Low-oxygen-content and high-yield spherical aluminum bronze alloy powder for thermal spraying and preparation method thereof

A technology of alloy powder and bronze alloy, which is applied in the field of aluminum bronze coating materials and coating preparation, can solve the problems of low fluidity and loose ratio, high coating porosity, and low powder performance, and achieve fluidity and loose ratio High, low oxide content, good sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1. Preparation of Alloy Powder

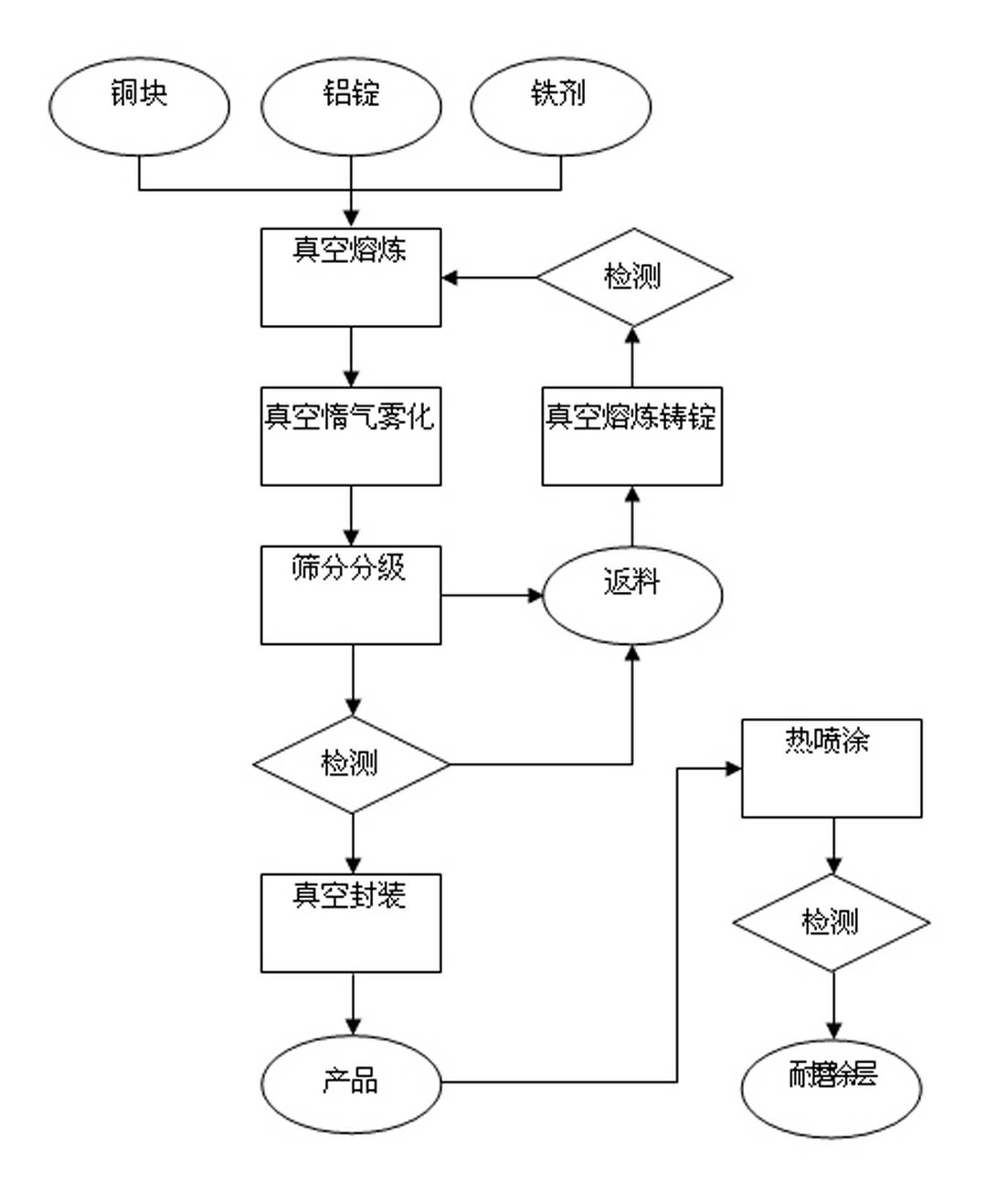

[0026] The preparation method of aluminum bronze coating material of the present invention comprises the following steps:

[0027] 1) Take metal material a): aluminum: 1-20wt%, iron: 0-5wt%, copper: balance; or take metal material b): aluminum: 1-20wt%, iron: 0-5wt%, copper The balance of aluminum-iron-copper alloy;

