Carbon electrode perovskite solar battery and preparation method thereof

A solar cell and perovskite technology, which is applied to circuits, electrical components, and electrical solid devices, can solve problems such as perovskite corrosion, and achieve the effect of reducing corrosion and drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

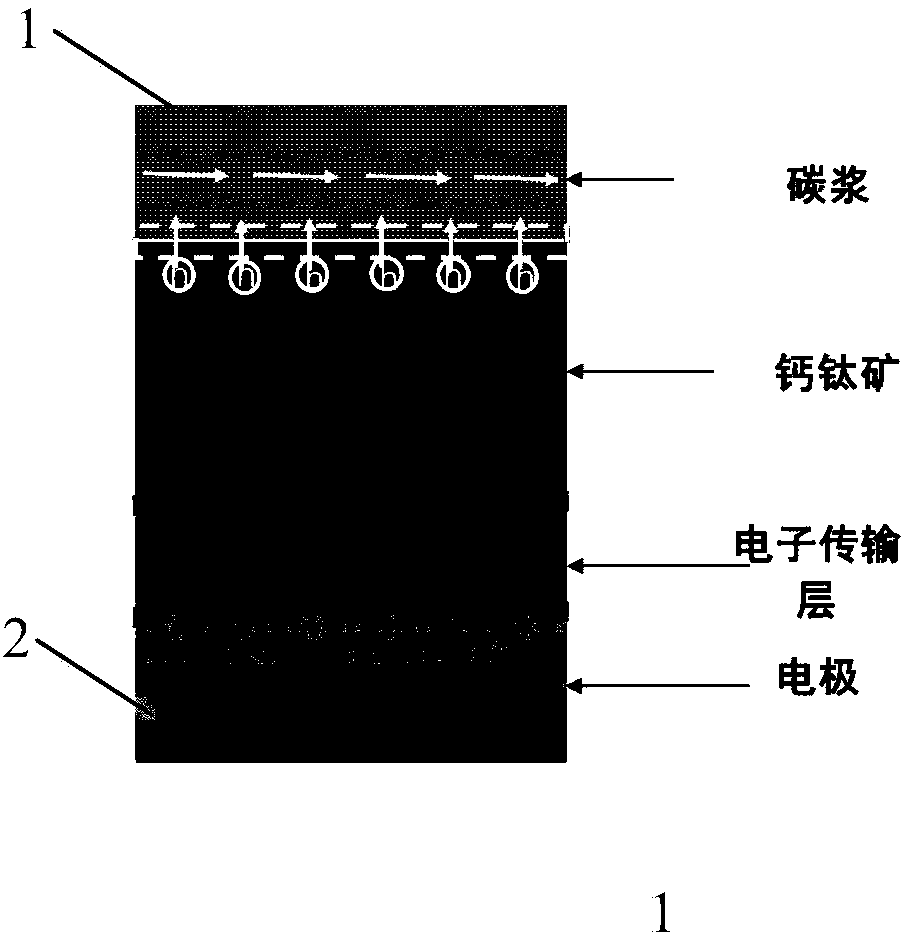

[0056] 1. On the ITO substrate, spin-coat TiO 2 Precursor, sintered at 500 degrees for half an hour to prepare dense TiO 2 Electron transport layer;

[0057] 2. In dense TiO 2 A layer of perovskite precursor was spin-coated on the electron transport layer and dried to prepare MAPbI 3 perovskite thin film.

