Desulfurization and deoxygenation process for smelting precise or special alloys by using medium-frequency induction furnace multi-slag method

An induction furnace, intermediate frequency technology, applied in the field of oxygen process, multi-slag method smelting precision or special alloy desulfurization, intermediate frequency induction furnace multi-slag method smelting precision or special alloy desulfurization field, can solve the weak electromagnetic stirring force, speed up inclusions in molten steel Floating, incomplete and other problems, to achieve good deoxidation and desulfurization, shorten the smelting time, avoid the effect of overheating of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

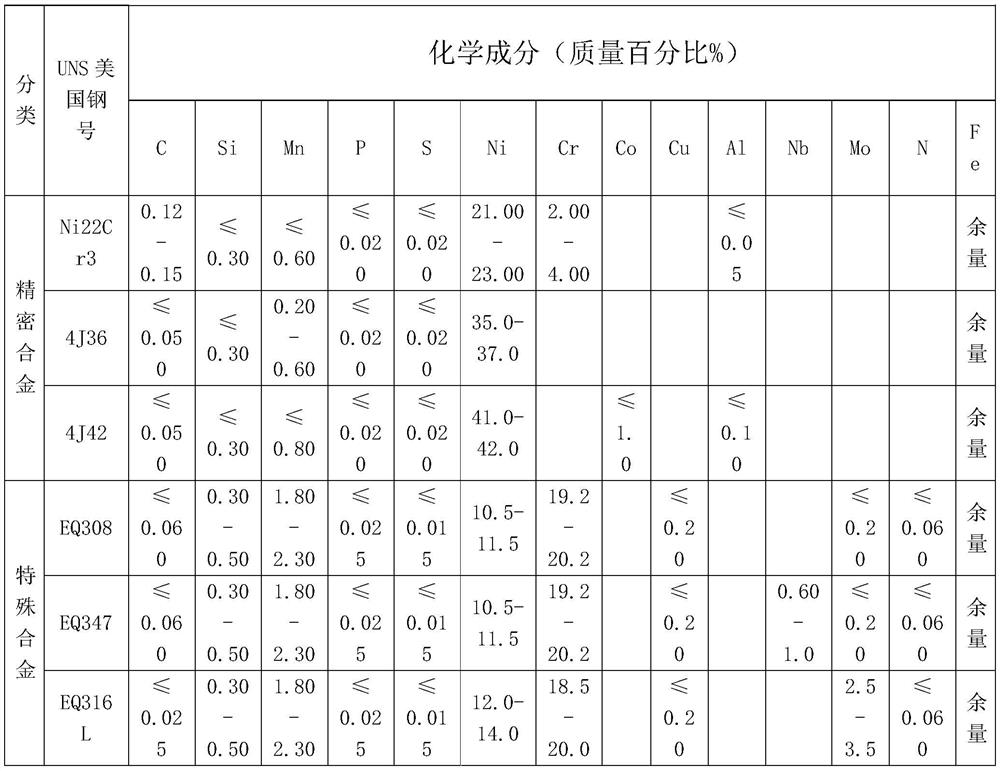

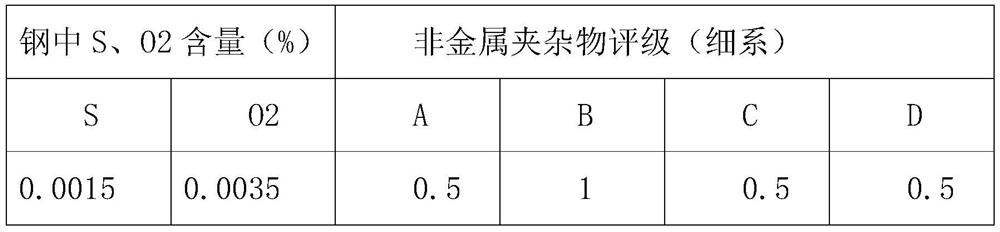

[0111] The medium frequency induction furnace for smelting Ni22Cr3 has a capacity of 4 tons.