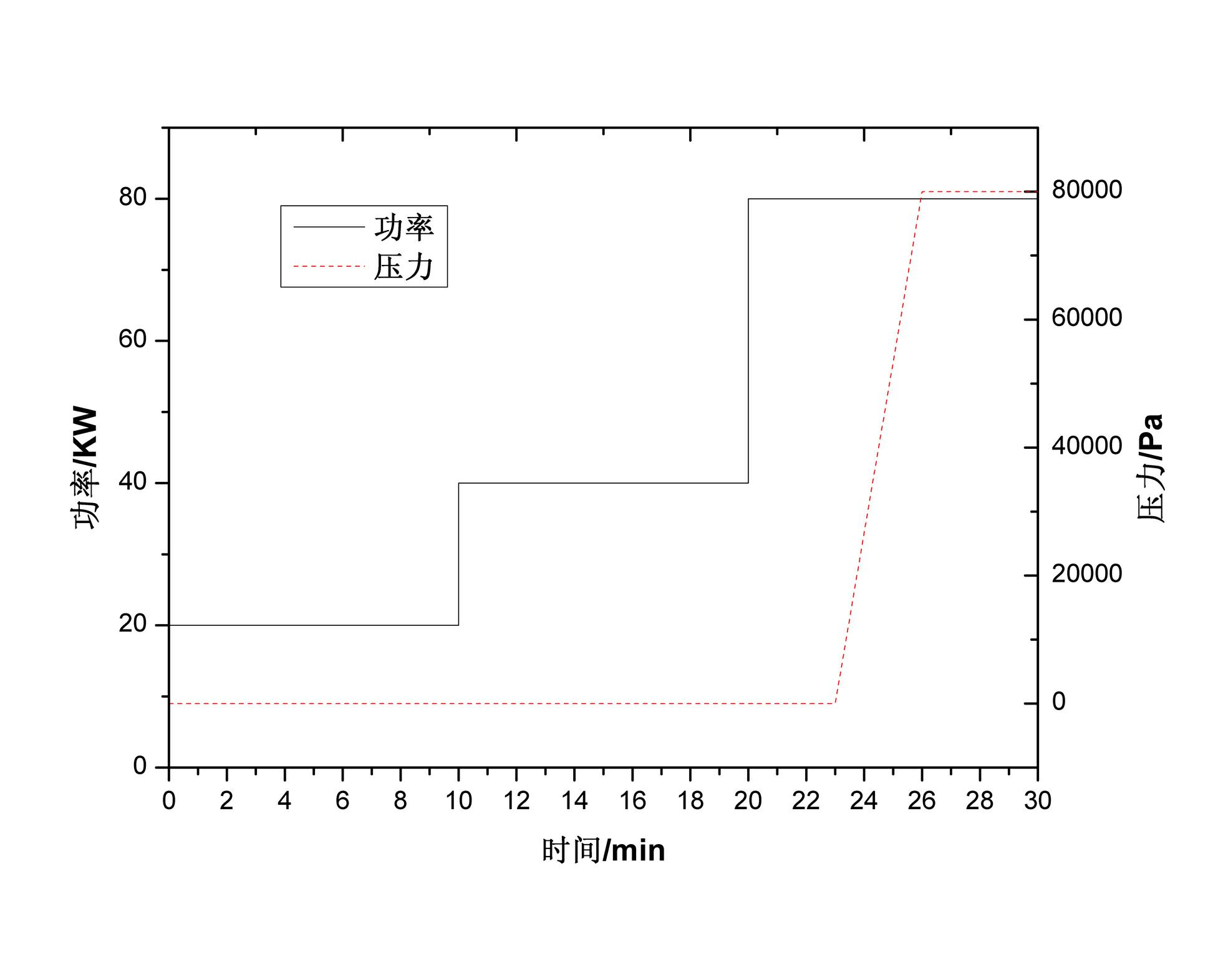

[0028] 2) Put the selected raw materials into a vacuum melting crucible; obtain aluminum bronze alloy powder through vacuum induction melting and inert gas atomization technology; the heating method and atmosphere control system are as follows: figure 2 shown;

