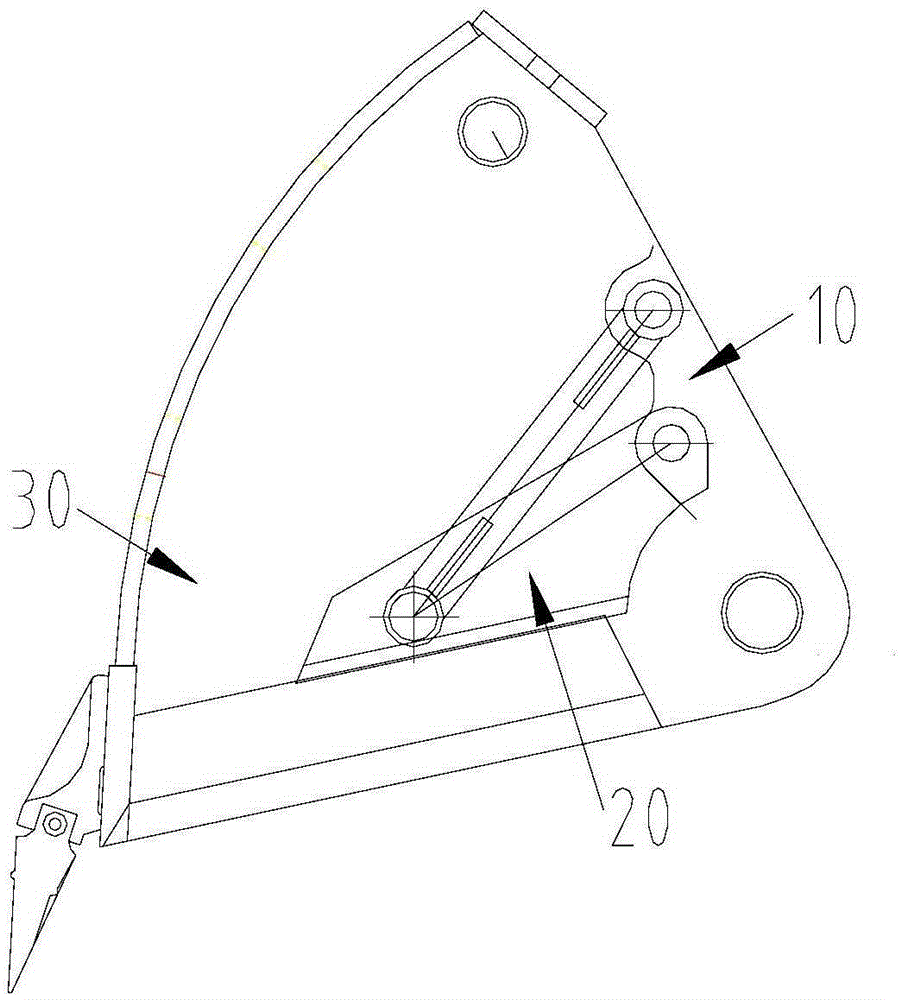

Grab, continuous wall hydraulic grab grooving machine and grab operation method

The technology of grab bucket and bucket shell is applied in the field of hydraulic grab bucket forming machine for continuous wall, which can solve the problems of long time, limited scraping area, and difficulty in scraping the soil out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

