Experiment method for adjusting local sate of titanium alloy Alpha/Beta phase interface

An experimental method and titanium alloy technology, applied in the field of titanium alloy materials, can solve the problems of high energy consumption, low energy utilization efficiency, and inability to target local phase interface states.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Taking the titanium alloy TC11 (Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) as an example, the experiment of adjusting the local state of the titanium alloy α / β phase interface is carried out, including steps:

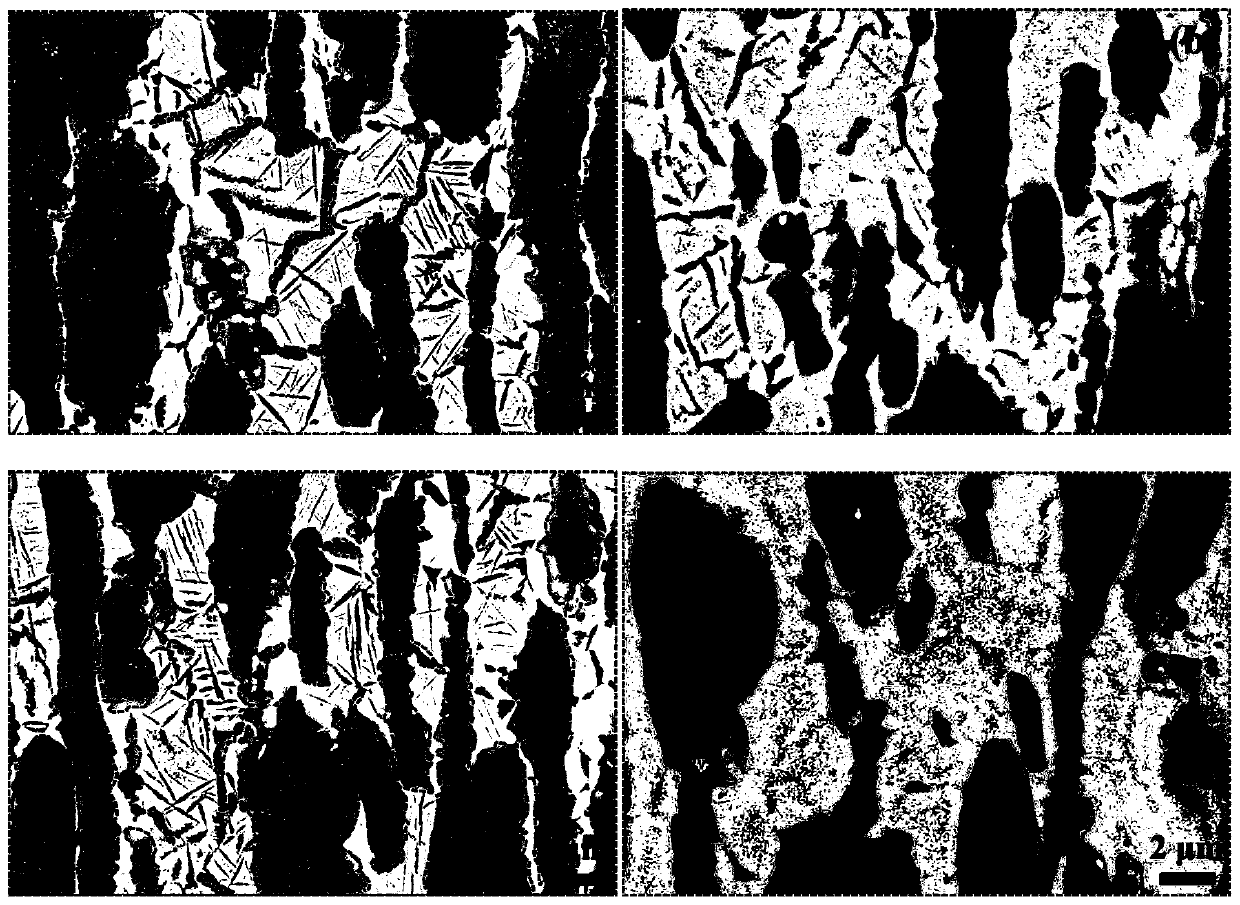

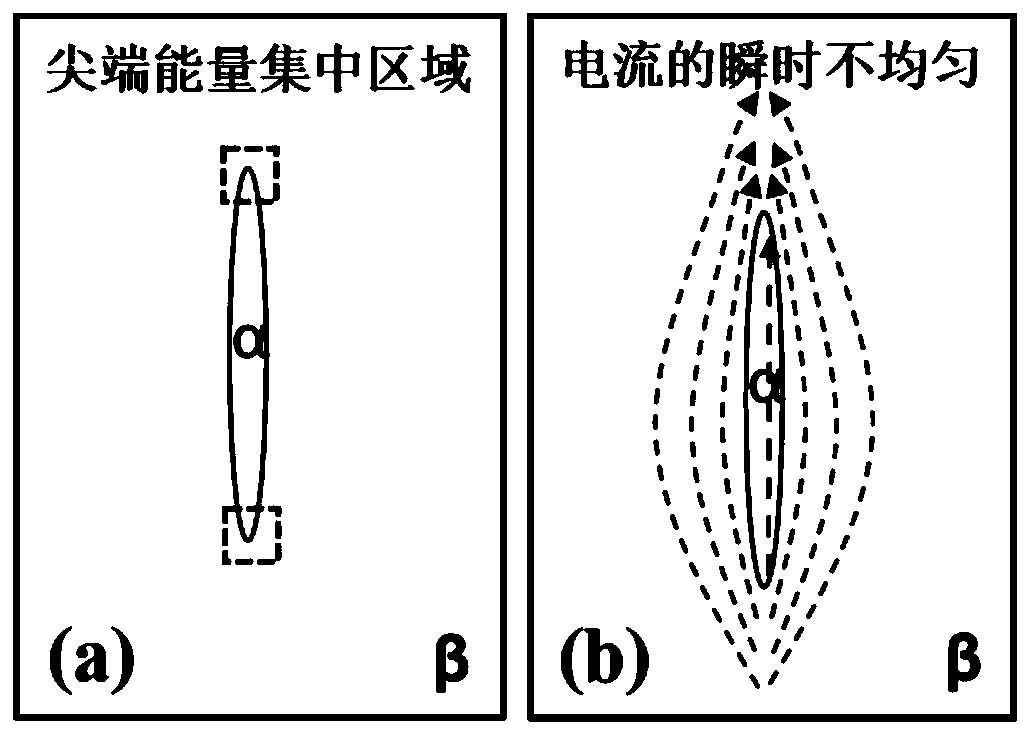

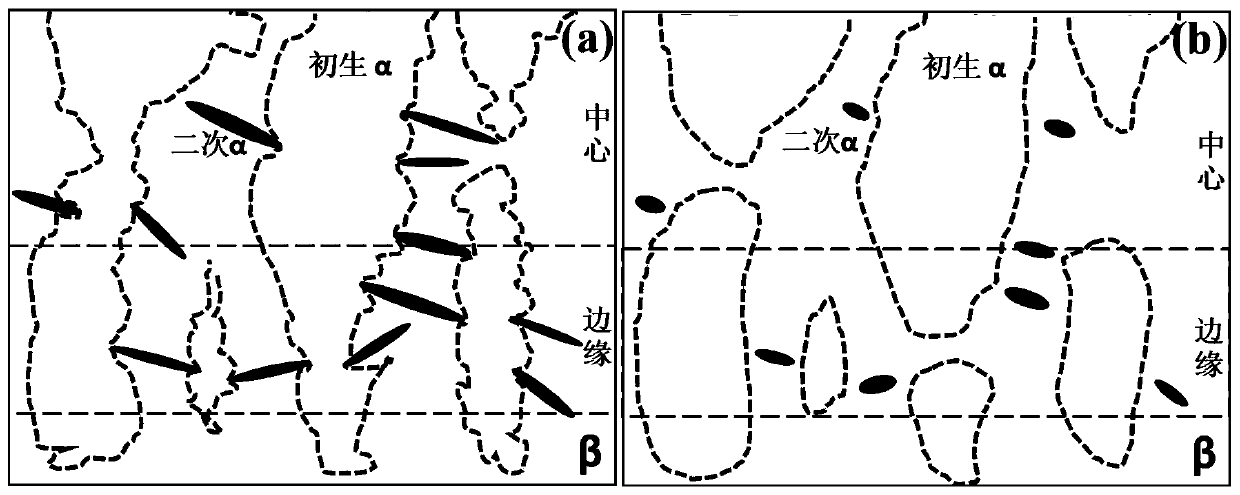

[0024] S1. Wire-cut the rod-shaped TC11 sample into a cylindrical sample with a diameter of 5 mm and a height of 10 mm. Part of the sample is supported with electrodes at both ends and subjected to pulse current impact treatment, and the other part of the sample is not subjected to pulse current impact treatment. Before pulse current impact treatment, (Grinding with sandpaper) to remove the oxide layer on the surface of the sample. When performing pulse current impact treatment, set the current value to 70A and the action time to 0.08s. Floor.

[0025] S2, the sample is cut along the midline, and the cut surface is successively subjected to thermal inlay, surface sandpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com