Patents

Literature

65results about How to "Low oxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

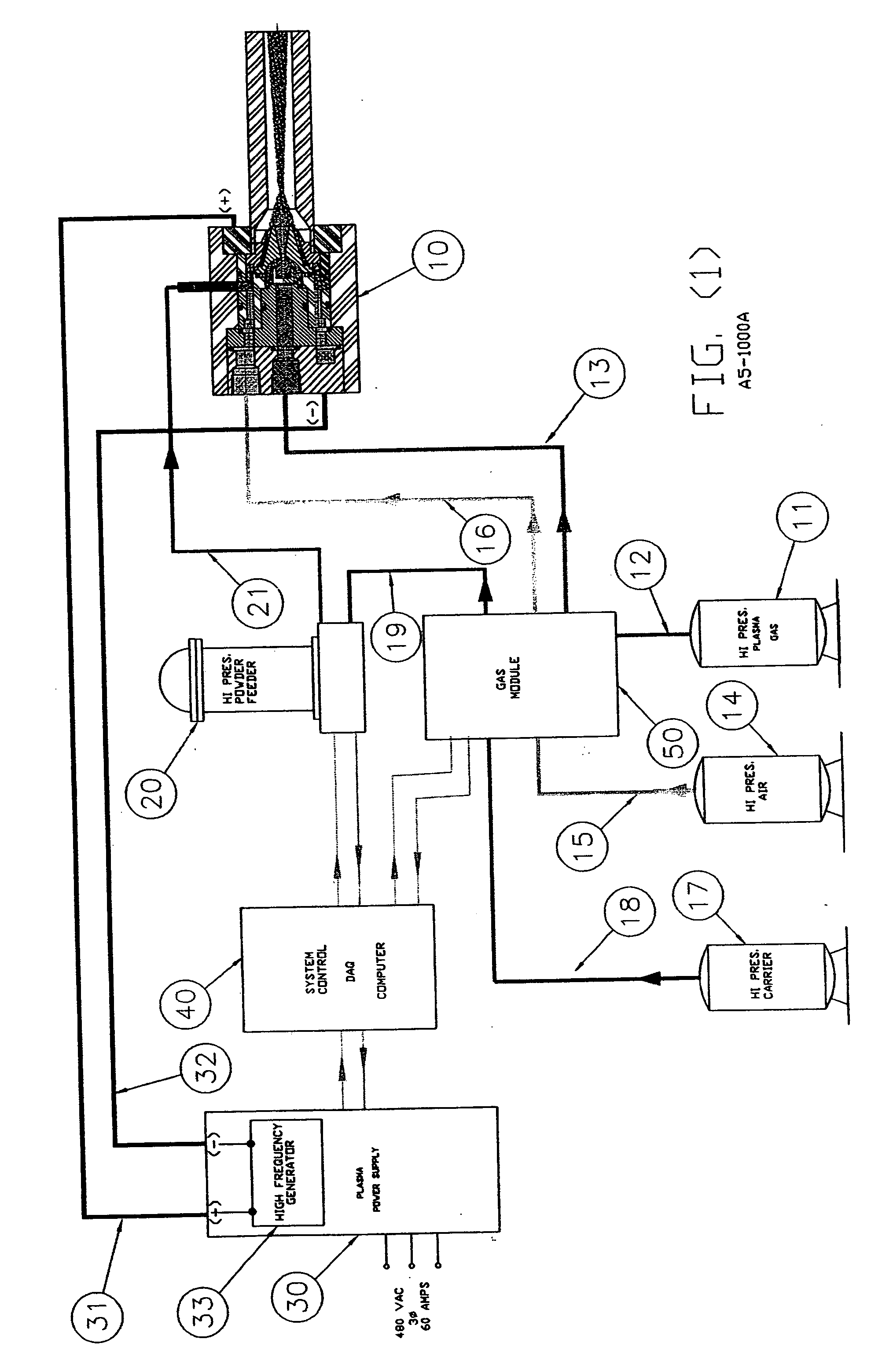

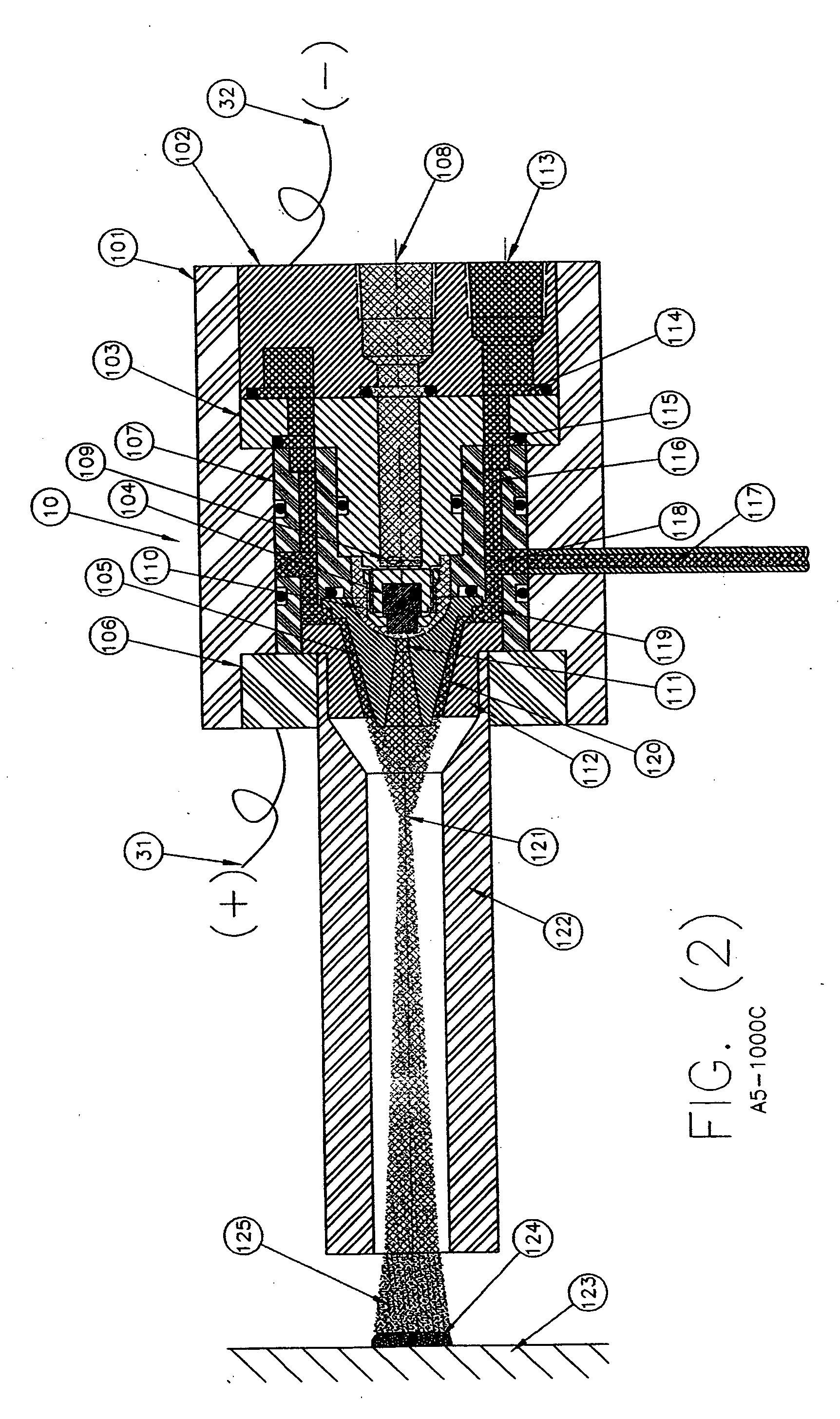

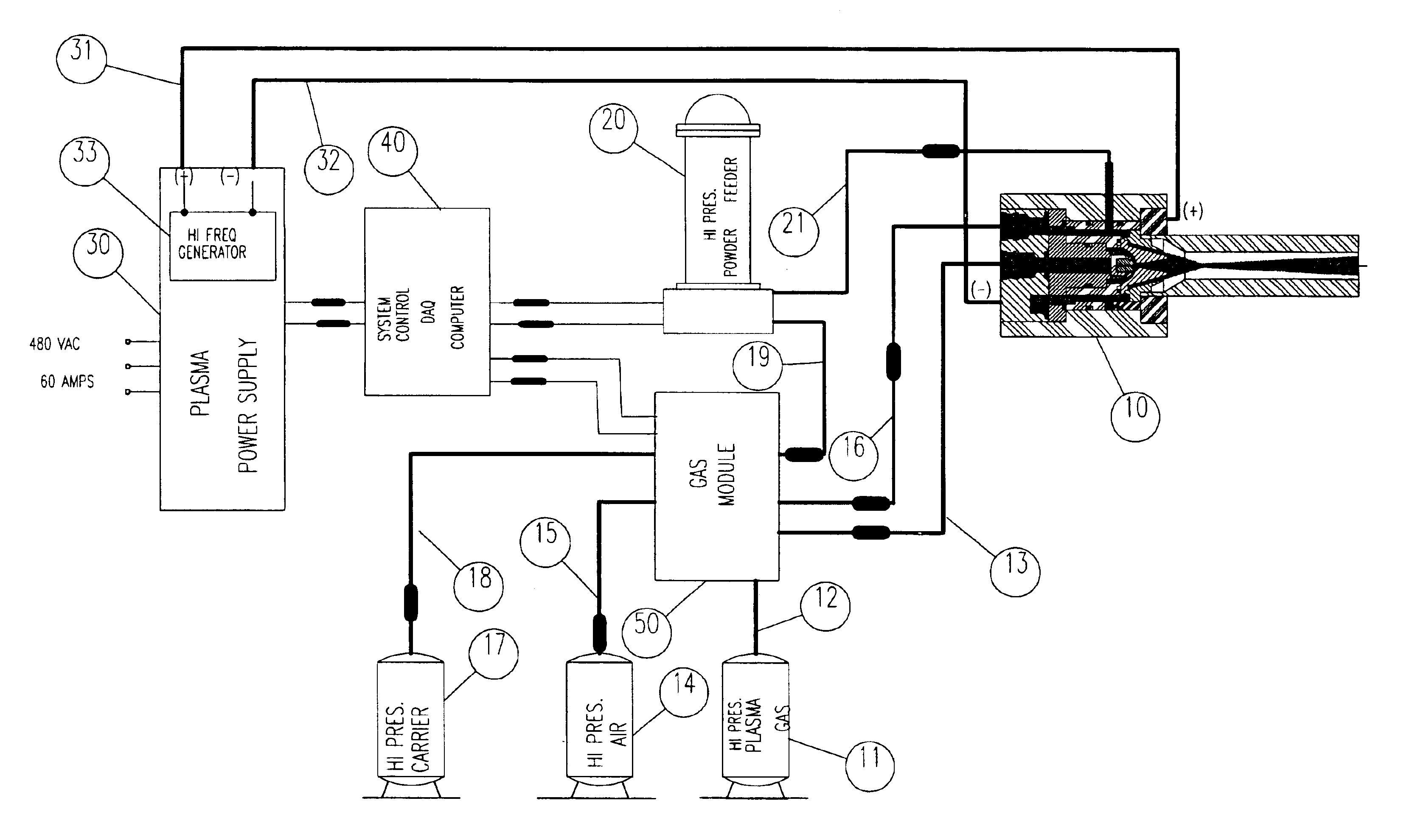

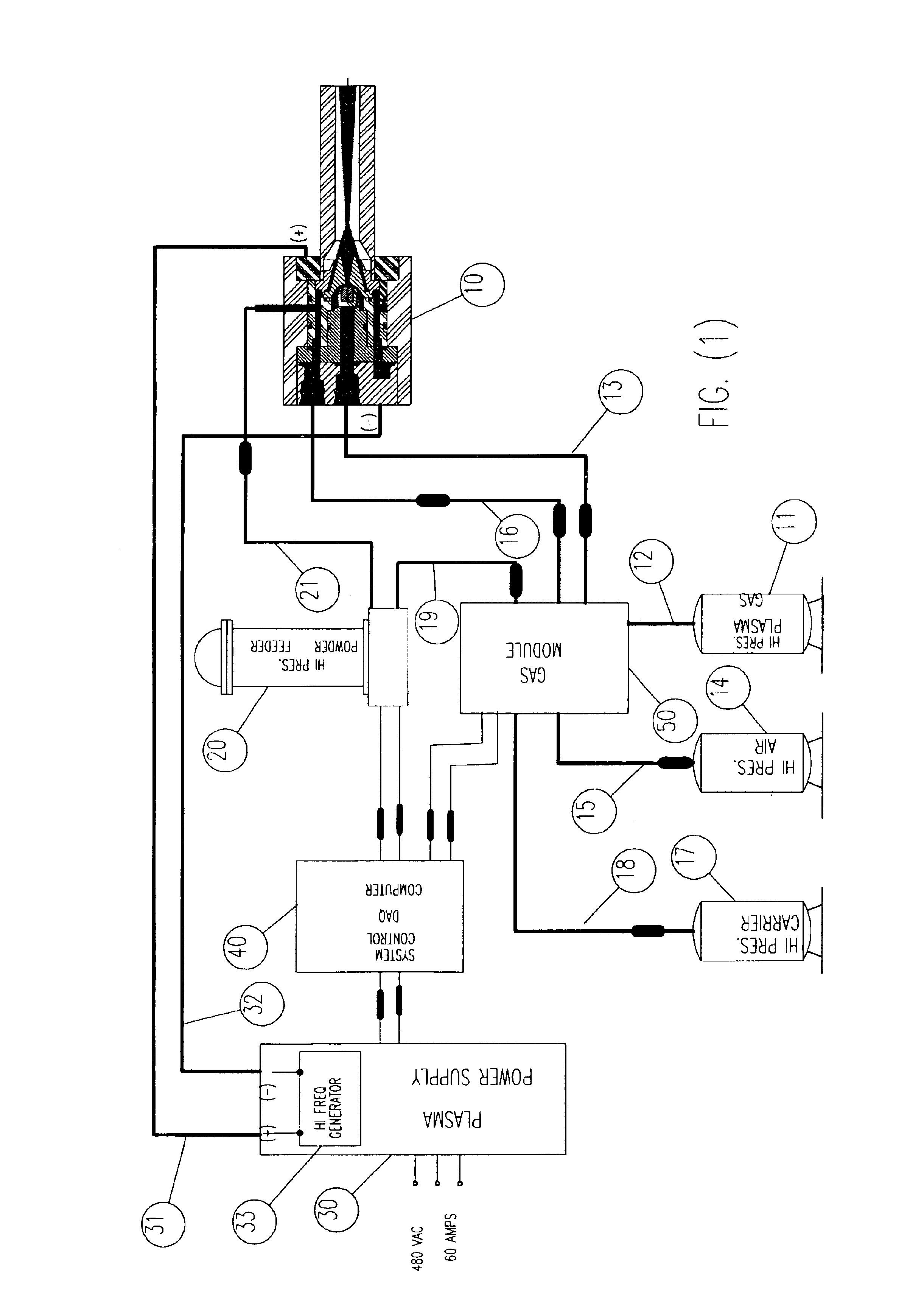

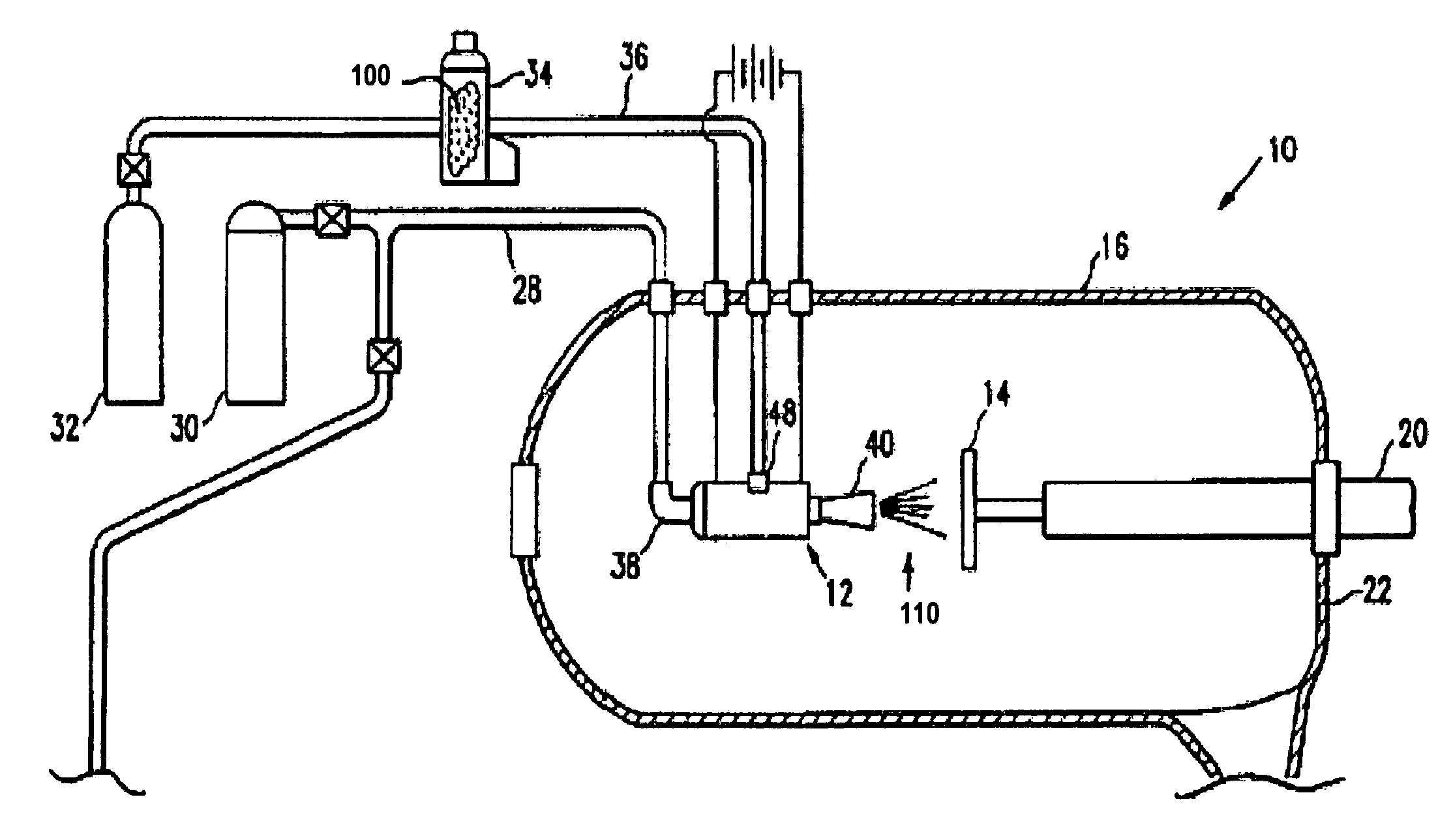

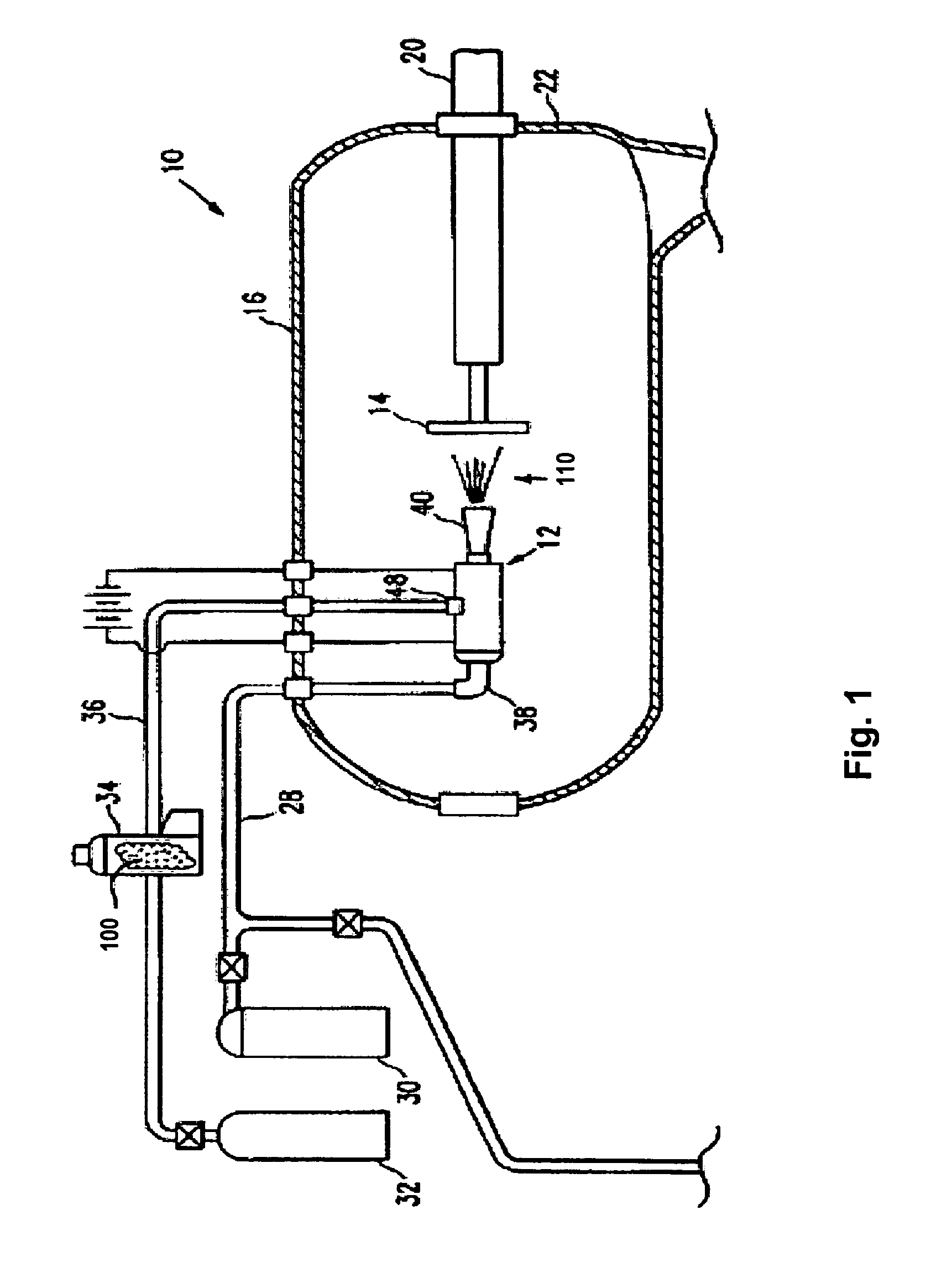

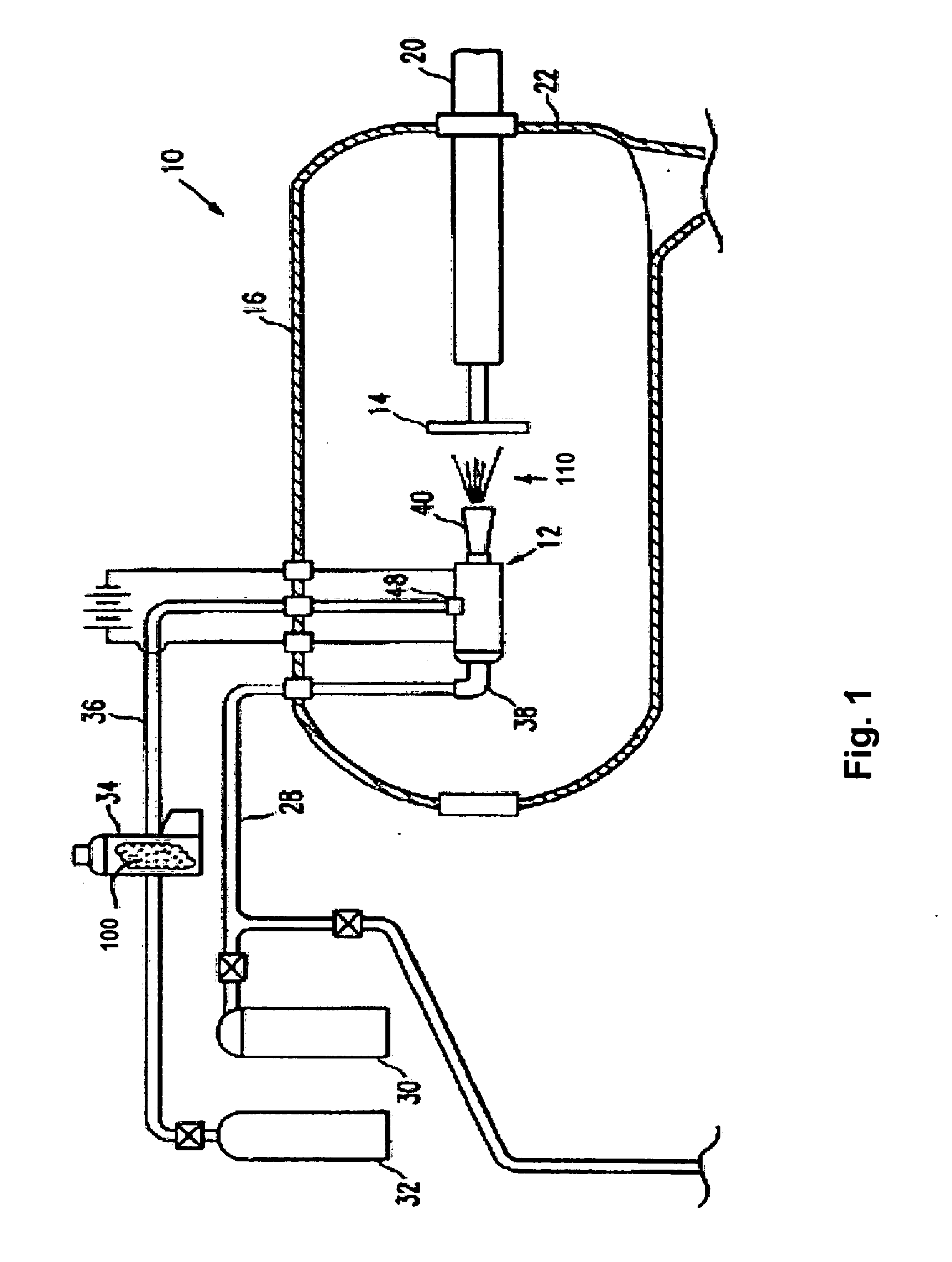

