Powder core wire material used for preparing coating with high amorphous content and preparation method and application for powder core wire material

A technology of powder core wire and content, which is applied in coating, metal material coating process, melt spraying and other directions, can solve the problem that the coating is difficult to obtain an amorphous structure, and achieves dense structure, low oxide content, The effect of excellent wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select a 430 stainless steel strip of 10×0.4mm (10mm in width and 0.4mm in thickness), and tie it into a U shape first. Take the powder core powder containing seven elements by mass percentage: 6wt.% Cr, 5wt.% B, 4wt.% Si, 4wt.% Nb, 12wt.% Mo, 1wt.% C, the balance is Fe, weigh ingredients. Put the obtained core powder into the powder mixer and mix for 4 hours, then put the mixed core powder into the U-shaped stainless steel belt groove, and the filling rate is 37%. Then close the U-shaped groove so that the powder core powder is coated in it, and then gradually reduce the diameter to Φ2mm through the wire drawing die. The arc spray coating was prepared on the steel substrate roughened by sandblasting, the spraying voltage was 34V, the spraying current was 130A, the spraying distance was 200mm, and the spraying air pressure was 0.7MPa.

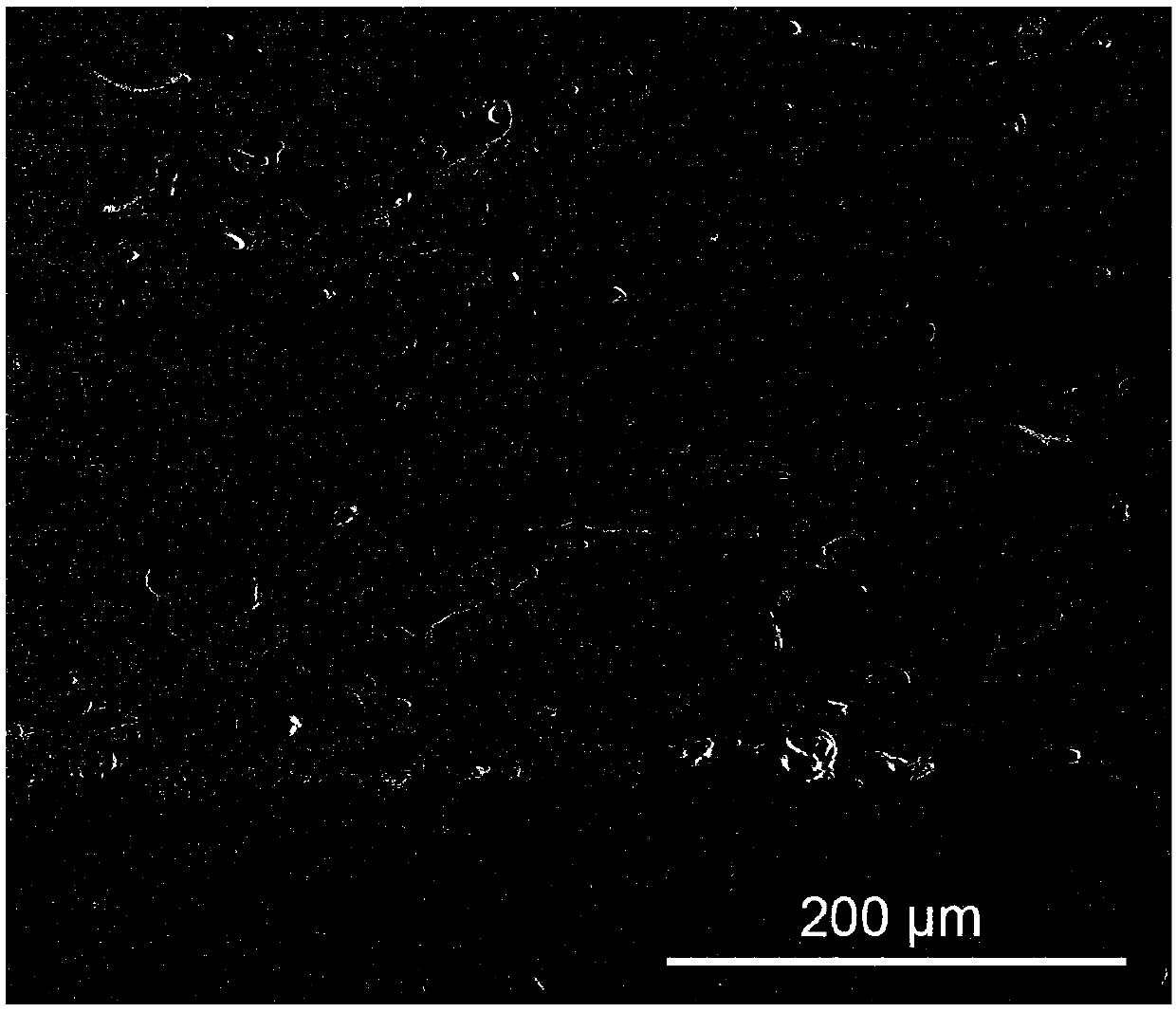

[0030] Example 1 prepares the cross-sectional morphology of the amorphous coating as figure 1 shown. It can be seen that the coatin...

