Water pipe man-made sound wave leakage checking method

An artificial, sonic technology, applied in the field of artificial sonic leak detection of water pipes, can solve problems such as expensive, quality of leak listeners, and inability to find leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

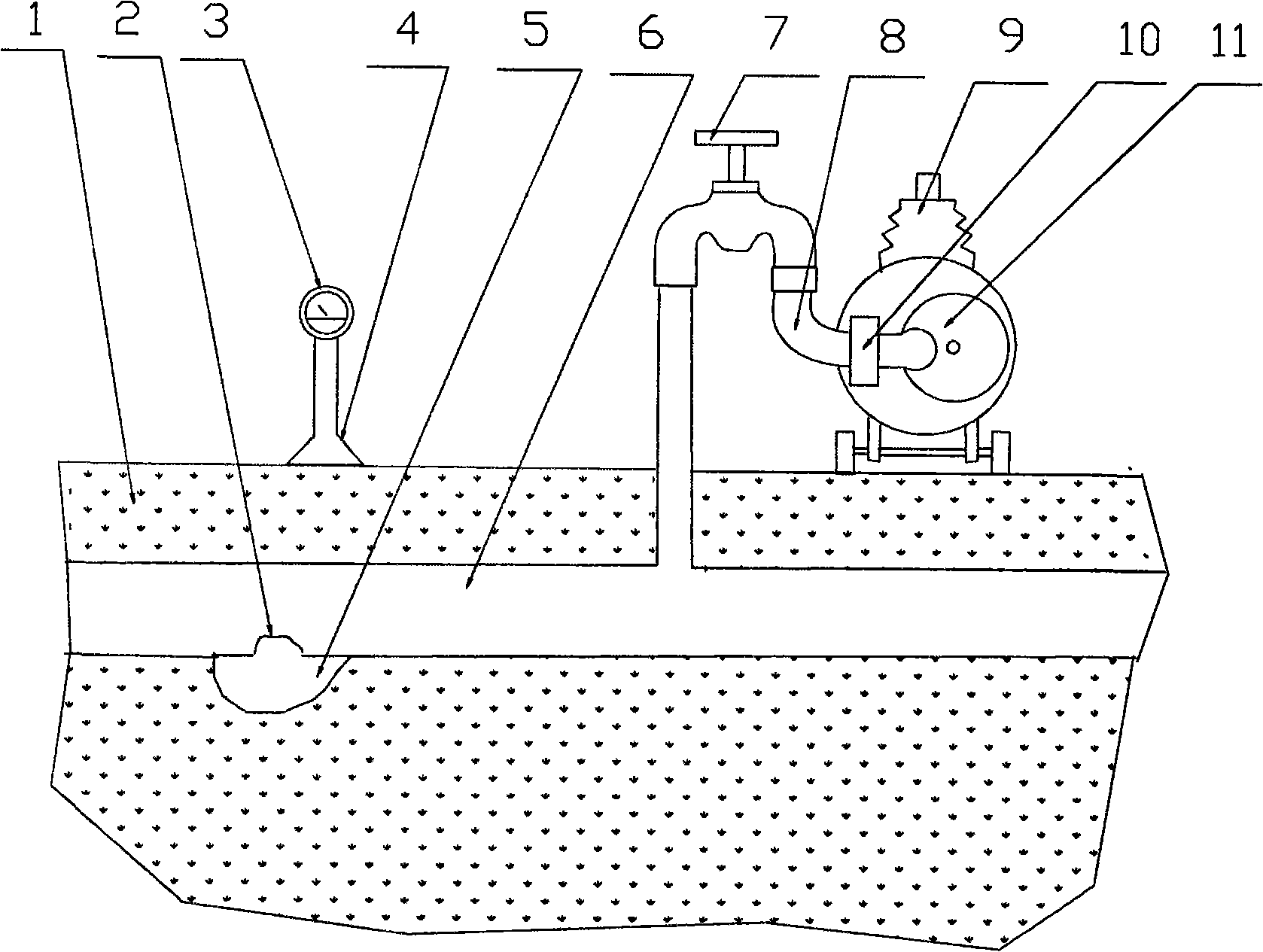

[0009] figure 1 1 is the earth, 2 is the leak, 3 is the instrument of the acoustic vibration receiver, which is particularly sensitive to the low frequency generated by the gas switch, 4 is the sound collection cover of the acoustic vibration receiver, 5 is the hole formed by water leakage, and 6 is the Water pipe, 7 is a water tap, 8 is a connecting pipe between a compressor and a water tap, 9 is a compressor, and 10 is a gap release switch (the gap release switch can be in the form of timing or remote control, and the transmitter is in the hands of the leak checker during remote control. ) 11 is a low-frequency air pressure generator on the compressor. When leak detection, first turn off other nearby water valves, use the pressure regulator on the compressor to set the maximum pressure of the compressor at a position greater than the water pressure of the water pipe, and then start the compressor 9 to store the compressor at the set pressure. Start the low-frequency air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com