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

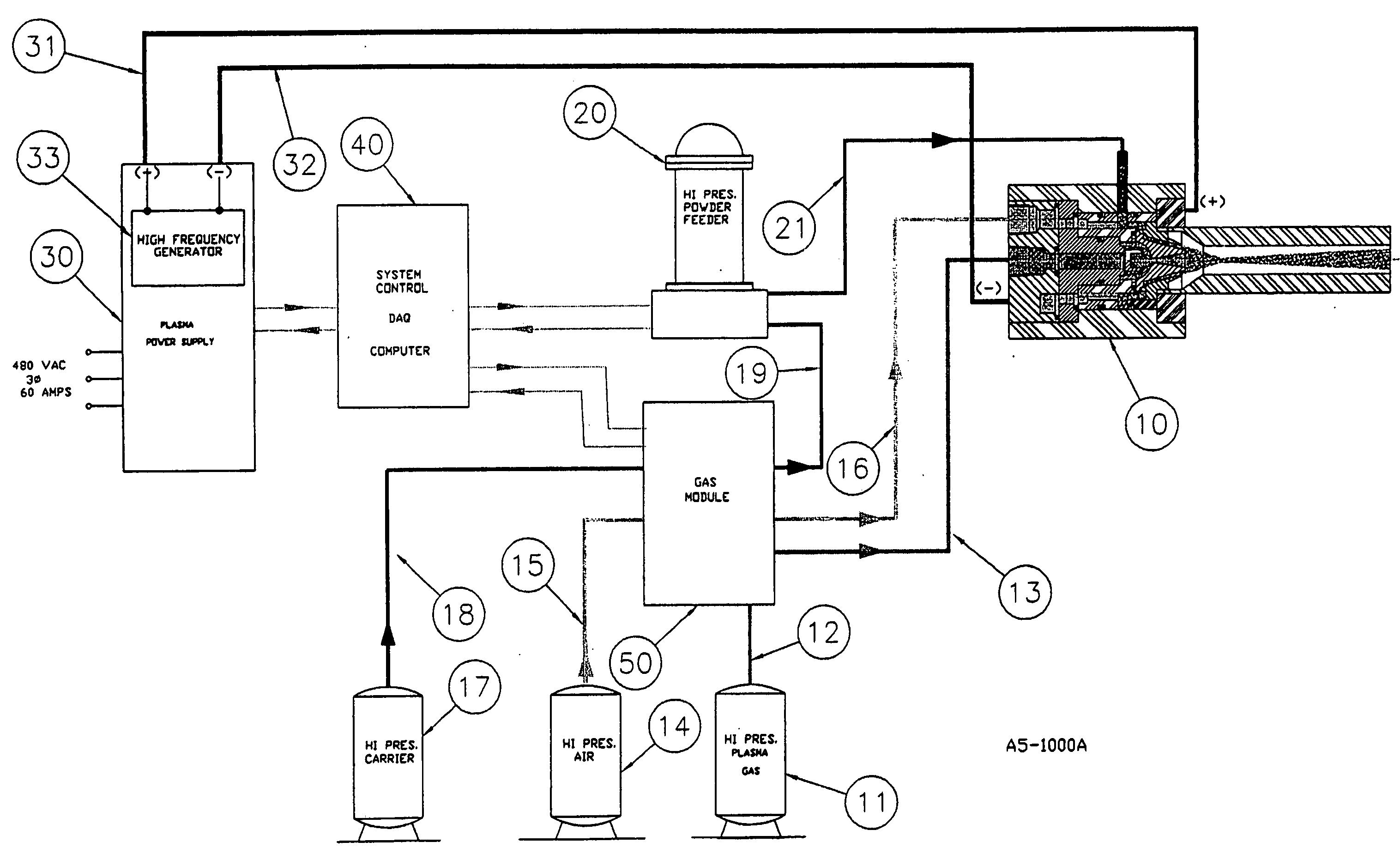

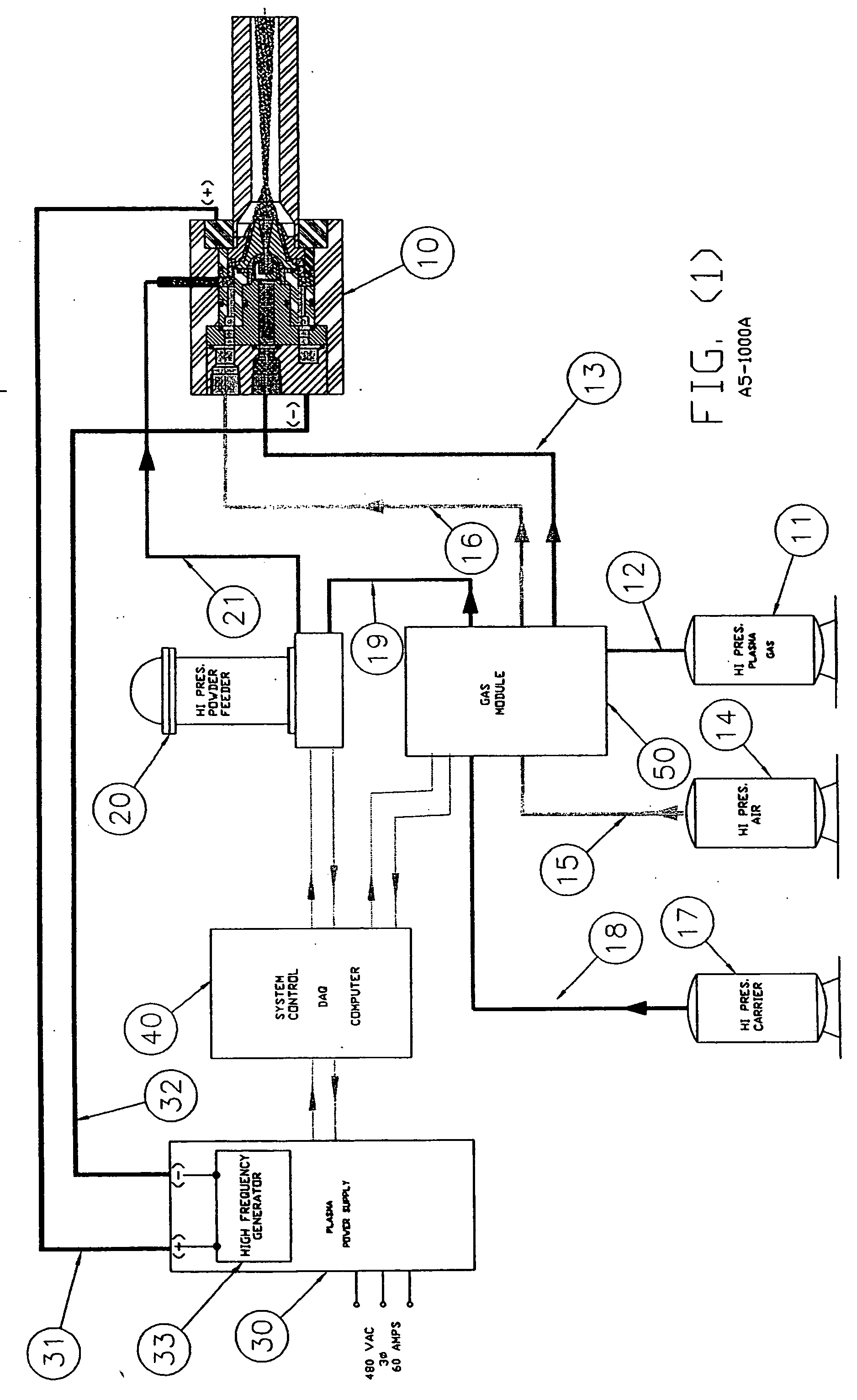

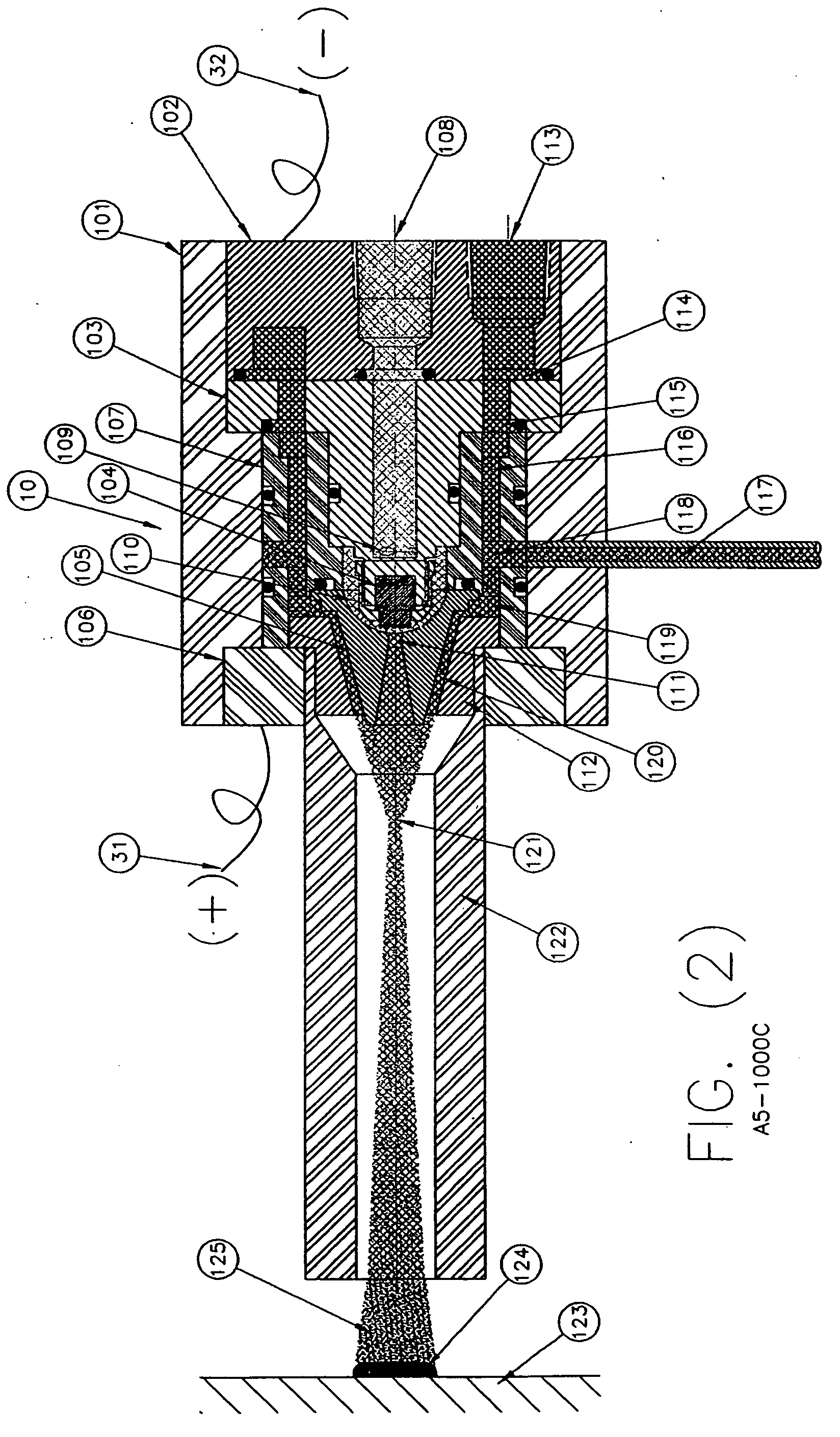

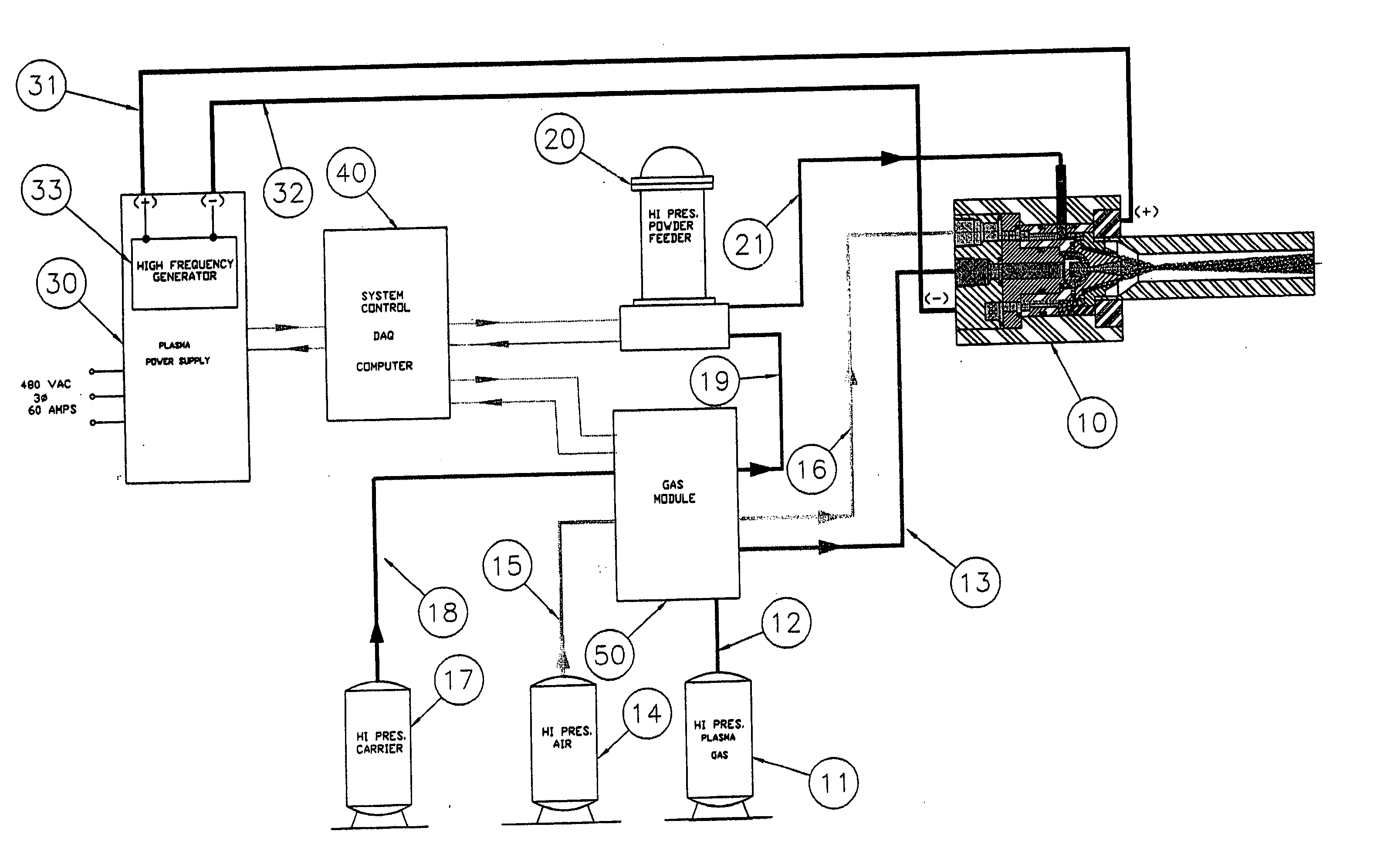

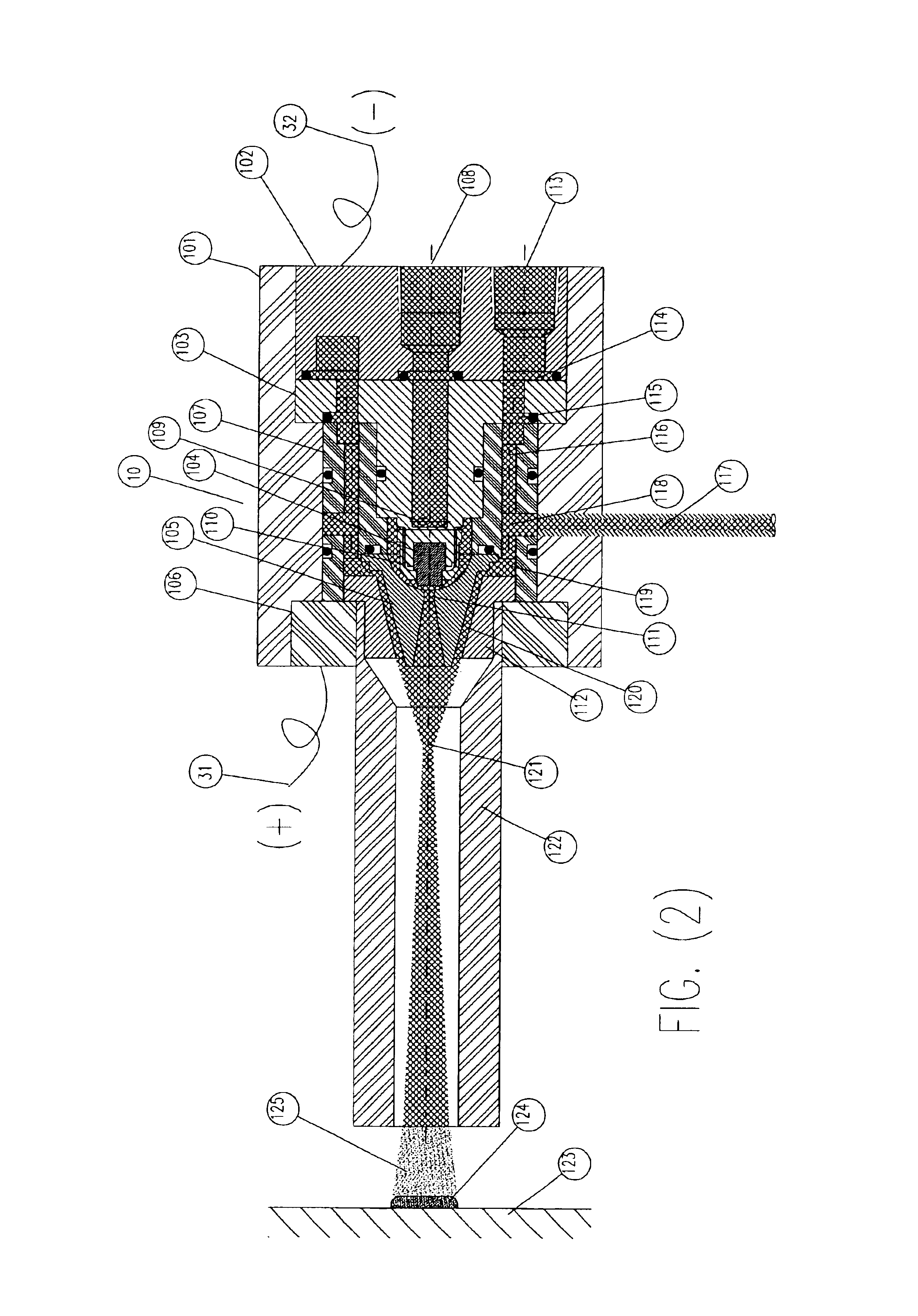

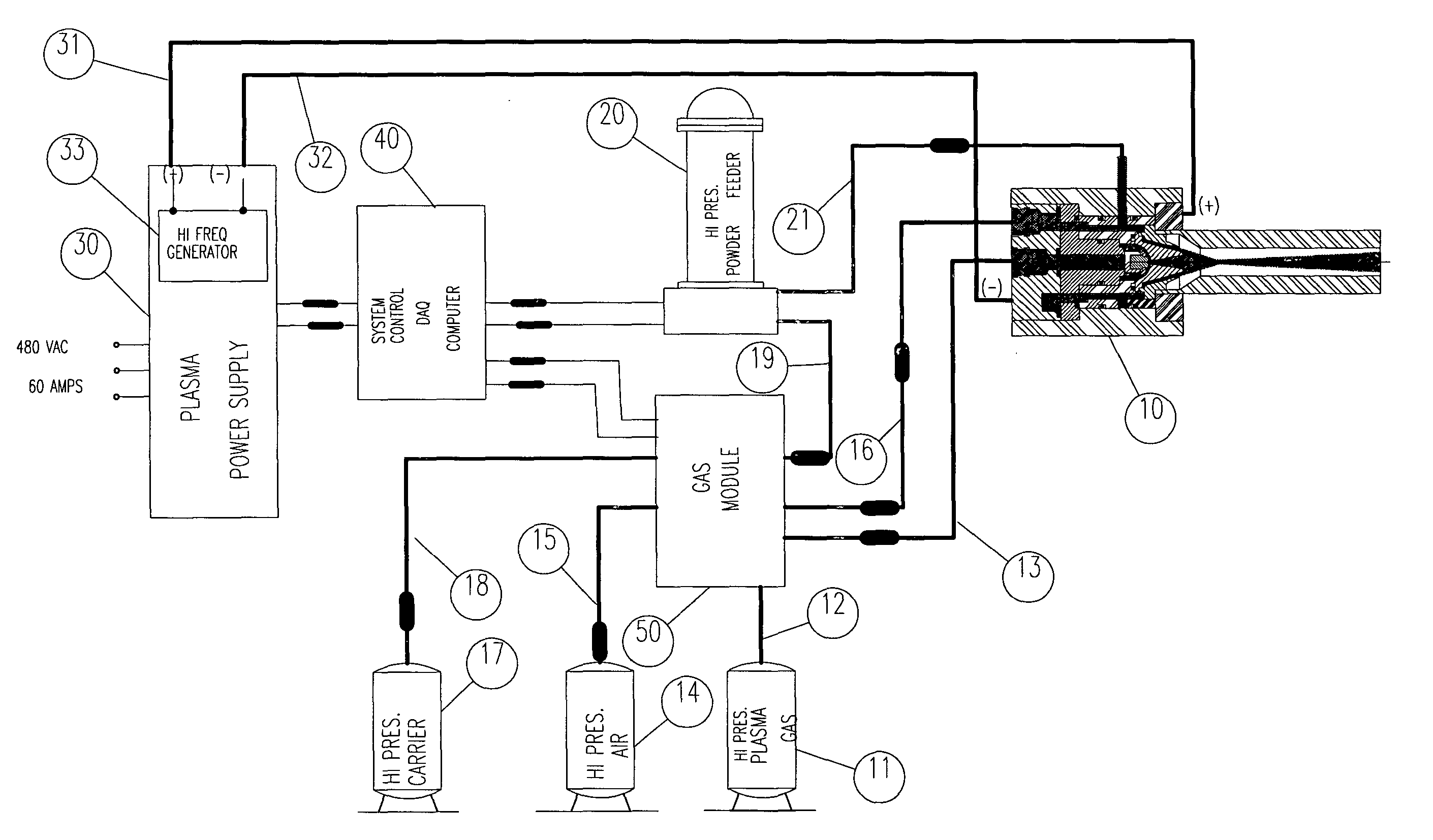

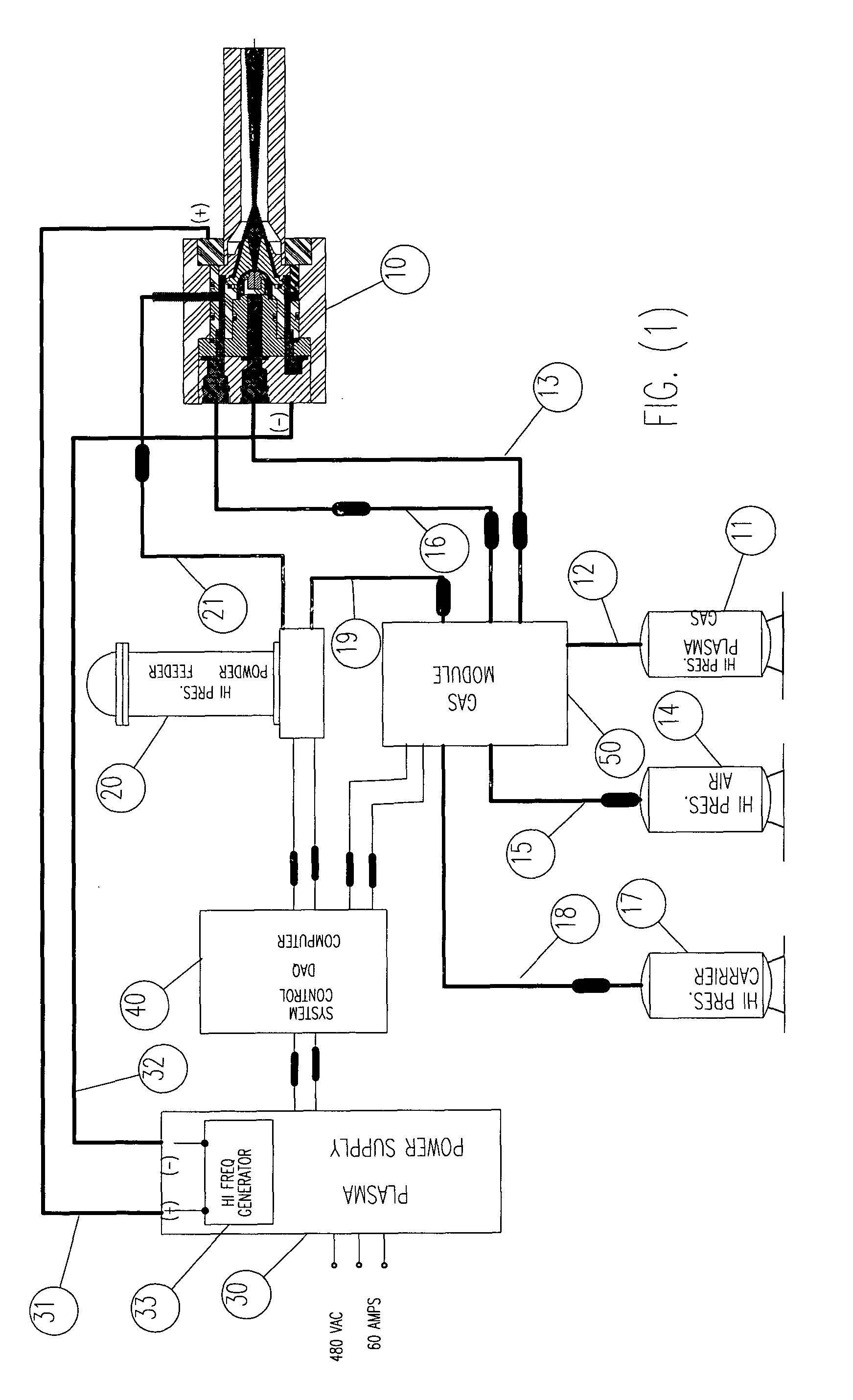

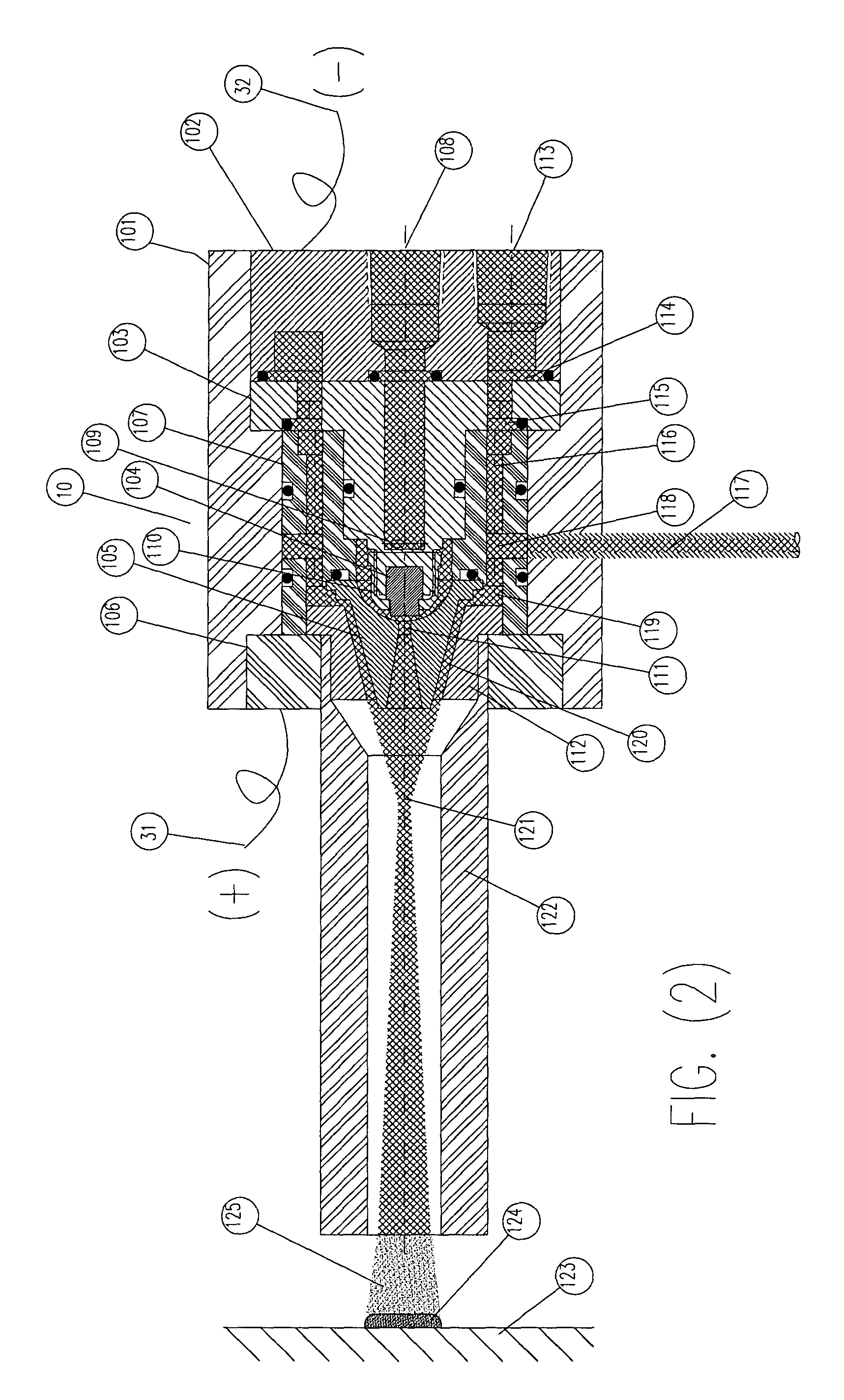

