Trifluoromethanesulfonic acid production device and method

A technology of trifluoromethanesulfonic acid and production device, which is applied in separation methods, sulfonic acid preparation, sulfonate preparation and other directions, can solve the problems of low production efficiency and poor quality of trifluoromethanesulfonic acid, and achieves elimination of substandard products , the effect of improving purity, ensuring efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

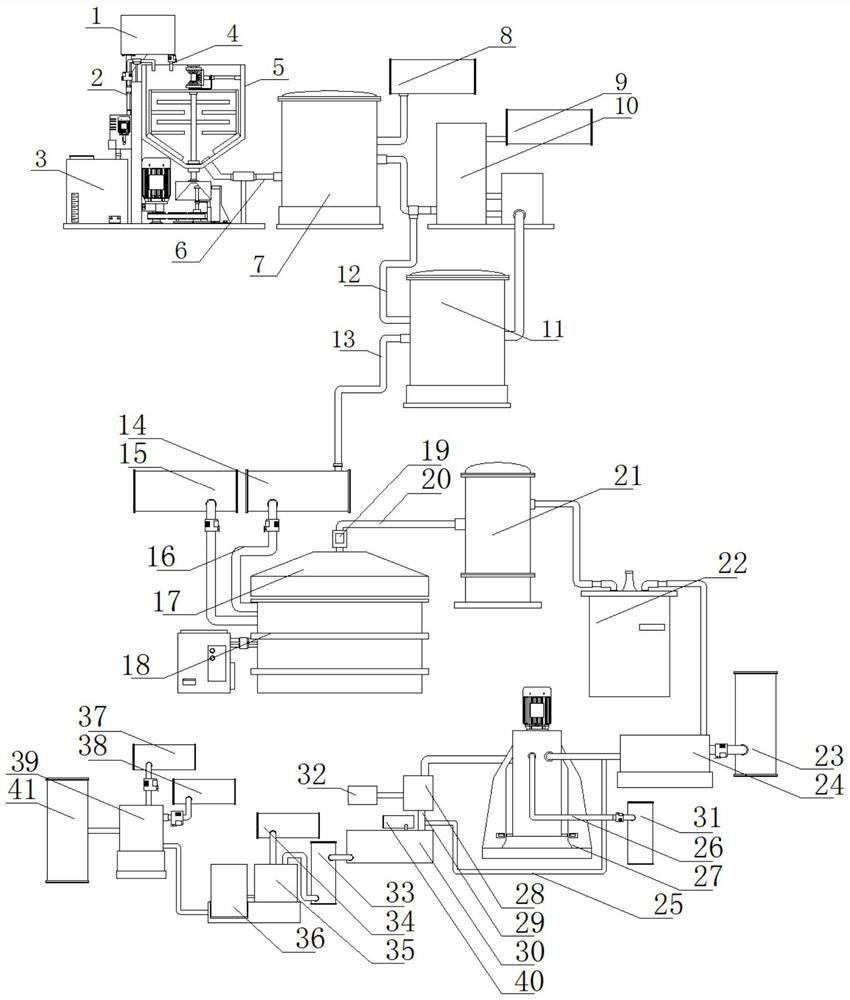

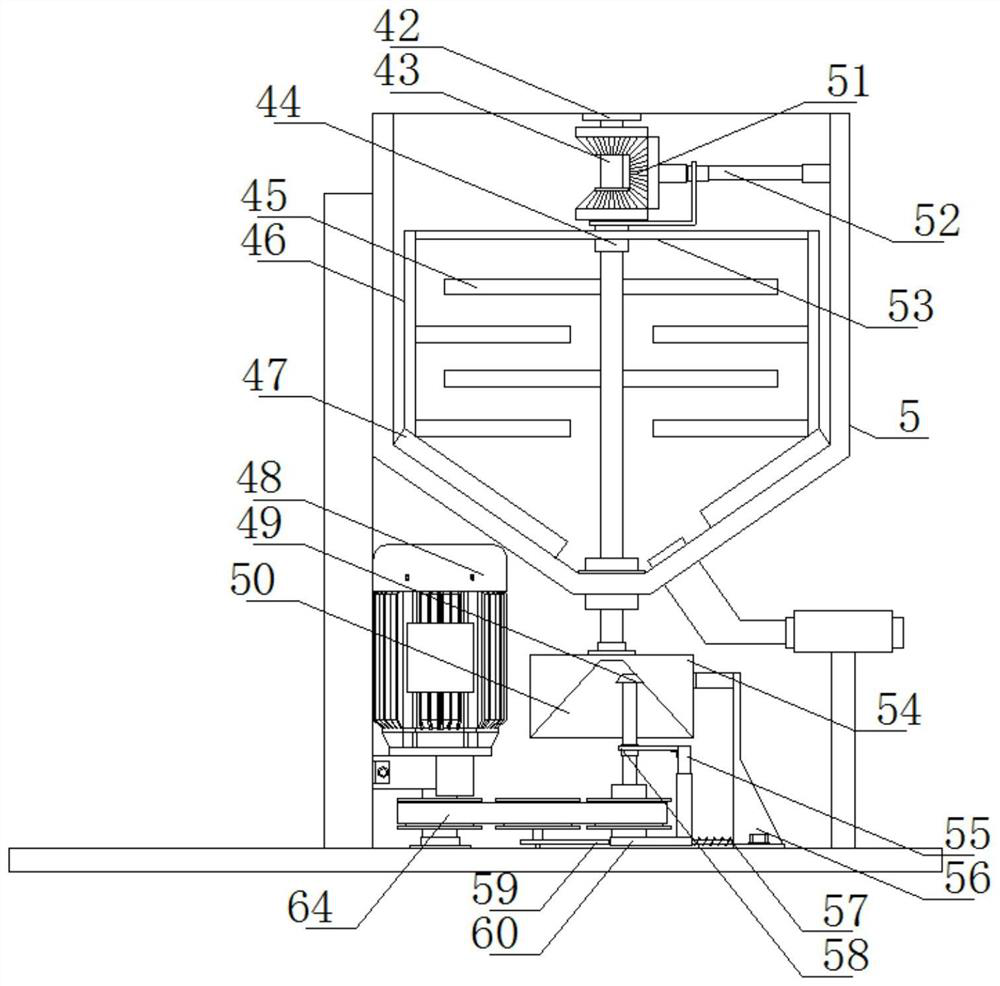

[0055] Such as Figure 1-3 Shown, a kind of production device of trifluoromethanesulfonic acid comprises agitator 5, and the first potassium fluoride storage tank 1 is connected with agitator 5 upper end by first delivery pipe 4, and methanesulfonyl chloride