is provided with a scraper 21, the rotating drive device 3 can drive the scraper 2 around the scraper The top of the plate rotates to make the four scrapers 21 abut the square pipe pile 1 at the same time, thereby scraping the sludge on the wall of the square pipe pile 1; the present invention also includes a bracket 4 on which the rotation driving device 3 is installed.

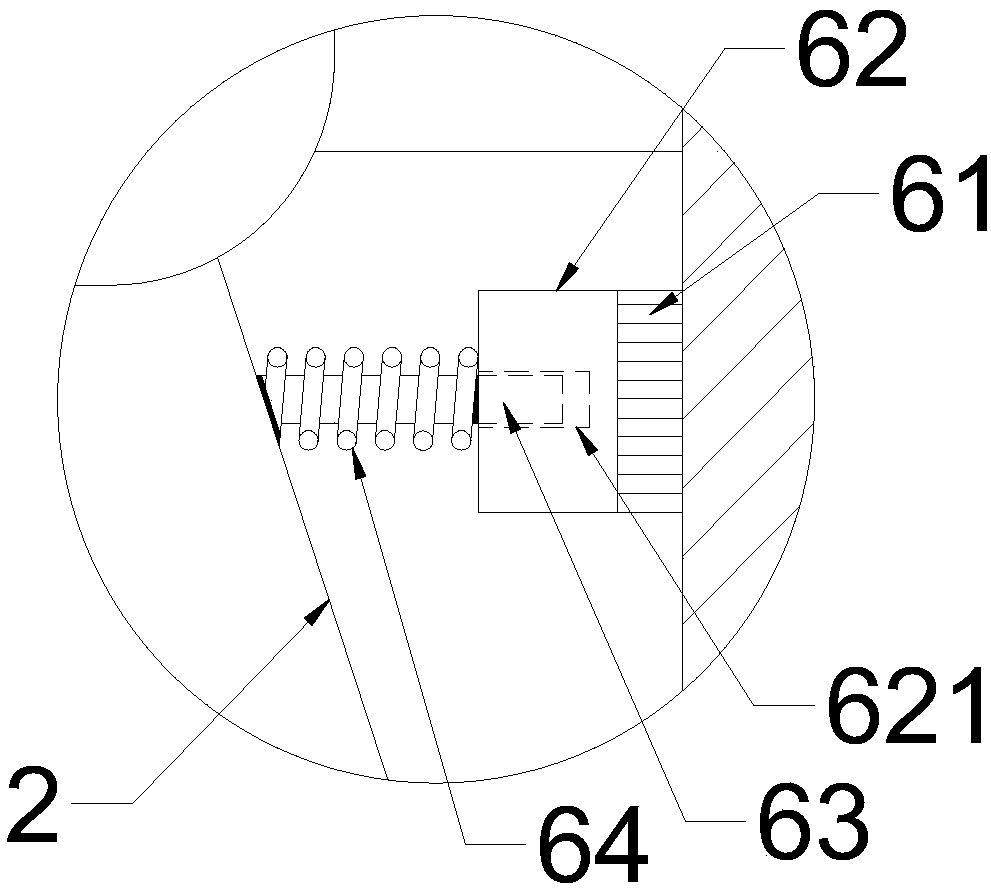

[0023] The top of the scraper 2 is fixed with a shaft sleeve 22. The shaft sleeve 22 is provided with a rotating shaft 23. The shaft sleeve 22 and the rotating shaft 23 are splined. When the rotating shaft 23 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com