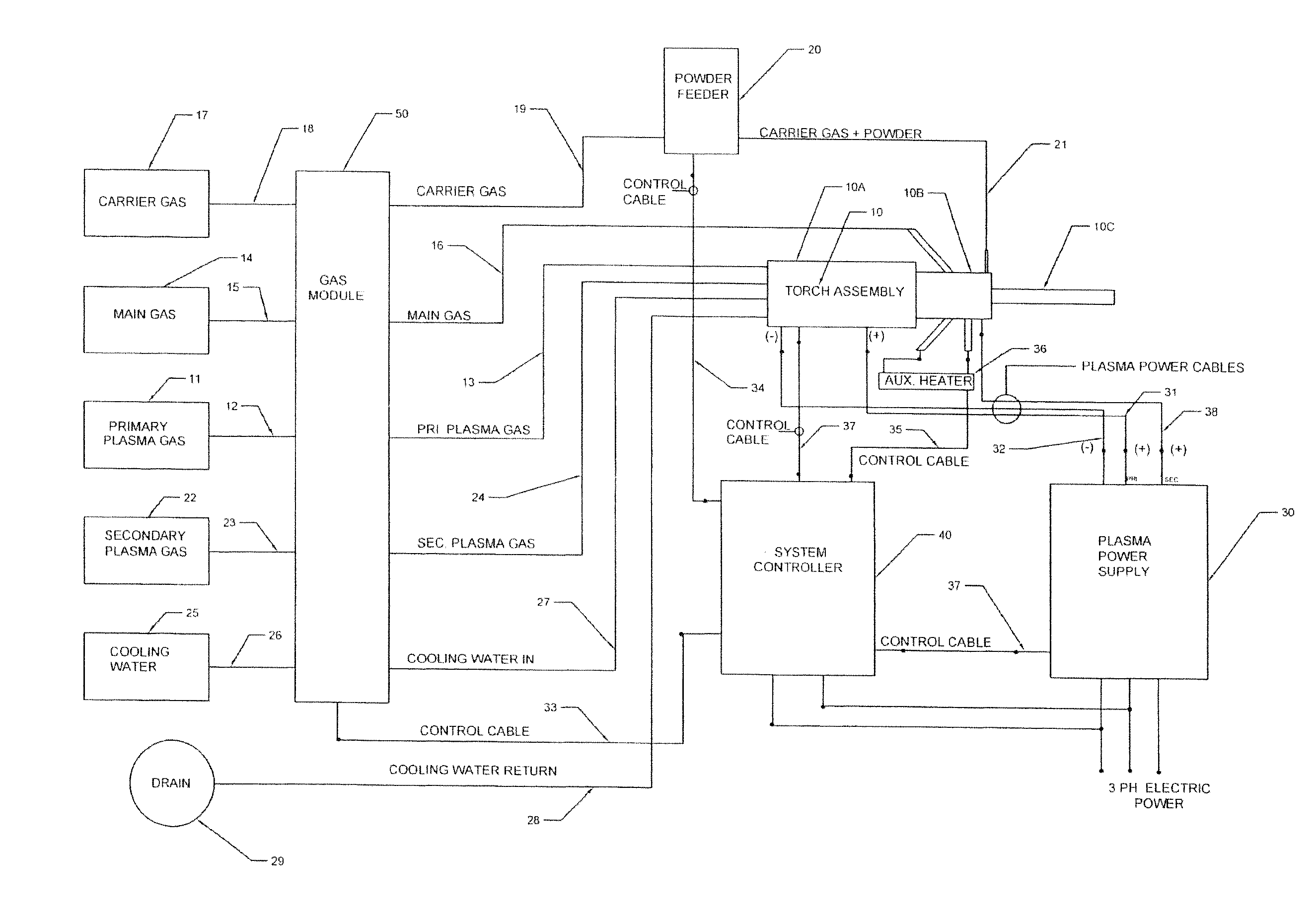

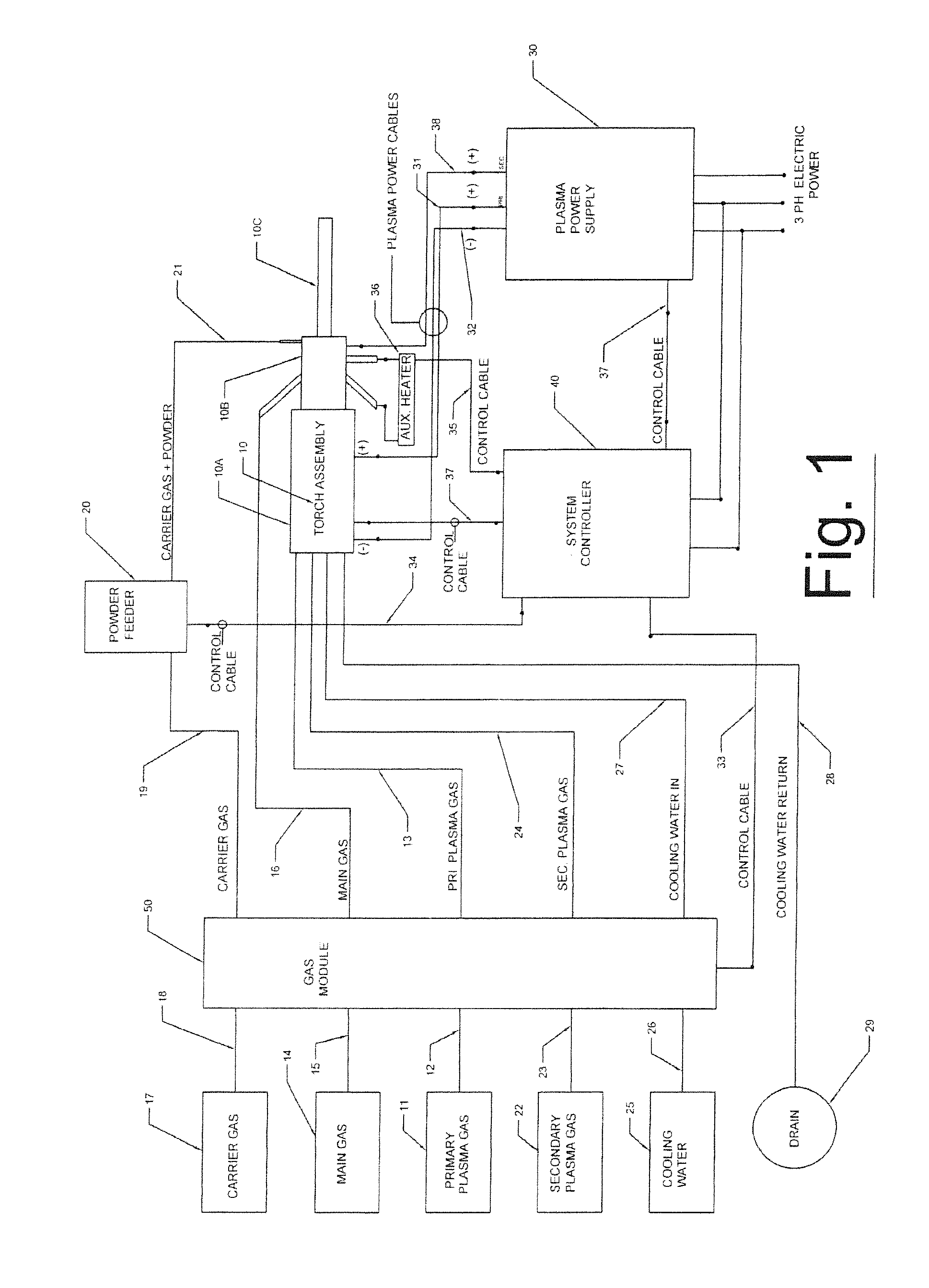

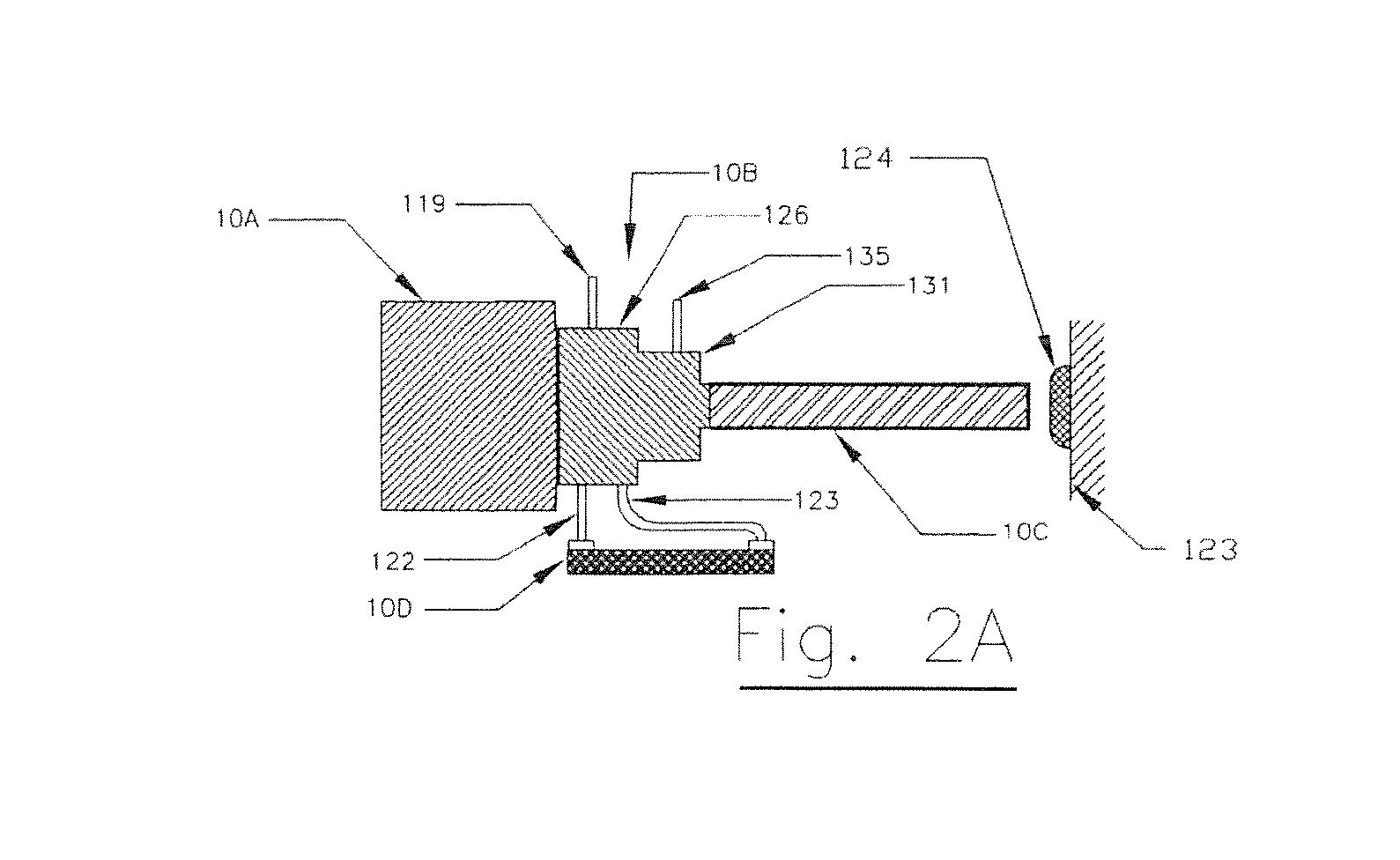

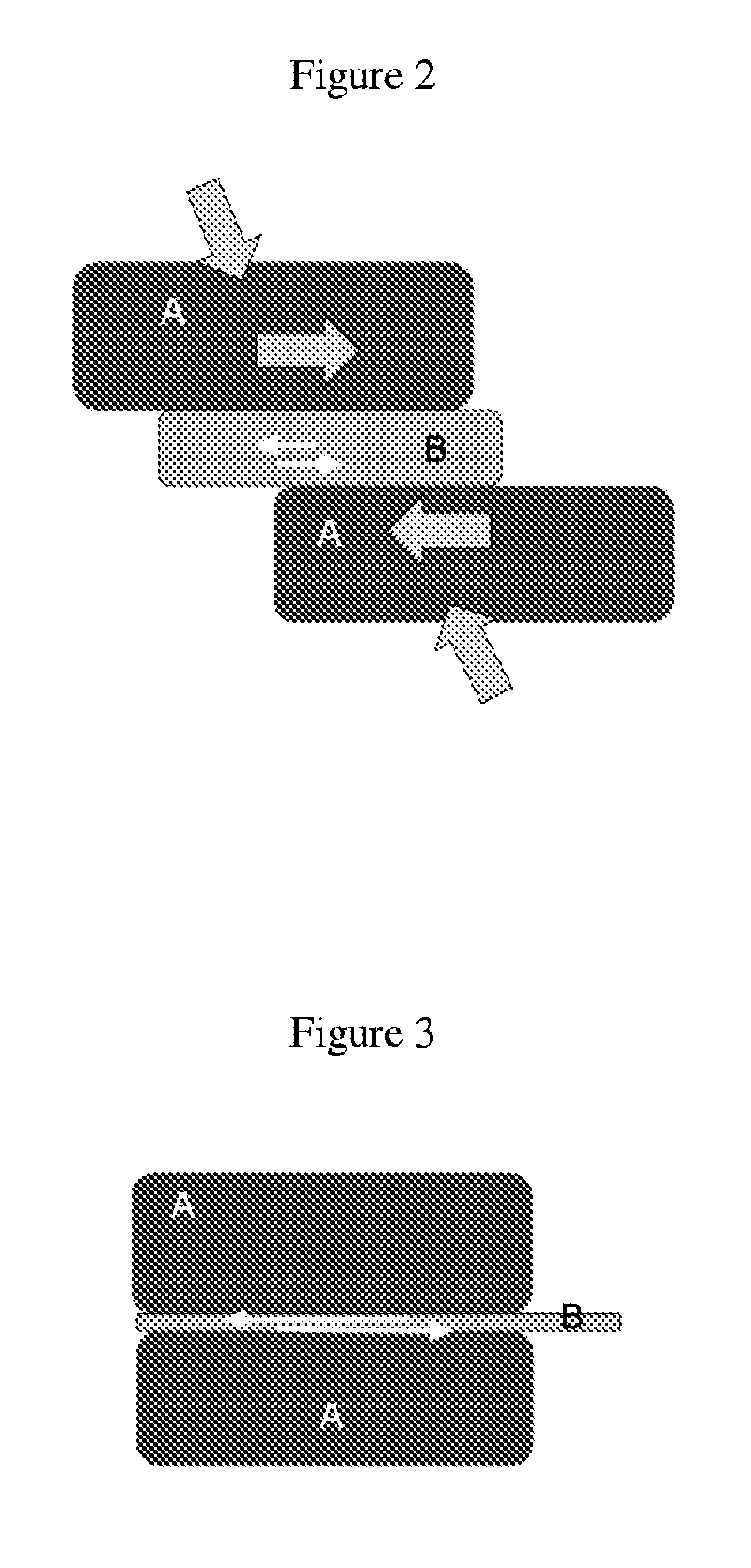

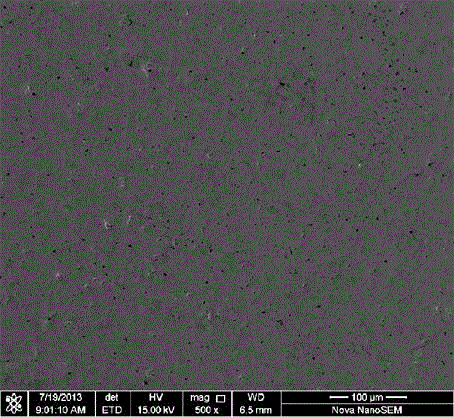

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

Rotary plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS6986471B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorMaterials science

