Method for preparing aluminum bronze powder by water atomization

A technology of aluminum bronze and water atomization, which is applied in the field of preparing aluminum bronze powder by water atomization, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

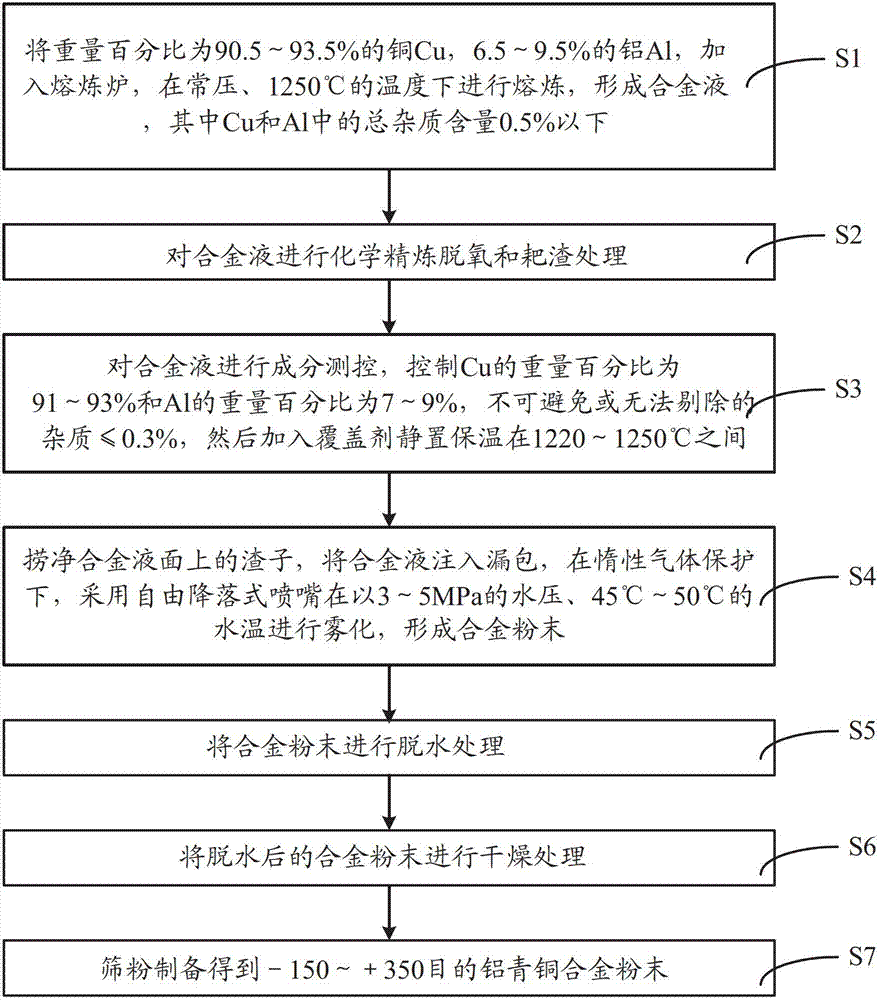

[0033] A method for preparing aluminum bronze powder by water atomization, comprising the following steps:

[0034] (1) Select the weight percentage of raw materials as follows: No. 1 electrolytic copper 92%, A00 aluminum ingot 8%, use 0.25T intermediate frequency melting furnace to weigh 230Kg of No. 1 electrolytic copper, A00 aluminum ingot 20Kg, add the raw materials that have been weighed Smelting in the air atmosphere in the intermediate frequency melting furnace, the melting temperature is 1250 ℃.

[0035] (2) After smelting, carry out chemical refining deoxidation and rake slag.

[0036] (3) Measure and control the composition of the alloy liquid, control the weight percentage of Cu to 91-93%, and the weight percentage of Al to 7-9%, and then add a covering agent and keep the temperature at 1220-1250°C.

[0037] (4) Remove the slag on the surface of the alloy liquid, inject the alloy liquid into the leakage bag, the diameter of the leakage hole is 4mm, use the free-fal...

Embodiment 2

[0043] A method for preparing aluminum bronze powder by water atomization, comprising the following steps:

[0044] (1) Cu with 90.5% by weight and 9.5% aluminum Al are added to the smelting furnace, smelted at normal pressure and a temperature of 1250°C to form an alloy liquid, wherein the total weight of the above-mentioned Cu, Al and total impurities is 100 %.

[0045] (2) Carry out chemical refining deoxidation and raking slag treatment on the alloy liquid.

[0046] (3) Measure and control the composition of the alloy liquid, control the weight percentage of Cu to be 91-93% and the weight percentage of Al to be 7-9%, and then add a covering agent and keep the temperature at 1220-1250°C.

[0047] (4) Remove the slag on the alloy liquid surface, inject the alloy liquid into the leakage bag, and under the protection of an inert gas, use a free-fall nozzle to atomize at a water pressure of 3MPa and a water temperature of 45°C to form alloy powder, wherein The leak hole diame...

Embodiment 3

[0053] A method for preparing aluminum bronze powder by water atomization, comprising the following steps:

[0054] (1) Add 93.5Cu and 6.5% Al by weight into a smelting furnace, and smelt under normal pressure at a temperature of 1250° C. to form an alloy liquid, wherein the total weight of the above-mentioned Cu, Al and total impurities is 100%.

[0055] (2) Carry out chemical refining deoxidation and raking slag treatment on the alloy liquid.

[0056] (3) Measure and control the composition of the alloy liquid, control the weight percentage of Cu to be 91-93% and the weight percentage of Al to be 7-9%, and then add a covering agent and keep the temperature at 1220-1250°C.

[0057] (4) Remove the slag on the alloy liquid surface, inject the alloy liquid into the leakage bag, and under the protection of inert gas, use a free-fall nozzle to atomize at a water pressure of 5MPa and a water temperature of 48°C to form alloy powder, wherein The leak hole diameter of the leak bag i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com