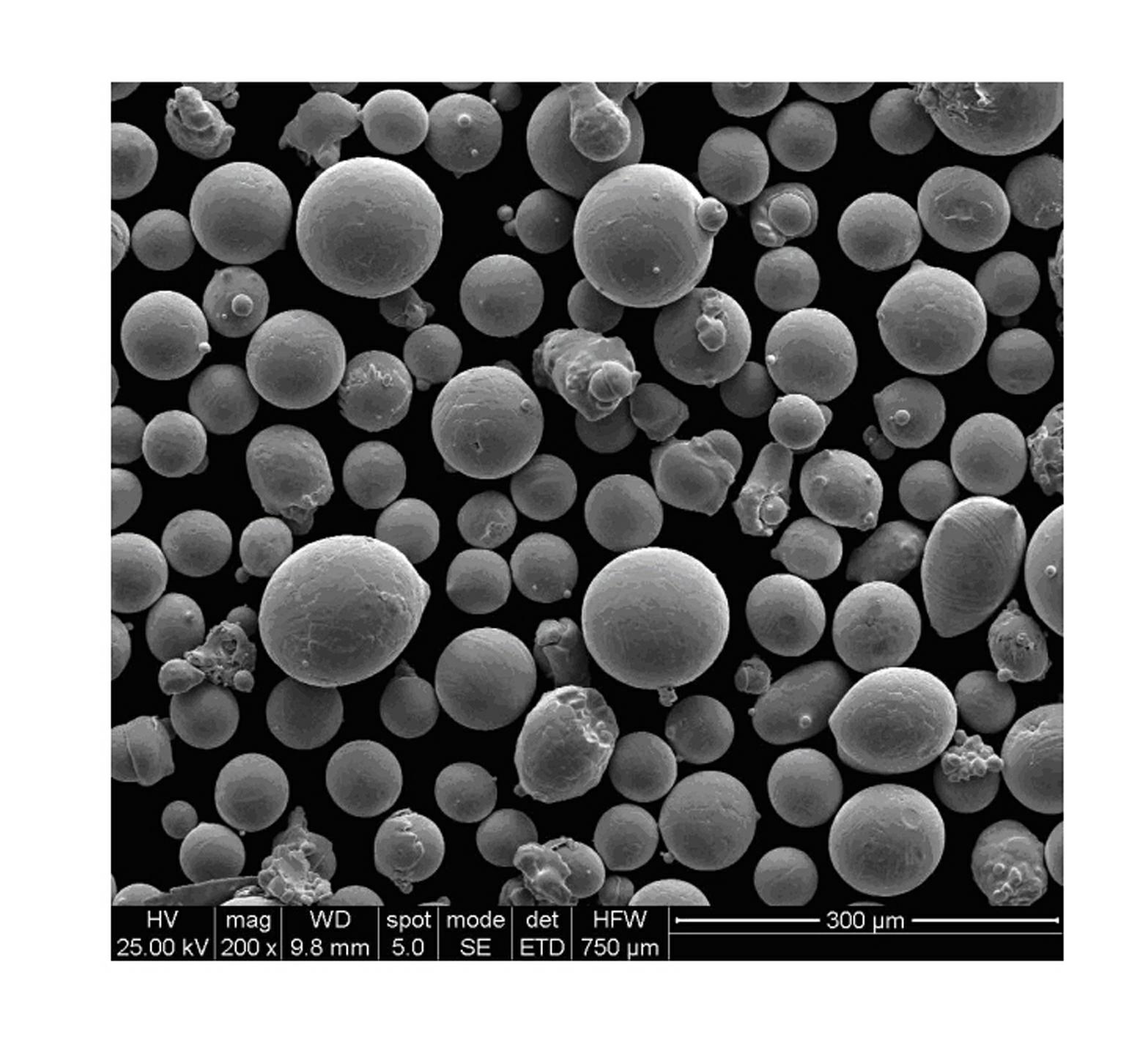

[0029] 3) Sieving or grading to prepare aluminum bronze coating materials with a powder particle size in the range of 25-124 μm. image 3 and Figure 4 It is the 200 times and 2000 times magnified photos of the scanning electron microscope SEM of the aluminum bronze prepared by the present invention. It can be seen that the particle size of the aluminum bronze ...

Embodiment 1

[0035] Metal materials: aluminum: 12wt%, iron: 3wt%, copper: balance. Put it into the vacuum atomization equipment and use intermediate frequency induction heating. When the temperature is heated to 1150°C, keep it warm for 10-20 minutes. After the alloy liquid is homogenized, use nitrogen atomization. The atomization process parameters are: atomization pressure is 1.8 MPa, the atomizer angle is 60°, and the aluminum bronze alloy powder is obtained.

[0036] The particle size of silver-copper alloy powder of the coating material prepared by classifying is in the range of 45-124 μm. Thus, the coating material aluminum bronze alloy powder is prepared. Atmospheric plasma spraying is used to spray aluminum bronze alloy powder. The spraying process parameters are: arc current 550A; arc voltage 65V; argon pressure 2.80MPa; hydrogen flow rate 0.36L / min; powder feeding speed 60g / min; spraying distance 140mm.

[0037] The prepared coating is dense, uniform and continuous, the powder ...

Embodiment 2

[0039] Alloy composition aluminum: 10wt%, iron: 2wt%, copper: balance. Put it into the vacuum atomization equipment and use intermediate frequency induction heating. When the temperature is heated to 1150°C, keep it warm for 10 to 20 minutes. After the alloy liquid is homogenized, use argon to atomize. The atomization process parameters are: atomization pressure is 1.5MPa, the atomizer angle is 75° to obtain aluminum bronze alloy powder.

[0040] The particle size of silver-copper alloy powder of the coating material prepared by classifying is in the range of 25-124 μm. Thus, the coating material aluminum bronze alloy powder is prepared. Atmospheric plasma spraying is used to spray aluminum bronze alloy powder. The spraying process parameters are: arc current 550A; arc voltage 65V; argon pressure 2.80MPa; hydrogen flow rate 0.36L / min; powder feeding speed 60g / min; spraying distance 140mm.

[0041] The prepared coating is dense, uniform and continuous, the powder is in a good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com