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

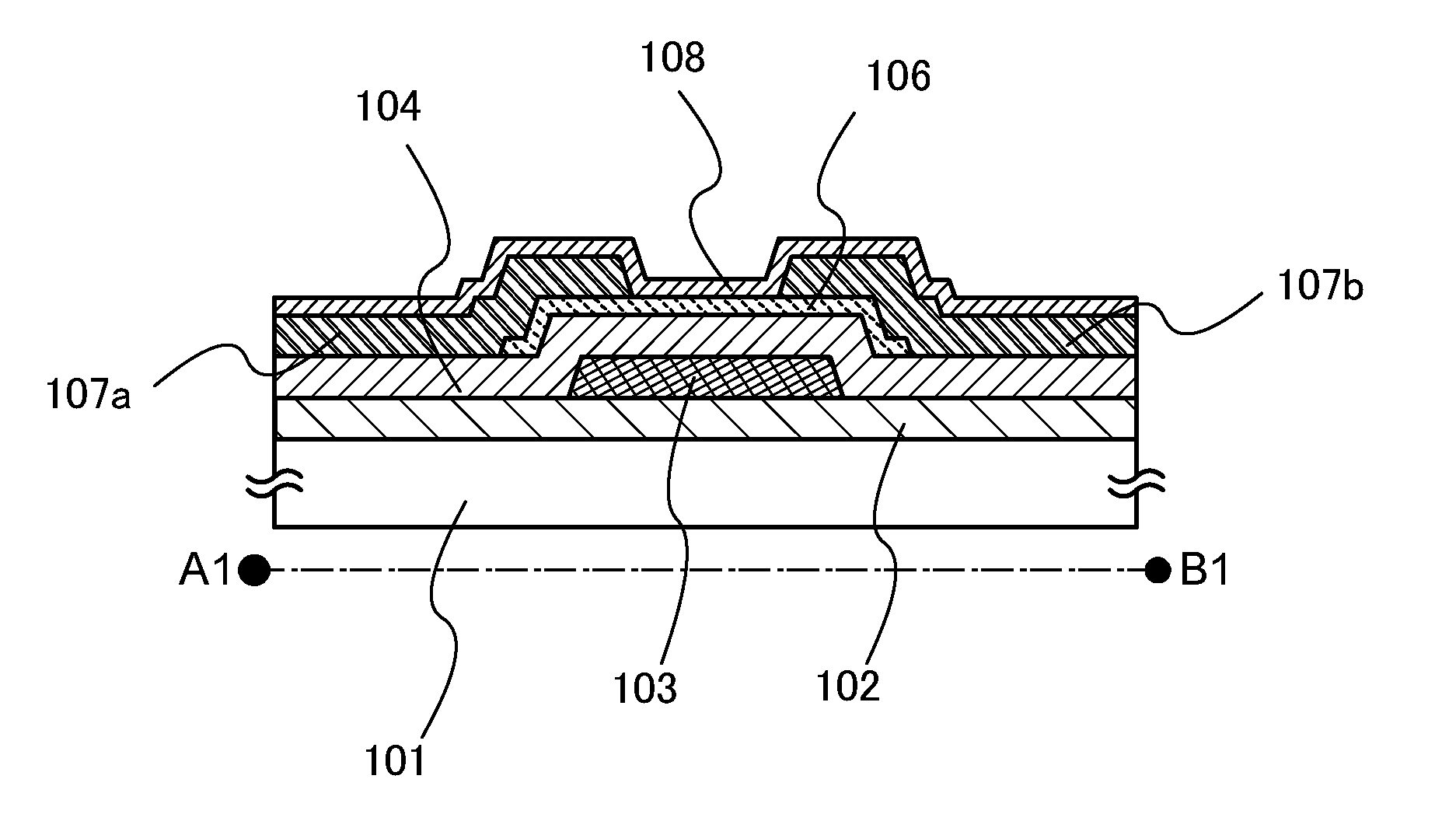

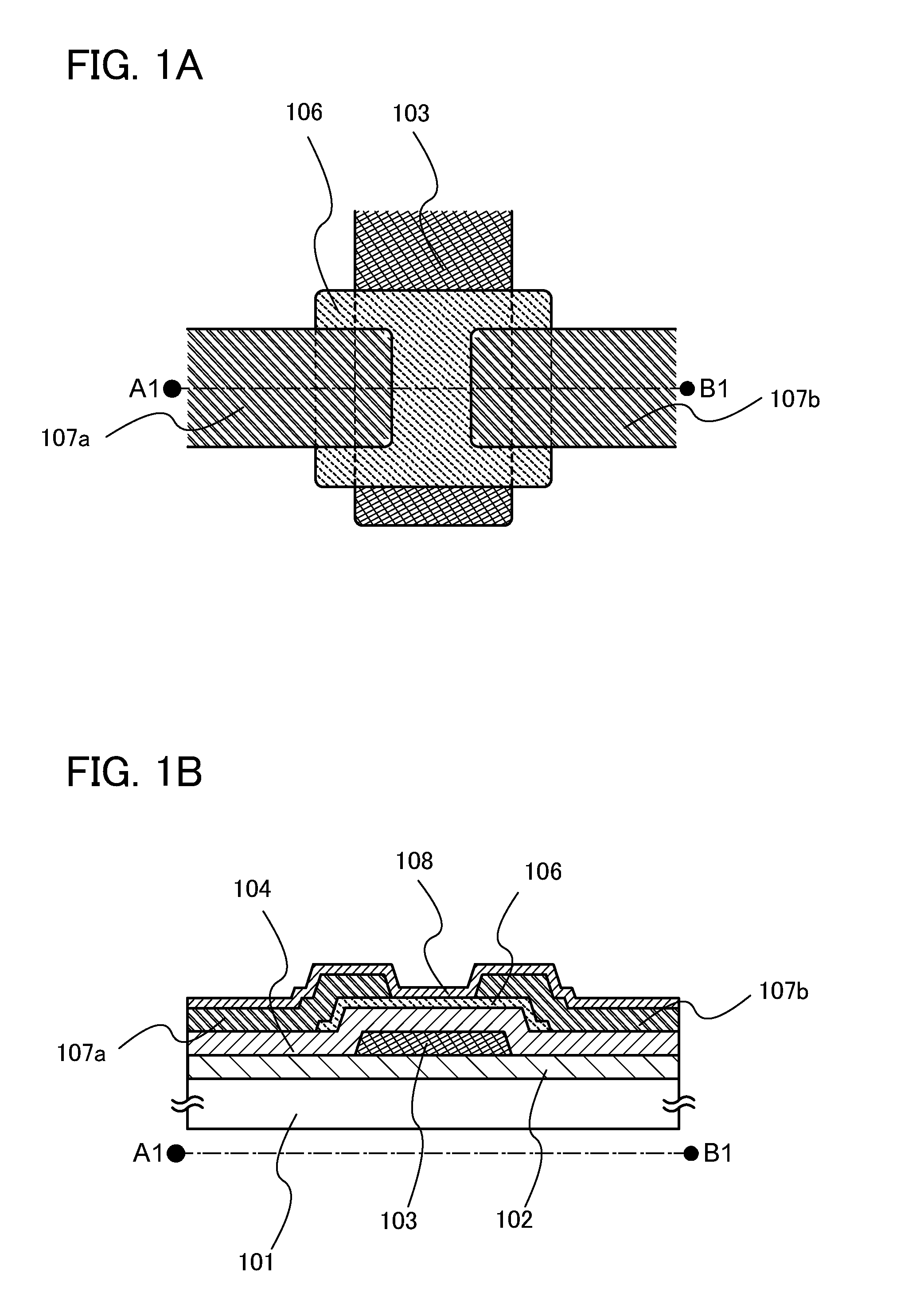

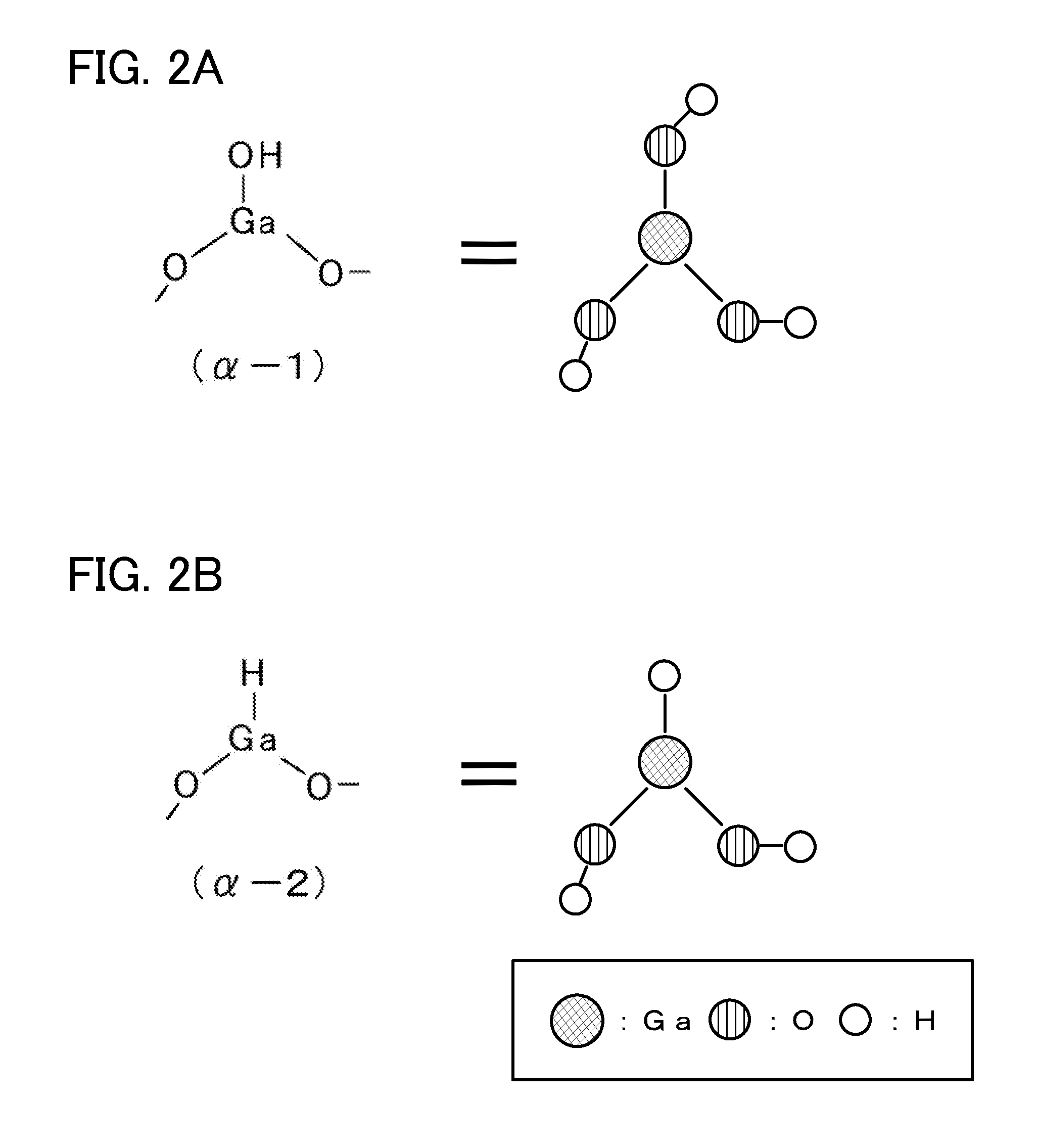

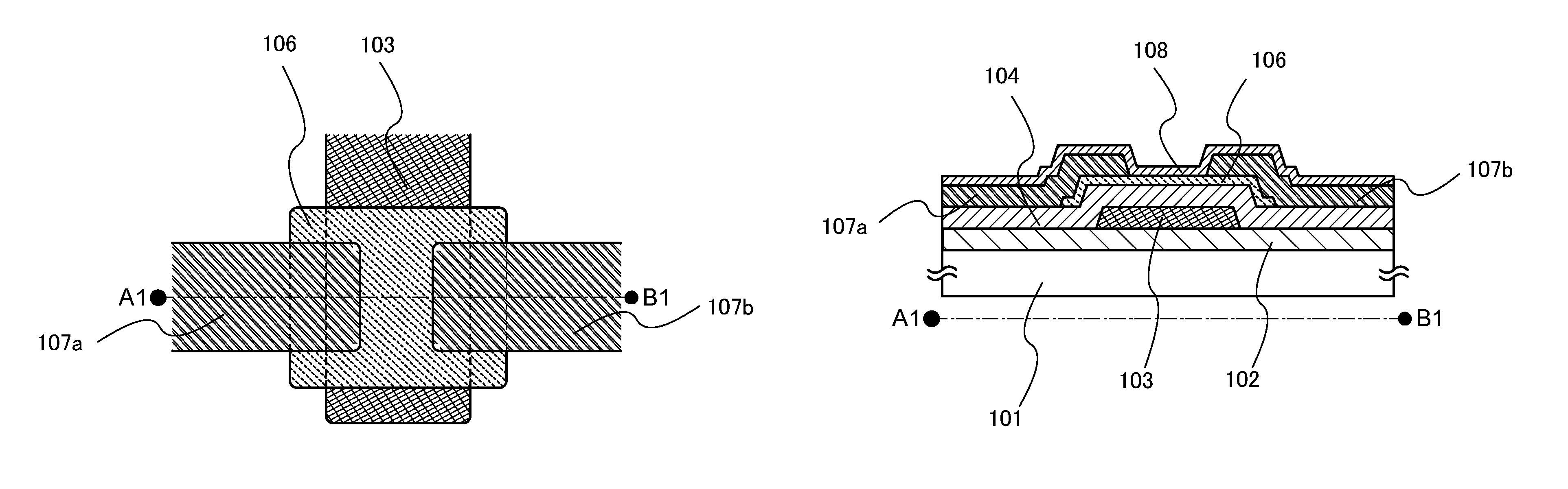

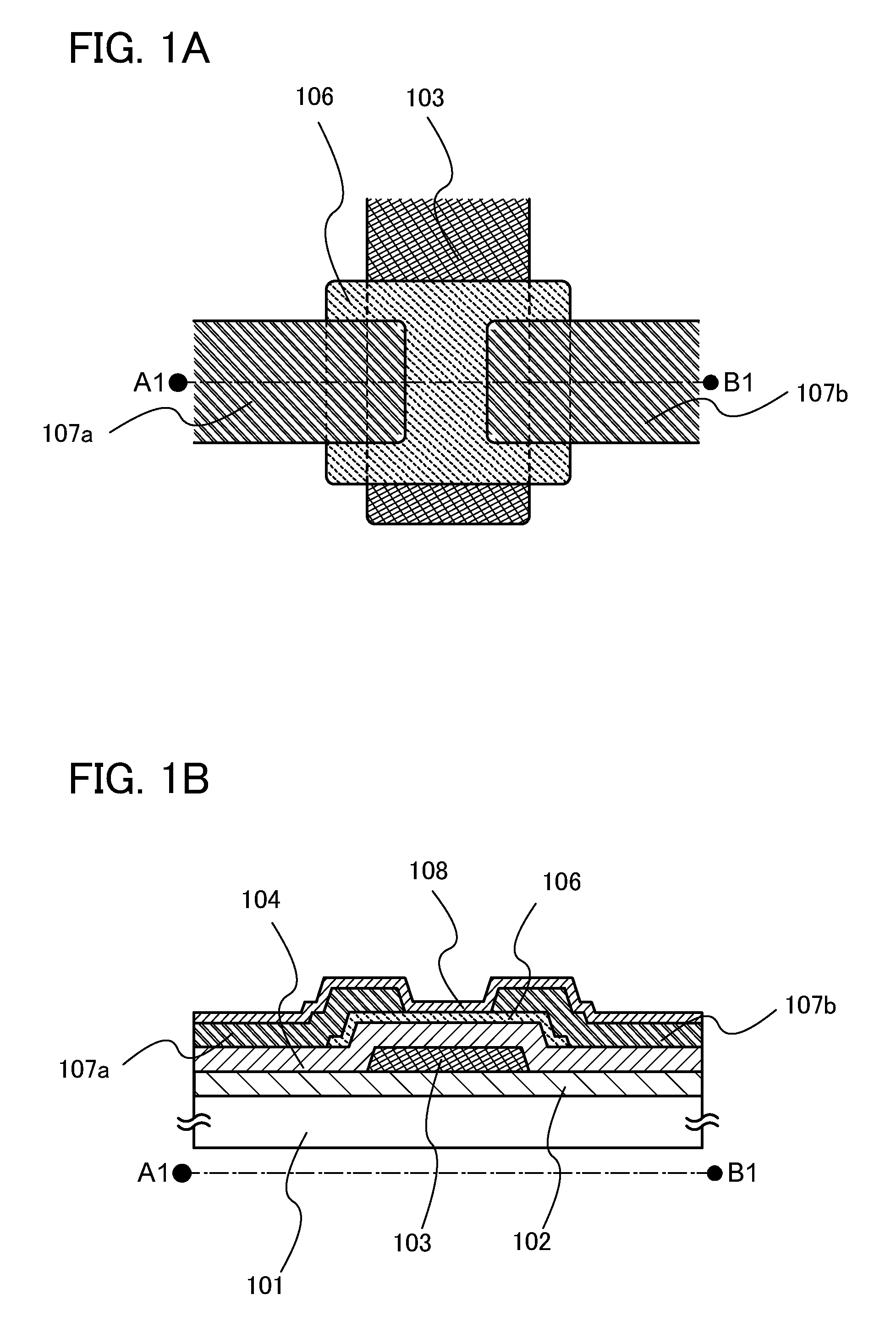

Semiconductor device

ActiveUS20120001168A1Excellent electrical propertiesEasy transferTransistorHydrogen concentrationSilicon

In a transistor including an oxide semiconductor, hydrogen in the oxide semiconductor leads to degradation of electric characteristics of the transistor. Thus, an object is to provide a semiconductor device having good electrical characteristics. An insulating layer in contact with an oxide semiconductor layer where a channel region is formed is formed by a plasma CVD method using a silicon halide. The insulating layer thus formed has a hydrogen concentration less than 6×1020 atoms / cm3 and a halogen concentration greater than or equal to 1×1020 atoms / cm3; accordingly, hydrogen diffusion into the oxide semiconductor layer can be prevented and hydrogen in the oxide semiconductor layer is inactivated or released from the oxide semiconductor layer by the halogen, whereby a semiconductor device having good electrical characteristics can be provided.

Owner:SEMICON ENERGY LAB CO LTD

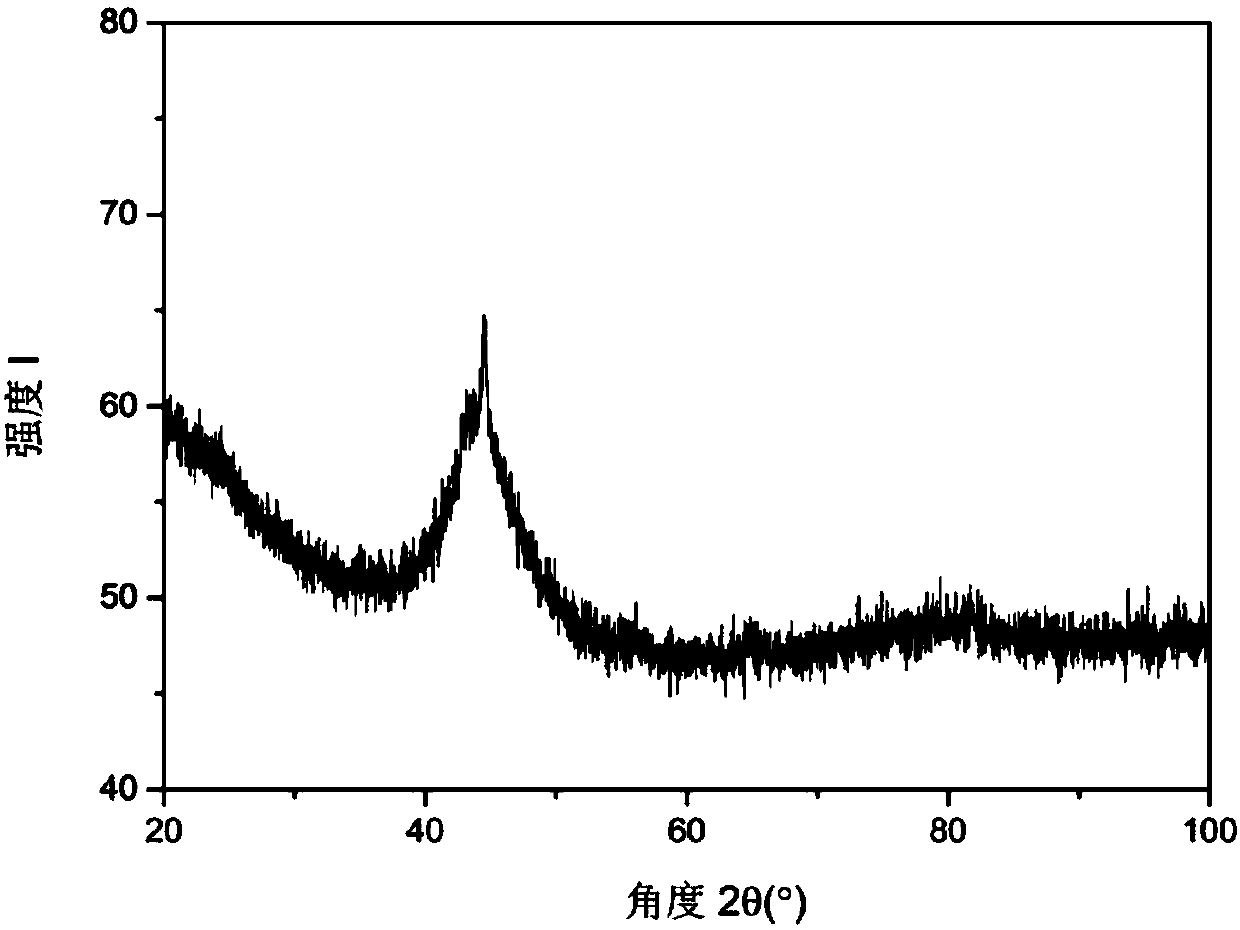

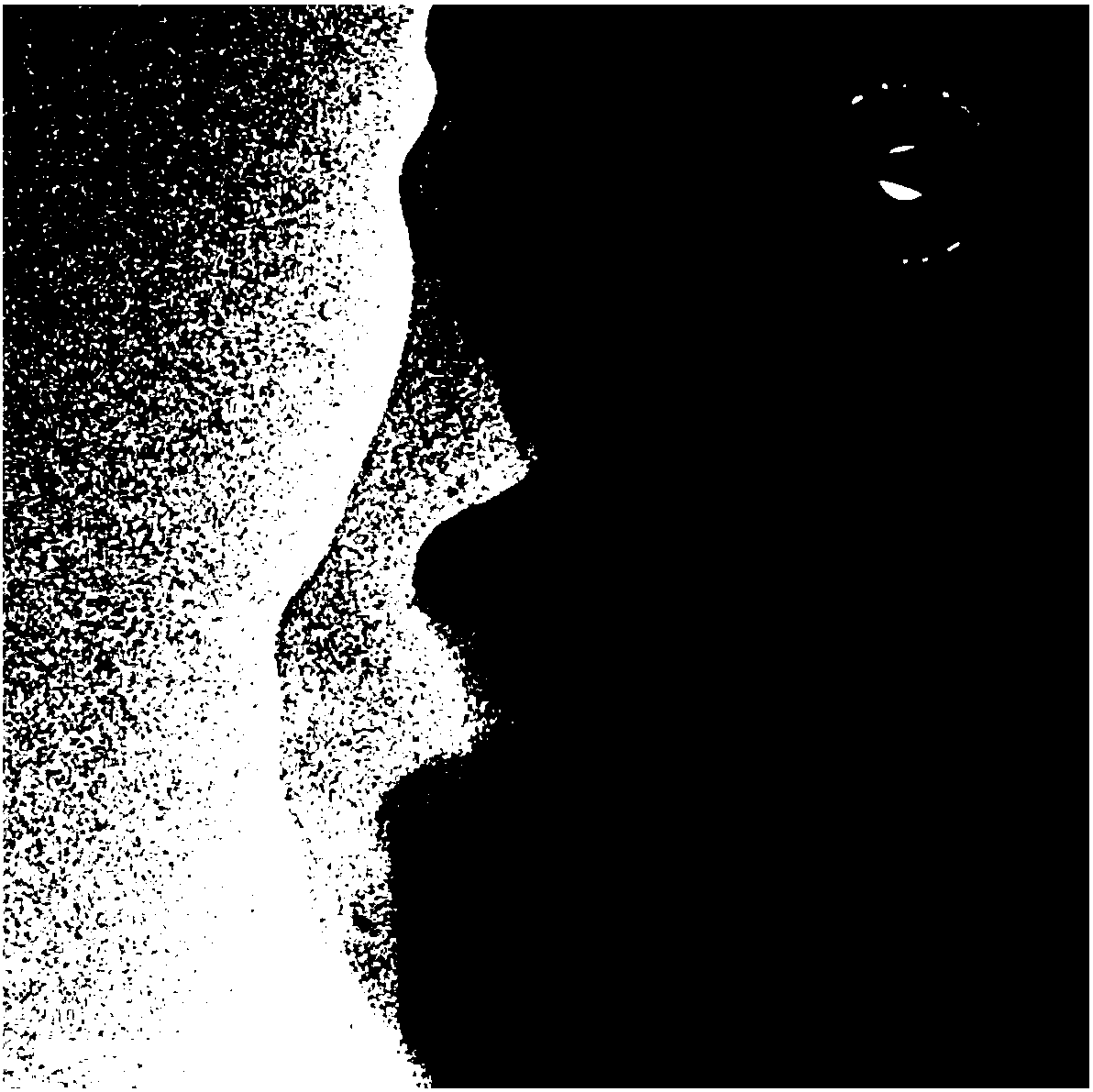

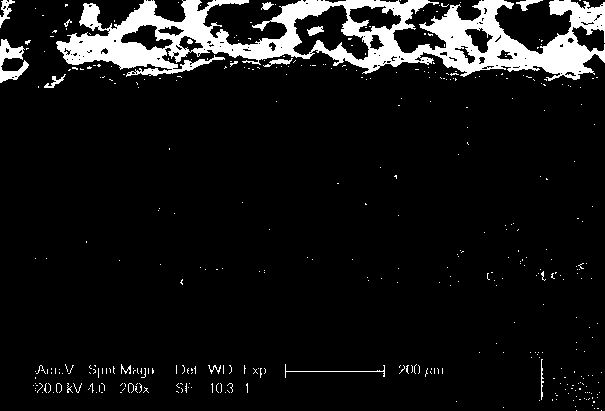

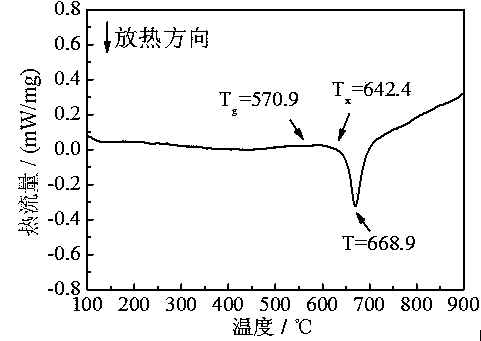

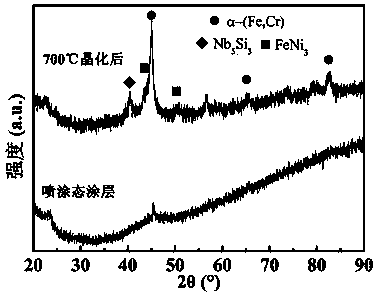

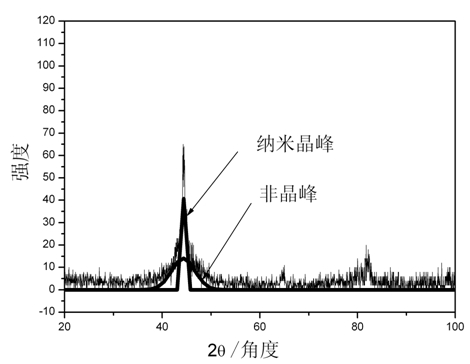

Powder core wire material used for preparing coating with high amorphous content and preparation method and application for powder core wire material

