Jet-propelled scraper

A mud scraper and air jet technology, which is applied to drilling equipment, earthwork drilling, drilling tools, etc., can solve the problems of different outer diameters of drilling tools, poor repeated use effect, and difficult inner diameter of rubber discs, etc., so as to save manpower, Reasonable structural design, easy to move and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

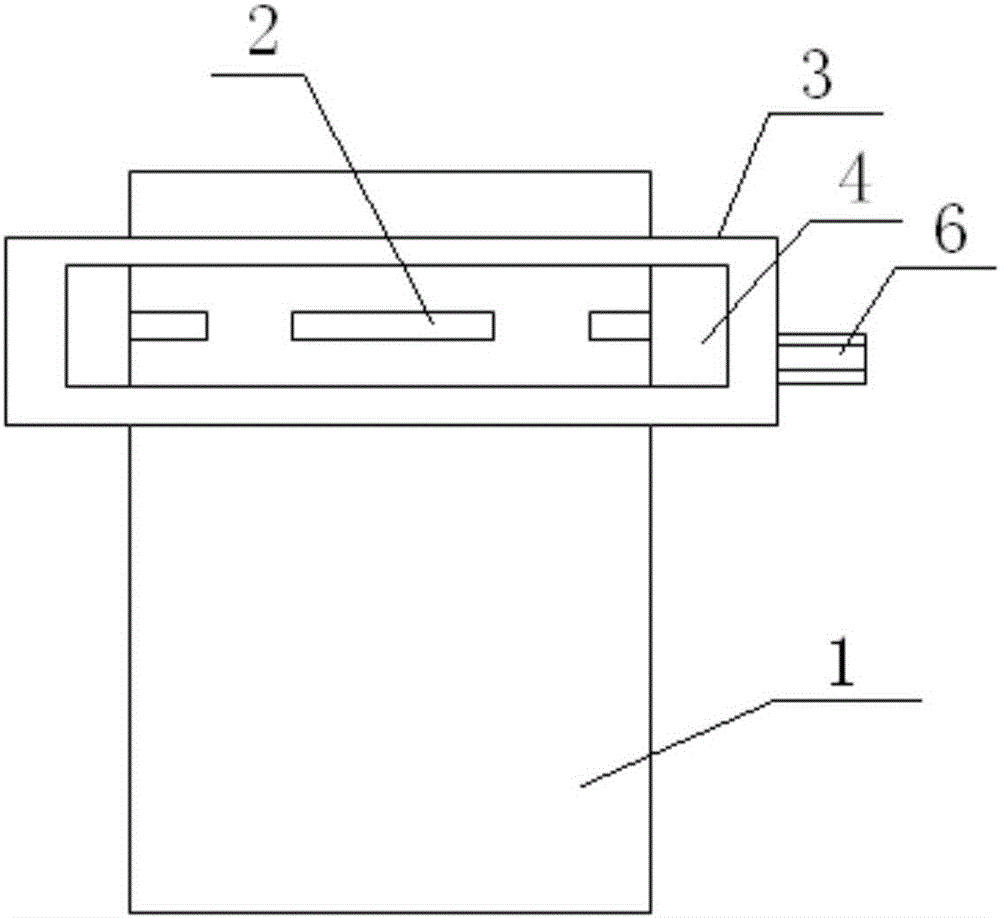

[0028] Such as figure 1 As shown, a jet mud scraper is mainly used in drilling rigs that can use overflow pipes. It includes an anti-overflow pipe 1, an air nozzle 2, an air supply hard line package 3, and an air line (this structure is not shown in the figure); A gas chamber 4 is formed between the outer wall and the inner wall of the air supply hard line package 3, the air supply hard line package 3 is connected to the gas pipeline, and the gas pipeline is connected to the gas source; multiple air nozzles are installed on the wall of the anti-overflow pipe 1 2. The air outlet 7 of the air nozzle 2 faces the lumen of the anti-overflow pipe 1 , and the air inlet 8 of the air nozzle 2 faces the gas cavity 4 .

[0029] How to use: The anti-overflow pipe 1 used by the mud scraper is equal to the size of the anti-overflow pipe commonly used by the drilling team, and can be directly welded to the upper end of the anti-overflow pipe of the drilling team, which is convenient for the...