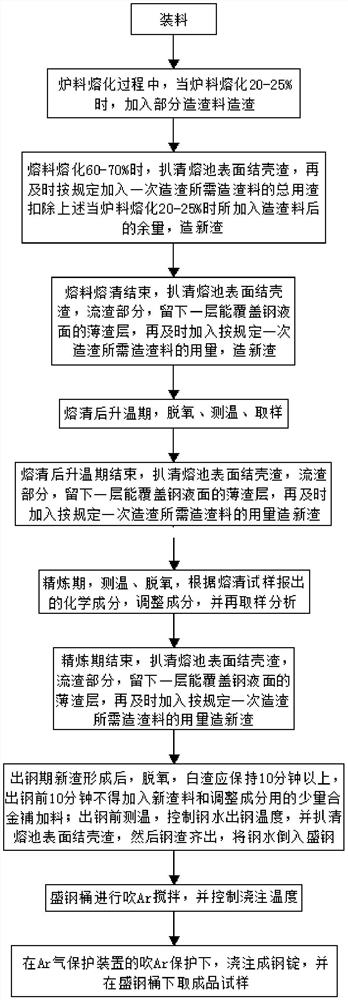

[0112] Load the metal raw materials with a clean, dry surface, no oil, rust and scale in the medium-frequency induction furnace with a block size that meets the compact charging principle of tight bottom and loose top. Among them, pure iron is cast into 6 bars, which are perpendicular to the The direction of the bottom of the furnace is inserted into the furnace. During the furnace charge melting process, when the furnace charge melts 20-25%, add 4 kg of lime and 1.5 kg of fluorite to cover the molten steel surface. Add in time the total amount of slag material used for one slag making: lime 4.5 kg / ton molten steel and fluorite 1.8 kg / ton molten steel, the balance after deducting the amount of lime and fluorite added when the furnace charge melts 20.-25%. , until molten. Then, before entering each period of molten steel heating up period, refining period and tapping period after me...

Embodiment 2

[0120] Smelting 4J36, the medium frequency induction furnace has a capacity of 4 tons.

[0121]Load metal raw materials with clean, dry, oil-free and scale-free surface in the medium-frequency induction furnace with a block size that meets the compact charging principle of tight bottom and loose top. Among them, pure iron is cast into 4 bars to be perpendicular to the bottom of the furnace. Insert it into the furnace in the direction. When the charge melts 20-25%, add 3 kg of lime and 1.5 kg of fluorite to cover the molten steel surface. When the charge melts 60-70%, remove the encrusted slag on the surface of the molten pool, and then add it in time. The total amount of slag materials used for slagging, that is: lime 5 kg / ton molten steel and fluorite 1.5 kg / ton molten steel minus the amount of lime and fluorite added when the furnace charge melts 20-25%, the balance until the melt is clear . Then, before entering each period of molten steel heating up period, refining peri...

Embodiment 3

[0130] Smelting 4J42, the medium frequency induction furnace has a capacity of 4 tons.

[0131] Load metal raw materials with a clean, dry surface, no oil and scale in the intermediate frequency induction furnace. Among them, pure iron is cast into 4 bars to be perpendicular to the furnace. Insert it into the furnace in the direction of the bottom. When the charge melts 20-25%, add 5 kg of lime and 2 kg of fluorite to cover the molten steel surface. When the charge melts 60-70%, remove the encrusted slag on the surface of the molten pool, and then add it in time. The total amount of slag materials used for slagging, that is: lime 6 kg / ton molten steel and fluorite 2.5 kg / ton molten steel minus the amount of lime and fluorite added when the furnace charge melts 20-25%, the balance until the melt is clear . Then, before entering each period of molten steel heating up period, refining period and tapping period after melting, slagging is carried out according to the following op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com