Arc-shaped scraper plate center transmission mud scraper

A center-driven mud scraping and center-driven technology, which is applied to the feeding/discharging devices, chemical instruments and methods, and separation methods of the settling tank, to achieve the effects of smooth mud scraping, reduced power consumption, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

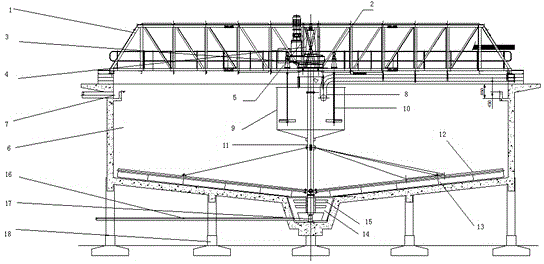

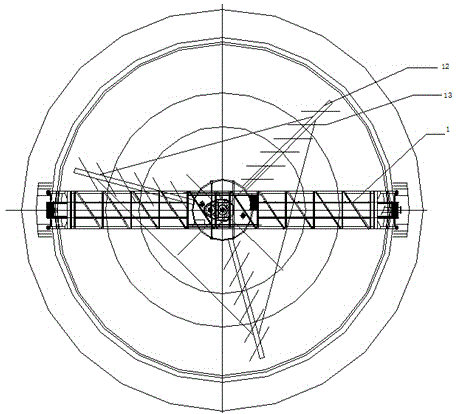

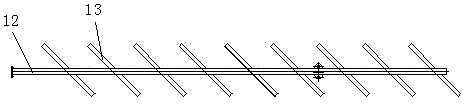

[0018] An arc-shaped scraper central drive mud scraper, which includes a bracket 19, a sewage bucket 6, a working bridge 1, a main drive motor 4, a reducer 5, a central drive shaft 11, a flocculation mixer 2, a flocculation reaction bucket 9 and a scraper arm 12, the working bridge 1 is set on the top of the sewage bucket 6, the sewage bucket 6 is set on the bracket 19, there is a circle of overflow weir 7 around the sewage bucket 6, and the middle part of the working bridge 1 is provided with a central support 3 , the main drive motor 4 and the reducer 5 are fixed on the central support 3, and the two sides of the central support 3 are respectively provided with a flocculation mixer 2, and the lower end of the flocculation mixer 2 is connected to the stirring device 10, and the stirring device 10 is placed in the flocculation reaction In the bucket 9, a water inlet pipe 8 is arranged between the working bridge 1 and the sewage bucket 6, and the outlet of the water inlet pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com