solution storage tank 3 passes through The infusion tube 2 is connected to the upper end of the agitator 5, and potassium fluoride and methanesulfonyl chloride solutions are transported to the agitator 5 as required, and the mixed solution is heated and stirred, so that the materials can fully react.

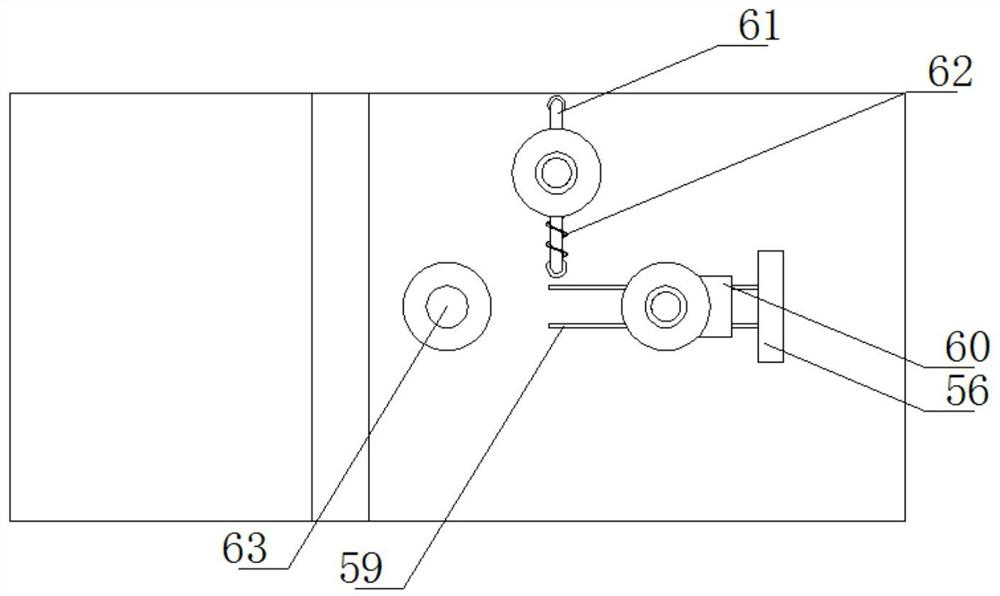

[0056] The upper end of the agitator 5 is fixed with a connecting plate 42, and the lower end of the connecting plate 42 is rotatably connected with a rotating shaft 43, which can ensure the stability of the rotating shaft 43 well. The lower end of the rotating shaft 43 runs through the agitator 5 and extends to the outside of the agitator 5. The speed regulating mechanism is connected, and the speed regulating mechanism can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com