Intelligent brick-making system equipment

A technology of system equipment and raw materials, applied in auxiliary molding equipment, manufacturing tools, supply devices, etc., can solve problems such as the inability to adjust the amount of feeding and filtering impurities, the inability to rotate and self-elevate raw materials, and the lack of spraying and heat dissipation functions, etc., to achieve Increase the automatic feeding function to ensure the improvement of safety and avoid the effect of splashing and dropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

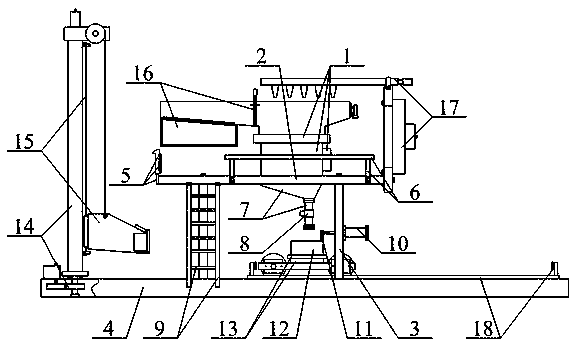

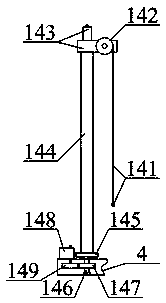

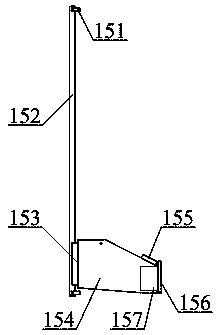

[0054] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the intelligent brick-making system equipment includes a brick-making raw material mixer 1, a mixing operation platform 2, a platform building pillar 3, a support base 4, an intelligent main control integrated machine 5, and a platform operation guardrail 6. After the brick-making raw materials are stirred Discharge pipe 7, discharge electromagnetic control valve 8, movable climbing ladder 9, auxiliary flattening cylinder 10, flattening plate 11, brick making mold 12, brick making vibrating table 13, rotatable self-elevating self-locking machine structure 14, The slidable self-control raw material lifting bucket structure 15, the controllable raw material filtering miscellaneous vibrating bucket structure 16, the heat dissipation type dust-proof spray branch pipe structure 17 and the self-moving brick-making rear export wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com