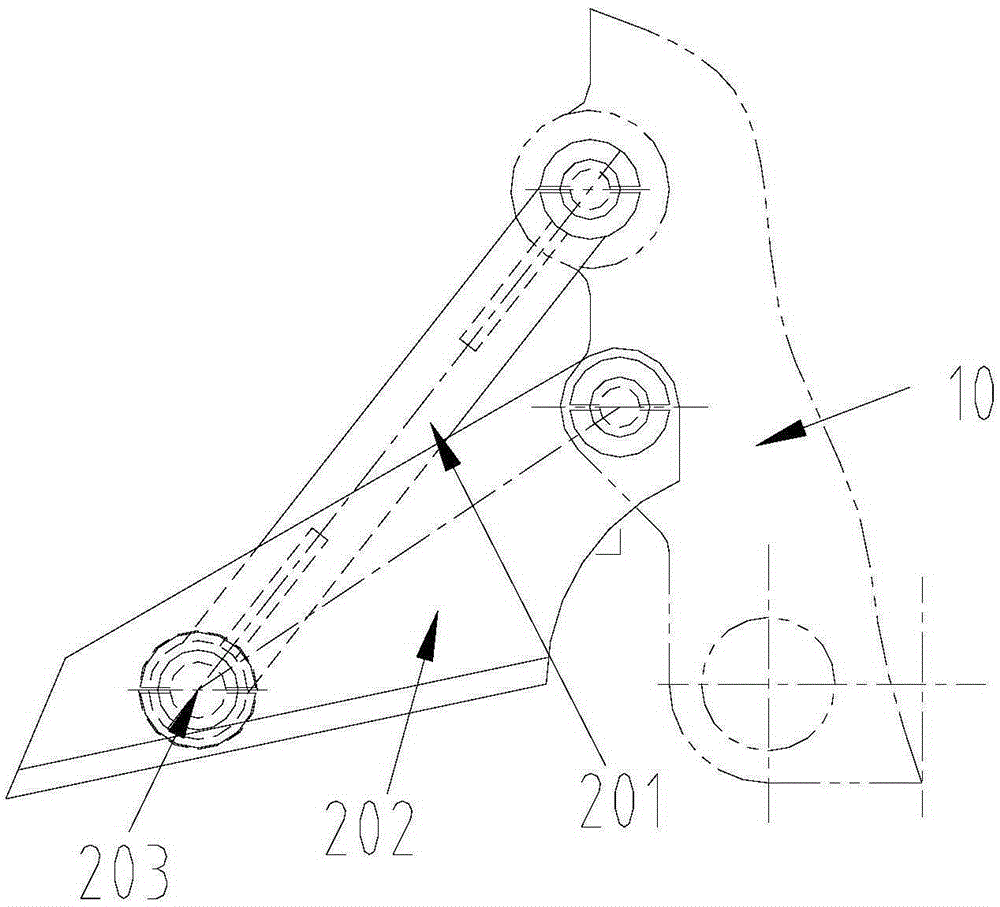

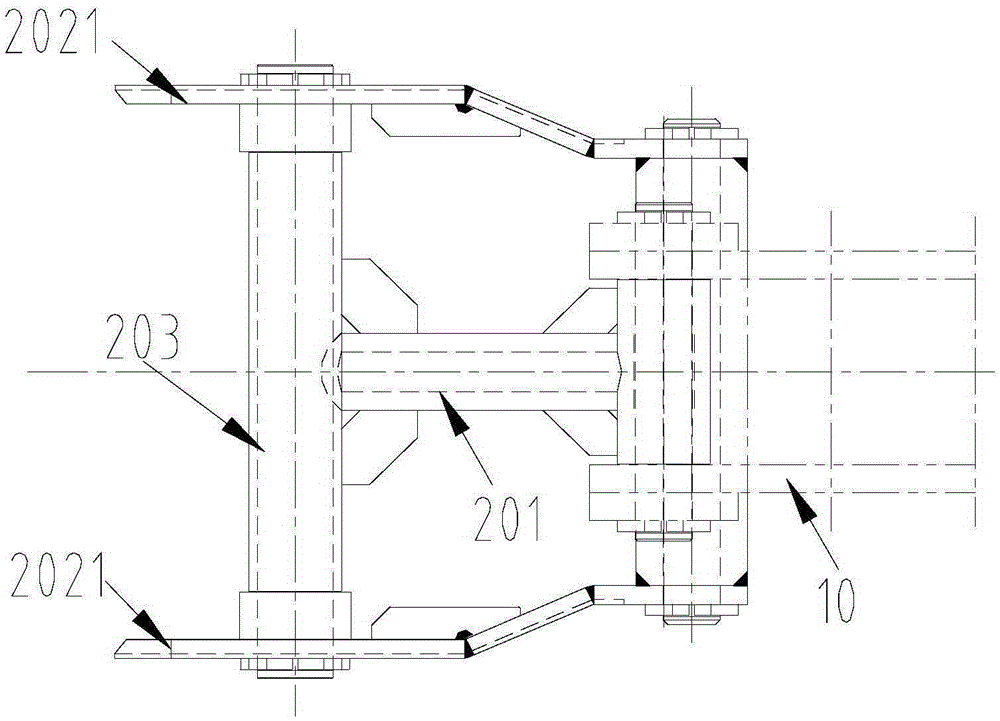

Examples

Embodiment approach

[0056] According to a preferred embodiment of the present invention, the grab operation method also includes a soil discharge step:

[0057] S20: The grab shell 30 starts to open to remove the grabbed rock and soil, and the residual rock and soil in the grab shell 30 pushes the mud scraper 20 to rotate to abut against the first stopper 14; specifically, when the grab When carrying out soil removal operations, such as Figure 7d As shown, the grab shell 30 along Figure 7d Rotate clockwise, in the process of gradually opening, the rock and soil in the grab shell 30 will be discharged from the grab shell 30 under the action of its own gravity. However, some rocks and soils in the grab shell 30 will adhere to the inner wall of the grab shell and fail to be discharged in time. These rocks and soils that have not been discharged in time also rotate clockwise, so that the mud scraper 20 is pushed by the adhesion force of the rocks and soils. down, along Figure 7d clockwise rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com