self-propelled hydraulic mixer

A kind of mixer, self-propelled technology, applied in the direction of cement mixing device, clay preparation device, unloading device, etc., can solve problems such as uneven distribution, affecting mixing efficiency and mixing uniformity, and achieve the effect of ensuring mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

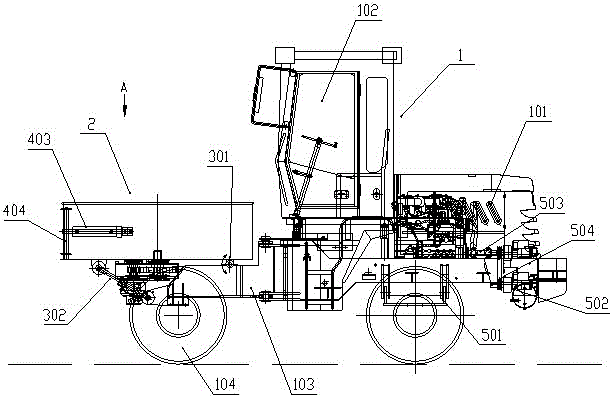

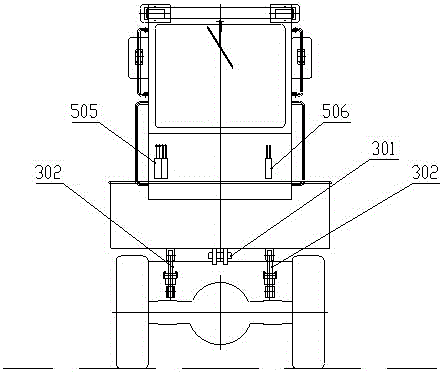

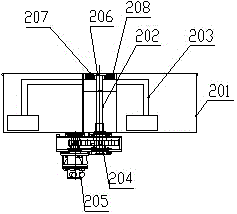

[0022] Such as Figure 1-4 Shown: the self-propelled hydraulic mixer of this embodiment includes a movable car body 1 and a mixer 2 installed on the car body, wherein: the car body 1 includes an operating room 102, a vehicle frame 103 and tires 104, in this embodiment The car body is refitted by removing the bucket from a wheel loader; the mixer 2 includes a mixing bucket 201, a mixing shaft 202 coaxially arranged in the mixing bucket, a mixing arm 203 uniformly distributed on the mixing shaft in the circumferential direction, and a mixing arm 203 installed in the mixing bucket 201. The lower gearbox 204 and the hydraulic motor 205 driving the gearbox 204, the stirring shaft 202 passes through the bottom of the mixing drum 201 and is connected to the output shaft of the gearbox 204, and the hydraulic motor 205 drives the stirring shaft 202 through the gearbox 204 And the stirring arm 203 rotates, and the rotating stirring arm 203 completes the stirring of materials such as con...

Embodiment 2

[0029] The first swing cylinder 302 in Embodiment 1 and the rotating horizontal shaft 301 of the mixer 2 are directly installed on the vehicle frame of the vehicle body. Such as Figure 7 As shown, the difference from Embodiment 1 is that this embodiment also includes a swing frame 601 located on the vehicle body frame, the mixer 2 and the first swing cylinder 302 are installed on the swing frame 601, correspondingly, the mixer 2 The horizontal axis 301 of rotation is also located on the swing frame 601; the swing frame 601 is hinged with the vehicle frame of the vehicle body 1 around the vertical axis 602 perpendicular to the vehicle axis, and is driven by the second swing cylinder 603 positioned on the vehicle body frame Pivot around this longitudinal axis 602 . When the car body 1 is on a left-right uneven road surface, the second swing cylinder 603 drives the swing frame 601 and the mixer 2 on the swing frame to swing around the longitudinal axis 602, and the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com