Preparation method of nickel-aluminum bronze

A nickel-aluminum bronze and copper plate technology, which is applied in the field of marine equipment, can solve the problems of material grain size increase and uneven composition, and achieve the effects of fine and uniform structure, improved comprehensive performance, strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare pure copper plate, copper-aluminum alloy block (copper-aluminum mass ratio is 1:1), pure nickel plate, pure iron plate and manganese powder, the masses are 37.4kg, 10.5kg, 2.3kg, 2.2kg and 0.65kg respectively. Before smelting, the surface of the plate is firstly treated to remove oil stains and surface oxide scales, and then the material is put into the furnace, where the copper and aluminum alloys are placed on the top, and the furnace is closed, then vacuumed, and melted at 1250 ° C for 40 minutes. During this period Stir continuously with a stirring rod, open the furnace, sprinkle some slagging agent on top of the solution, and cast into cylindrical molds. After cooling, use a lathe to remove the scale on the surface of the casting until the large inclusions and pores are no longer visible. The tensile sample was cut by electric discharge wire to obtain the national standard cast aluminum bronze 9-4-4-2, and the tensile performance data at room temperature wa...

Embodiment 2

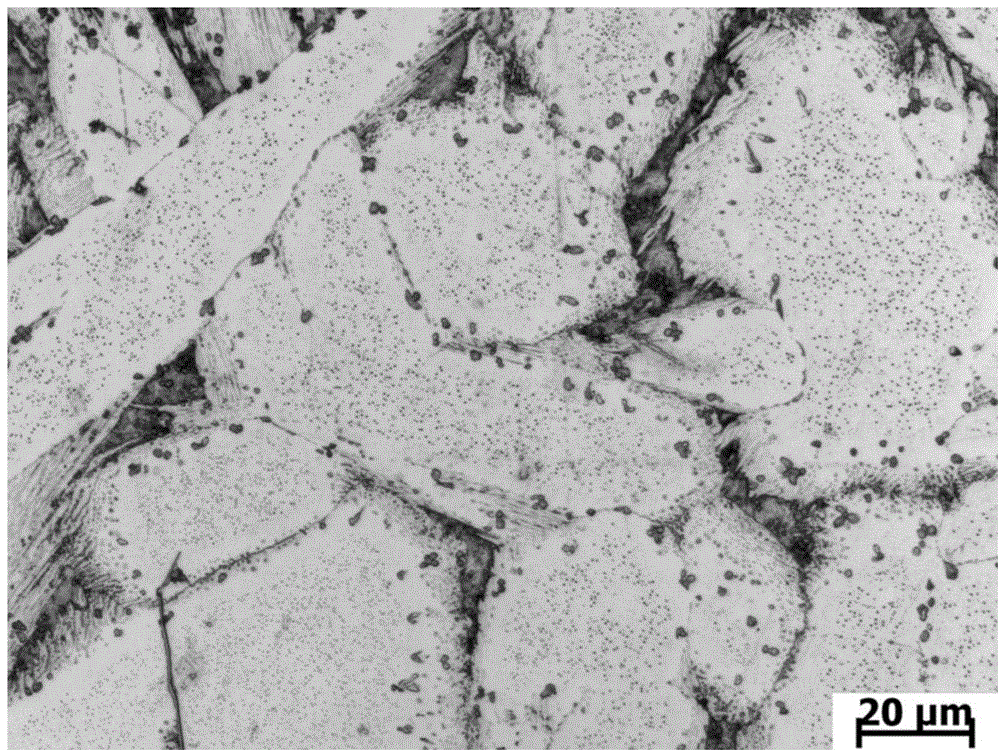

[0027] Other conditions are the same as in Example 1. Non-vacuum smelting is adopted in Example 2. When boiling is reached at 1250° C., some covering powder is sprinkled on the top and smelted for 40 minutes. During this period, stir with a stirring rod constantly, and the covering powder is pulled out before casting. Sprinkle in some slagging powder and cast. figure 1 It shows that nickel-aluminum-bronze alloy with less impurity and less burning loss rate can be successfully obtained by this process. The measured room temperature tensile performance data is:

[0028] Tensile strength: 597MPa, yield strength: 413MPa, elongation: 7.0%, microhardness: 170HV.