Embodiment 2

[0032] Select a 430 stainless steel strip of 10×0.4mm (10mm in width and 0.4mm in thickness), and tie it into a U shape first. Get the powder core powder that contains seven kinds of elements by mass percentage: 9wt.%Cr, 5wt.%B, 4wt.%Si, 5wt.%Nb, 10wt.%Mo, 1.5wt.%C, the balance is Fe, carry out Weigh the ingredients. Put the obtained core powder into the powder mixer and mix for 4 hours, then put the mixed core powder into the U-shaped stainless steel belt tank, and the filling rate is 38%. Then close the U-shaped groove, so that the powder core powder is coated in it, and then gradually reduce the diameter to Φ2mm finished wire through the wire drawing die. The arc spray coating was prepared on the steel substrate roughened by sandblasting, the spraying voltage was 35V, the spraying current was 150A, the spraying distance was 200mm, and the spraying air pressure was 0.7MPa.

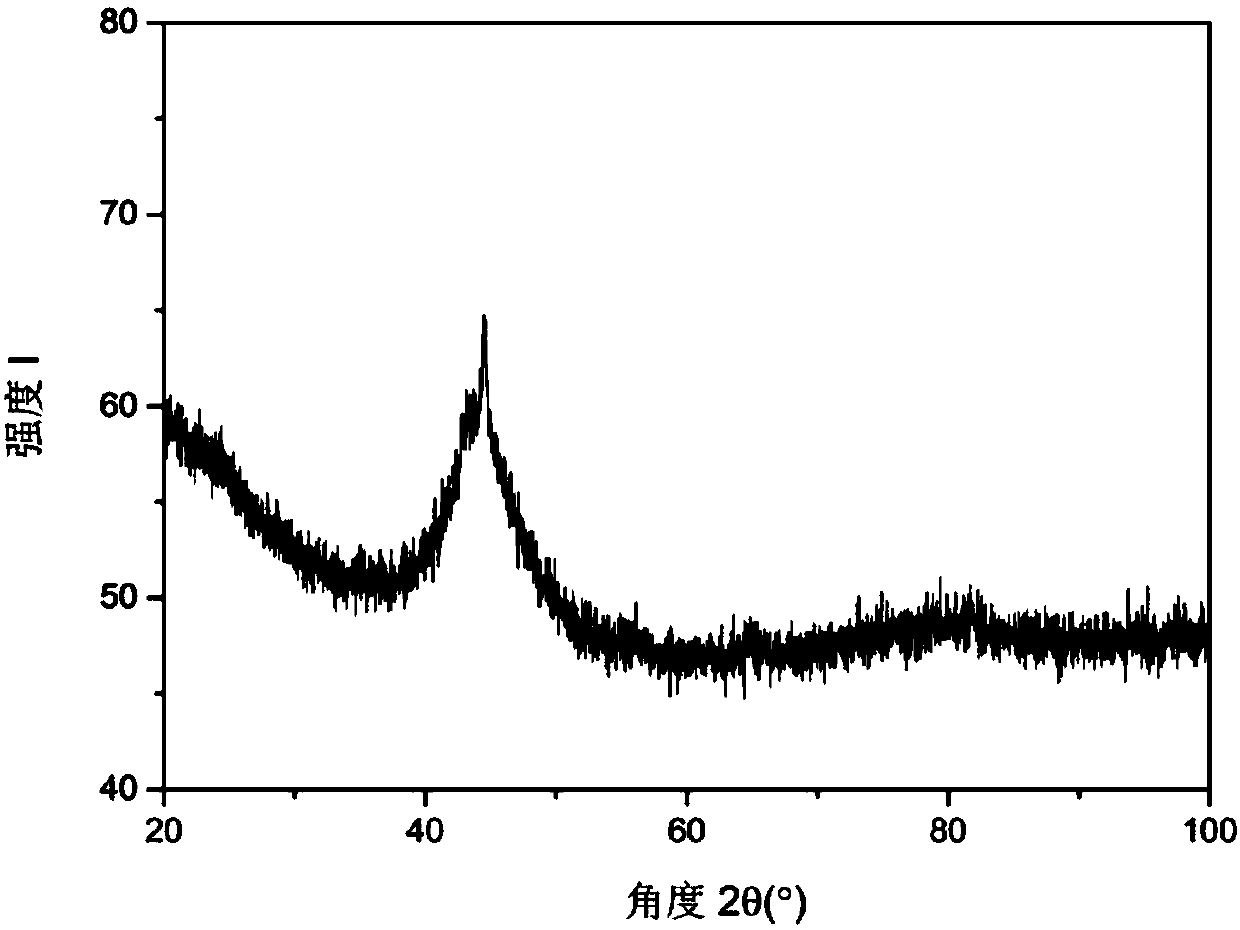

[0033] The X-ray diffraction pattern of the iron-based amorphous coating prepared in embodiment 2 i...

Embodiment 3

[0035] Select a 430 stainless steel strip of 10×0.4mm (10mm in width and 0.4mm in thickness), and tie it into a U shape first. Get the powder core powder containing seven kinds of elements by mass percentage: 12wt.%Cr, 6wt.%B, 3wt.%Si, 6wt.%Nb, 9wt.%Mo, 2.5wt.%C, the balance is Fe, carry out Weigh the ingredients. Put the obtained powder core powder into the powder mixer and mix for 60 minutes, then put the mixed powder core powder into the U-shaped stainless steel belt groove, and the filling rate is 38%. Then close the U-shaped groove, so that the powder core powder is coated in it, and then gradually reduce the diameter to Φ2mm finished wire through the wire drawing die. The arc spray coating was prepared on the steel substrate roughened by sand blasting, the spraying voltage was 36V, the spraying current was 120A, the spraying distance was 200mm, and the spraying air pressure was 0.7MPa.

[0036] The average bond strength of the amorphous coating prepared in Example 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com