Embodiment 2

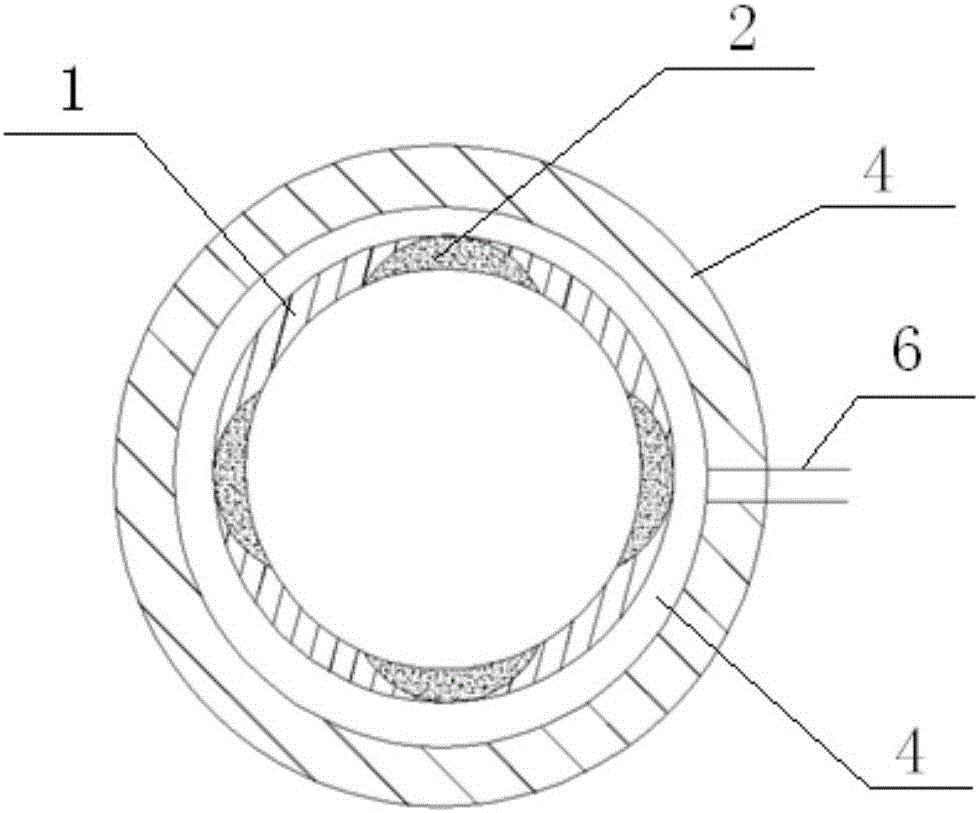

[0036] On the basis of Example 1, please refer to figure 2 and 3 , the anti-overflow pipe 1 evenly offers a plurality of installation holes (not marked) on the same circumference, and one of the air nozzles 2 is installed in each installation hole.

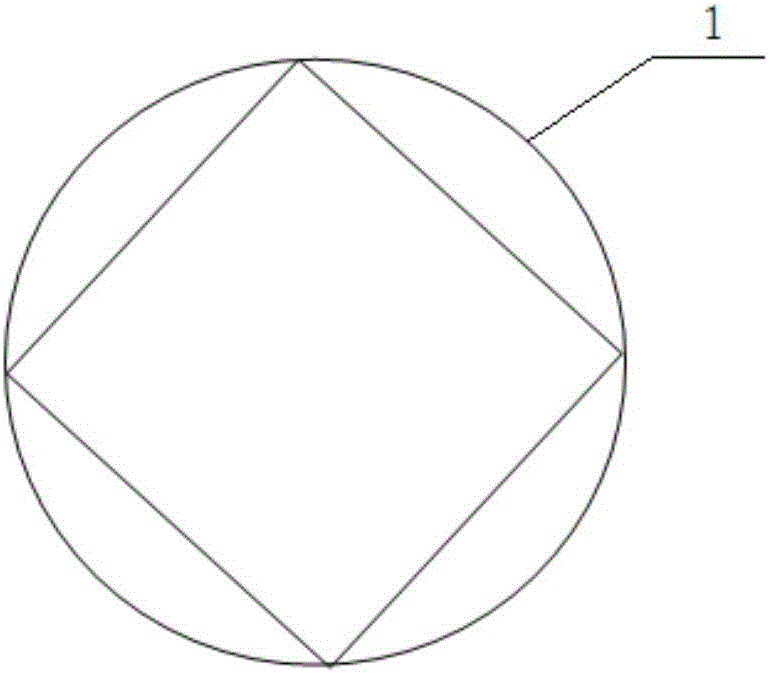

[0037] The present invention evenly distributes a plurality of mounting holes on the anti-overflow pipe 1, so that the gas ejected from a plurality of air nozzles 2 can be stably and evenly blown to the surface of the drilling tool, just as image 3 As shown, the gas can basically be blown to most of the cross-section of the overflow prevention pipe 1, so that the mud on each area on the surface of the drilling tool can be blown clean, and the gas concentration can only be blown away to the mud on a certain area on the surface of the drilling tool. problem occurs.

Embodiment 3

[0039] On the basis of implementation 2, the anti-overflow pipe 1 is connected in the installation hole by gluing or welding, so that the air nozzle 2 is firmly connected to the anti-overflow pipe 1 to ensure smooth and stable air blowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com