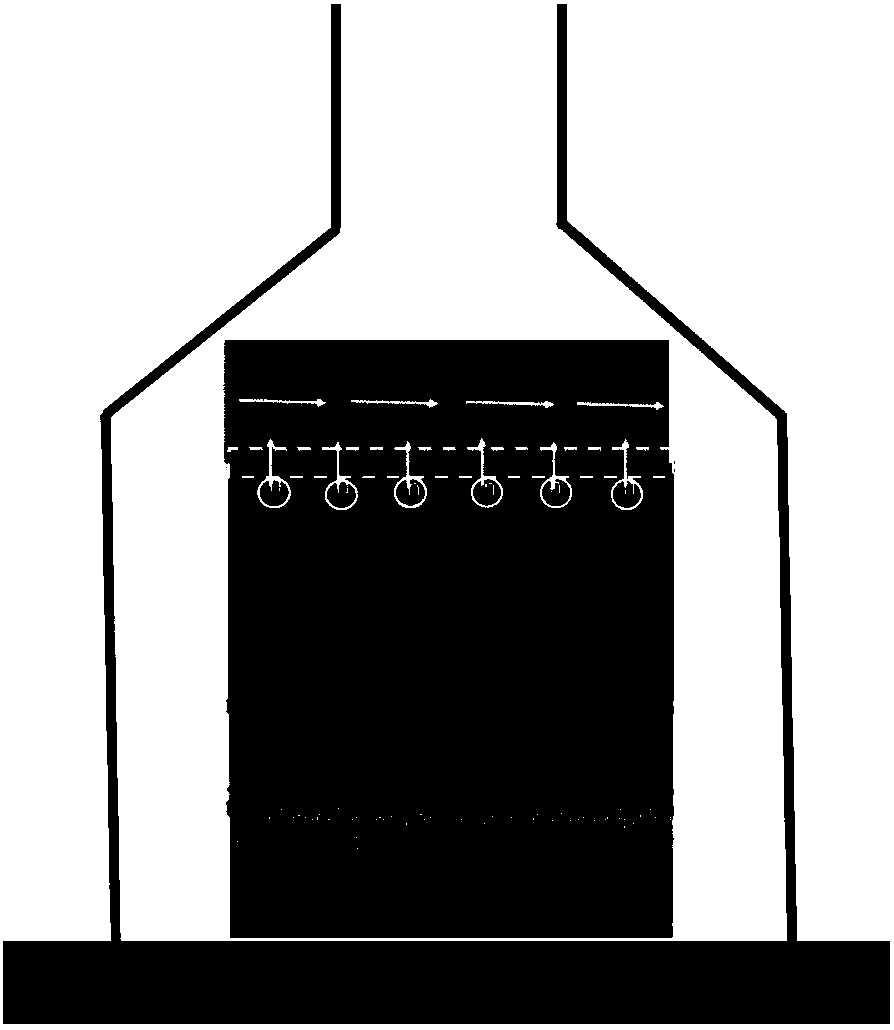

[0058] 3. On the dense perovskite film, use a scraper method to scrape a layer of commercial carbon slurry with a thickness of about 15 μm whose solvent is isophorone, then heat on the surface of the carbon slurry, cool the ITO side, and dry it under a pressure of 100Pa , to accelerate the volatilization of the solvent, that is, to obtain a carbon electrode perovskite solar cell.

[0059] Test and record the cross-sectional morphology of the carbon film, such as Figure 3-1 , Figure 3-2 As shown, the perovskite morphology remained intact and no corrosion occurred. Battery performance such as Figure 3-3 shown

Embodiment 2

[0061] 1. On the ITO substrate, spin-coat TiO 2 Precursor, sintered at 500 degrees for half an hour to prepare dense TiO 2 Electron transport layer;

[0062] 2. In dense TiO 2 A layer of perovskite precursor was spin-coated on the electron transport layer and dried to prepare FAPbI 3 perovskite thin film.

[0063] 3. On the hole transport layer, use a scraper method to scrape a layer of commercial carbon slurry with a thickness of about 20 μm whose solvent is butyl acetate, then heat on the surface of the carbon slurry, cool the ITO side, and dry it under a pressure of 100 Pa to make the solvent Accelerate volatilization to obtain carbon electrode perovskite solar cells.

Embodiment 3

[0065] 1. On the ITO substrate, spin-coat TiO 2 Precursor, sintered at 500 degrees for half an hour to prepare dense TiO 2 Electron transport layer;

[0066] 2. In dense TiO 2 A layer of perovskite precursor was spin-coated on the electron transport layer and dried to prepare FAPbI 3 Perovskite film, spin-coated with a layer of P3HT hole transport layer.

[0067] 3. On the hole transport layer, use a scraper method to scrape a layer of commercial carbon slurry with a thickness of about 20 μm as the solvent of butyl acetate, then heat the surface of the carbon slurry, cool the ITO side, and dry it under a pressure of 10 Pa to make the solvent Accelerate volatilization to obtain carbon electrode perovskite solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com