Nickel-aluminum bronze alloy and preparation method thereof

A nickel-aluminum bronze and alloy technology, applied in the field of nickel-aluminum bronze alloy materials and its preparation, can solve problems such as lack of data support performance, improve hardness and wear resistance, improve hardness and wear resistance, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

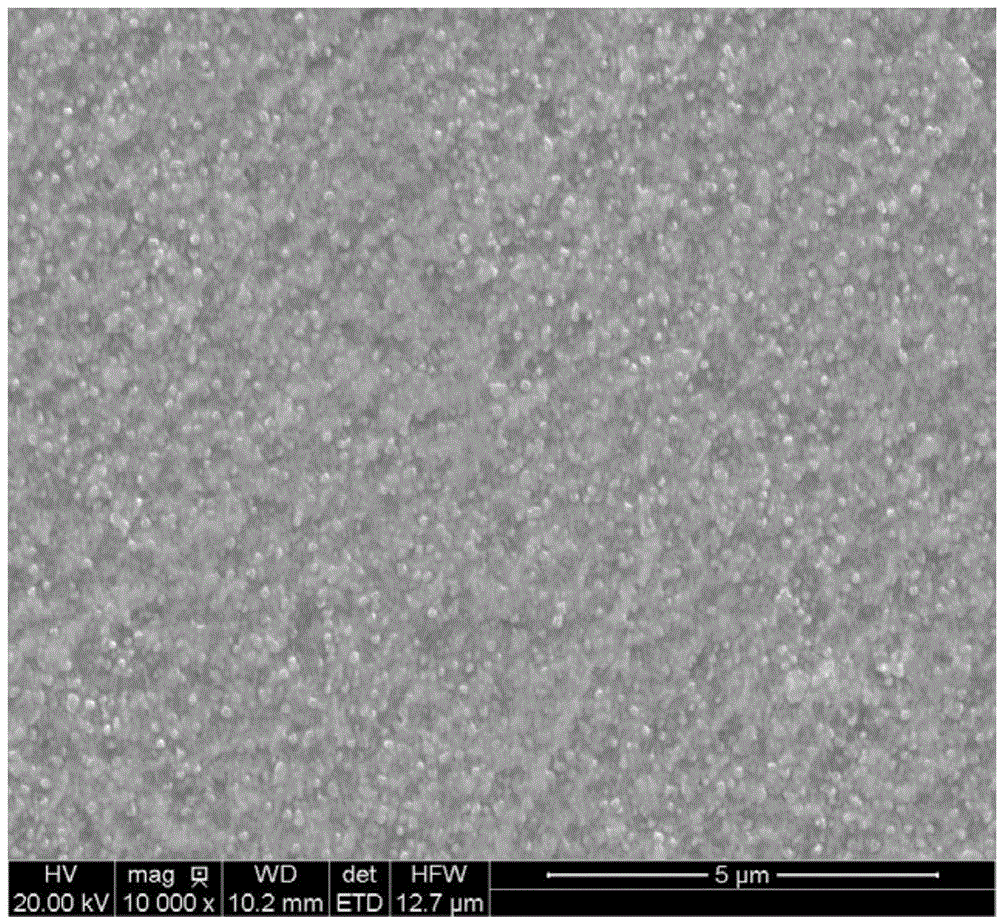

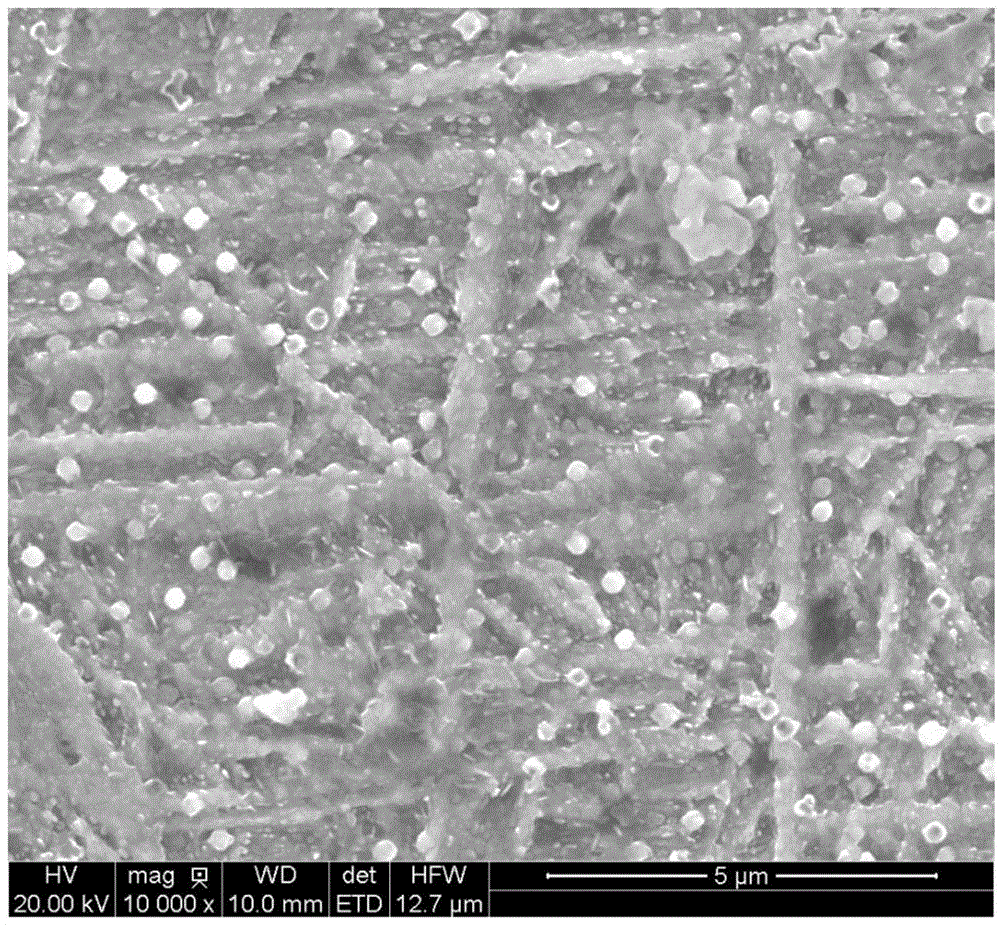

Image

Examples

Embodiment 1

[0027] Electrolytic copper, pure aluminum, pure nickel, pure iron and pure manganese are respectively used as raw materials, and the mass ratio of raw materials is 74:10:4:4:8. Fill the raw materials into the crucible at one time and heat it, first preheat it and then heat it quickly, stir after the copper block starts to melt, so that the high melting point metal iron, nickel and manganese can be melted faster. After all the metals are completely melted, continue to stir to achieve the effect of uniform composition and degassing. After standing for a period of time, the molten metal is cooled into ingots.

[0028] Heat the above ingot from room temperature at a rate of 8-10°C / min to 950°C for 2 hours, take out the sample and immediately put it in water for quenching. Then heat it up to 450°C at a speed of 10°C / min, keep it warm for 2 hours, put it in the air to cool, and you get it.

[0029] The chemical elements and mass percentages contained in the nickel-aluminum-bronze a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

| Microhardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com