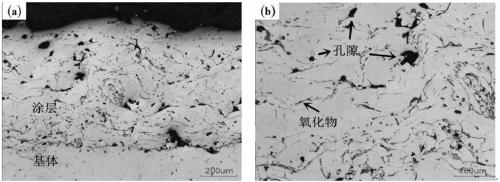

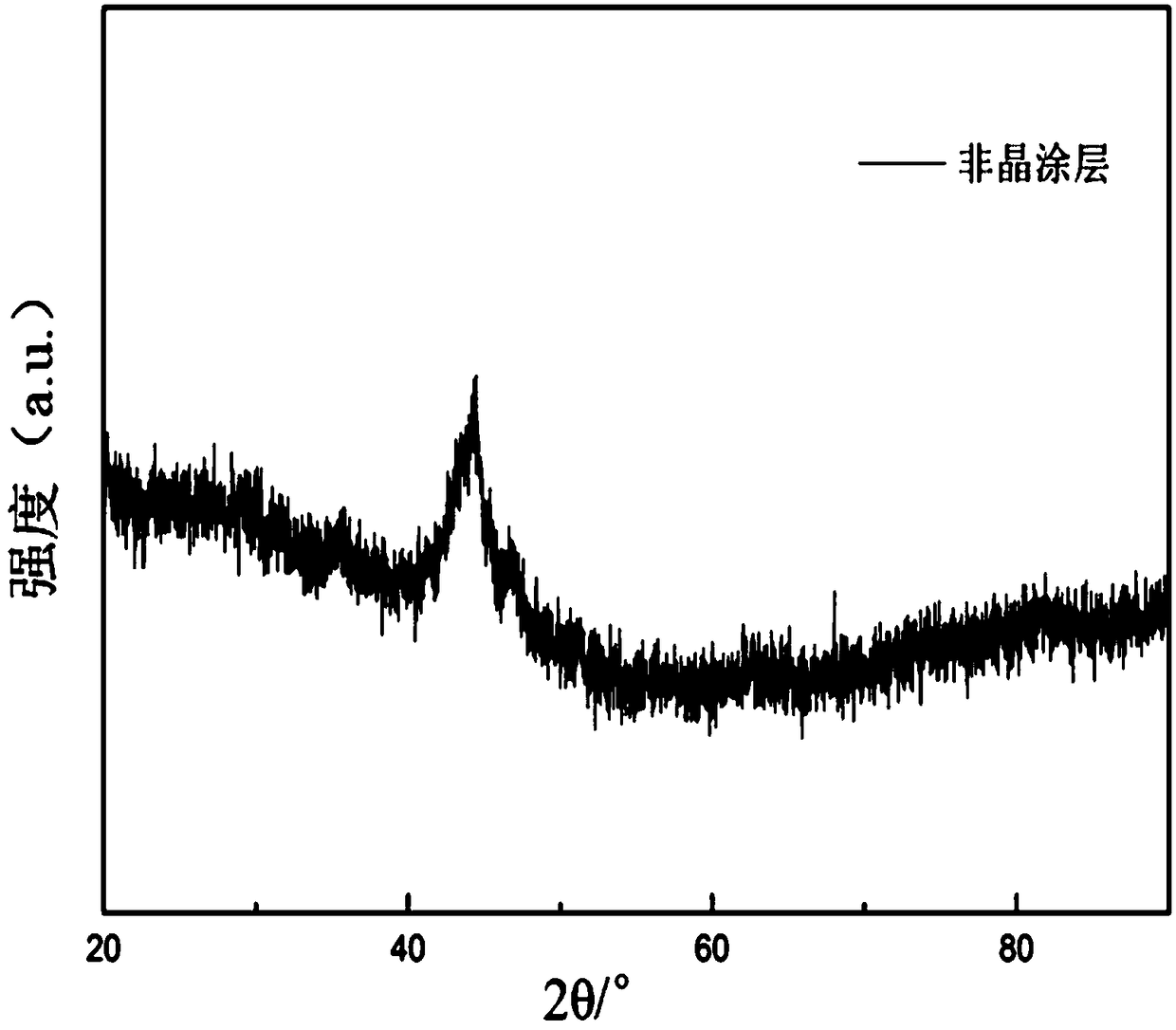

ActiveCN107699843AImprove wear and corrosion resistanceReduce powder costMolten spray coatingPorosityAlloy

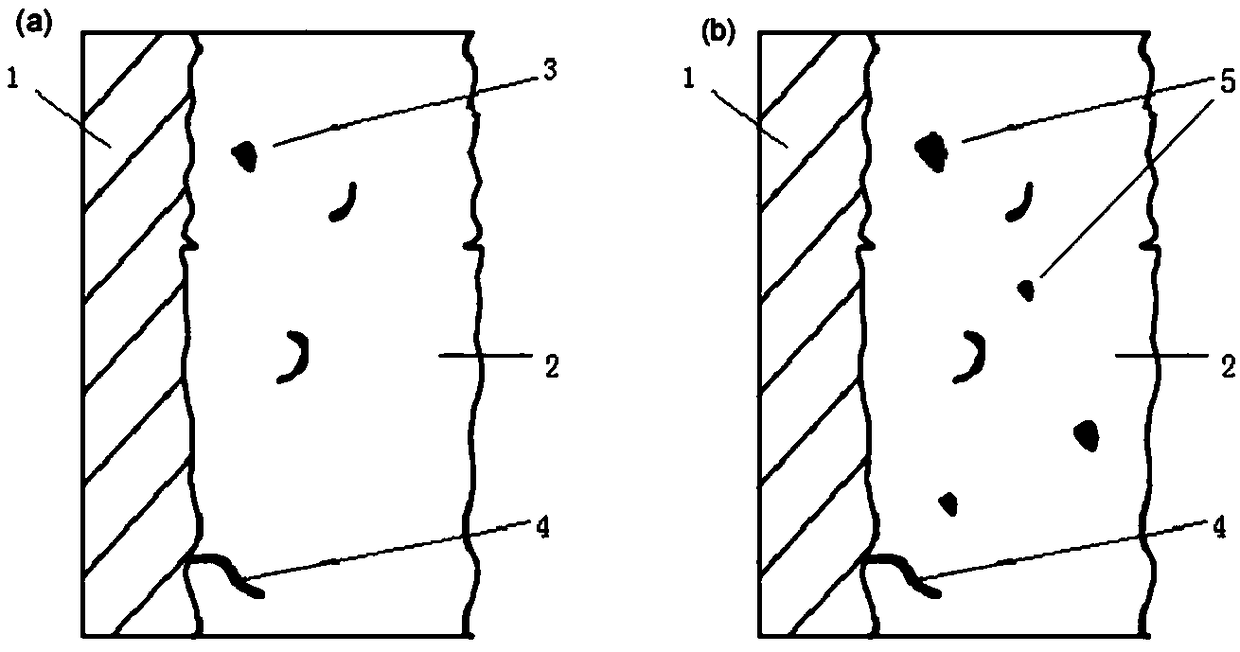

The invention discloses a powder core wire material used for preparing a coating with the high amorphous content and a preparation method and application for the powder core wire material. The powdercore wire material is made by wrapping a power core with a 430 stainless steel outer skin, and the powder core is formed by mixing alloy powder of seven elements; and the filling rate of the powder core is 37-39%, and the diameter of the powder core wire material is 2 mm. The powder core wire material has the strong amorphous forming ability, and the high speed arc spraying technology is adopted to form the low-oxide-content, compact, continuous amorphous coating with a certain shape on a cooled steel base body; and the coating has the compact structure, the amorphous content is greater than or equal to 90%, the porosity is less than 2%, the bonding strength of the coating is greater than or equal to 50 MPa, the hardness of the coating is in the range of 1000-1300 HV100, and the coating has excellent abrasion resistance and corrosion resistance comprehensive performance. The powder core wire material can be widely applied to preparation of the large area anticorrosion and abrasion-resistant coating of a steel structure piece and can remarkably prolong the long lasting anticorrosion and abrasion service life of mechanical engineering equipment.

Owner:HOHAI UNIV

Powder core wire as well as preparation method and application thereof

ActiveCN104032251AEnhanced Amorphous Formation AbilityImprove corrosion resistanceMolten spray coatingVulcanizationSand blasting

The invention discloses a powder core wire as well as a preparation method and application thereof. The powder core wire is prepared by coating a powder core in a stainless steel strip; the powder core is prepared by mixing seven element powder in percentage by weight: 30-50% of Cr, 2-10% of B, 1-5% of Al, 1-5% of Si, 3-15% of Nb, 2-10% of Mo and the rest amount of Fe; the skin of the powder core wire selects the stainless steel strip; the weight ratio of the powder core to the stainless steel strip is (0.43-0.67): 1; when a coating layer is prepared by adopting an electric arc spraying technology, oil and rust on the surface of a matrix are removed firstly; and then, the pretreatment such as sand blasting is performed. The powder core wire can obtain the coating layer with low porosity, high hardness and excellent high-temperature oxidization and sulphuration corrosion resistance, and is suitable for such high-temperature structural members as a boiler pipe, a roller and an engine cylinder body.

Owner:HOHAI UNIV

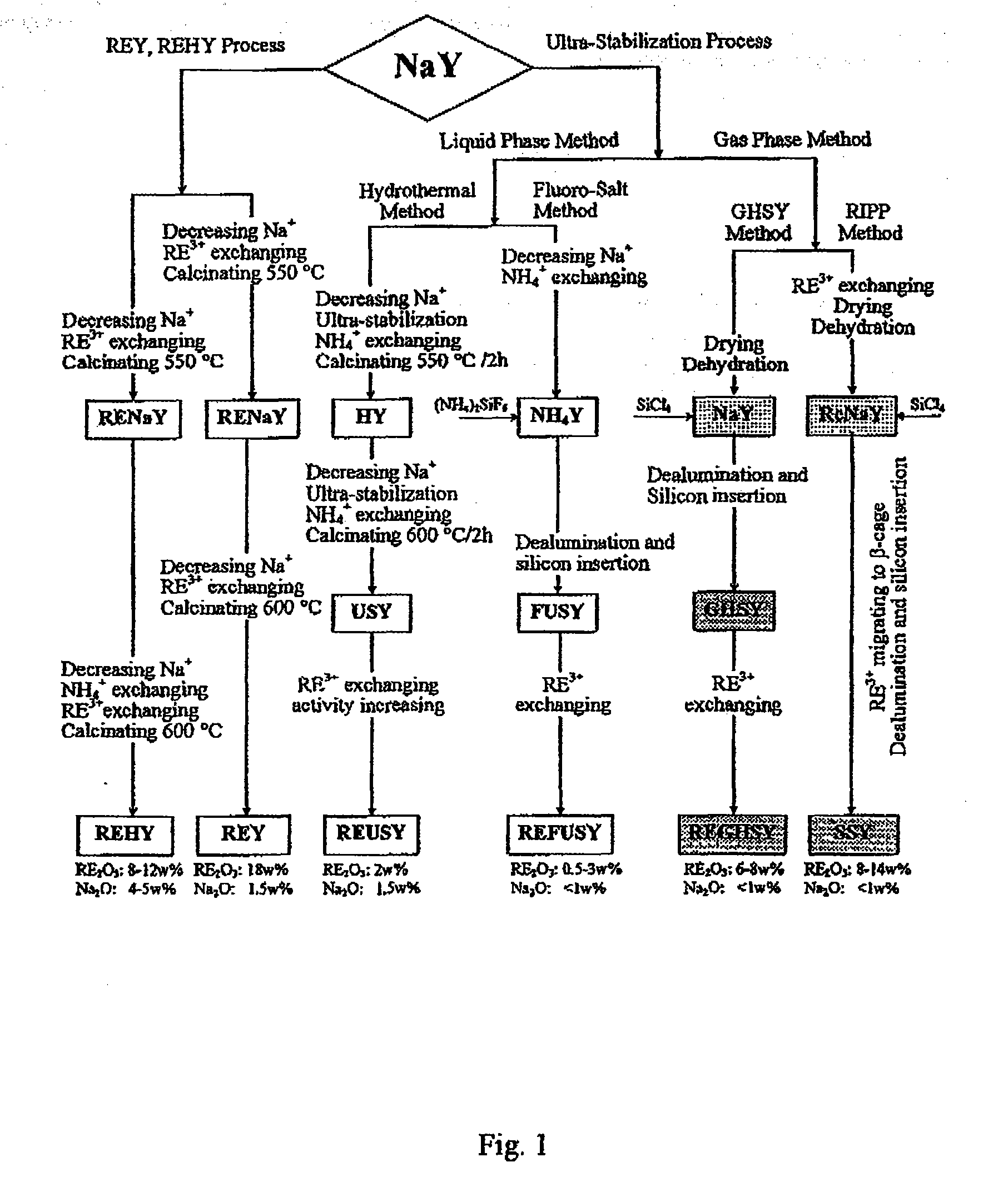

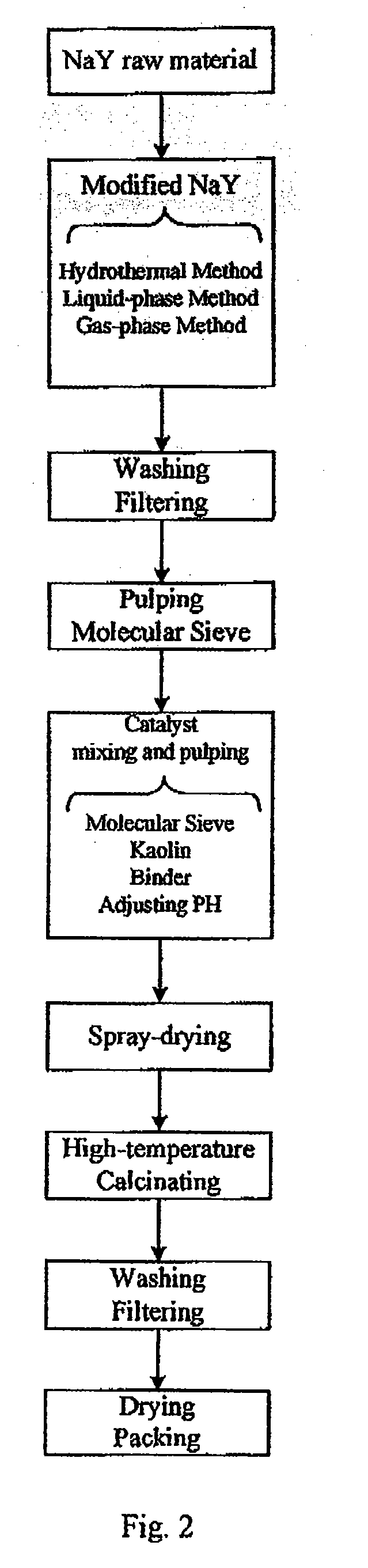

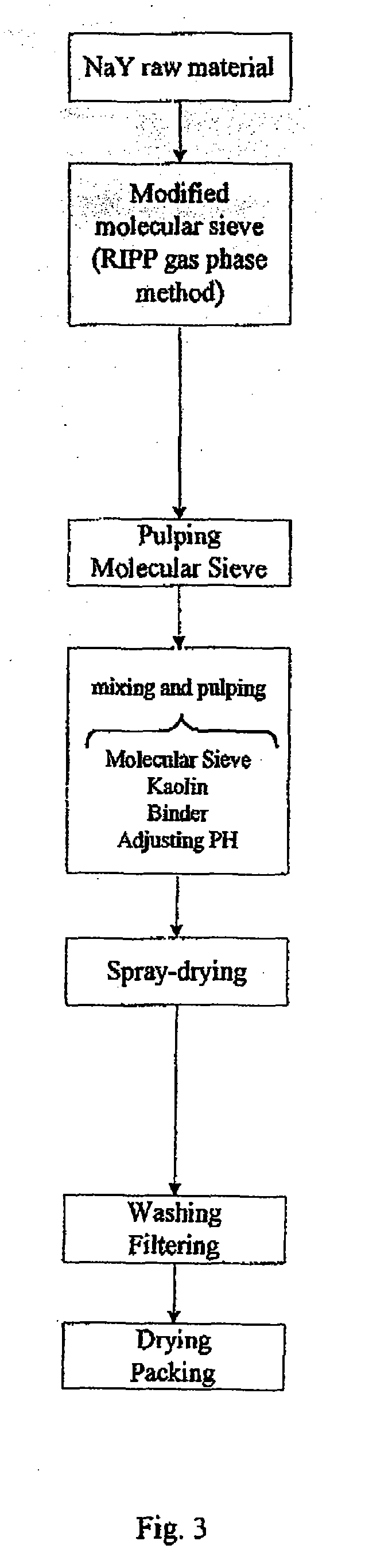

Cracking Catalyst and a Preparation Process for the Same

ActiveUS20080261802A1Improve catalyst binding propertyImprove catalyst strengthCatalytic crackingMolecular sieve catalystsRare earthCell size

The present invention provides a cracking catalyst, containing a rare-earth Y-zeolite and a support, which is characterized in that the rare-earth content in crystal lattice of the rare-earth Y-zeolite is 4-15 wt % of RE2O3; the original unit cell size is 2.440-2.465 nm; the equilibrium unit cell size of the catalyst after 100% stream-aging at 800° C. for 17 hours is larger than 2.435 nm; the rare-earth atom content in the support is 1.0-8.0 wt % of the support. The present invention also relates to a preparation process for the same catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Semiconductor device

ActiveUS8441010B2Easy transferLow oxide contentTransistorSemiconductor/solid-state device manufacturingHydrogen concentrationSilicon

In a transistor including an oxide semiconductor, hydrogen in the oxide semiconductor leads to degradation of electric characteristics of the transistor. Thus, an object is to provide a semiconductor device having good electrical characteristics. An insulating layer in contact with an oxide semiconductor layer where a channel region is formed is formed by a plasma CVD method using a silicon halide. The insulating layer thus formed has a hydrogen concentration less than 6×1020 atoms / cm3 and a halogen concentration greater than or equal to 1×1020 atoms / cm3; accordingly, hydrogen diffusion into the oxide semiconductor layer can be prevented and hydrogen in the oxide semiconductor layer is inactivated or released from the oxide semiconductor layer by the halogen, whereby a semiconductor device having good electrical characteristics can be provided.

Owner:SEMICON ENERGY LAB CO LTD

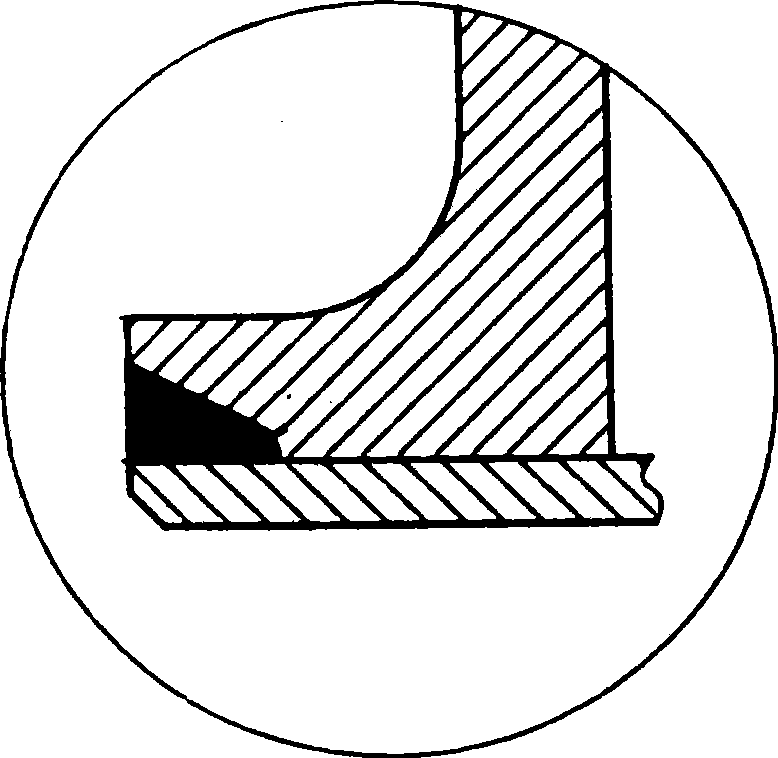

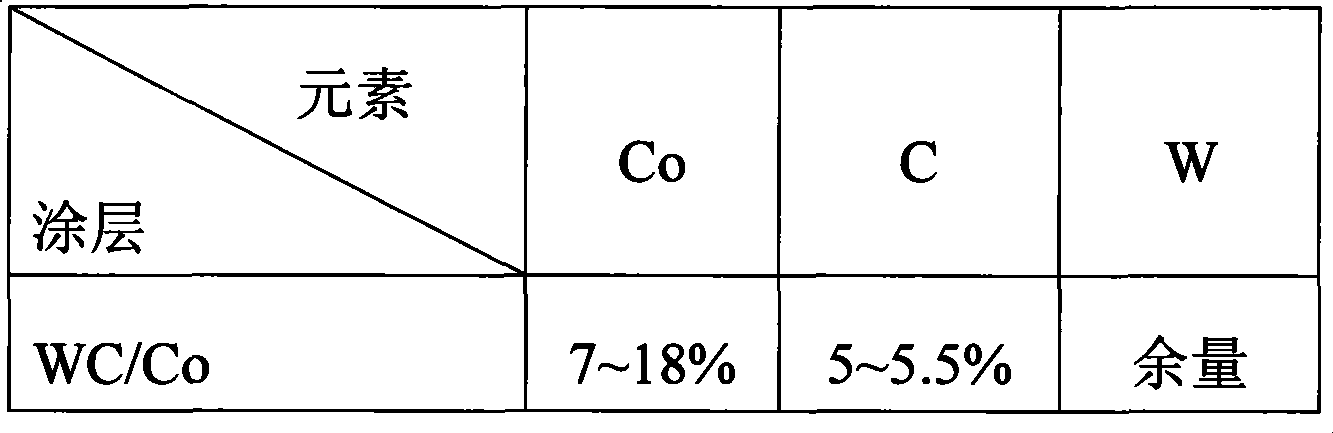

Intermediate-frequency quenching hard-surface strain roller and manufacture method thereof

ActiveCN101362152AReduce oxidationLow oxide contentMolten spray coatingFurnace typesProduction lineIntermediate frequency

The invention relates to a tension roller used in a cold rolling production line, in particular to a tension roller with a mid-frequency quenching hard surface, and a manufacturing method thereof. The tension roller comprises a roller and round side covers which are fixedly and closely covered at the openings of the two ends of the roller, and the circle centers of the two side covers are in coupling connection with a left axle head and a right axle head respectively. The tension roller is characterized in that: the outer surface of the roller is covered with a spaying layer, the outsides of the two side covers are provided with concave grooves in a surrounding way, the concave groove is internally provided with a through hole communicated with the interior of the roller; the spaying layer adopts the functional metal ceramic coating which is composed of compound metal ceramics of WC / Co metal ceramics and metal or alloy. The tension roller mainly solves the technical problems that the existing product roller surface is sprayed with hard chromium plating on the outer surface and is easy to be pressed into concave pits or protuberances by sundries such as ferric oxide, etc. When in use, drawing stamps or stains are formed on the surface of the finished product, the band steel, thus influencing the surface quality of the band steel, and the tension roller is beneficial to radiating the interior of the roller when in use.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Material and method of manufacture of a solder joint with high thermal conductivity and high electrical conductivity

ActiveUS7758916B2Increased thermal and electrical conductivityEasy to controlMolten spray coatingPrinted circuit aspectsElectricityPowder mixture

