Heat dissipation element, preparation method thereof and IGBT module

A heat dissipation element and module technology, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve problems such as low bonding force, poor heat transfer performance of aluminum columns, and difficulty in meeting product use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

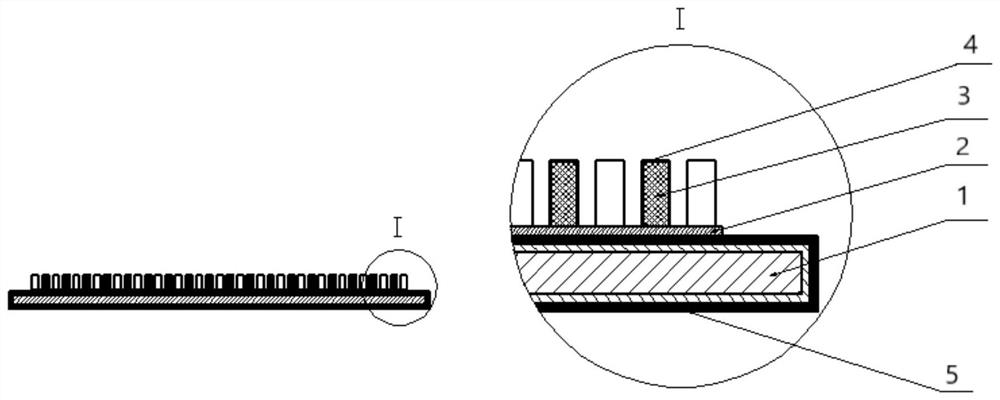

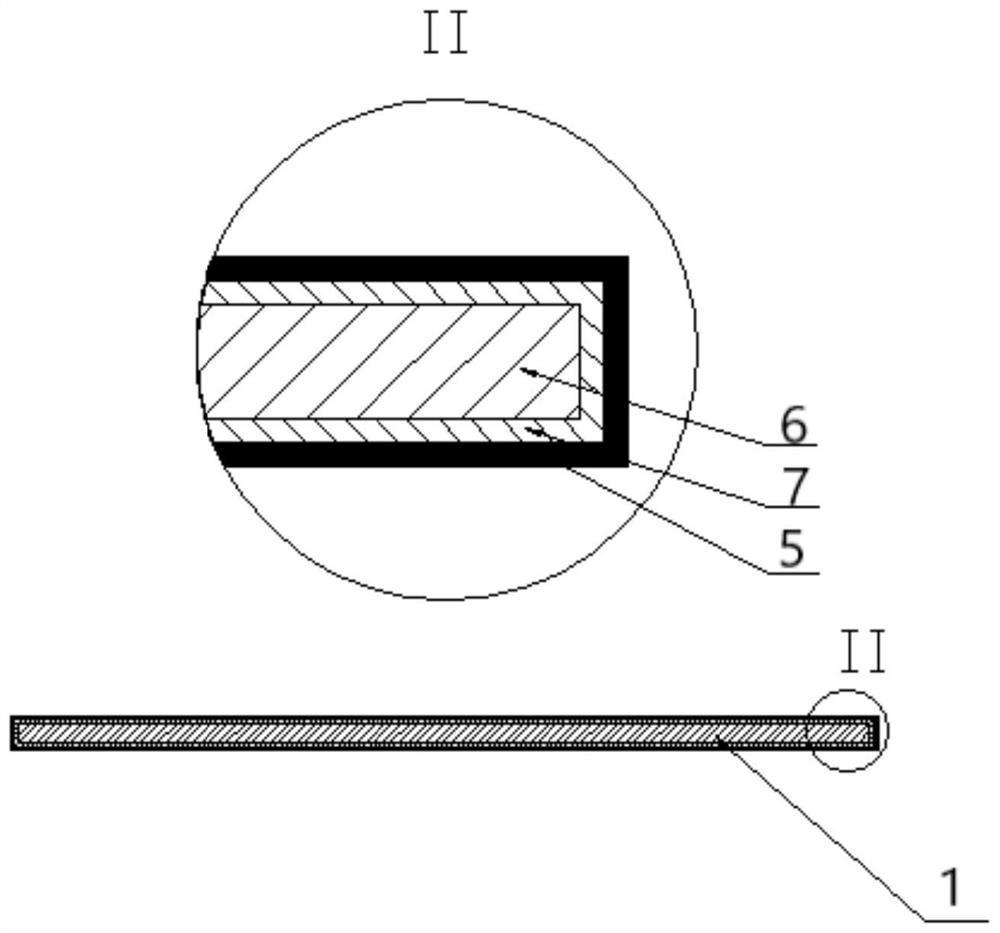

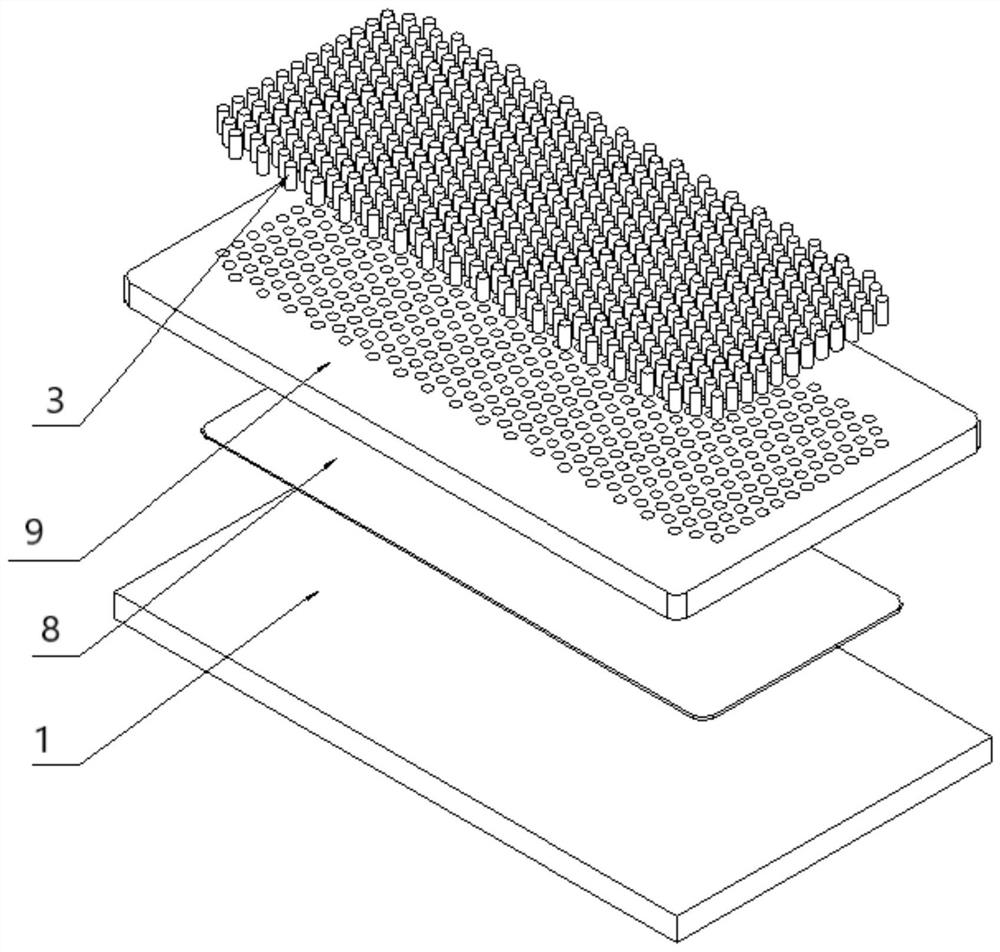

[0076] A copper column with a diameter of 4.18mm and an axis height of 8mm is subjected to nickel plating at 85°C to obtain a copper column with a nickel-plated layer, and the nickel-plated layer on one end surface (ie, the second surface) of the copper column is polished by sandpaper. Remove, obtain the copper post with the first nickel-plated layer 4 (such as Figure 8), the thickness of the first nickel plating layer is 8 μm.

[0077] At 80°C, use an alkaline chemical cleaning agent consisting of sodium hydroxide (concentration: 15g / L), sodium carbonate (concentration: 20g / L) and sodium phosphate (concentration: 10g / L) The second surface of the nickel-plated copper pillar was ultrasonically cleaned for 15 minutes, then rinsed with water, and then rinsed with a sulfuric acid solution with a concentration of 5% by weight for 5 minutes to remove the oxide layer on the surface of the copper pillar. Then at 30° C., an ethanol solution containing benzotriazole (concentration of ...

Embodiment 2

[0081] Prepare the cooling element according to the method of Example 1, the difference is that the alkaline chemical cleaning agent is composed of sodium hydroxide (concentration is 10g / L), sodium carbonate (concentration is 15g / L) and sodium phosphate (concentration is 15g / L) , copper protective agent is the ethanol solution containing benzotriazole (concentration is 0.5g / L).

Embodiment 3

[0083] Prepare the cooling element according to the method of Example 1, the difference is that the alkaline chemical cleaning agent consists of sodium hydroxide (concentration is 15g / L), sodium carbonate (concentration is 20g / L) and sodium lauryl sulfate (concentration is 10g / L), the copper protective agent is a self-made protective agent containing 15% by weight of amines, 20% by weight of alcohols and 20% by weight of nonionic surfactant BCu-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com