Embodiment 3

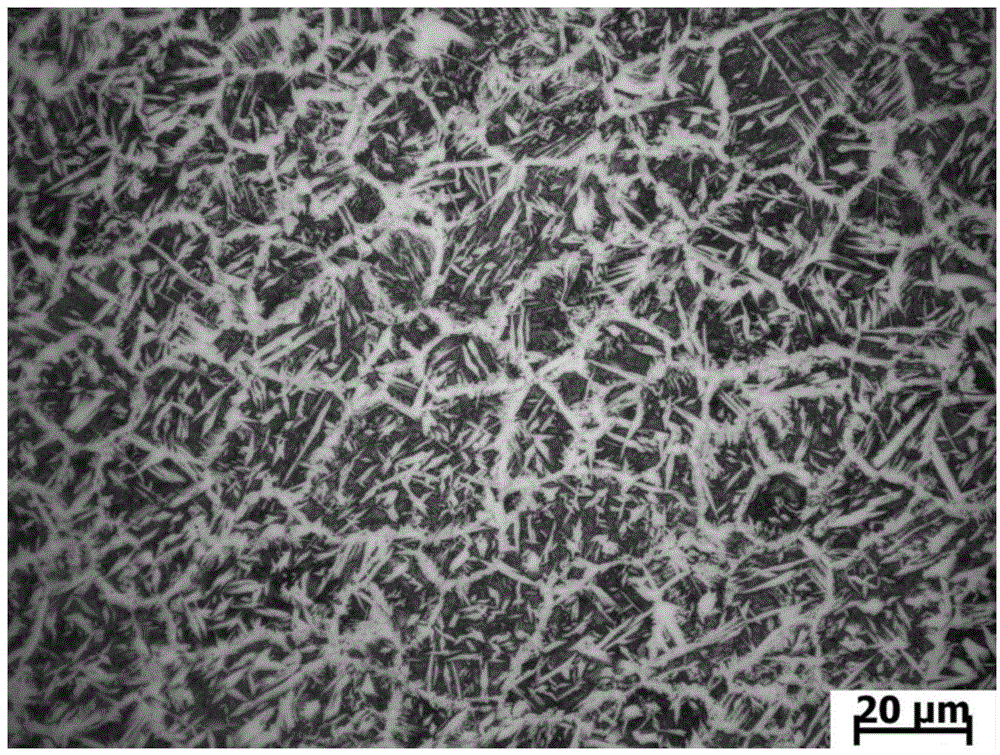

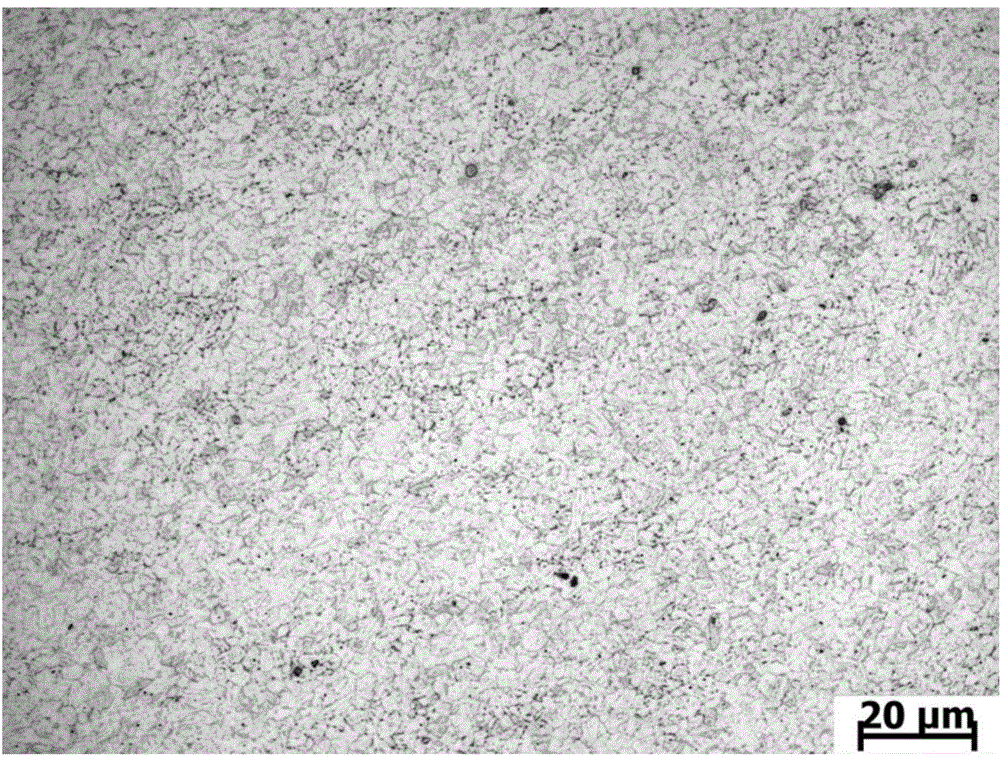

[0030] Other conditions are the same as in Example 1. In Example 3, the casting line cut by the car is cut into a 50mm × 120mm × 5mm rectangular block, the oil stain on the top is cleaned, and then the surface is smoothed with a grinder, and the surface is subjected to friction stir processing. Aiming at a rotational speed of 2000rpm / min, a processing speed of 150mm / min, and an inclination angle of 3°, argon gas is blown for cooling during processing. The microhardness measured after polishing the surface of the sample is 292HV, but the microstructure of the sample is mainly composed of widmanstatte α and residual β phase (see figure 2 ), with poor corrosion performance. Depend on figure 2 It can be seen that after surface treatment by friction stir processing, a nickel-aluminum bronze with uniform and fine structure is obtained, and the microstructure is mainly composed of Widmanstattenite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com