Owner:SULZER METCO (US) INC

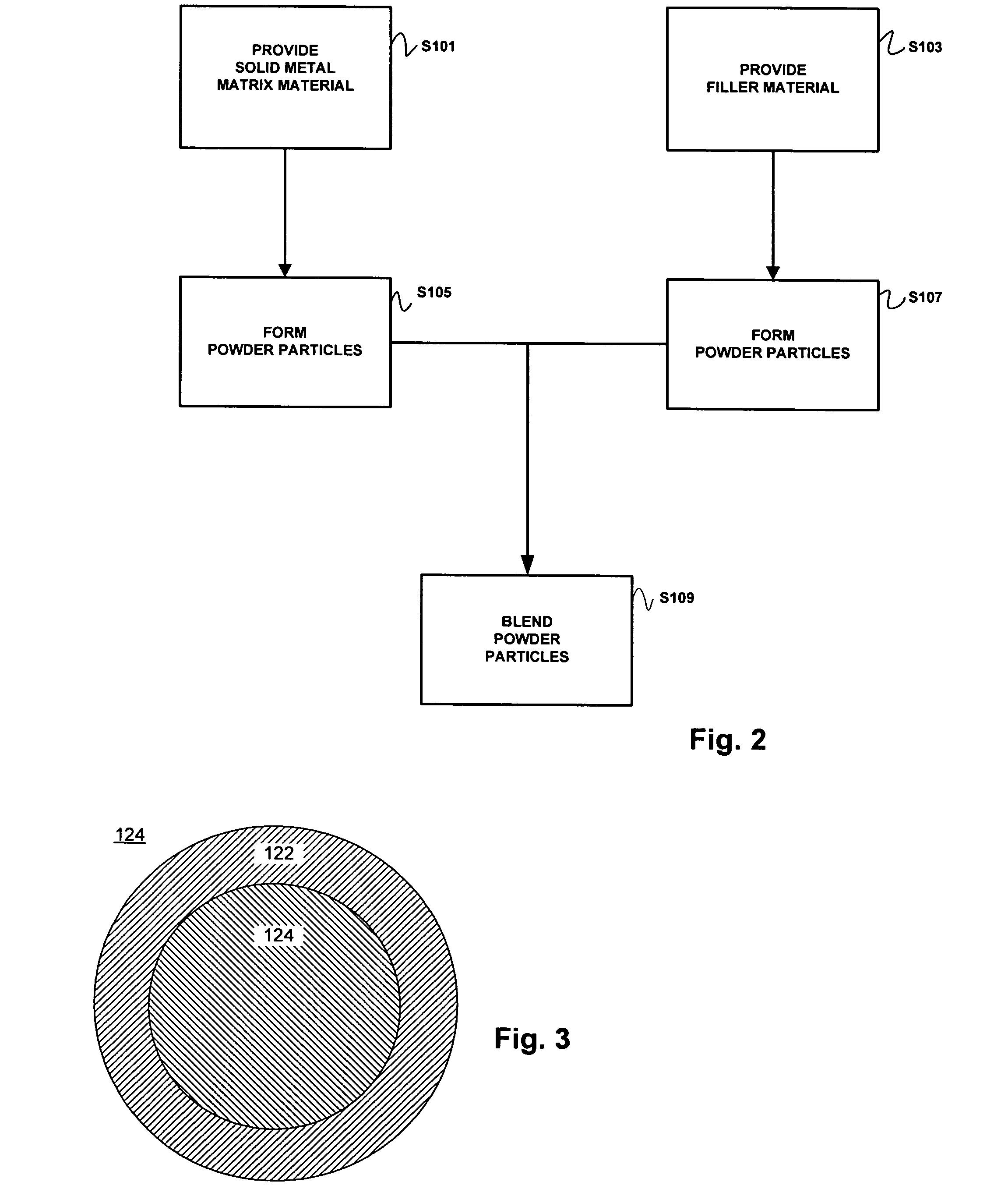

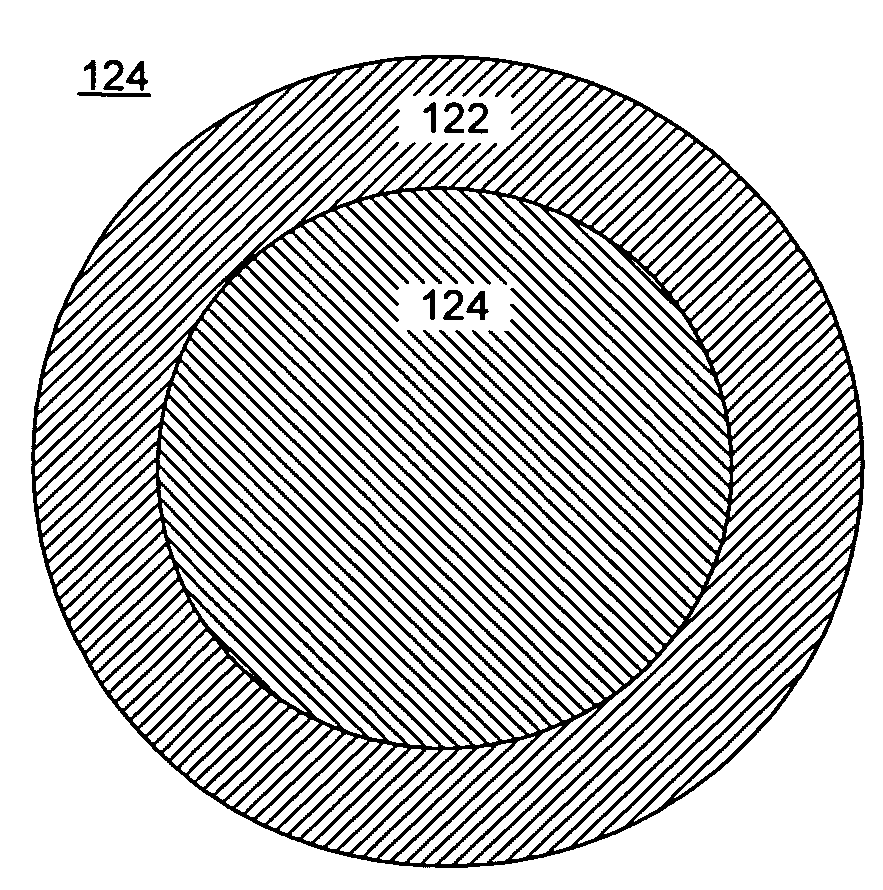

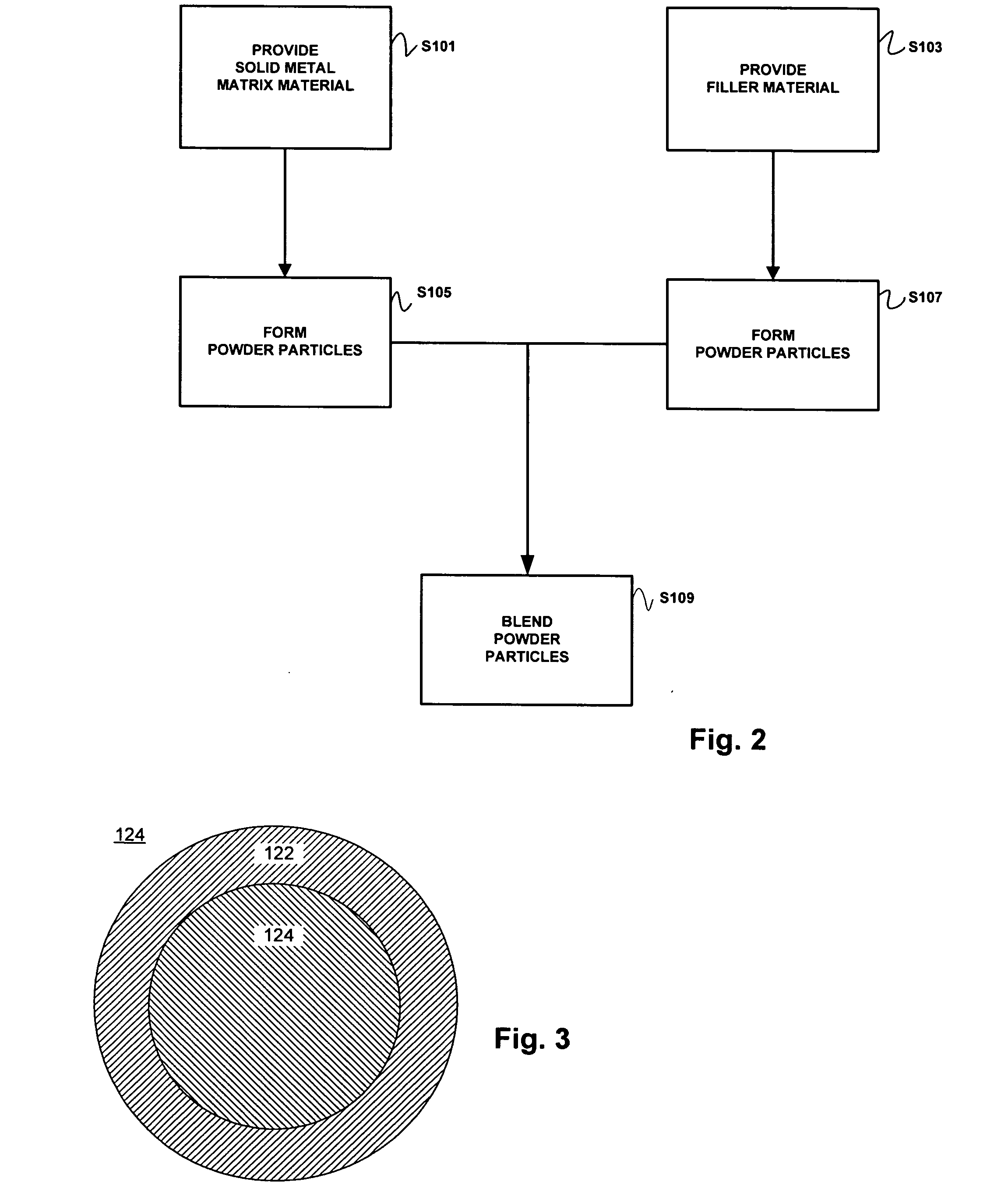

Material and method of manufacture of a solder joint with high thermal conductivity and high electrical conductivity

ActiveUS20080110531A1Increased thermal and electrical conductivityEasy to controlMolten spray coatingPrinted circuit aspectsElectricityPowder mixture

The present invention provides a powder blend or composite powder that is fed into a kinetic spray device, accelerated towards a substrate or part in order to form a composite solder with thermal and electrical properties better than existing solder. The other advantages of building a solder layer in this manner include a low oxide content to improve subsequent solderability, excellent control of the deposition thickness, excellent control of the deposition chemistry and lastly, high speed of manufacture.

Owner:SULZER METCO (US) INC

Plasma-Kinetic Spray Apparatus and Method

InactiveUS20150225833A1Uniform compositionImprove performanceLiquid surface applicatorsMolten spray coatingCoating systemPlasma generator

A coating system that applies a coating of particles to a surface of an article. The coating system comprises a hybrid plasma torch which may include a cathode, a first plasma gas chamber, a first mixing chamber, a plasma generator for generating an arc column of plasma, a second mixing chamber for mixing a main gas, an at least partially ionized first plasma gas and a second gas that was mixed in the first mixing chamber, wherein the second mixing chamber is dimensioned to receive a plurality of powder particles suspended in a carrier gas, and an accelerator assembly for accelerating the mixture of the main gas, the at least partially ionized first plasma gas, the second plasma gas and the powder particles into a high-velocity stream and for directing the high-velocity stream against the surface of the article. A method of applying the coating of particles is also provided.

Owner:FLAME SPRAY IND

Casting method of anti-corrosion wear-resisting low-chromium alloy material

InactiveCN106191637AImprove wear resistanceImprove corrosion resistanceFoundry mouldsFoundry coresImpurityChromium Alloys

The invention discloses a casting method of an anti-corrosion wear-resisting low-chromium alloy material. The casting method comprises the following steps that raw materials are added into a smelting furnace, heat is preserved until the raw materials are melted completely, then deslagging is carried out, melted alloy liquid is obtained, and all elements comprise C, Si, Cr, Cu, Ca, Mn, Mo, N, Ni, Mg, Ti, Zr, S, P and the balance iron and unavoidable impurities; the alloy liquid is poured into a sand mould cavity with the surface coated with nanometer paint, the nanometer paint is prepared from a nanometer material and refractory aggregate, and a casting green body is obtained; and the casting green body is subjected to thermal treatment to obtain the anti-corrosion wear-resisting low-chromium alloy material. According to the casting method of the anti-corrosion wear-resisting low-chromium alloy material, the alloy material obtained through casting can be used in multiple environments and has good corrosion resistance and wear resistance, the hardness can reach over 70 HRC, and the requirement for the wear-resisting alloy material in the actual using process is met.

Owner:蚌埠市北晨微型机床厂

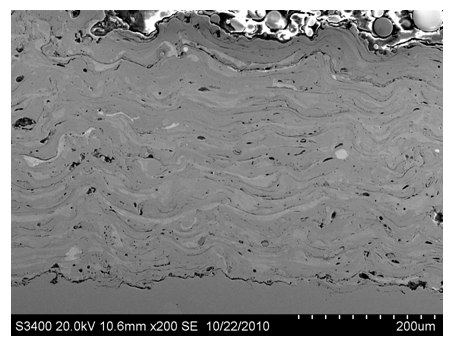

Amorphous protection corrosion resisting steel bar and preparing method thereof

The invention discloses an amorphous protection corrosion resisting steel bar and a preparing method thereof. A powder core wire used in a coating on the steel bar comprises following components including, by weight percent, 25-28 wt% of Cr, 11-13 wt% of B, 0.2-0.7 wt% of C, 0.5-2.5 wt% of P, 3-4.5 wt% of Cu, 1.5-3.5 wt% of Ni, 5-10 wt% of Mo, 2-4 wt% of Mn, 0.35-0.57 wt% of Ti and the balance Fe.After the components are dried and placed in a powder mixing machine according to the proportion to be evenly mixed, the components are placed in a U-shaped 304 stainless steel strip groove, the U-shaped groove is sealed, and drawing is conducted to form filaments through a wire drawing die. A steel bar body is pretreated, the powder core wire serves as the raw material, the coating is prepared through the supersonic speed arc spraying technology, and hole sealing treatment is conducted. The coating is high in amorphous content and bonding strength, low in porosity, high in corrosion resistance and low in cost, and a new path is provided for steel bar corrosion resisting.

Owner:HOHAI UNIV

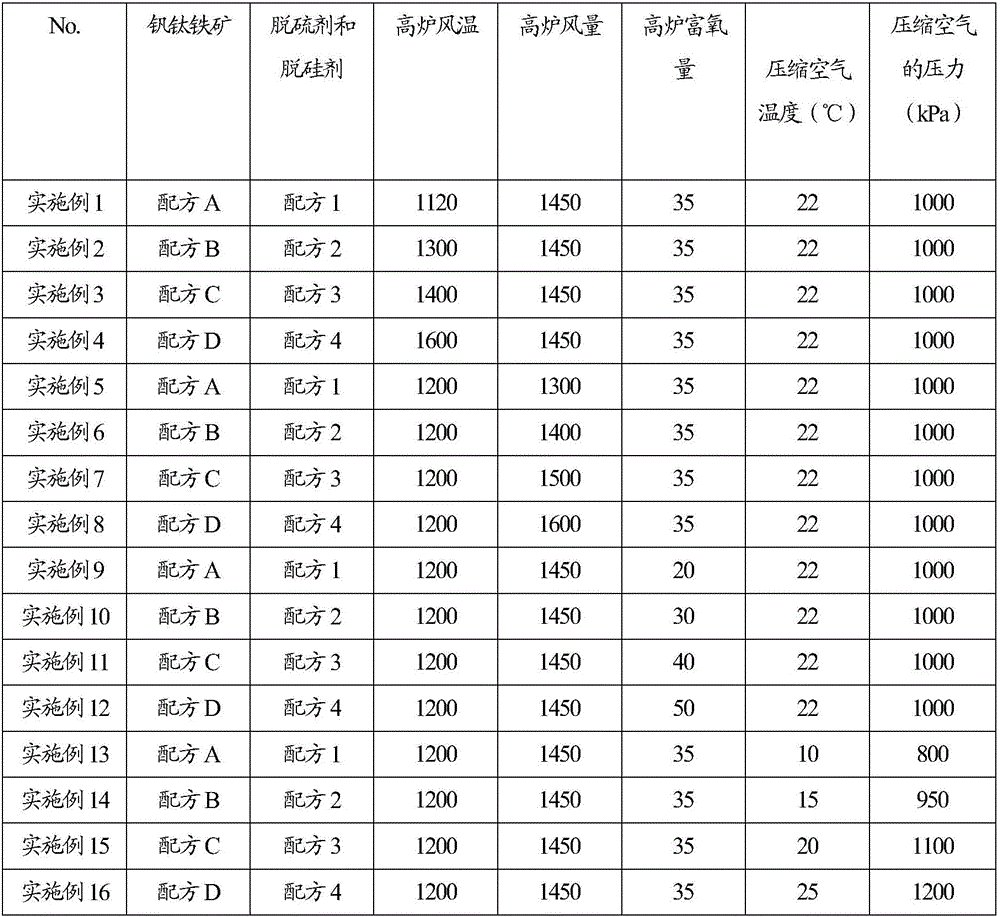

Blast furnace smelting method for sefstromite

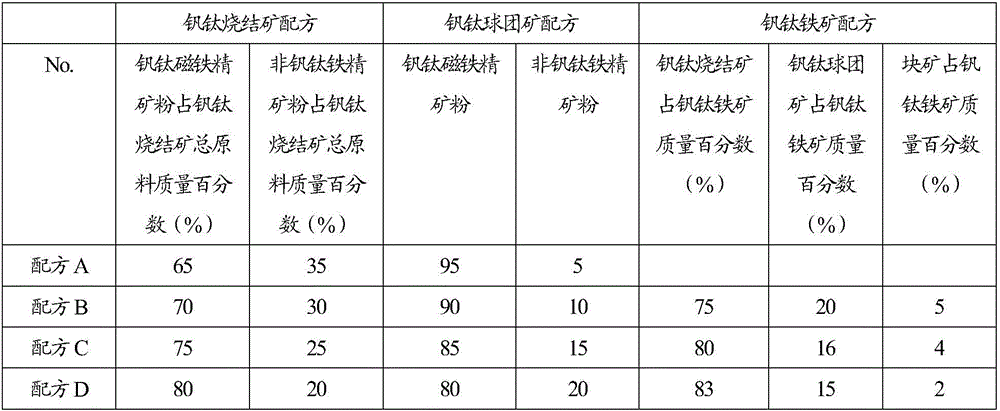

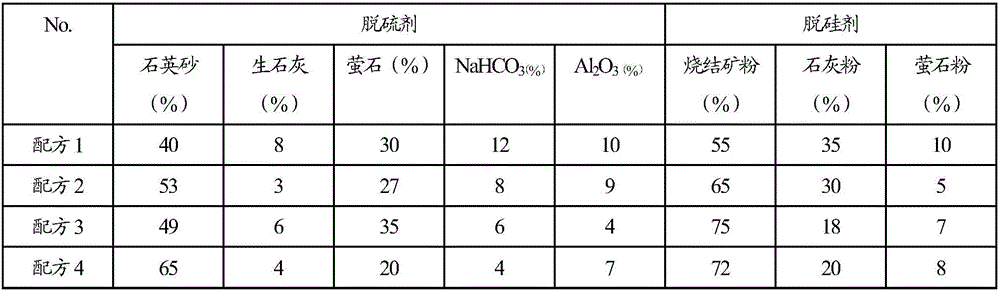

InactiveCN106282453AEasy to recycleSmooth dischargeBlast furnace detailsProcess efficiency improvementBlast furnace smeltingTitanium

The invention discloses a blast furnace smelting method for sefstromite. The method comprises the step of smelting a furnace charge into a blast furnace, wherein the furnace charge comprises sefstromite, a fluxing agent and fuel, the sefstromite is composed of vanadium-titanium sinters, vanadium-titanium pellets and lump ores, the fuel is composed of cokes, coke blocks and pulverized coal, blast furnace slag contains 14-28% of TiO2, and molten iron contains 0.25-0.4% of sulfur and 0.15-0.4% of silicon. The method is beneficial to the recycle of vanadium and titanium, and the blast furnace smelting cost is reduced.

Owner:YUNNAN DESHENG STEEL CO LTD

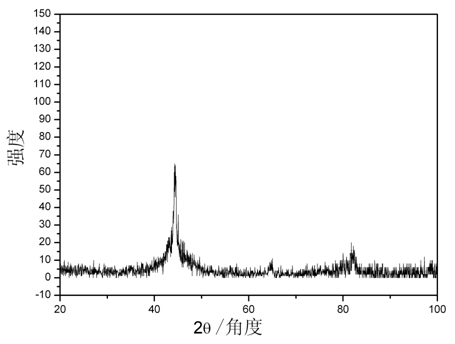

Cored wire for electric arc spraying of amorphous and nano-crystalline anti-cavitation coating layer

The invention discloses a cored wire for electric arc spraying of an amorphous and nano-crystalline anti-cavitation coating layer. The cored wire is prepared from a low-carbon steel casing coated cored wire, and the powdered core is obtained by mixing four types of metal alloy powder. The cored wire is characterized in that the powdered core comprises the following chemical components in percentage by mass: 2 to 6 percent of boron, 3 to 7 percent of silicon, 2 to 7 percent of phosphorus, 2 to 5 percent of nickel, and the balance of Fe. The preparation method of the cored wire comprises the following steps of: rolling a low-carbon steel strip into a U shape, and adding alloy powder which accounts for 30 to 40 percent of the total weight of cored wire into a U-shaped groove; healing up the U-shaped groove to enwrap the powder in the groove; gradually drawing and reducing the diameter through a wire-drawing die to ensure that the final diameter of the cored wire is 2.0 mm; and forming an amorphous and nano-crystalline coating layer on a cooled steel substrate by adopting a high-speed electric arc spraying technique, wherein the coating layer is compact in organization structure and high in thermal stability, the porosity is less than 3 percent, the amorphous content is more than or equal to 70 percent, the bonding strength of the coating layer is more than or equal to 45 MPa, and the average hardness is more than or equal to 1,000 HV0.1, so the cored wire can significantly improve the anti-cavitation performance of key flow passage components of hydraulic machinery.

Owner:HOHAI UNIV

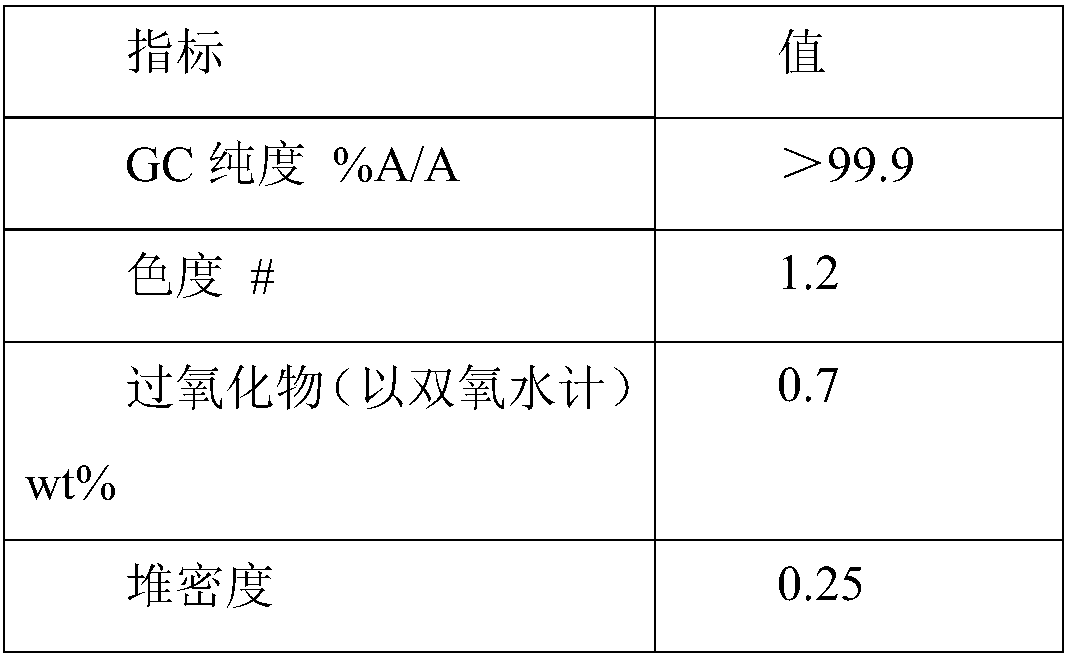

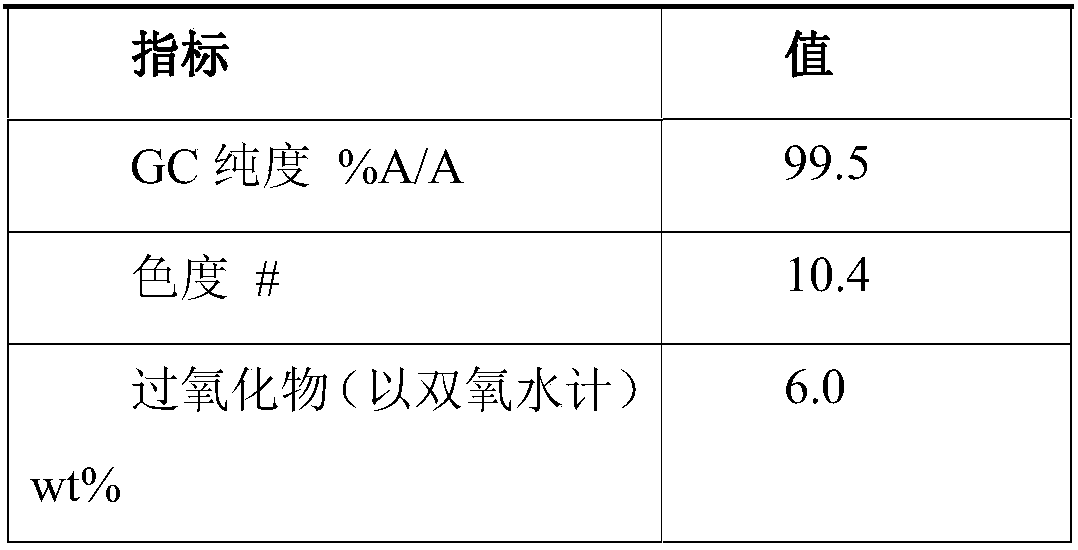

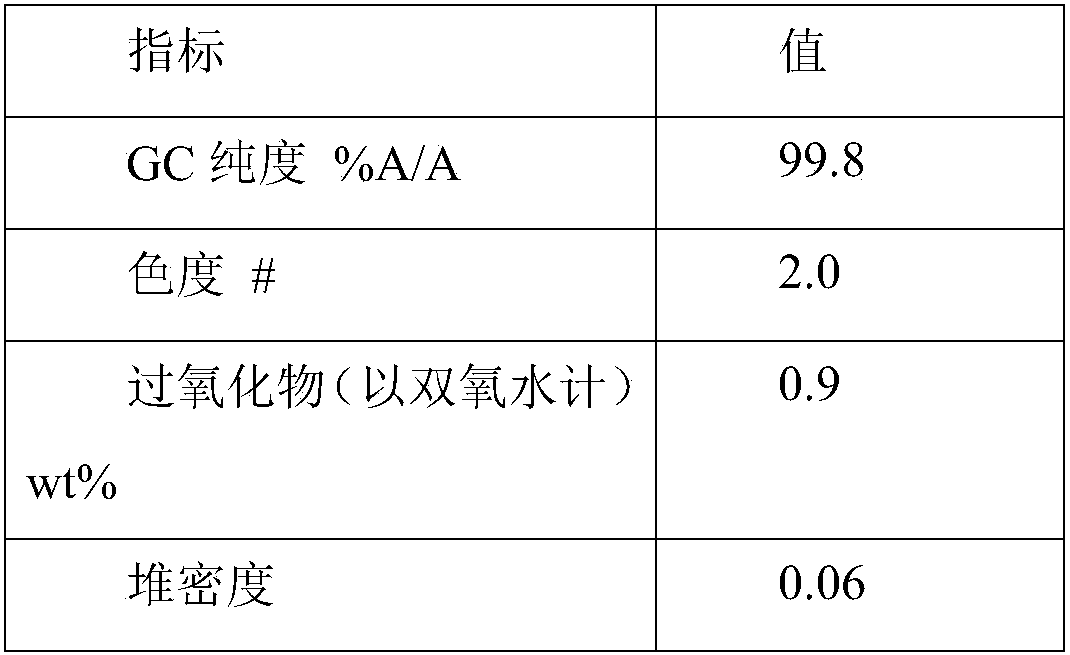

Production method of dodecalactam

ActiveCN109867616AThe oximation reaction is fastEasy to purifyLactams preparationBeckmann rearrangementHydroxylamine

The invention relates to a production method of dodecalactam with high purity. The method comprises the following steps: carrying out a reaction of cyclododecanone and hydroxylamine, and adding a solvent a to assist the liquid separation; and recovering the remaining cyclododecanone from the oil phase obtained from the liquid separation by vacuum rectification, mixing the solution rich in cyclododecanoxime with concentrated sulfuric acid, carrying out a Beckmann rearrangement reaction, neutralizing the mixed solution with ammonia water after the reaction is finished, performing the liquid separation to obtain dodecalactam a solution, adsorbing impurities by alumina and then adding a solvent b, and cooling and crystallizing the solution in the mixed solvents of a and b to obtain the dodecalactam solid product. The dodecalactam product obtained by the method has high purity and light color, and is suitable for producing high-grade resin materials.

