Method for measuring content of aluminum, iron, silicon, lead, tin and manganese in aluminum copper alloy simultaneously

A technology of aluminum-copper alloy and aluminum-iron-silicon, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems of low efficiency and high detection limit of detected element range, and achieve accurate analysis results, good application effect and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Make working curve by above-mentioned method, curve correlation coefficient r is greater than 0.999, prepare 11 parts of blank solutions by experimental method and measure for 3 times, according to the detection limit formula CL=3Sb / k defined by International Union of Pure and Applied Chemistry (IUPAC) (Sb is the standard deviation of the blank, k is the slope of the corresponding calibration curve) The calculated method detection limit is Al 0.003%; Mn, Fe, Si, Pb, Sn 0.001at%.

Embodiment 2

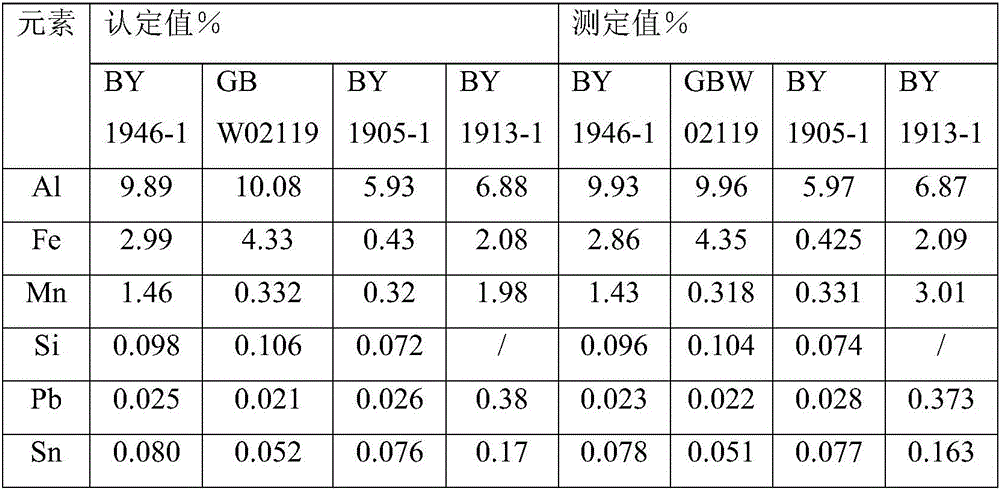

[0047] Weigh aluminum brass (BY1946-1), aluminum bronze (GBW02119), aluminum brass (BY1905-1), (BY1913-1) and measure according to the above method, the results are shown in Table 1.

[0048] Table 1 Determination results of standard samples

[0049]

Embodiment 3

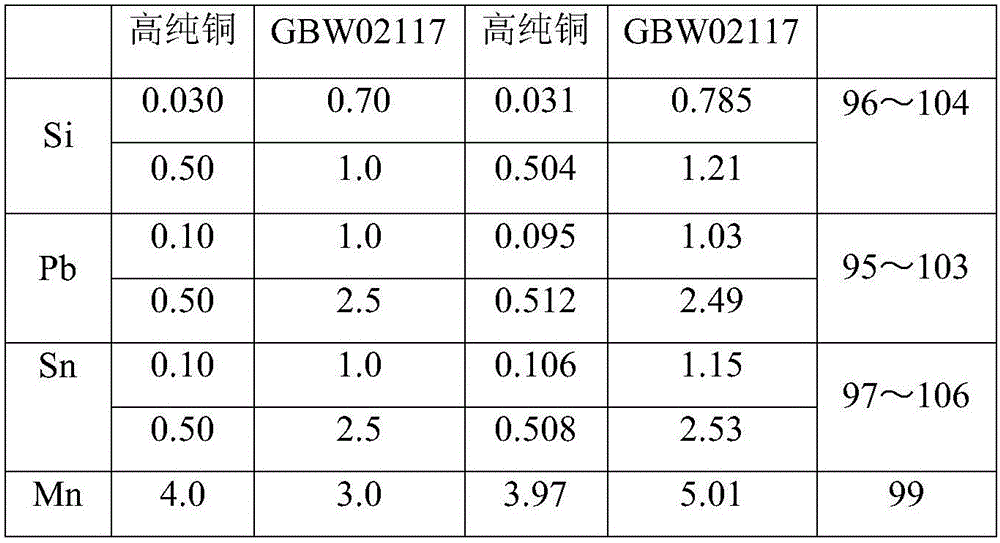

[0051] Weigh two parts of high-purity copper, add Si, Pb, Sn, Mn standard solution respectively; method, and the results are shown in Table 2.

[0052] Table 2 Determination results of standard sample spiked recovery

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com