Powder core wire as well as preparation method and application thereof

A kind of powder core wire material and powder core technology, which are applied in the field of powder core wire material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

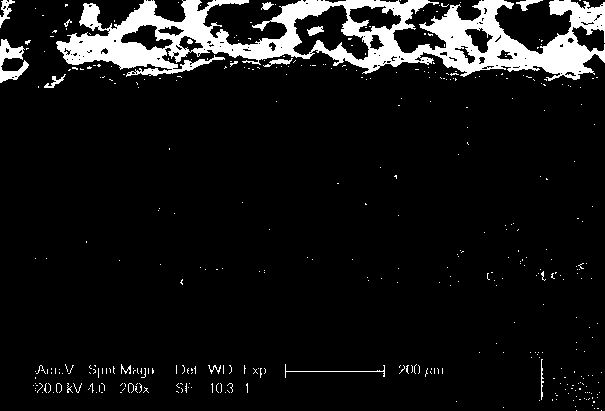

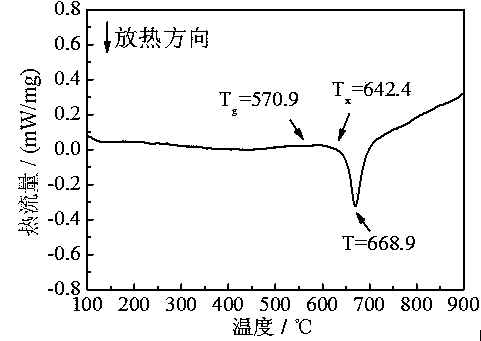

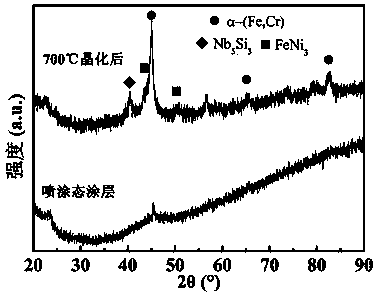

Image

Examples

Embodiment 1

[0043] A kind of powder core wire material, which is made of a stainless steel belt covering a powder core. The powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 45% Cr, 5% B, 2% Al, 3% Si, 3% Nb, 10% Mo, and the balance is Fe. The stainless steel belt is made of 304L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.43:1.

[0044] The preparation method of powder core wire material comprises the following steps:

[0045] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 5 hours to obtain a mixture. The volume ratio of alcohol to powder is 2:5, and the weight ratio of stainless steel balls to mixed powder in the ball mill 5:1, ball mill speed ≤150r / min;

[0046] (2) Place the mixture in a rotary evaporator, dry until the alcohol evaporates, then put the dried mixture in an oven at a temperature lower than 60 ℃ for 5 hours, a...

Embodiment 2

[0056] A kind of powder core wire material, which is made of a stainless steel belt covering a powder core. The powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 35% Cr, 2% B, 1% Al, 5% Si, 5% Nb, 10% Mo, and the balance is Fe. The stainless steel belt is made of 304L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.67:1.

[0057] The preparation method of powder core wire material comprises the following steps:

[0058] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 6.25 hours to obtain a mixture, in which the volume ratio of alcohol to powder is 1:2, and the weight ratio of stainless steel balls to the mixed powder in the ball mill 6:1, ball mill speed ≤150r / min;

[0059] (2) Place the mixture in a rotary evaporator, dry until the alcohol volatilizes, then put the dried mixture in an oven at a temperature lower than 60...

Embodiment 3

[0069] A kind of powder core wire material, which is made of a stainless steel belt covering a powder core. The powder core composition is a mixture of seven element powders, and its weight percentage range is as follows: 30% Cr, 5% B, 5% Al, 3% Si, 15% Nb, 2% Mo, the balance being Fe. The stainless steel belt is made of 316L stainless steel belt, and the weight ratio of the powder core to the stainless steel belt is 0.61:1.

[0070] The preparation method of powder core wire material comprises the following steps:

[0071] (1) Mix the seven element powders of the powder core, add alcohol, and wet mix in a ball mill for 7.5 hours to obtain a mixture. The volume ratio of alcohol to powder is 3:5, and the weight ratio of stainless steel balls to mixed powder in the ball mill 7:1, ball mill speed ≤150r / min;

[0072] (2) Place the mixture in a rotary evaporator, dry until the alcohol volatilizes, then put the dried mixture in an oven at a temperature lower than 60 ℃ for 7 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com