Owner:WANHUA CHEM GRP CO LTD

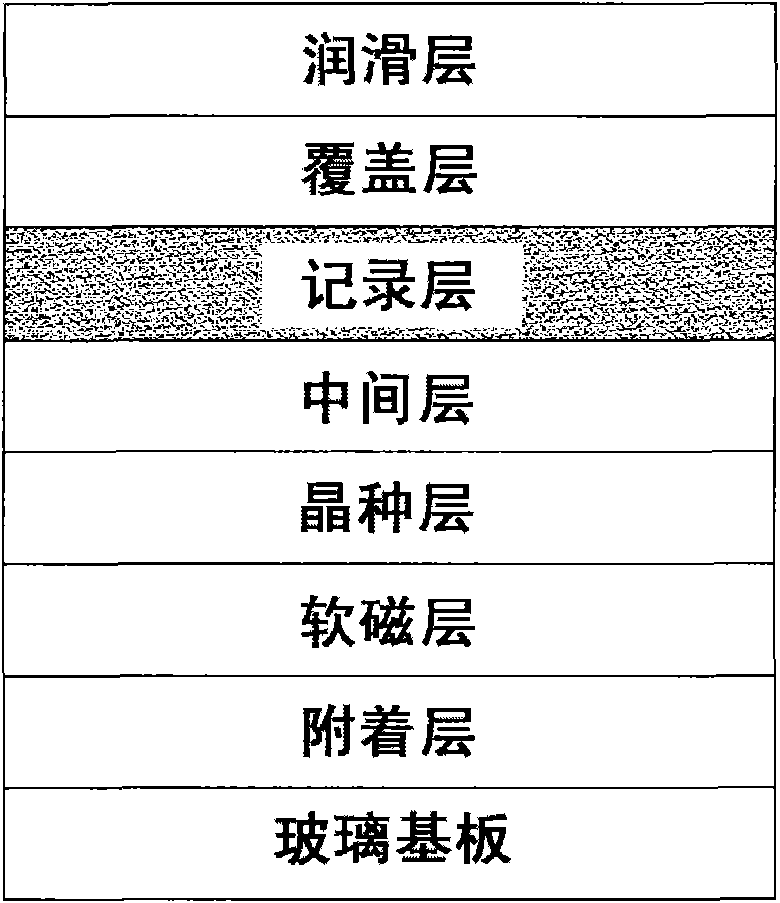

Target material and its application in recording layer material of magnetic recording media

InactiveCN102465265AEnhance the advantagesImprove efficacyVacuum evaporation coatingSputtering coatingCopper oxideRecording density

The invention discloses a target material, which is formed by the main material of: CoPt-copper oxide-oxide or CoCrPt-copper oxide-oxide or CoCrPtB-copper oxide-oxide. The added copper oxide is the main technological characteristic. With the application of the target material in the sputtering process of a recording layer material of a magnetic recording media, the sputtering process is stable and the required thickness of an intergranular layer of magnetic particles in the recording layer can be reduced. In addition, thermal stability is high. Therefore, recording density of the recording layer of the magnetic recording media can be raised, and recording capacity of the whole storage media is enhanced.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

Ethylene oxychlorination catalyst and its preparation method and application

ActiveCN100457260CLow oxide contentIncrease profitCatalyst activation/preparationHalogenated hydrocarbon preparationMicrosphereRare earth

A catalyst for the oxychlorinating reaction of ethene to prepare dichloroethane is composed of the carrier (aluminum oxide-titanium oxide microballs), primary active component (Cu) and secondary active component consisting of at least one of La, Ce, Nd, Pr and Y, one transition metal and at least one alkali metal. Its preparing process includes preparing carrier by codeposition, and dipping in active components.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold gas spray coating methods and compositions

InactiveUS20180258539A1Reduce porosityLow oxide contentTransportation and packagingMetal-working apparatusPorous coatingMetal alloy

Cold gas spray coating methods, compositions and articles. A cold gas spray method is described including spraying a composition containing at least one nickel or iron based material blended with a softer, shear-deformable, secondary phase metal and / or metal alloy, onto a surface to deposit a dense, porous coating. The compositions used in and articles produced by such methods are also described.

Owner:SULZER METCO (US) INC

Mo2NiB2 base metal ceramic with nickel base alloy serving as binding phase and preparing method of Mo2NiB2 base metal ceramic

The invention discloses a Mo2NiB2 base metal ceramic with a nickel base alloy serving as a binding phase. The Mo2NiB2 base metal ceramic is prepared from multiple of MoB powder, NiB powder, Mo powder, B powder and Ni powder. By weight, 3.5-7 parts of B, 31.5-65 parts of Mo and 28-65 parts of Ni are mixed, and a proper amount of glucose, a proper number of binding agent and a proper number of dispersion medium are added in the mixture. The invention further discloses a preparing method of the Mo2NiB2 base metal ceramic. The preparing method includes the steps that multiple of the MoB powder, the Nib powder, the Mo powder, the B powder and the Ni powder are evenly mixed with the glucose, the binding agent and the dispersion medium to obtain sizing; spray drying and pelletizing are conducted; the powder is treated in the hydrogen atmosphere at the temperature being 900-1100 DEG C; and then the powder is packed into a machined cover to be subjected to hot isostatic pressing, wherein the temperature ranges from 1100 DEG C to 1300 DEG C, and the pressure ranges from 100 MPa to 200 MPa. The prepared Mo2NiB2 base metal ceramic material is small in oxide inclusion amount, high in material strength and high in toughness, and a blank is shrunk evenly and regularly in the hot isostatic pressing process and is not likely to twist or deform.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

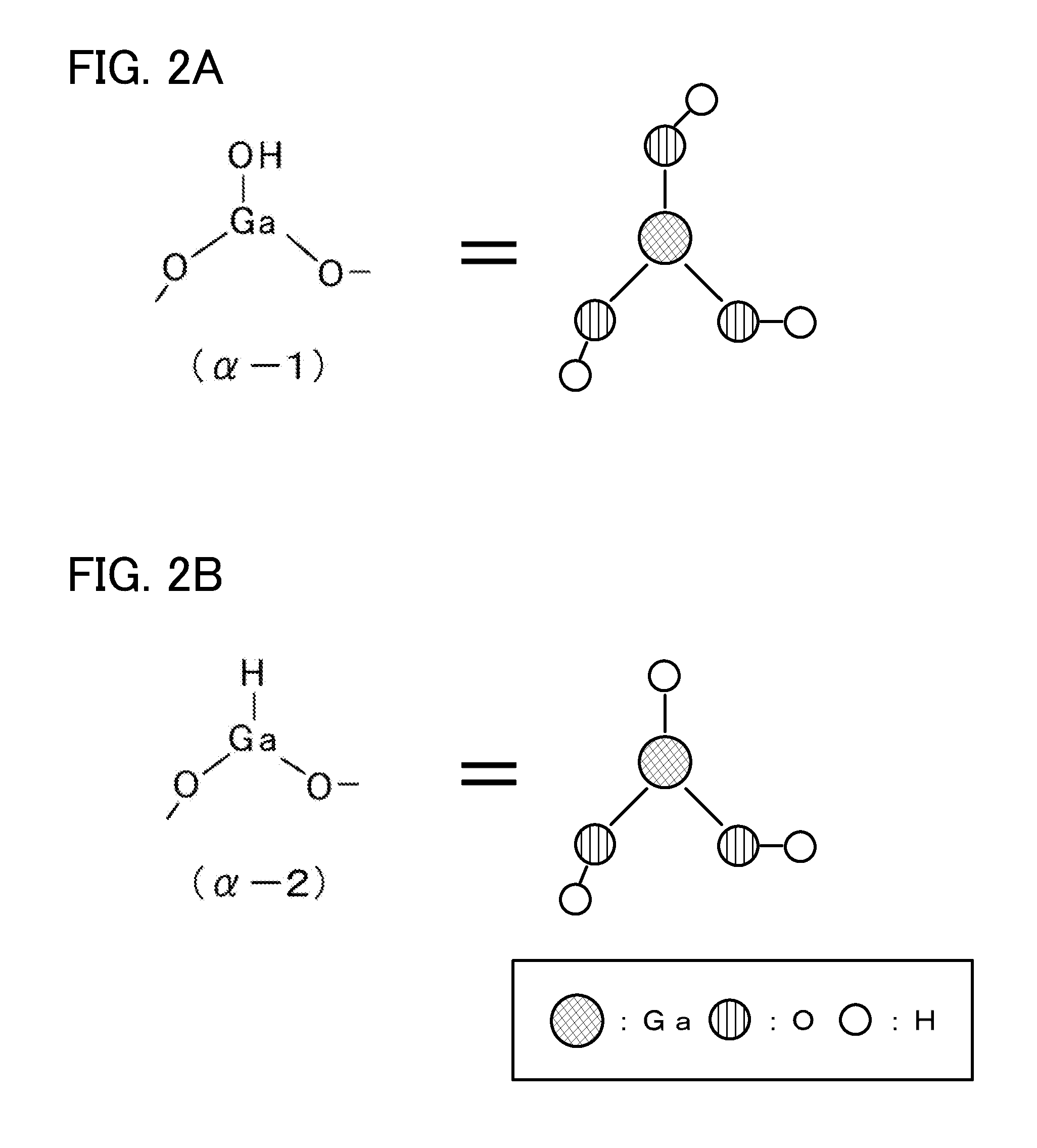

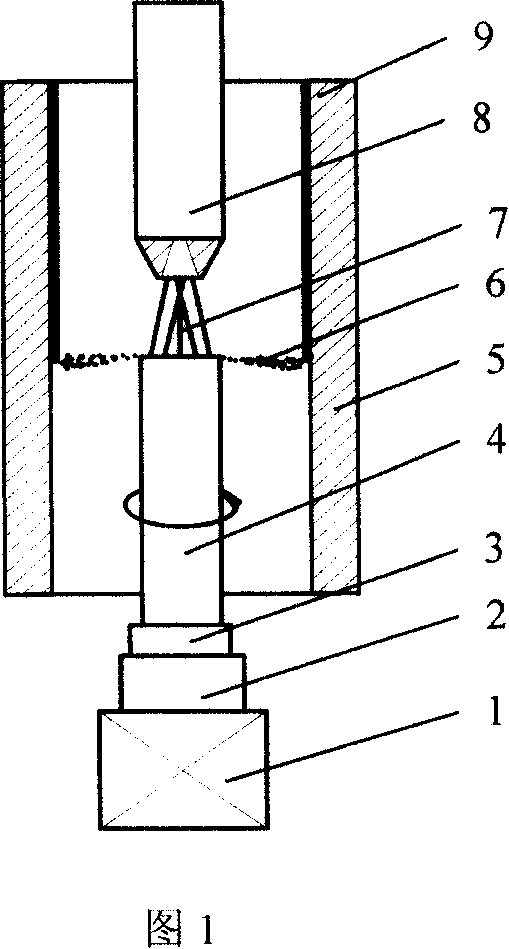

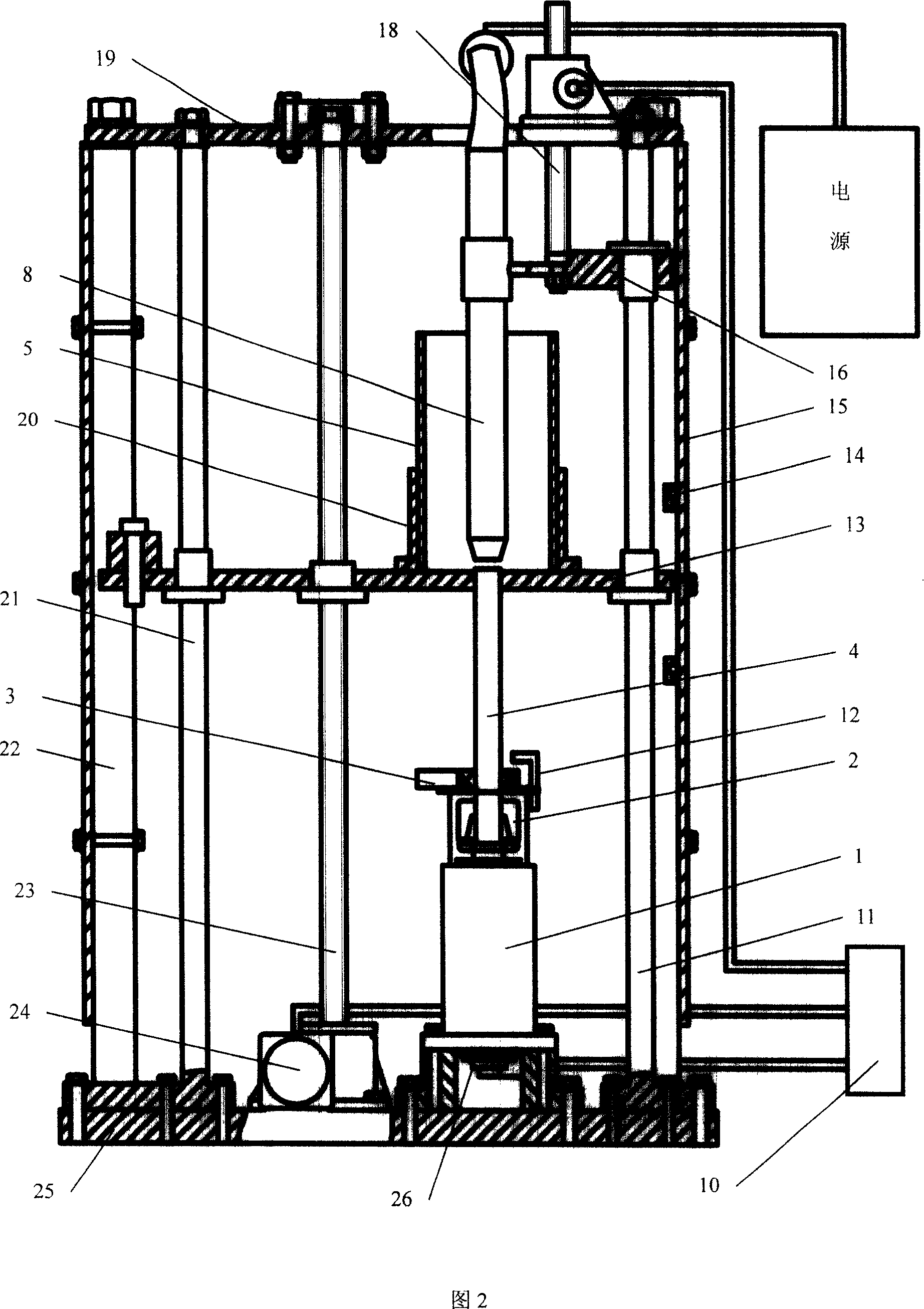

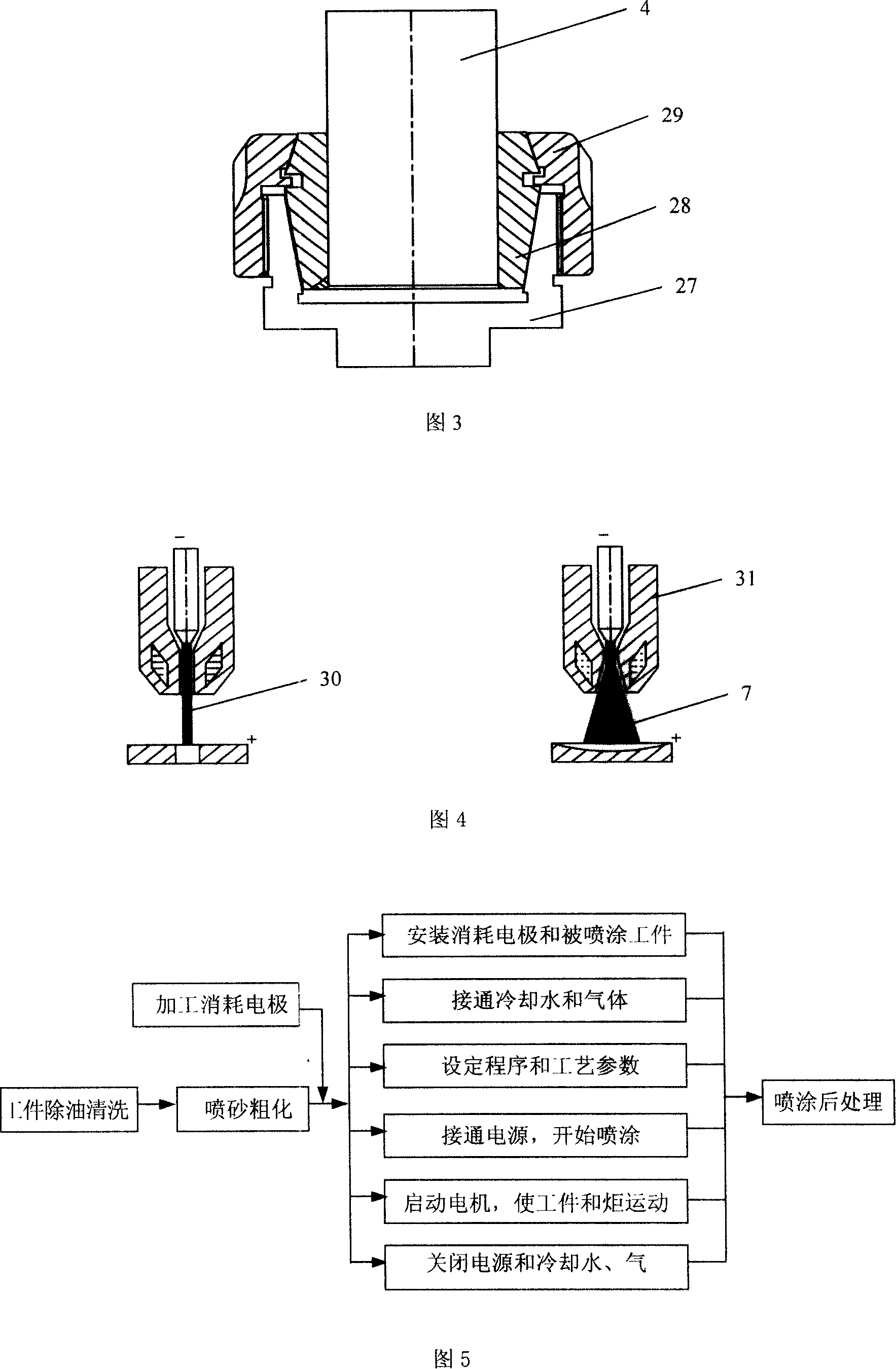

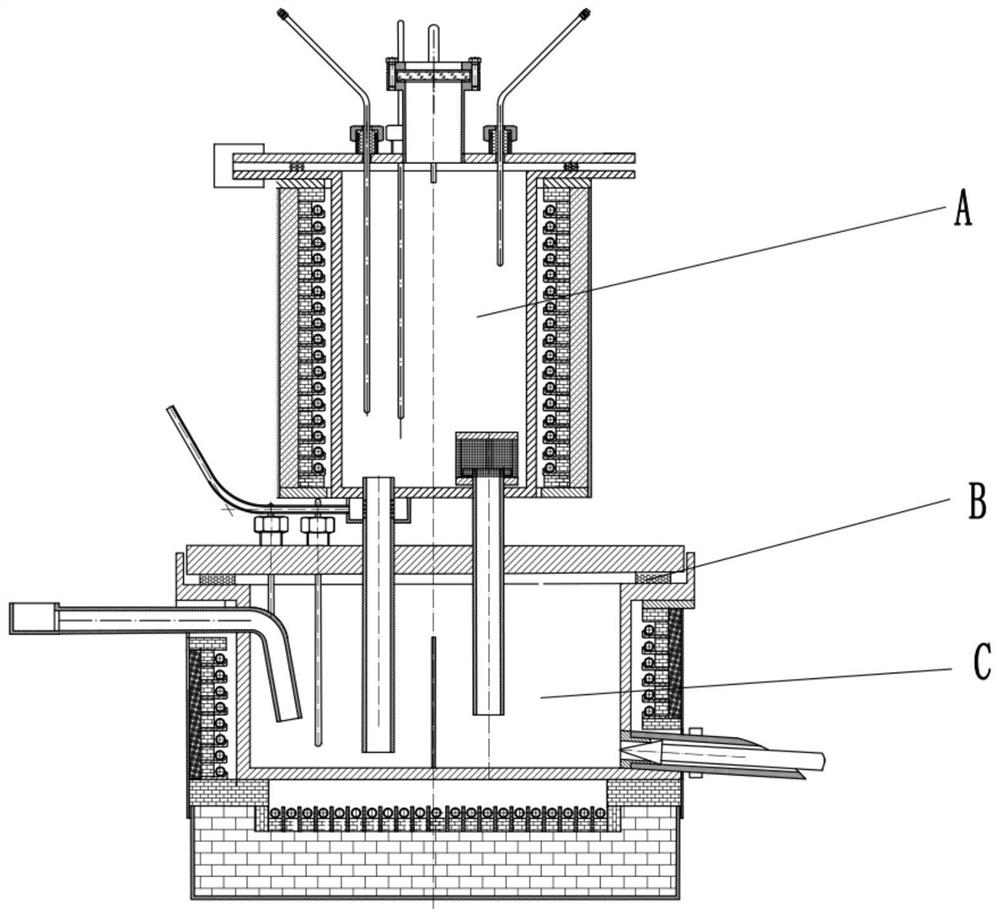

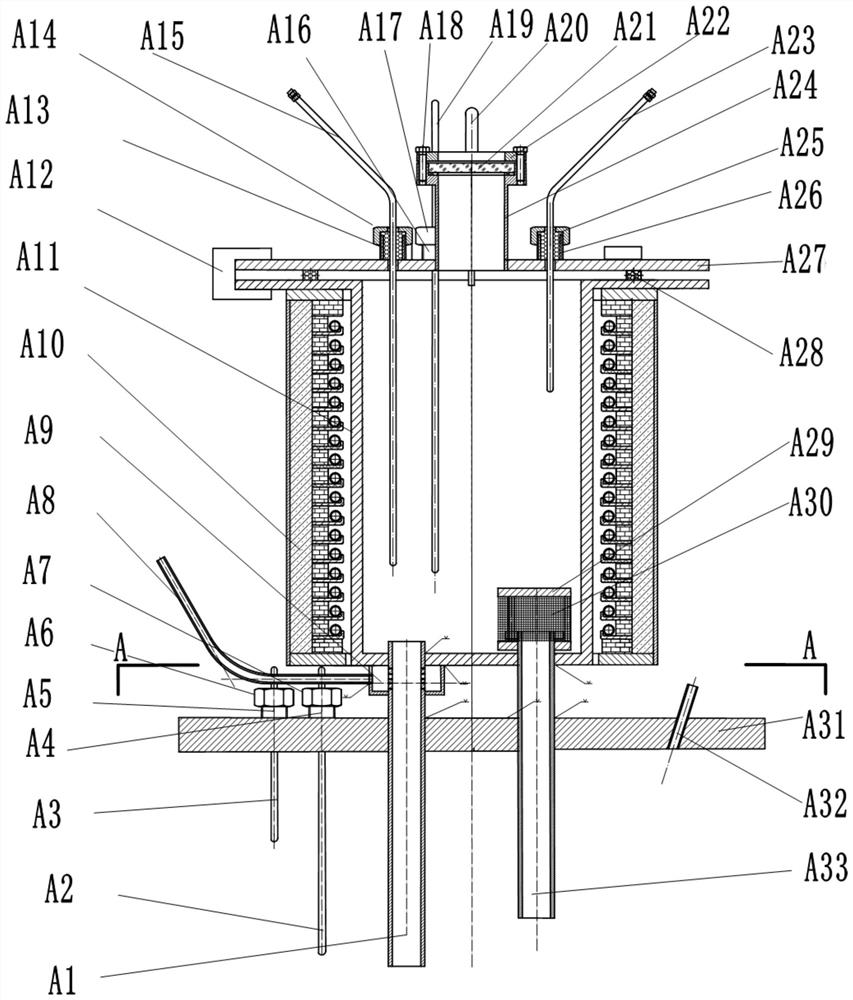

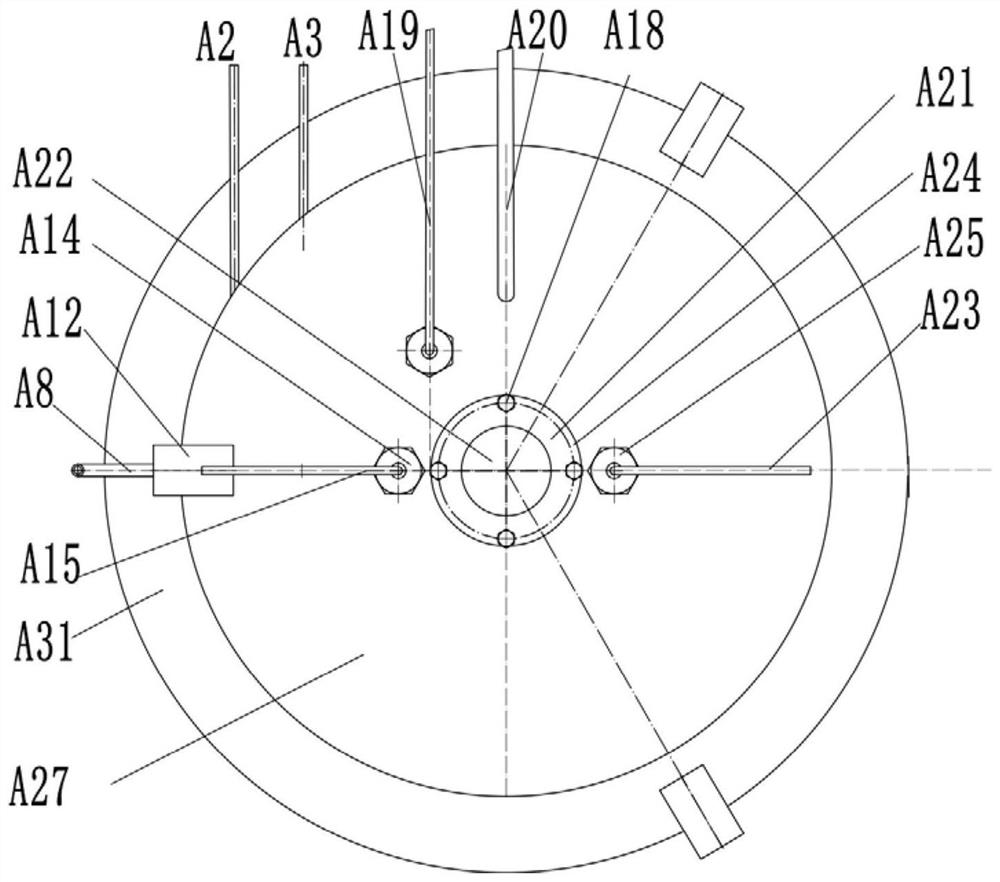

Centrifugal atomizing plasma spraying machine and its spray coating technique

InactiveCN101130851AMeet spraying requirementsLow oxide contentMolten spray coatingVacuum evaporation coatingThermal sprayingControl system

The present invention discloses a plasma spraying machine based on centrifugal atomization principle and thermal spraying process by utilizing said spraying machine. Said plasma spraying machine is formed from centrifugal atomization mechanism, plasma cutting torch, feeding mechanism, control system, cooling system, machine frame and protective device. Said invention can be used for thermal-spraying surface of internal hole whose minimum hole diameter is 70mm.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for repairing size of casing spigot by supersonically spraying NiCrFeMn coating

InactiveCN108220864AHigh bonding strengthImprove stabilityMolten spray coatingKeroseneMaterials science

The invention relates to a method for repairing the size of a part, in particular to a method for repairing the size of a casing spigot by supersonically spraying a NiCrFeMn coating. The method comprises the following steps of 1, carrying out sand blowing treatment on the casing spigot; 2, performing oil removal treatment on the casing spigot; 3, carrying out protection on the part, which does notneed to be subjected to spraying repair, of the casing spigot before sand blowing; 4, carrying out sand blowing treatment on the area, which needs to be repaired in size, of the casing spigot, wherein 50-60 mesh magnesia sand is adopted, and sand blowing pressure is 0.2-0.5 MPa; and 5, supersonically spraying the NiCrFeMn coating on the area, which needs to be repaired, of the casing spigot, wherein the specific parameters are as follows that a kerosene flow rate is 2.5-5.5 L / min, an oxygen flow rate is 800-1200 L / min, a powder feeding rate is 75-80 g / min, spraying distance ranges from 120 mmto 240 mm and a spraying angle ranges from 60 degrees to 65 degrees. According to the method, a repaired part meets the assembling requirements, part reproduction cost is saved, and the production cost is reduced.

Owner:新锐咨询(辽宁)有限公司

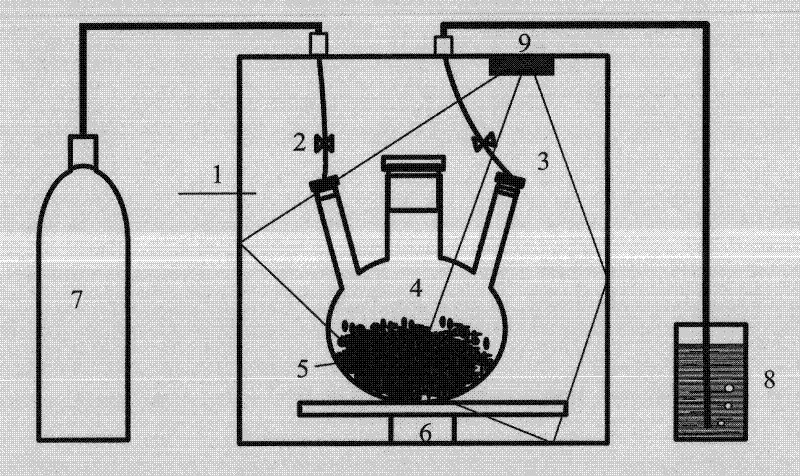

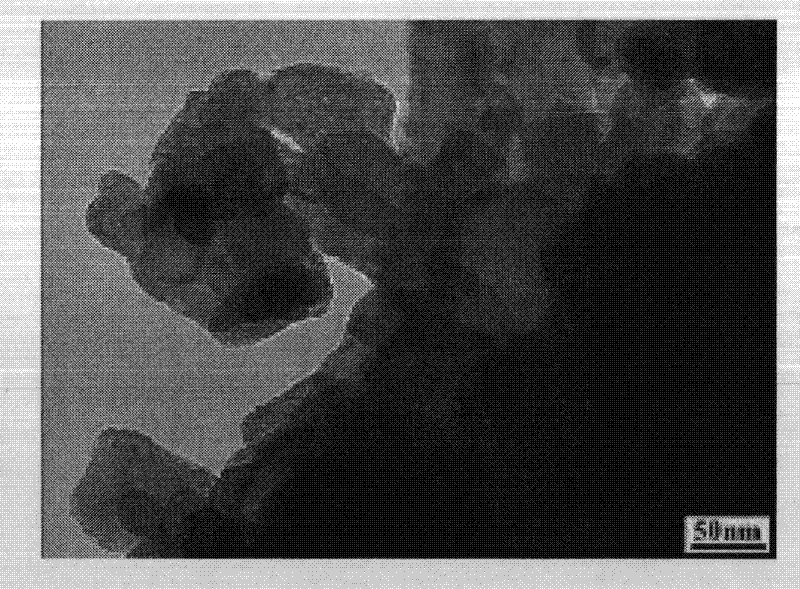

Preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials

InactiveCN102583391AHigh surface energyImprove internal energyChemical industryMetal silicidesThermoelectric materialsMicrowave oven

Disclosed is a preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials, which belongs to the field of thermoelectric material preparation and particularly relates to a technical scheme of preparation method of high-purity nano-powder Mg2-xSiTMx thermoelectric materials through a microwave reaction method. The preparation method is characterized in that magnesium hydride(MgH2) power, silicon powder and transition metal hydride TMHy powder are reacted under the protection of flowing argon air in a microwave oven, a decomposition temperature of the magnesium hydride powder and a decomposition temperature of the TMHy powder are both under 350 DEG C, reactants are easy to be decomposed and distributed in a substrate uniformly during the reaction process, the strong reducibility of the reactants can inhibit a substrate surface from absorbing oxygen and avoid further forming of oxidation products, and high-purity nano-powder Mg2-xSiTMx powder with a purity of not less than 99.95% is obtained. According to method, the process is simple, efficiency is high, energy is saved, and the prepared Mg2-xSiTMx thermoelectric materials have good thermoelectric performance.

Owner:TAIYUAN UNIV OF TECH

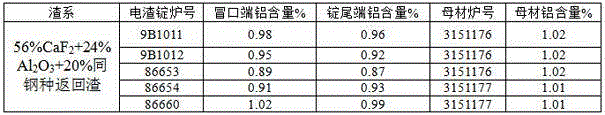

Electroslag re-melting process for controlling aluminum uniformity of high-aluminum steel

The invention relates to an electroslag re-melting process for controlling aluminum uniformity of high-aluminum steel. The electroslag re-melting process is characterized in that a binary slag system is adopted, wherein parts of CaF2 and Al2O3 are replaced by returned slag of the same steel type. During slag melting, aluminum powder which accounts for 2%-4% of the slag is added to remove unstable oxides in the slag. Aluminum burning loss is severe because of large current fluctuation in first two hours of a re-melting initial stage, the aluminum powder is added to regulate aluminum in electrode blank until the aluminum amount exceeds upper limit of a range by 0.1%, and then, aluminum powder is added according to component upper limit for deoxidation. A melting rate (kg / h) during the electroslag re-melting process is equal to (0.75-0.85)*an average diameter (mm) of a crystallizer, so that surface smooth of an electroslag ingot can be guaranteed, and surfaces pits and insufficient steel-slag separation are avoided.

Owner:ZHONGYUAN SPECIAL STEEL

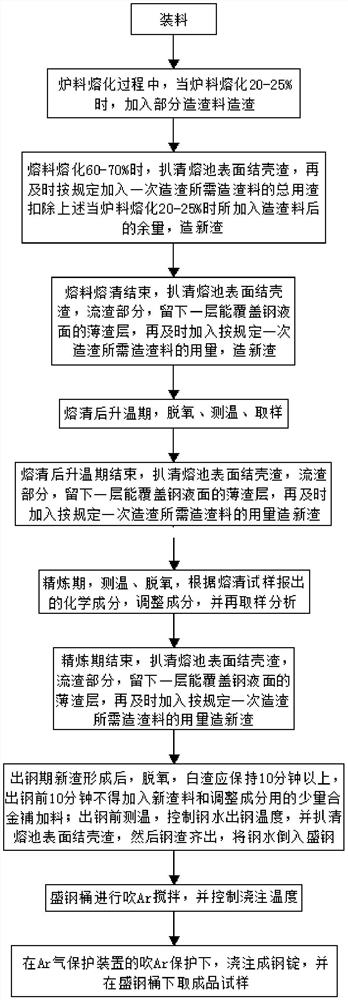

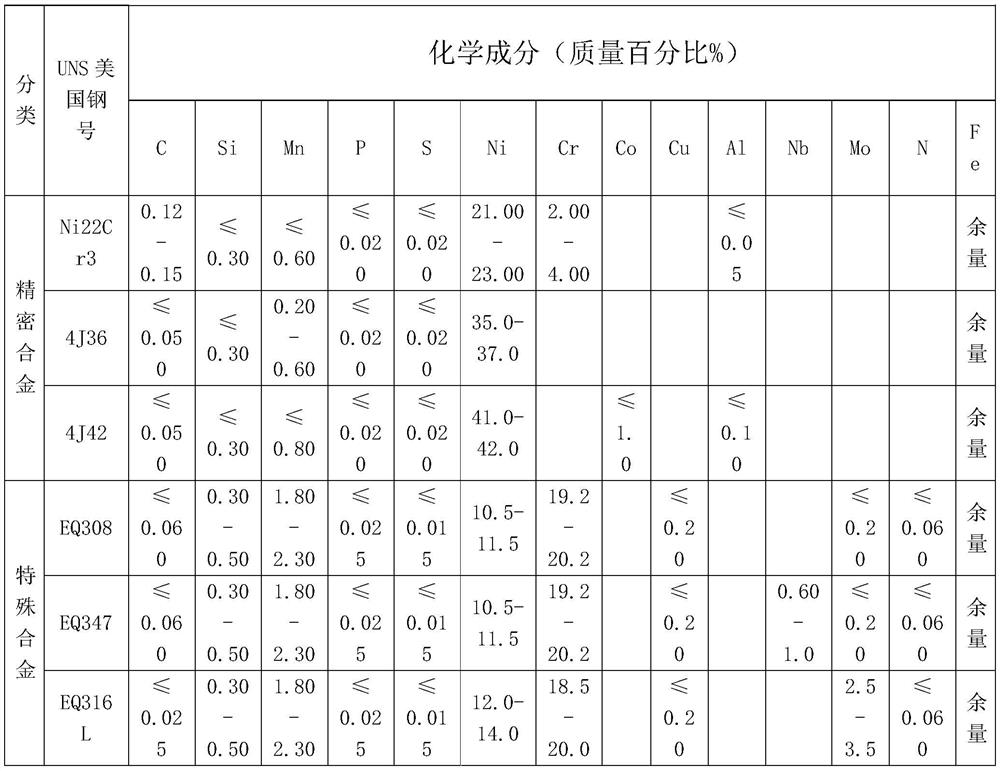

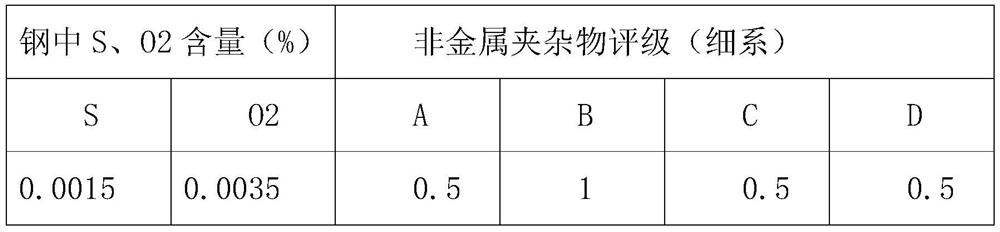

Desulfurization and deoxygenation process for smelting precise or special alloys by using medium-frequency induction furnace multi-slag method

InactiveCN111996330AGood desulfurization and deoxidationReduce power consumptionProcess efficiency improvementElectric furnaceDeoxygenationSlag

The invention discloses a desulfurization and deoxygenation process for smelting precise or special alloys by using a medium-frequency induction furnace multi-slag method. The process is characterizedin that the capacity of a medium-frequency induction furnace is less than or equal to 6 tons, metal raw materials loaded into the furnace must be clean and rust-free, and pure iron is inserted into the furnace in the form of a cast rod. During smelting of one heat steel, the total number of times of repeated new slag making reaches two or more, crusting slag and flowing slag on the surface of a molten pool need to be removed clearly every time slag making is conducted, and a thin slag layer capable of covering the molten steel surface is reserved, and then new slag is made in time. The alkalinity of the slag is 3-3.6, and precipitation and diffusion deoxidation are preformed according to requirements. In the refining period, the temperature of molten steel is controlled to be 1590-1610 DEG C, and the tapping temperature is controlled to be 1610-1630 DEG C. After the molten steel is poured into a steel containing barrel, Ar is blown and stirred, and then the molten steel is cast into asteel ingot under an Ar gas protection device. According to the process, the contents of sulfur and oxygen in the steel can be remarkably reduced, and high-end metal products such as precision or special alloys for cold or hot working can be successfully smelted.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

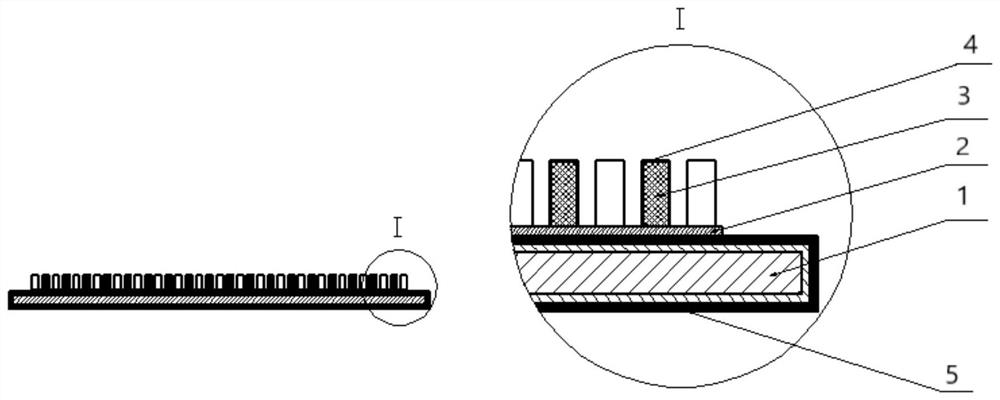

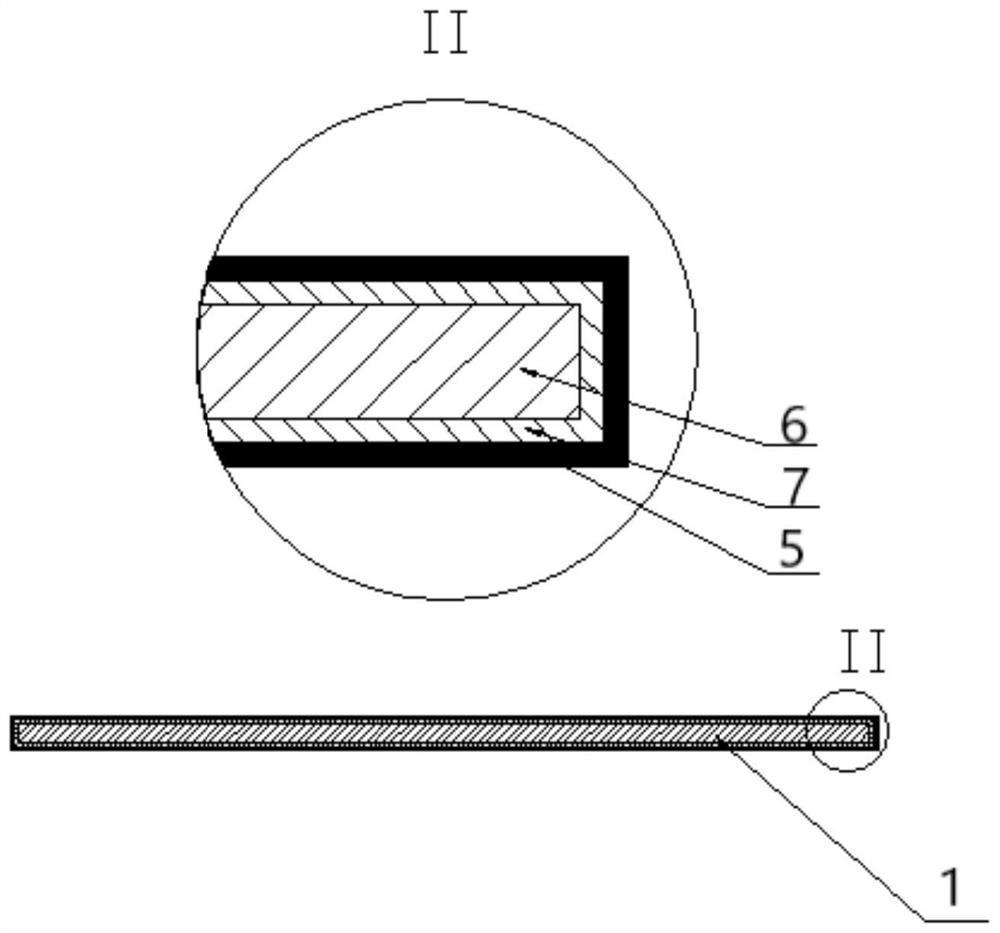

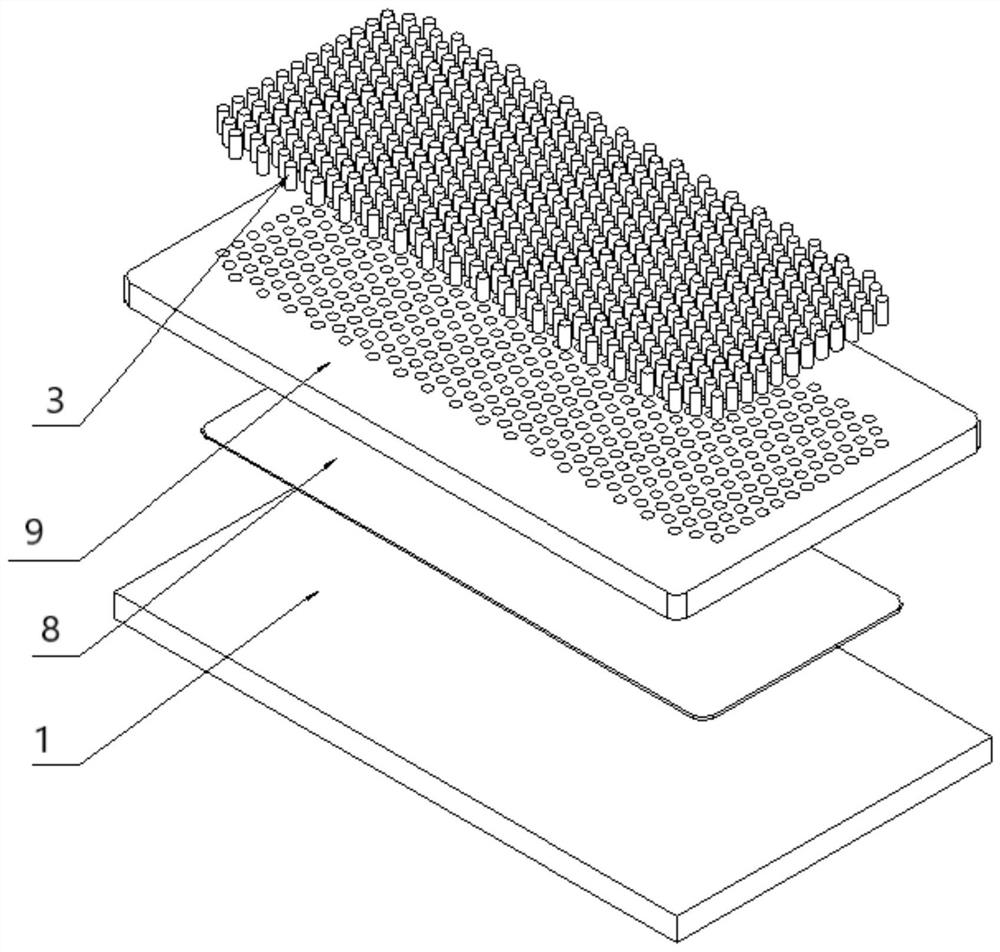

Heat dissipation element, preparation method thereof and IGBT module

ActiveCN111755400ALow oxide contentImprove bindingSemiconductor/solid-state device detailsSolid-state devicesCarbide siliconCopper

The invention relates to a heat dissipation element, a preparation method thereof and an IGBT module. The heat dissipation element comprises an aluminum silicon carbide substrate (1) and a copper column (3) connected to the aluminum silicon carbide substrate (1) through a welding layer (2), and the copper column (3) is provided with a first surface which is not connected with the welding layer (2)and a second surface which is connected with the welding layer (2); a first nickel plating layer (4) is arranged on the first surface; a second nickel plating layer (5) is arranged on the surface ofthe aluminum silicon carbide substrate (1); the bonding force between the copper pillar (3) and the aluminum silicon carbide substrate (1) is 9-33 N / mm2 on the basis of the surface area of the secondsurface of the copper pillar (3), and the oxide content of the second surface of the copper pillar (3) is 0.05-0.18 g / m2 on the basis of the total surface area of the copper pillar (3). The heat dissipation element disclosed by the invention has relatively high strength and better heat dissipation performance.

Owner:BYD CO LTD

Preparation method of water-soluble tri(m-sulfonate phenyl)phosphine

ActiveCN103254232AShorten the timeReduce contentGroup 5/15 element organic compoundsTPPTSWater soluble

The invention relates to a preparation method of water-soluble tri(m-sulfonate phenyl)phosphine (TPPTS). The preparation method comprises the following steps of: adding sodium metaborate which is 1.5-20wt% of total reactants into 100% concentrated sulfuric acid, then adding triphenylphosphine in batches, stirring and dissolving; and then adding fuming sulphuric acid containing 50-60wt% of SO3, carrying out sulfonation reaction at a temperature of 25-45 DEG C for 38-58 hours, extracting a sulfonated product by using a toluene solution of phosphite ester; then adding an alkali solution to neutralize the product till the pH value is 8-9; and then separating and recycling the product, wherein in the reaction system, the molar ratio of the fuming sulphuric acid containing 50-60wt% of SO3 to the triphenylphosphine is 6-18, and the molar ratio of the concentrated sulfuric acid to the triphenylphosphine is 10-25. By adopting the preparation method, the operation is simple and easy to control, the reaction time is shortened, and the content of by-product oxides is reduced.

Owner:成都欣华源科技有限责任公司 +1

Device and method for deeply purifying aluminum-lithium alloy melt

ActiveCN112626350AAchieve deep melt dehydrogenationRealize slag removalProcess efficiency improvementHydrogen contentThermocouple device

The invention discloses a device and method for deeply purifying an aluminum-lithium alloy melt. A purification furnace in the device comprises a purification furnace crucible, a purification furnace body, an upper plate and a lower plate. An upper liquid level rod, a lower liquid level rod, a purification furnace thermocouple and a vacuum pipe are assembled on the upper plate. A holding furnace thermocouple, a holding furnace liquid level rod and a measuring pipe are assembled on the lower plate. A holding furnace comprises an upper furnace body, a holding furnace crucible and a lower furnace body. The method comprises the following steps that (1) the purification furnace crucible and the holding furnace furnace crucible are heated; (2) the upper liquid level rod, the lower liquid level rod and the holding furnace liquid level rod respectively form a liquid level measuring circuit; (3) the aluminum-lithium alloy melt is introduced into the holding furnace crucible; (4) vacuumizing is carried out to enable the aluminum-lithium alloy melt to enter the purification furnace crucible; (5) argon is introduced, and the argon is mixed with the aluminum-lithium alloy melt for dehydrogenation; (6) the liquid level of the aluminum-lithium alloy melt is controlled; (7) the aluminum-lithium alloy melt in the holding furnace crucible enters the purification furnace crucible to form circulating purification; and (8) when the hydrogen content is less than or equal to 0.10 ppm, deep purification is finished. According to the device and method, the hydrogen content of an aluminum-lithium alloy can be reduced by 20 times or above.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com